Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DS30 012 PDF

Caricato da

Bala LakshmanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DS30 012 PDF

Caricato da

Bala LakshmanCopyright:

Formati disponibili

INTERNATIONAL DESIGN CONFERENCE - DESIGN 2002

Dubrovnik, May 14 - 17, 2002.

INCREASING LOAD CAPACITY OF SPLINES DUE

TO DESIGN

Günter Schäfer and Martin Garzke

Keywords: shaft/hub-connection, design-options, manufacturing

1. Introduction

The spline is a common element for shaft/hub-connections with high performance in torque

transmission. Regarding to spline connections several national and international standards exist (e.g.

ISO 4156, ANSI B92, DIN 5480, DIN 5466).

These standards offer a lot of information about the main features and basic use of splines. For special

applications referring to loads, dimensions, materials and manufacturing the designer has to use his

freedom in splines micro-design to increase the load capacity above the ordinary limits. This paper

shows some industrial applications of modified splines.

2. Design options

2.1 Root radius

The variation of root radius and geometry (flat/fillet) can be used to reduce the stress concentration

factor. A simple two dimensional consideration of the spline geometry leads to the requirement of a

fillet root with maximum radius. The consequence is that the core area of the shaft is reduced, which

caused a minor torque resistance. By means of examples will be shown how to balance this restrictions

on a high level.

Figure 1. Profile of the basic rack for 30° flat root spline

INDUSTRIAL SOLUTIONS 695

Figure 2. Profile of the basic rack for 30° fillet root spline

2.2 Flank line

The elasticity of the shaft and hub material caused different torque deformations in the two elements.

The result is a different micro geometry which leads to an unbalanced load distribution with load

peaks at one end of the spline. One way to improve the balance of the load distribution over the length

is the amendment of flank line angle (helix). The calculation of this flank correction based on the

elastic behaviour of the spline materials and geometry.

Figure 3. Cracked spline

696 INDUSTRIAL SOLUTIONS

Figure 4. Hub modification

Figure 5. Shaft torque deformation

In order to the aspired constant torque load over the whole axial length L of the connection the torque

deformation angle ϕ(x) can be calculated by the following equations:

ϕ(z ) = Mt (z ) dz

1

G ⋅ Ip ∫

(1)

Mt (z ) =

T

with ⋅z (2)

L

T ⋅L

ϕmax = (3)

2 ⋅ G ⋅ Ip

INDUSTRIAL SOLUTIONS 697

This corrected flank geometry is easy to manufacture by plastic forming due to the GROB process.

The advantage of this process is the inducted compression stress in the root area, especially in the run-

out. The compression stress in combination with the sleek flank surface leads to higher fatigue

resistance. A flank geometry correction is also useful for shaft-hub connections with the

recommended ratio of length to diameter equal 0,6 or greater.

2.3 Centering

The additional centering by a cylindrical surface for partial load transmission according to the

principle „division of tasks“ grants an advanced radial force suitability. Radial forces often exist in

practical applications, but they are the main reason for high friction wear which leads from a hidden to

a direct damage. By the principle „division of tasks“ the designer is able to dedicated features to the

different types of loads (torque, radial forces). In figure 6 the radial centering by doubletooth is shown.

The number of doubleteeth can be up from 3. Another way of radial centering is the design of rings

located at both axial ends of the connection. This is not so easy to manufacture as the doubletooth.

Figure 6. “Doubletoothed” shaft for centering

Problematical in use of such additional centering surfaces is the potential competition with the self

centering behaviour of the spline. It may cause high internal loads if the center axis of both entities are

not the same.

2.4 Pressure angle

Another possibility to handle radial forces in such self-centering splines is the variation of the pressure

angle from 20° up to 45° due to the combination of torque and radial load. The greater values yields to

a higher capability for radial loads but in combination with greater tangential stresses in the hub. The

designer has to decide what is the better solution for his application. Some industrial examples are

interpreted to this facts to help the designer finding the right decision.

698 INDUSTRIAL SOLUTIONS

Figure 7. Profile of the basic rack for 45° fillet root spline

2.5 Run-out geometry

The current research work at the Institut für Maschinenwesen on splines in co-operation with the

industry are the design versions of run-out geometry at the end of the toothed length which is a critical

area with high stress levels. Under this topic shall be discussed the design options related to the

manufacturing resources.

Figure 8. Stress distribution at the run-out

INDUSTRIAL SOLUTIONS 699

3. Results

The regular design and calculation of a spline has to be done according to the standards (e.g. DIN

5480, DIN 5466, ISO 4146). For complex applications in matters of geometry, load or material the

designer can use his freedom in splines micro-design. The main stress concentration depends on the

tooth root geometry. By changing from the flat to the fillet root this critical concentration will be

decreased at 0,8. For uniformly distributed load on the flanks in axial direction it is necessary to use a

geometry correction in reference to the elastic deformation behaviour of the spline. To reduce the

friction wear it is a common feature to add circular surfaces to the tooth to transmitt the radial forces.

The same goal is achievable by increasing the pressure angle if the hub is able to endure the additional

load. Further possibilities are in the manufacturing process, e.g. the plastic forming. Using the

visualised notions enables the designer to increase the load capability of a common spline connection

above the ordinary limitations.

References

Dietz, P.: Die Berechnung von Zahn- und Keilwellenverbindungen. Selbstverlag des Verfassers, Büttelborn 1978

Dietz, P.; Wesolowski, K.: Zahnwellenfestigkeit. Abschlußbericht zum DFG-Forschungsvorhaben Di 289/9-1.

Institut für Maschinenwesen der TU Clausthal, 1994

Dietz, P; Schäfer, G.; Wesolowski, K.: Betriebsverhalten und Lebensdauer von Zahnwellen-Verbindungen.

DVM-Tagung: "Maschinenelemente und Lebensdauer - Gestaltung und Optimierung", Dresden 1995, DVM-

Bericht 121

Schäfer, G.: Der Einfluß von Oberflächenbehandlungen auf das Verschleißverhalten flankenzentrierter Zahn-

wellen-Verbindungen mit Schiebesitz. Dissertation TU Clausthal 1995

Dietz, P.; Garzke, M.: Statische und dynamische Beanspruchbarkeit von Zahnwellen-Verbindungen unter

elastischem und teilplastischem Werkstoffverhalten. Abschlußbericht zum DFG-Forschungsvorhaben Di 289/9-

2. Institut für Maschinenwesen der TU Clausthal, 1998

Schäfer, G.: Gleichmässigkeit zur Leistungssteigerung. Institutsmitteilung Nr. 25, ISSN 0947-2247, IMW TU

Clausthal 2000, pp 23-24

Dr.-Ing. Günter Schäfer

Fritz-Süchting-Institut für Maschinenwesen

Technische Universität Clausthal

Robert-Koch-Str. 32, D-38678 Clausthal-Zellerfeld, Germany

Phone: +49 5323/72-3894, Fax: +49 5323/72-3501

Email: schaefer@imw.tu-clausthal.de

700 INDUSTRIAL SOLUTIONS

Potrebbero piacerti anche

- 01028393Documento9 pagine01028393Powerranger2.0Nessuna valutazione finora

- A Methodology For Obtaining Optimum Gear Tooth Microtopographies For Noise and Stress Minimization Over A Broad Operating Torque RangeDocumento14 pagineA Methodology For Obtaining Optimum Gear Tooth Microtopographies For Noise and Stress Minimization Over A Broad Operating Torque RangevijaykumarnNessuna valutazione finora

- Materials Science and Technology of Optical FabricationDa EverandMaterials Science and Technology of Optical FabricationNessuna valutazione finora

- Optimization Approach For Common Steel Open Section Under Applying Direct Torque at Warpless End of A Cantilever BeamDocumento8 pagineOptimization Approach For Common Steel Open Section Under Applying Direct Torque at Warpless End of A Cantilever BeamInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Face Gears: Geometry and Strength: Ulrich Kissling and Stefan BeermannDocumento8 pagineFace Gears: Geometry and Strength: Ulrich Kissling and Stefan BeermannbennyfergusonNessuna valutazione finora

- SST Turbulence ModelDocumento8 pagineSST Turbulence Modelmatteo_1234Nessuna valutazione finora

- Optimisation of Double Box Girder Overhead Crane in Function of Cross Section Parameter of Main GirdersDocumento4 pagineOptimisation of Double Box Girder Overhead Crane in Function of Cross Section Parameter of Main GirdersAjla BećirovićNessuna valutazione finora

- Analysis of Pressure For 3lobe Hydrodynamic Journal BearingDocumento5 pagineAnalysis of Pressure For 3lobe Hydrodynamic Journal BearingseventhsensegroupNessuna valutazione finora

- 1.steam Turbine Rotor GroovesDocumento7 pagine1.steam Turbine Rotor GroovesRaheem JunaidiNessuna valutazione finora

- 10 5923 S Ijee 201601 04Documento9 pagine10 5923 S Ijee 201601 04Guillermo TubillaNessuna valutazione finora

- Shear Capacity of Steel Plate Girders With Large Web OpeningsDocumento3 pagineShear Capacity of Steel Plate Girders With Large Web OpeningsPauloAndresSepulvedaNessuna valutazione finora

- Design of Rounded Dovetail JointsDocumento6 pagineDesign of Rounded Dovetail JointsJerry ZhangNessuna valutazione finora

- Beam-To-Beam Joints With Bolted End-Plate Connections Concerning Steel Platforms Angra 2 NPPDocumento10 pagineBeam-To-Beam Joints With Bolted End-Plate Connections Concerning Steel Platforms Angra 2 NPPihpeterNessuna valutazione finora

- Fatigue of Grouted Joint ConnectionsDocumento5 pagineFatigue of Grouted Joint Connectionsscrane@Nessuna valutazione finora

- Belt Conveyor Pulley Design - Why The Failures - Terry KingDocumento11 pagineBelt Conveyor Pulley Design - Why The Failures - Terry KingJakesNessuna valutazione finora

- 01 Olleak Egypt JapanUnivofScienceandTechnology PDocumento8 pagine01 Olleak Egypt JapanUnivofScienceandTechnology PaykutartacNessuna valutazione finora

- New SplineDocumento20 pagineNew SplineHiyeedNessuna valutazione finora

- Session 6 Plate Girder PDFDocumento17 pagineSession 6 Plate Girder PDFAgung MahendraNessuna valutazione finora

- 0192 Design Optimization of Eot Crane BridgeDocumento9 pagine0192 Design Optimization of Eot Crane BridgeJignesh Tala100% (1)

- Strength Design Optimization of Structural Steel Members According To Eurocode3Documento20 pagineStrength Design Optimization of Structural Steel Members According To Eurocode3Malik AtikNessuna valutazione finora

- 1 s2.0 S0007850607000972 MainDocumento4 pagine1 s2.0 S0007850607000972 Mainmohammadamin.abdollahzadehNessuna valutazione finora

- Through-Thickness Shape Optimisation of Bonded Repairs and Lap-JointsDocumento15 pagineThrough-Thickness Shape Optimisation of Bonded Repairs and Lap-JointsAdil KaplanserenNessuna valutazione finora

- ReleasenotesDocumento35 pagineReleasenotesdenise_rosales_1Nessuna valutazione finora

- 2.ISCA RJMatS 2013 002Documento5 pagine2.ISCA RJMatS 2013 002balaguru78Nessuna valutazione finora

- 3D Finite Element Stress Analysis of Reinforced DoDocumento11 pagine3D Finite Element Stress Analysis of Reinforced DoScribd01mai2019Nessuna valutazione finora

- JSCE2017 Suthiwarapirak&EricDocumento2 pagineJSCE2017 Suthiwarapirak&Ericeric bargasNessuna valutazione finora

- Acoustic Analysis of Power Units With An ABAQUS Integrated Application Workflow PDFDocumento15 pagineAcoustic Analysis of Power Units With An ABAQUS Integrated Application Workflow PDFPeet89Nessuna valutazione finora

- COB-2019-0527 Linear Elastic Fracture Mechanics Analysis of A Square Hollow Structural Steel Section ProfileDocumento9 pagineCOB-2019-0527 Linear Elastic Fracture Mechanics Analysis of A Square Hollow Structural Steel Section ProfileAlbert AlmeidaNessuna valutazione finora

- Multiple-Grooved Magnetic Traction SheavesDocumento14 pagineMultiple-Grooved Magnetic Traction SheavesJorge Prado DiazNessuna valutazione finora

- Fillet Weld DesignDocumento2 pagineFillet Weld Designsaj0205037Nessuna valutazione finora

- Analysis of Wind Loads Acting On Large Span Double-Arched Roof Structure With Opening EndsDocumento4 pagineAnalysis of Wind Loads Acting On Large Span Double-Arched Roof Structure With Opening EndsKhắc ĐăngNessuna valutazione finora

- Musonda 2018 IOP Conf. Ser. Mater. Sci. Eng. 423 012162Documento7 pagineMusonda 2018 IOP Conf. Ser. Mater. Sci. Eng. 423 012162JUANNessuna valutazione finora

- Optimal Gear Design For Medical Applications: Alexander L. Kapelevich Akgears, LLC, Thomas M. Mcnamara Thermotech CoDocumento7 pagineOptimal Gear Design For Medical Applications: Alexander L. Kapelevich Akgears, LLC, Thomas M. Mcnamara Thermotech CoAvinash KumarNessuna valutazione finora

- Engineering Journal Optimal Design of Steel and Composite Vessels With Tube Branch JointDocumento12 pagineEngineering Journal Optimal Design of Steel and Composite Vessels With Tube Branch JointEngineering JournalNessuna valutazione finora

- Lee2008 Elbow LWTDocumento5 pagineLee2008 Elbow LWTKurra SrikanthNessuna valutazione finora

- BindDocumento21 pagineBindHenry MarcellaNessuna valutazione finora

- Impact of Blade Geometry Differences For The CFD Performance Analysis of Existing TurbinesDocumento11 pagineImpact of Blade Geometry Differences For The CFD Performance Analysis of Existing TurbinesFabio FolpiniNessuna valutazione finora

- How To Design Roof Purlins - A Solved Example - Structville...Documento23 pagineHow To Design Roof Purlins - A Solved Example - Structville...Charles Vladimir SolvaskyNessuna valutazione finora

- A Study On The Nose Radius Influence in Press Brake Bending Operations by Finite Element AnalysisDocumento12 pagineA Study On The Nose Radius Influence in Press Brake Bending Operations by Finite Element AnalysisRui MatiasNessuna valutazione finora

- Eurosteel Subsequent ModificationsDocumento11 pagineEurosteel Subsequent ModificationsMuraliNessuna valutazione finora

- Finite Element Simulation of Non LinearDocumento11 pagineFinite Element Simulation of Non LinearmostafaNessuna valutazione finora

- Sorrentino 2014Documento18 pagineSorrentino 2014Hiến Đinh VănNessuna valutazione finora

- SSRN Id4163209Documento7 pagineSSRN Id4163209Deepak KumarNessuna valutazione finora

- Optimizing Efficiency of Square Threaded Mechanical Screw Jack by Varying Helix AngleDocumento5 pagineOptimizing Efficiency of Square Threaded Mechanical Screw Jack by Varying Helix AnglegrewalgurNessuna valutazione finora

- QTR Ch8Documento6 pagineQTR Ch8Lim Chia SeangNessuna valutazione finora

- Design - Springs: D J D A D F D FDDocumento3 pagineDesign - Springs: D J D A D F D FDIsa GomNessuna valutazione finora

- Mattey 2017Documento7 pagineMattey 2017Mahfoud AMMOURNessuna valutazione finora

- Artigo de Salles - 2017Documento9 pagineArtigo de Salles - 2017Leonardo Pereira SilvaNessuna valutazione finora

- Design Sensitivity Analysis of Air-Lubricated Slider BearingsDocumento3 pagineDesign Sensitivity Analysis of Air-Lubricated Slider BearingsDeepak SharmaNessuna valutazione finora

- Localized Web Buckling of Double Coped BeamsDocumento14 pagineLocalized Web Buckling of Double Coped BeamsKLNessuna valutazione finora

- Design and Analysis of Multi-Angular Gearless Transmission SystemDocumento9 pagineDesign and Analysis of Multi-Angular Gearless Transmission SystemShrikkNessuna valutazione finora

- Generating Interchangeable 20° Spur Gear Sets With Circular Fillets To Increase Load Carrying CapacityDocumento7 pagineGenerating Interchangeable 20° Spur Gear Sets With Circular Fillets To Increase Load Carrying Capacityah waNessuna valutazione finora

- Effect of Material Properties On DesignDocumento32 pagineEffect of Material Properties On DesignKumaravel SivamNessuna valutazione finora

- Sliding Parts of Bridge Bearings: Steel Structures and Bridges 2012Documento5 pagineSliding Parts of Bridge Bearings: Steel Structures and Bridges 2012ShaileshRastogiNessuna valutazione finora

- Paper MSF FinalDocumento7 paginePaper MSF Final918Kiss Secret TipsNessuna valutazione finora

- Stco 201310014Documento10 pagineStco 201310014DamirNessuna valutazione finora

- Hybrid Steel Plate Girders Subjected To Patch LoadingDocumento7 pagineHybrid Steel Plate Girders Subjected To Patch LoadingArnela HodzicNessuna valutazione finora

- Structural Analysis of Turbine Blade Disc Fir-Tree Root Using ANSYSDocumento4 pagineStructural Analysis of Turbine Blade Disc Fir-Tree Root Using ANSYSRahul VermaNessuna valutazione finora

- Hev 4Documento1 paginaHev 4Bala LakshmanNessuna valutazione finora

- Vot 3Documento1 paginaVot 3Bala LakshmanNessuna valutazione finora

- Cylindrical Roller Bearings Single Row-NUP 209 ECJDocumento2 pagineCylindrical Roller Bearings Single Row-NUP 209 ECJBala LakshmanNessuna valutazione finora

- Emission 4Documento1 paginaEmission 4Bala LakshmanNessuna valutazione finora

- Concrete Types 1Documento1 paginaConcrete Types 1Bala LakshmanNessuna valutazione finora

- Concrete Properties PDFDocumento1 paginaConcrete Properties PDFBala LakshmanNessuna valutazione finora

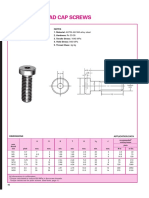

- Metric Low Head CapDocumento1 paginaMetric Low Head CapBala Lakshman0% (1)

- Metric Low Head CapDocumento1 paginaMetric Low Head CapBala Lakshman0% (1)

- Increasing Load Capacity of Splines Due To Design: Günter Schäfer and Martin GarzkeDocumento6 pagineIncreasing Load Capacity of Splines Due To Design: Günter Schäfer and Martin GarzkeBala LakshmanNessuna valutazione finora

- Spline DIN 5480Documento27 pagineSpline DIN 5480ewillia13100% (3)

- Spline DIN 5480Documento27 pagineSpline DIN 5480ewillia13100% (3)

- CHAPTER 6 - ELE290 INDUCTION MotorDocumento10 pagineCHAPTER 6 - ELE290 INDUCTION MotorKamaruz DanialNessuna valutazione finora

- Mmmme 05 PPT CH 6Documento33 pagineMmmme 05 PPT CH 6rahpooye313Nessuna valutazione finora

- Data Sheet 6ES7972-0CB20-0XA0: Supply VoltageDocumento2 pagineData Sheet 6ES7972-0CB20-0XA0: Supply VoltageRenan Ribeiro RodriguesNessuna valutazione finora

- Decoherence-Free Entropic Gravity For Dirac FermionDocumento23 pagineDecoherence-Free Entropic Gravity For Dirac Fermionubik59Nessuna valutazione finora

- Virtus TCTPDocumento417 pagineVirtus TCTPPablo100% (1)

- TOS - 3rd - Science 7Documento2 pagineTOS - 3rd - Science 7Ley CanasaNessuna valutazione finora

- 2002, Hirano Et Al.Documento9 pagine2002, Hirano Et Al.sumitNessuna valutazione finora

- Ib Maths PDFDocumento2 pagineIb Maths PDFNaga Satya Narayana SomarajuNessuna valutazione finora

- Crude Oil Emulsions - Petroleum Engineers Handbook PDFDocumento34 pagineCrude Oil Emulsions - Petroleum Engineers Handbook PDFMichael Grayson100% (3)

- CH 101Documento2 pagineCH 101nagravNessuna valutazione finora

- Potential Flow Theory: 2.016 HydrodynamicsDocumento2 paginePotential Flow Theory: 2.016 HydrodynamicsJorge EstebanNessuna valutazione finora

- Interference Well TestDocumento6 pagineInterference Well TestParitosh DoshiNessuna valutazione finora

- Simulation of Statcom For Voltage Improvement in An Electric Power NetworkDocumento14 pagineSimulation of Statcom For Voltage Improvement in An Electric Power NetworkOladeji Ifedayo RNessuna valutazione finora

- 106資優特訓班Documento96 pagine106資優特訓班utaNessuna valutazione finora

- Plastic Analysis AssignmentDocumento6 paginePlastic Analysis AssignmentLeo DoeNessuna valutazione finora

- Science 7 Third Quarter ExamDocumento7 pagineScience 7 Third Quarter ExamKenny Ann Grace Batiancila100% (1)

- Light and Architectural Lighting SystemsDocumento17 pagineLight and Architectural Lighting SystemsCrystal Kaye CortezNessuna valutazione finora

- Characteristics Optical Physics in Solid State: Optical Properties of Solids BY Mark FoxDocumento16 pagineCharacteristics Optical Physics in Solid State: Optical Properties of Solids BY Mark FoxMuhammad YaseenNessuna valutazione finora

- Science: Quarter 2 - Module 1: Different Forms of EM WavesDocumento25 pagineScience: Quarter 2 - Module 1: Different Forms of EM WavesMercy Mangaoil100% (3)

- UnificationDocumento318 pagineUnificationoperationmanagerNessuna valutazione finora

- Horizontally Connected High-Rise Buildings Under Earthquake LoadingsDocumento15 pagineHorizontally Connected High-Rise Buildings Under Earthquake LoadingsMaulana Nur IkhsanNessuna valutazione finora

- Polyurethene Foam Using LS-DYNA Material ModelsDocumento9 paginePolyurethene Foam Using LS-DYNA Material Modelsaoki186Nessuna valutazione finora

- C15 Excitation Module EM10 LEHE0449-00Documento5 pagineC15 Excitation Module EM10 LEHE0449-00Jose Rodriguez100% (1)

- Hamiltonian Mechanics: 4.1 Hamilton's EquationsDocumento9 pagineHamiltonian Mechanics: 4.1 Hamilton's EquationsRyan TraversNessuna valutazione finora

- Olp Igcse Mechanics CT 4 - New - Batch 1Documento5 pagineOlp Igcse Mechanics CT 4 - New - Batch 1Shabbir H. KhanNessuna valutazione finora

- 45zelio RM17 35Documento96 pagine45zelio RM17 35Dauceanu Ciprian100% (1)

- Magnetic Design MethodDocumento19 pagineMagnetic Design MethodKataria GauravNessuna valutazione finora

- Crystal Defects PDFDocumento1 paginaCrystal Defects PDFJohan Steven Rivera RomeroNessuna valutazione finora

- Dynamic Behavior of Materials - I - Meyers PDFDocumento684 pagineDynamic Behavior of Materials - I - Meyers PDFAamir RazaNessuna valutazione finora

- A Complete Guide to Safety Officer Interview Questions and AnswersDa EverandA Complete Guide to Safety Officer Interview Questions and AnswersValutazione: 4 su 5 stelle4/5 (1)

- Guidelines for Auditing Process Safety Management SystemsDa EverandGuidelines for Auditing Process Safety Management SystemsNessuna valutazione finora

- Rules of Thumb for Maintenance and Reliability EngineersDa EverandRules of Thumb for Maintenance and Reliability EngineersValutazione: 4.5 su 5 stelle4.5/5 (12)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDa EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Workbook to Accompany Maintenance & Reliability Best PracticesDa EverandWorkbook to Accompany Maintenance & Reliability Best PracticesValutazione: 3.5 su 5 stelle3.5/5 (3)

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityDa EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityValutazione: 5 su 5 stelle5/5 (2)

- Plutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersDa EverandPlutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersValutazione: 4 su 5 stelle4/5 (32)

- Introduction to Petroleum Process SafetyDa EverandIntroduction to Petroleum Process SafetyValutazione: 3 su 5 stelle3/5 (2)

- Chemical Process Safety: Learning from Case HistoriesDa EverandChemical Process Safety: Learning from Case HistoriesValutazione: 4 su 5 stelle4/5 (14)

- Fire Fighting Pumping Systems at Industrial FacilitiesDa EverandFire Fighting Pumping Systems at Industrial FacilitiesValutazione: 4.5 su 5 stelle4.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Tensor Technology Guide: Tensor Ring Benefits and UsesDa EverandTensor Technology Guide: Tensor Ring Benefits and UsesValutazione: 5 su 5 stelle5/5 (2)

- Culture, Health and Illness: An Introduction for Health ProfessionalsDa EverandCulture, Health and Illness: An Introduction for Health ProfessionalsNessuna valutazione finora

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationDa EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNessuna valutazione finora

- Handbook of Hazardous Chemical PropertiesDa EverandHandbook of Hazardous Chemical PropertiesValutazione: 5 su 5 stelle5/5 (1)

- Epidemiology and Demography in Public HealthDa EverandEpidemiology and Demography in Public HealthJaphet KillewoValutazione: 5 su 5 stelle5/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemDa EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNessuna valutazione finora

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsDa EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsValutazione: 4 su 5 stelle4/5 (11)

- Incidents That Define Process SafetyDa EverandIncidents That Define Process SafetyNessuna valutazione finora

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeDa EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNessuna valutazione finora

- The Invisible Rainbow: A History of Electricity and LifeDa EverandThe Invisible Rainbow: A History of Electricity and LifeValutazione: 4.5 su 5 stelle4.5/5 (21)

- Radium Girls: Women and Industrial Health Reform, 1910-1935Da EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Valutazione: 4.5 su 5 stelle4.5/5 (4)