Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Feasibility and acceptability of sweetpotato bakery products

Caricato da

tanginan sheilaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Feasibility and acceptability of sweetpotato bakery products

Caricato da

tanginan sheilaCopyright:

Formati disponibili

1

FEASIBILITY AND ACCEPTABILITY FOR SWEETPOTATO BAKERY

PRODUCTS.

A. BREAD

Description of the product

Materials

Sweetpotato roots

Fresh sweetpotato storage roots used in this study were from two popular clones found in Kampala: "Tanzania"1

and "New Kawogo". They were purchased from the Kalerwe market. Tanzania is characterized by a white skin

and yellowish fresh color whereas New Kawogo has a red skin and whitish flesh colour.

Sweetpotato dry matter determination

Dry matter content was determined as follows: triplicate 100-g samples of fresh roots were weighed to 0.1 mg, dried

at 70°C in a forced-air oven until the weight became constant (about 48 hours), removed, allowed to cool for 5 min

in a desiccator, and again weighed. It was 31.7 ± 0.4% for variety Tanzania and 31.5 ± 0.9% for New Kawogo.

Sweetpotato flour

Sweetpotato flour used in this study was processed out of dried sweetpotato slices purchased from a farmer at

Soroti, Uganda. They were from variety Tanzania and processed according to the general schema described in

Figure 1. After harvesting, sweetpotato storage roots are usually kept in the sun for 2-3 days, hand-peeled, sliced,

and sun-dried. After peeling, they are often crushed instead of slicing2 and dried. Sun-dried sweetpotato slices are

reportedly very sensitive to attack by storage weevils. To prevent such damage, some farmers in Tanzania parboil

or blanch the slices at the boiling temperature of water for 3-5 min and then dry them for 2-3 days before storage

(Dr. Kapinga, personal communication). After parboiling, a hard protective layer forms during the sun-drying

period because of gelatinized starch at the surface of the slices. This hard layer seems to prevent storage weevils

1Tanzania is occasionally referred to as "Mbale".

2Farmers report that slicing is labour-intensive and even dangerous (sharpened knife used in that process

could be perilous).

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

2

from penetrating into the slices. The blanching technique has not yet been reported in Uganda, but it is a common

practice in some parts of Tanzania (Ewell, 1993).

Sweetpotato slices used in our study were redried before use in forced-air cabinet drying at the KARI-Postharvest

Program in Kawanda to a moisture of 8% dry weight and then ground into flour in a "Posho" mill at the Nakawa

market.

Wheat flour

The wheat flour used was that generally used for bread-making in Uganda. It was milled in Uganda Grain Millers

Ltd. at Jinja (Unga Millers Limited, P.O. Box 895, Jinja, Uganda).

Baking trials

Baking trials were conducted under commercial baking conditions at FADCA Quality Foods, P.O. Box 2997,

Kampala, Uganda, using a mixture containing various proportions of wheat flour, sweetpotato flour or fresh-grated

or boiled and mashed sweetpotato storage roots. Table 1 gives the recipe for commercial baking using composite

flour with sweetpotato.

Baking procedure

Sweetpotato (flour, raw and grated3, or boiled and mashed4), wheat flour, baking yeast (Fermipan, Gist-brocades,

P.O. Box 1, 2600 MA Delft, Holland), dough improver (preparatory mix of dough improvers and raising agents),

and sugar were mixed together and a quarter of total water added. Figure 2 shows the technological process

schema.

The dough was kneaded using a mixer for 2 minutes at the first speed, and fat slowly added. The mixer continued

at this speed for two more minutes. The remaining water5 was slowly added to the mixture and mixing continued

for 8-10 min at n° 2 speed until an elastic dough was formed. The dough was cut into pieces of 560 g (which

should give a normal bread loaf weight of 500 g after baking), moulded, and then put in a fermentation cabinet kept

at about 30°C and 80% relative humidity for 2 hours. The dough was then baked at 240°C for 25-30 min. Eight

3Grating is usually hard and time-consuming work because of the latex content in sweetpotato storage

roots. In this study, it was done manually using a small kitchen grater. In Figure 2, the peeling operation

could be omitted when white-skinned variety Tanzania is used.

4Refers to peeled roots maintained in boiling water for about 25-30 min and then hand-mashed into

puree.

5In bread-making, water used in the recipe is usually not measured. It will depend on the protein content

of flour and the protein capacity of water retention. Experienced bread-makers normally know how to

check whether water is sufficient by feeling the dough elasticity in their hands.

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

3

samples of baked bread loaves were weighed 20 hours after baking. The day after baking, loaves were sliced,

packed and then taken to the Middle East or Kalerwe markets for consumer acceptability testing6.

The end product

Table 2 presents the calculated yield and changes in weight for a bread loaf of 500 g by adding sweetpotato as an

ingredient. The yield in bread is about three loaves from 1 kg of wheat flour or sweetpotato flour. From about 1 kg

of raw and grated sweetpotato roots, you can obtain one bread loaf of 500 g, whereas this ratio is about 800 g from

boiled and mashed sweetpotato roots (Table 2). It is interesting to note the heaviness of the loaves from raw and

grated, and from cooked and mashed, sweetpotato roots. In fact, they are about 10 g heavier than the loaves

processed from wheat flour or wheat flour plus sweetpotato flour.

Much more work is needed to determine the effect of that heaviness on the storability of the bread loaves in which

raw and grated or boiled and mashed sweetpotato have been incorporated. Many consumers have raised questions

about how long such loaves could be kept without deteriorating and becoming unfit for human consumption7.

Sweetpotato flour in bread-making

From discussions we had with commercial bakers, we learned that sweetpotato flour would be easy to handle and

use as a potential substitute for wheat flour in bread-making.

Various test loaves using increasing amounts of sweetpotato flour in lieu of wheat flour were made to see how much

wheat flour could be replaced and still provide an acceptable bread. We undertook to process 500-g bread loaves

using 16.6%, 23.3%, 30%, and 50% sweetpotato flour to replace wheat flour with FADCA's equipment. The 0%

loaf was the bread type "salty" usually processed at the FADCA bakery.

Sweetpotato flour bread

Table 3 lists some properties of bread baked at FADCA's bakery from composite flours containing different

proportions of sweetpotato flour. We observed the characteristics indicated or FADCA's workers noticed them after

6During our first-day test made on loaves with FADCA's workers, we decided to remove from the survey

the bread containing the boiled and mashed sweetpotato because it was too heavy, the crust was very

rough, and the loaves were not commercially acceptable. We believe the mixing was not adequate. More

mixing tests are required to establish the correct mixing time.

7Increased moisture in the baked product produces a softer crumb and increased shelf life.

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

4

seeing and tasting the bread made from the composite flour. Our results corroborate and generally agree with those

reported by Sammy (1970).

Use of 16.6 % sweetpotato flour produced a loaf almost identical to the standard wheat loaf, except for the light

grey colour with yellowish particles because of the sweetpotato flour (yellowish fresh variety, Tanzania) of the

crumb8. A 23.3% introduction produced a smaller and less attractive loaf. It had a very slight sweetpotato off-

odour and taste when hot, but this seemed to disappear on cooling. This loaf was acceptable, but less so than the

16.6% loaf. The 30% loaf was unacceptable as a formal bread because of its distinct sweetpotato off-flavour, taste,

and insufficient rising. There was no rising with the introduction of 50% sweetpotato flour. Figure 3 shows the

loaves with 16.6%, 23.3%, and 30% sweetpotato.

This experiment indicated to us that sweetpotato flour could replace wheat flour up to 20% if it is well processed

and of high quality9. Studies in terms of particle size, colour and drying conditions are still needed in order to

improve sweetpotato flour and its end products.

Consumer acceptability

Acceptability was evaluated by comparing sweetpotato bread (using raw, grated sweetpotato or sweetpotato flour to

substitute for wheat flour10) with the bread the consumer has just bought from the market. Attributes such as

sugary taste, colour, apparent freshness, heaviness, appearance (grain, texture, symmetry, crust and crumb colour),

and general acceptability were judged subjectively by bread consumers. Bread consumers were asked to compare

sweetpotato bread with the one they had just bought and had in their hands or were used to buying. In the Middle

East market, consumers compared sweetpotato bread with raw, grated sweetpotato roots (var. Tanzania) (#1) and

raw and grated roots (var. New Kahogo) (#2). In the Kalerwe market, consumers were asked to compare

sweetpotato bread with raw, grated sweetpotato roots (var. Tanzania) (#3) and to bread with flour processed from

sweetpotato roots (var. Tanzania) (#4). We did not inform consumers whether our product contained sweetpotato as

an ingredient.

Consumer acceptability characteristics

Figure 4 summarizes bread characteristic acceptability at the Middle East and Kalerwe markets and shows

consumers' choice between two types of sweetpotato bread and the type they have just bought at the respective

8The bread produced using the recipes indicated in Table 1 was like a standard European-type bread. It

contained 2-3% sugar whereas the popular bread in Kampala usually contained about 10% sugar in the

total ingredients. The standard European-type bread is labeled "salty".

9The dried sweetpotato slices used to produce flour were not highly cleaned and the fineness of the flour

was poor.

10We used 16.6% sweetpotato flour loaves.

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

5

market. At the Middle East market 73 bread consumers (purchasers) were interviewed, and 68 at the Kalerwe

market.

Sweetness

Most consumers from both markets indicated for their first choice that the bread loaf usually bought was much more

sugary. The bread loaf containing raw and grated sweetpotato was their second choice at both markets. At the

Middle East market, where we used two varieties but the same process of grating, there was no difference in choice

of consumer acceptability between varieties Tanzania and New Kawogo (Figure 5, second choice at Middle East).

Sweetpotato flour introduction in bread-processing seemed to reduce the sugary taste as a characteristic in bread

acceptability. The popular bread in Kampala is very sweet, and sugar usually represents about 10% of the total

ingredients.

In Uganda, bread is not a staple food like it is in other many countries around the world where the sugar content in

bread rarely exceeds 2-3%. In Kampala, bread is often consumed by a certain group of people (usually with a high

income) for breakfast and in the evening with tea. It is preferred very sweet perhaps as a substitute cake, or as a

cheap cake.

This fact is confirmed by the popularity and high preference of sweet yellow bread loaves in which artificial yellow

food colorants11 have been used to give to loaves the yellowish cake aspect or impression that eggs have been

added.

Colour

The colour of the bread loaf usually bought was the first choice at Middle East market and almost tied with one

containing raw and grated sweetpotato (variety Tanzania) at the Kalerwe market (Figure 4). The yellowish aspect

of variety Tanzania had a good record in colour acceptability as well at the Middle East market, where bread

containing raw and grated Tanzania was the second choice. Definitely, yellowish colour is an important

characteristic in acceptability of bread colour in Kampala.

Filling

For the filling aspect among consumers, bread containing raw and grated Tanzania tied with the one usually bought

at the Middle East market, as the first choice. The same figures for the first choice were observed at the Kalerwe

market, but this time between the loaf usually bought and the one containing sweetpotato flour. As the second

11Food grade colour used is orange or yellow obtained by a blend of tartrazine, sunset yellow, ponceau

4R and NaCl.

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

6

choice, bread with raw and grated New Kawogo was preferred at the Middle East market whereas the one with raw

and grated Tanzania was preferred at the Kalerwe market.

Appearance

As the first choice, the bread loaf usually bought looked better at the Middle East Market, followed by a tie between

the bread with raw and grated Tanzania and New Kawogo (Figure 4). At the Kalerwe market, the loaf usually

bought tied with the one containing raw and grated Tanzania for the first choice. The second choice was the bread

with raw and grated Tanzania that was preferred at both markets.

Freshness

At the Middle East market, consumers found that the three different bread types were highly fresh whereas at the

Kalerwe market their first choice was the bread with raw and grated Tanzania. As the second choice for consumers,

bread with raw and grated Tanzania tied with the one with raw and grated New Kawogo at the Middle East market

whereas the loaf usually bought led at the Kalerwe market, followed by the one with raw and grated Tanzania

(Figure 4).

Taste

The loaf usually bought was the first choice at the Middle East and Kalerwe markets. Bread with raw and grated

Tanzania was the first second choice at both markets.

Conclusion on the bread characteristic acceptability

The acceptability characteristics recorded among bread consumers at the Middle East and Kalerwe markets for

loaves made from ingredients including raw and grated sweetpotato were similar to those for bread usually bought

except for the sweetness characteristic for which the preference was very clearly favored the bread usually bought.

The bread made from ingredients including sweetpotato flour had acceptability characteristics in general poorer than

those of the one usually bought.

Price

Some 60% of consumers interviewed at the Kalerwe market said they would pay the same price for the bread loaf

made from ingredients including raw and grated sweetpotato (variety Tanzania) as for bread loaf just or usually

bought (Figure 5), 2% would pay more and 38% would pay less. The same figures have been recorded at the

Middle East market for the loaves containing raw and grated Tanzania. Those willing to pay the same price as for

bread loaf just bought reached 98% among consumers for the bread containing raw and grated New Kawogo. Only

40% of the consumers interviewed at the Kalerwe market would pay the same price for the bread loaf made from

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

7

ingredients containing sweetpotato flour as for bread loaf just or usually bought. Of the consumers interviewed,

60% said they would pay less for the bread with sweetpotato flour.

B. CHAPATI

Description of the product

Materials

Sweetpotato roots

The same common sweetpotato varieties Tanzania and New Kawogo were used for chapati trials.

Wheat flour

Wheat flour used was that generally used for chapati-making in the Nakawa and Wandegeya markets. It was milled

by UNGA Limited, Commercial Street P.O. Box 30386, Nairobi, Kenya.

Processing

Chapatis were made from the following recipe : 1.0 kg of wheat flour, 1.0 kg of sweetpotato (boiled and mashed or

raw and grated), 1 teaspoon (about 1.7 g) of salt (Salt Manufacturers Kenya Ltd., P.O. Box 81665, Mombasa,

Kenya), 3 teaspoons (about 5 mL) of baking powder12 (Kapa Oil Refineries Ltd., P.O. Box 18492, Nairobi, Kenya),

1/4 cup (about 100 mL) of vegetable oil (Mukwano Industries Ltd., P.O. Box 2671, Kampala, Uganda) and 2 cups

of water.

The chapatis for our trials were processed by one of the chapati makers from the respective market following the

appropriate commercial chapati procedure. Figures 6 and 7 indicate the process schemas of chapati-making using

boiled and mashed sweetpotato and raw and grated sweetpotato roots.

Sweetpotato and dry ingredients were mixed together. Water was added and the mixture hand-kneaded to make a

soft, smooth dough. The resulting dough was divided into approximately equal portions and formed into balls.

These were rolled13 into circular shapes of about 12 cm in diameter and about 3 mm thick using a floured pastry

board, and grilled on a hot and oily griddle iron for about 1 minute each (about 30 sec for each side) (Figures 6 and

7).

12Some processors in Kenya and Uganda do not use the baking powder.

13Chapatiprocessors told us that the mixing and rolling of dough containing raw and grated sweetpotato

was harder than usual, whereas the one with boiled and mashed sweetpotato was easier.

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

8

The end product

Chapati in Kampala is a kind of simple, flat, salty bread (Figure 8) generally characterized by the size, oiliness, and

heaviness. The main quality components of chapati are discussed later in this report.

Consumer acceptability

Acceptability was evaluated by comparing sweetpotato chapatis (substituting raw and grated or cooked and mashed

sweetpotato for wheat flour) with the chapatis the consumer has just bought from the market. Attributes such as

taste, colour, apparent freshness, filling, heaviness, oiliness, appearance (texture, symmetry, crust), and general

acceptability were judged subjectively by chapati consumers. Chapati consumers were asked to compare

sweetpotato chapati with the one they had just bought and had in their hands or were used to buying. In the Nakawa

and Wandegeya markets, consumers were asked to compare chapati with raw and grated sweetpotato roots (var.

Tanzania) with chapati of boiled and mashed sweetpotato roots (var. New Kawogo).

Consumer acceptability characteristics

Figure 8 summarizes chapati acceptability characteristics at the Nakawa and Wandegeya markets as indicated by

consumers. They compared sweetpotato chapati with the one they have just bought at the respective market, and

ranked them as their first or second choice. At the Nakawa market, 29 chapati consumers (purchasers) were

interviewed, and 51 at the Wandegeya market.

Sweetness

Most consumers from the Nakawa and Wandegeya markets indicated the chapati with the boiled and mashed New

Kawogo sweetpotato ingredient as their first choice for sugar content and sweetness (Figure 9). As their second

choice, chapati containing raw and grated Tanzania was indicated at the Nakawa market whereas the chapati usually

bought is as sweet as the one containing raw and grated Tanzania for consumers (purchasers) of the Wandegeya

market14.

Oiliness

Chapati with boiled and mashed New Kawogo as an ingredient was chosen first by consumers from the Nakawa and

Wandegeya markets for its well-measured oil content. Chapati usually bought and the one with raw and grated

Tanzania followed at the same level as the first choice for oil content (Figure 9). As for the second choice,

14Although consumers have classified the chapati according to its sweetness, the chapati sweetness

component is not a quality usually desired in the product. Consumers indicated that the sweet chapati

adds a new choice on the market.

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

9

consumers did not show a clear difference for the three types of chapati although the one with raw and grated

Tanzania was the second choice by a slight margin.

Colour

For consumers from the Nakawa market, chapati made from ingredients containing boiled and mashed New

Kawogo was definitely their first choice. At the Wandegeya market, the first choice was not clear. The colour of

the three types of chapati was good, but chapatis with raw and grated Tanzania and the ones just and usually bought

had the best first colour. As for the second choice, chapati usually bought and the one with raw and grated Tanzania

were indicated at the Nakawa market. The three types of chapati tied at the Wandegeya market as the second choice

for consumers.

Filling

For consumers from the Nakawa market, chapati with boiled and mashed New Kawogo was their first choice,

followed by the one with raw and grated Tanzania (Figure 9). At Wandegeya, the first choice was not distinctively

clear for consumers because the three types were highly accepted. As the second choice, chapati with raw and

grated Tanzania was preferred at both markets. Consumers indicated chapati usually bought and the one with boiled

and mashed New Kawogo as their first second choice.

Appearance

As the first choice, chapati with boiled and mashed New Kawogo looked nice at the Nakawa market (Figure 8). At

the Wandegeya market, chapati with raw and grated Tanzania led as the first choice of consumers, followed by a tie

between the one with boiled and mashed New Kawogo and the one usually bought. As the second choice, chapati

with raw and grated Tanzania was preferred by consumers at the Nakawa market. At the Wandegeya market,

consumers did not find any difference in appearance and shape between the chapati just bought and the one with

raw and grated Tanzania (Figure 9).

Freshness

At the Nakawa and Wandegeya markets, consumers found that the chapati with boiled and mashed New Kawogo

was their first choice in freshness. The figures for the second choice were similar at both markets and the chapati

with raw and grated Tanzania was their first second choice. The ones just and usually bought followed with an

equally record of acceptability.

Taste

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

10

The taste of chapati with boiled and mashed New Kawogo was the first choice for consumers from the Nakawa

market. Consumers from the Wandegeya market indicated that the taste of the three types of chapati was very good

and all could be considered as the first choice. As the second choice, chapatis just and usually bought with the one

containing raw and grated Tanzania were preferred at both markets.

Conclusion on chapati acceptability characteristics

Acceptability characteristics recorded for chapatis made from ingredients including boiled and mashed sweetpotato

were superior to those for chapati usually bought. Chapatis made from raw and grated Tanzania were similarly

acceptable as the one usually bought.

Price

Some 78% of consumers interviewed at the Nakawa market said they would pay the same price for chapati made

from ingredients containing raw and grated Tanzania (Figure 10) as for chapati usually bought, 10% would pay

more and 12% would pay less. The same figures were recorded at the Wandegeya market for chapati with raw and

grated Tanzania. For chapati with boiled and mashed New Kawogo, 80% of consumers at the Nakawa market

would pay the same price as for the chapati usually bought, 18% would pay more and 2% would pay less. At the

Wandegeya market, 78% of consumers would pay the same price, 20% would pay less and 2% would pay more.

C. MANDAZI

Description of the product

Sweetpotato roots

The same common sweetpotato varieties Tanzania and New Kawogo were used for mandazi trials.

Wheat flour

Wheat flour used was that generally used for mandazi-making at the Wandegeya market. It was milled by UNGA

Limited, Commercial Street P.O. Box 30386, Nairobi, Kenya.

Processing

Mandazis were made from the following recipe : 1.5 kg of wheat flour, 1.5 kg of sweetpotato (cooked and mashed

or raw and grated), 250 g of sugar, 2 tablespoons (about 10 mL) of baking powder, 5 tablespoons (about 25 mL) of

vegetable oil and 21/4 cups (about 500-600 mL) of water. The mandazis were processed by one of the mandazi

makers from the Wandegeya market following the appropriate commercial mandazi procedure. Figures 11 and 12

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

11

indicate the process schemas of mandazi-making using boiled and mashed sweetpotato and raw and grated

sweetpotato roots.

Sweetpotato and dry ingredients were mixed together and a well was made in the centre where the oil was put and

mixed. Sweetpotato was added and then water was slowly and added gradually and hand-kneaded until a soft

dough formed. The dough was left to relax for 10-15 min and was then rolled on a floured pastry board to the

thickness of 1.25 cm (Oyunga, 1994). It was then cut into approximately equal pieces that were deep-fried until

browning.

The end product

Mandazi is a kind of doughnut (Figure 13) characterized by its round size, sweetness, brownish colour, and

heaviness. The main quality components of mandazi are discussed later in this report.

Consumer acceptability

Acceptability was evaluated by comparing sweetpotato mandazis (subtituting raw, fresh grated or fresh cooked and

mashed sweetpotato for wheat flour) with mandazis the consumer has just bought from the market. The attributes

such as sugary taste, colour, apparent freshness, filling, heaviness, appearance (grain, texture, symmetry, crust and

crumb colour), and general acceptability were judged subjectively by mandazi consumers. Mandazi consumers

were asked to compare sweetpotato mandazis to the ones they had just bought and had in their hands or they were

used to buying. Sweetpotato mandazis had raw and grated sweetpotato roots (var. Tanzania) and boiled and mashed

sweetpotato roots (var. New Kawogo).

Consumer acceptability characteristics

Figure 14 summarizes mandazi acceptability characteristics at the Wandegeya market as the first or second choice

for sweetpotato mandazi compared with the ones the consumer just bought at the market. Some 43 mandazi

consumers (purchasers) were interviewed.

Sugar

Consumers from the Wandegeya market found that mandazis made from ingredients containing boiled and mashed

New Kawogo were their first choice, followed by a tie between the mandazis with raw and grated Tanzania and the

ones just or usually bought. As the second choice, mandazis with raw and grated Tanzania were the first second

choice for those consumers.

Oiliness

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

12

Mandazis with boiled and mashed New Kawogo were indicated as the first choice for oil content, followed by the

ones just or usually bought. As the first second choice, boiled and mashed New Kawogo was again preferred by

consumers.

Colour

Mandazis with boiled and mashed New Kawogo were indicated as the first choice for having the best color,

followed by the ones with raw and grated Tanzania. As the second choice, the colour of mandazis with raw and

grated Tanzania was the first second choice, followed by the ones just or usually bought.

Filling

As the first choice, the difference was not distinctively clear between mandazis containing raw and grated Tanzania

and the ones with boiled and mashed New Kawogo. The filling aspect was high for both. Consumers indicated

mandazis with raw and grated Tanzania as their first second choice, followed by a tie between mandazis usually

bought and the ones with boiled and mashed New Kawogo.

Appearance

Mandazi with boiled and mashed New Kawogo were indicated by consumers to have a highly pleasing appearance.

As the second choice, mandazis with raw and grated Tanzania were preferred, followed by the ones just or usually

bought.

Freshness

Consumers indicated mandazis with boiled and mashed New Kawogo as their first choice (Figure 14). The ones

with raw and grated Tanzania were indicated as the first second choice, followed by the ones just or usually bought.

Taste

The taste of mandazis with boiled and mashed New Kawogo was the first choice for consumers from the

Wandegeya market (Figure 14). The ones with raw and grated Tanzania were the first second choice, followed by

mandazis just or usually bought.

Conclusion on mandazi acceptability characteristics

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

13

According to consumers interviewed, the acceptability characteristics recorded for mandazis made from ingredients

including boiled and mashed sweetpotato New Kawogo were superior to those for mandazis usually bought,

whereas those made from raw and grated Tanzania were similar to mandazis usually bought.

Price

Some 80% of consumers interviewed at the Wandegeya market said they would pay the same price for mandazis

made from ingredients including raw and grated Tanzania or boiled and mashed New Kawogo (Figure 15), about

19% would pay less and 1% would pay more.

D. CONSUMER SUGGESTIONS TO IMPROVE PROCESSED

SWEETPOTATO PRODUCTS

Quality product components

Quality is defined by Kader (1985) as any of the features that make something what it is or the degree of excellence

or superiority. The word quality could be used in various ways. For sweetpotato roots and end products, it can

refer to market quality, edible quality, shipping quality, table quality, nutritional quality, internal quality, and

appearance quality. Fresh sweetpotato quality is a combination of characteristics, attributes, and properties that

give the valuable to humans as food. Farmers worry whether their commodity has a good appearance and few

visual defects, so for them a useful cultivar must score high for yield, disease resistance, ease of harvest, and should

have good shipping quality. People receiving roots and market distributors, appearance quality is the most

important (in many different Kampala markets, sweetpotato sellers put the best roots on the top of the heap or the

basket, whereas the smallest roots with an often bad look go to the bottom). Distributors are also keenly interested

in firmness and long storage life. Table 4 lists quality components for fresh sweetpotato and many of them are

similar for processed products from sweetpotato roots.

Although quality components are known, well documented, and almost standardized for bread, for chapati and

mandazi they are perhaps known by consumers and processors, but have not yet been standardized, or well

documented. Consumers and processors of such products usually refer to appearance, texture, and flavour.

Nutritive value and safety factors are not often highlighted. Consumers consider good-quality chapati or mandazi to

be those that look good, are soft, and offer good flavour and nutritive value. Although chapati or mandazi

consumers generally buy on the basis of appearance and feel, their satisfaction and repeat purchases depend upon

good edible quality and low price.

The appearance of sweetpotato processed products can be influenced by many defects related to mechanical damage

during processing, such as splitting and crushing (mandazi). Colour is important for such products, but not always

essential for chapati or mandazi consumers. The texture of fried processed products is also very important. Soft

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

14

chapati and mandazi are required by consumers while oiliness in these products does not constitute a problem of

acceptability.

Flavour quality that involves perception of tastes and aromas of many compounds is perhaps the most important

quality component for fried processed sweetpotato products. Sweetness is required in mandazi as is saltiness for

chapati. All quality components are usually interrelated.

Quality components to be improved in processed sweetpotato products

Bread

The main criticism for the bread loaf made from ingredients containing sweetpotato is related to flavour (taste) and

especially to the lack of sweetness in the product (Table 5). This issue was discussed earlier in this report.

The appearance and texture of the product are hardly pointed out, except for the bread loaf made from ingredients

containing sweetpotato flour, in which quality related to appearance, such as coarseness, stickiness, compactness,

and shape were indicated by consumers as poor for the product. Some consumers suggested that we put yellow

colour in our product . In fact, this suggestion is because the popular bread and buns are often coloured yellow with

food colorants in Kampala. Some bakers effectively add eggs in the dough together with food colorants, but most

of them only add food colorants. The main quality components are generally met for the bread with ingredients

containing raw and grated sweetpotato.

Chapati

The quality problem in chapati made from ingredients containing sweetpotato is related to texture. The product is

reportedly oily and brittle (mainly for chapati made from ingredients containing raw and grated sweetpotato), and

lacks homogeneity in hand-mixing. It is also not as soft as the one usually bought.

Consumers indicated that components related to taste (increase saltiness and reduce sweetness), and appearance

(increase the size, thickness, and whiteness caused by non-enzymatic browning) should be improved.

Nutritive value for chapati refers to the lack of heaviness of the product whereas safety aspects refer to cleanliness

during the frying process and to the quality and change of used oil (Table 5).

Mandazi

Quality components to be improved in mandazis are size (which should be increased) and the sweetness (which

should be reduced). For texture, oiliness should be reduced in mandazis with raw and grated Tanzania, and softness

increased. Products made from boiled and mashed New Kawogo were found to be of high quality.

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

15

Reasons given for not paying the same price as for the product usually bought

Consumers were usually ready to pay the same price for products containing sweetpotato as for products they

usually bought except for bread made from ingredients containing sweetpotato flour15 (Table 6). We have already

discussed these reasons, which are related to quality factors.

Flavour is a key quality factor for all of the products, followed by appearance and then texture. Nutritive value and

safety aspects are not important for consumers interviewed in Kampala.

It is interesting to note quality factors for bread compared with ones for chapati or mandazi. According to the

figures reported in Table 6, bread consumers require product quality (flavour, appearance, texture, and even

nutritive value) before buying, whereas chapati and mandazi consumers pay little attention to quality factors before

purchasing the product. Consumer income and level of education could explain this observation.

15We believe the sweetpotato flour was badly processed.

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

16

References

Ewell, P.T. 1993. Sweetpotato in Africa : Research priorities to stimulate increased marketing. Paper presented at

International Workshop on Methods for Agricultural Marketing Research, IARI Campus, New Dehli, India,

16-20 March 1993.

Kader, A. A. 1985. Quality factors : Definition and evaluation for fresh horticultural crops, pp 118-121. In Kader,

A.A., Kasmire, R.F., Mitchell, F.G., Reid, M.S., Sommer, N.F., and Thompson, J.F. Postharvest Technology of

Horticultural Crops, Univ. of California

Oyunga, M.A. 1994. Sweetpotato product development course outline. In : Seminar to promote processed

sweetpotato products in Uganda. September 10-17, 1994, Mukono, Uganda.

Hamed, M.G.E., Refai, F.Y., Hussein, M.F., and El-Samahy, S.K. 1973. Effect of adding sweetpotato flour to

wheat flour on physical dough properties and baking. Cereal Chem. 50 : 140-146.

Sammy, G.M.. 1970. Studies in composite flours. I. The use of sweetpotato flour in bread and pastry making.

Trop. Agric. Trinidad 47 : 115-125.

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

17

Table 1: Recipes for making bread using flour composite with sweetpotato.

Ingredients Quantity (kg)

Sweetpotato 2.10 (flour) 4.20 (raw & grated) 4.20 (boiled &mashed)

Wheat flour 10.50 10.50 10.50

Yeast 0.12 0.10 0.10

Improver 0.20 0.20 0.20

Sugar 0.40 0.40 0.40

Fat 0.25 0.25 0.25

Water About 6.50 About 4.50 About 5.00

500-g bread loaves

obtained 38 36 38

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

18

Table 2: Yield and changes in weight for bread loaf of 500 g by adding sweetpotato as an ingredient.

Wheat flour Sweetpotato Weight of baked Yield of baked bread

(parts) (parts) bread loafb loaves

(g) (pieces of 500 g)

100a 0.0 501±3 300

100 13.3 (flour) 501±5 342

100 16.6 (flour) 501±2 353

100 23.3 (flour) 500±1 365

100 30.0 (flour) 500±5 400

100 41.2 (raw and grated) 510±5 342

100 41.2 (boiled and mashed) 511±4 353

a Estimation from the manager of the FADCA bakery.

b Weight of dough before fermentation and baking was 560 g.

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

19

SP KAMPALA STUDY, NOV. 1994 VITAL HAGENIMANA

Potrebbero piacerti anche

- Organoleptic and Nutritional Analysis of Taro and Wheat Flour Composite BreadDocumento5 pagineOrganoleptic and Nutritional Analysis of Taro and Wheat Flour Composite BreadGul ZakkaNessuna valutazione finora

- Instant Cassava Noodles ProductionDocumento7 pagineInstant Cassava Noodles ProductionSiegLailNessuna valutazione finora

- Nutrition Vol 6 No1 P 113-119Documento7 pagineNutrition Vol 6 No1 P 113-119Samuel OlagunjuNessuna valutazione finora

- Ripe Banana Flour As A Source of Antioxidants in Layer and Sponge CakesDocumento7 pagineRipe Banana Flour As A Source of Antioxidants in Layer and Sponge CakesErika -Nessuna valutazione finora

- 1 SM PDFDocumento11 pagine1 SM PDFCandraNessuna valutazione finora

- Evaluation of Cookies Produced From Blends of Wheat, Cassava and Cowpea FloursDocumento11 pagineEvaluation of Cookies Produced From Blends of Wheat, Cassava and Cowpea FloursALVARONessuna valutazione finora

- Flour Treatise Part 1Documento4 pagineFlour Treatise Part 1madbakingNessuna valutazione finora

- Go2015 Article SensoryEvaluationShelflifeAndNDocumento7 pagineGo2015 Article SensoryEvaluationShelflifeAndNSourav GargNessuna valutazione finora

- Tigernuts Flour / Harina de ChufasDocumento11 pagineTigernuts Flour / Harina de ChufasBeida Omenesa VictorNessuna valutazione finora

- Acceptability Attributes of Crackers Made From Different Types of Composite FlourDocumento4 pagineAcceptability Attributes of Crackers Made From Different Types of Composite FlourIvana HalingkarNessuna valutazione finora

- Jurnal KesehatanDocumento8 pagineJurnal KesehatanrilleyNessuna valutazione finora

- AENG 95 - Learning Activity 1Documento19 pagineAENG 95 - Learning Activity 1Rufina RiveraNessuna valutazione finora

- Food processing technology I course explores snacks productionDocumento19 pagineFood processing technology I course explores snacks productionAmeshe MogesNessuna valutazione finora

- Flour Making: Marawi CampusDocumento8 pagineFlour Making: Marawi CampusErnie Mark Patosa MaratasNessuna valutazione finora

- Pengaruh Substitusi Tepung Ubi Jalar Ungu Terhadap Karakteristik Kue KeringDocumento6 paginePengaruh Substitusi Tepung Ubi Jalar Ungu Terhadap Karakteristik Kue KeringRippie RifdahNessuna valutazione finora

- Effect of Blanching and Ripening of Functional Properties of PlantainDocumento10 pagineEffect of Blanching and Ripening of Functional Properties of PlantainAndrea Osorio AlturoNessuna valutazione finora

- Flour quality and breadmaking improved by wheat grain polishingDocumento8 pagineFlour quality and breadmaking improved by wheat grain polishingMaría Belén VignolaNessuna valutazione finora

- A Study On Possible Use of Calcium Propionate and Ascorbic Acid in The Production of Cassava BreadDocumento6 pagineA Study On Possible Use of Calcium Propionate and Ascorbic Acid in The Production of Cassava BreadNajmi NasirNessuna valutazione finora

- Grade 10 Physicochemical and Functional Properties of WheatDocumento12 pagineGrade 10 Physicochemical and Functional Properties of Wheatapi-283862617Nessuna valutazione finora

- Production and Sensory Evaluation of Biscuits Using The Composite Flours of African Yam Bean and Wheat FlourDocumento2 pagineProduction and Sensory Evaluation of Biscuits Using The Composite Flours of African Yam Bean and Wheat FlourIOSRjournalNessuna valutazione finora

- Organizational Structure and History of Tat Macaroni IndustryDocumento20 pagineOrganizational Structure and History of Tat Macaroni Industrydamla6k6yl6Nessuna valutazione finora

- Art Formulasi Terigu Dan Tepung KeladiDocumento10 pagineArt Formulasi Terigu Dan Tepung KeladiWahyu FebriansyahNessuna valutazione finora

- Tepung SorghumDocumento8 pagineTepung Sorghumnugraha widyatmonoNessuna valutazione finora

- EBSCO FullText 2023 01 02Documento13 pagineEBSCO FullText 2023 01 02Haruki AkemiNessuna valutazione finora

- Informe PanificaciónDocumento9 pagineInforme PanificaciónTatiana CristanchoNessuna valutazione finora

- Amino Acid Composition and Protein Quality of Wheat Flour Biscuits Fortified With Soybean and Bambara Groundnut FloursDocumento12 pagineAmino Acid Composition and Protein Quality of Wheat Flour Biscuits Fortified With Soybean and Bambara Groundnut FloursGJESR100% (1)

- Yam FlourDocumento5 pagineYam Flouramdbilal123Nessuna valutazione finora

- LatestpublishedDocumento10 pagineLatestpublishedHiệp Lê QuangNessuna valutazione finora

- Bihon From Sweet PotatoDocumento6 pagineBihon From Sweet Potatodiwata444Nessuna valutazione finora

- Characteristics of White Bread With Fermented and Unfermented SORGHUM FLOUR (Sorghum Bicolor (L) MOENCH)Documento5 pagineCharacteristics of White Bread With Fermented and Unfermented SORGHUM FLOUR (Sorghum Bicolor (L) MOENCH)kikyNessuna valutazione finora

- Castronuevo, Rogelio Iii - Tem Act. 3 MidtermDocumento10 pagineCastronuevo, Rogelio Iii - Tem Act. 3 Midtermit.rjcastronuevoNessuna valutazione finora

- PlantFoods ISSUE 14 Wheat, Flour, BreadDocumento3 paginePlantFoods ISSUE 14 Wheat, Flour, Breadelina18202Nessuna valutazione finora

- Abjna 5 1 33 39Documento7 pagineAbjna 5 1 33 39Just nowNessuna valutazione finora

- Pr2 Final CookieDocumento18 paginePr2 Final CookieRed VailNessuna valutazione finora

- Parle PresentationDocumento33 pagineParle PresentationMuzamil Quadir0% (1)

- Evaluating The Effects of Sweet Potato Varieties On Flour QualityDocumento28 pagineEvaluating The Effects of Sweet Potato Varieties On Flour QualityInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Amino Acid Profile, Physicochemical and Sensory Properties of Noodles Produced From Wheat-Bambara Protein Isolate - ScienceDirectDocumento13 pagineAmino Acid Profile, Physicochemical and Sensory Properties of Noodles Produced From Wheat-Bambara Protein Isolate - ScienceDirectHalimat Usman AdemolaNessuna valutazione finora

- PURPLE CORN FLOUR STA MARIA THESIS OUTLINE Final Revised2Documento43 paginePURPLE CORN FLOUR STA MARIA THESIS OUTLINE Final Revised2Jain EpifanioNessuna valutazione finora

- Pengaruh Konsentrasi Gluten Terhadap Karakteristik Pasta Kering GanyongDocumento18 paginePengaruh Konsentrasi Gluten Terhadap Karakteristik Pasta Kering GanyongasramabukitNessuna valutazione finora

- IJRPR1352Documento4 pagineIJRPR1352Just nowNessuna valutazione finora

- Sliced Bread: The Science ofDocumento4 pagineSliced Bread: The Science ofGayatri PrameswariNessuna valutazione finora

- Assessment of Functional Properties of Different Flours: Full Length Research PaperDocumento4 pagineAssessment of Functional Properties of Different Flours: Full Length Research PaperTushar KastureNessuna valutazione finora

- Gluten Free Bread Making Trials From Cassava Manihot Esculenta Crantz Flour and Sensory Evaluation of The Final ProductDocumento13 pagineGluten Free Bread Making Trials From Cassava Manihot Esculenta Crantz Flour and Sensory Evaluation of The Final ProductVirda Ayu Nia SaputriNessuna valutazione finora

- Sagostarch NoodlequalityDocumento7 pagineSagostarch NoodlequalityAfiq Rico SusantoNessuna valutazione finora

- Physico-Chemical and Sensory Evaluation of Breads Supplemented With Pumpkin FlourDocumento8 paginePhysico-Chemical and Sensory Evaluation of Breads Supplemented With Pumpkin FlourMinh Hằng ĐặngNessuna valutazione finora

- Pembuatan Mie Subtitusi Tepung Terigu Dengan Tepung Jagung Putih (ZeaDocumento8 paginePembuatan Mie Subtitusi Tepung Terigu Dengan Tepung Jagung Putih (ZeaGunawanNessuna valutazione finora

- Properties of StarchDocumento13 pagineProperties of StarchPadmavati KarthicNessuna valutazione finora

- Tepung Ampas Kelapa SBG Cookies Ubi Jalar UnguDocumento9 pagineTepung Ampas Kelapa SBG Cookies Ubi Jalar UnguSakinah AMNessuna valutazione finora

- Wu Et Al-2016-Journal of Food ScienceDocumento7 pagineWu Et Al-2016-Journal of Food ScienceJor GeNessuna valutazione finora

- (Paperhub - Ir) 10.1002 Jsfa.3197Documento7 pagine(Paperhub - Ir) 10.1002 Jsfa.3197jesus viamonteNessuna valutazione finora

- Spaghetti - Paste FainoaseDocumento7 pagineSpaghetti - Paste FainoaseEder IzakiNessuna valutazione finora

- 1 s2.0 S096399699800091X MainDocumento7 pagine1 s2.0 S096399699800091X Mainlarrain lsdNessuna valutazione finora

- BreadfruitDocumento6 pagineBreadfruitningrumNessuna valutazione finora

- Production of Powdered Maize Ogi (Indigenous Complementary Food) Flours Complemented With Soybean and Sorghum MaltDocumento14 pagineProduction of Powdered Maize Ogi (Indigenous Complementary Food) Flours Complemented With Soybean and Sorghum MaltSharif HossenNessuna valutazione finora

- Acceptability and Marketability of Laing SiopaoDocumento6 pagineAcceptability and Marketability of Laing SiopaogjaymarNessuna valutazione finora

- Processing and Quality Evaluation of Crackers From Cassava FlourDocumento4 pagineProcessing and Quality Evaluation of Crackers From Cassava FlourDBNessuna valutazione finora

- CHAPTER 2 Corn DoughnutDocumento8 pagineCHAPTER 2 Corn Doughnutrhynz banastonNessuna valutazione finora

- Wholegrain Durum Wheat Bread Fortified With Citrus Fibers: Evaluation of Quality Parameters During Long StorageDocumento13 pagineWholegrain Durum Wheat Bread Fortified With Citrus Fibers: Evaluation of Quality Parameters During Long StorageFarmasi 2016/BNessuna valutazione finora

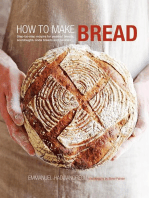

- How to Make Bread: Step-by-step recipes for yeasted breads, sourdoughs, soda breads and pastriesDa EverandHow to Make Bread: Step-by-step recipes for yeasted breads, sourdoughs, soda breads and pastriesValutazione: 3.5 su 5 stelle3.5/5 (4)

- Aacivity Sheets 9Documento71 pagineAacivity Sheets 9Joyce Anne De Vera RamosNessuna valutazione finora

- Chef Eric LeVine's Thanksgiving RecipesDocumento6 pagineChef Eric LeVine's Thanksgiving RecipesNews12NJWebNessuna valutazione finora

- Kumpulan Soal Procedure TextDocumento6 pagineKumpulan Soal Procedure TextRoniIndraGNessuna valutazione finora

- Recipe Mod - JorjaLoewenDocumento5 pagineRecipe Mod - JorjaLoewenJorja LoewenNessuna valutazione finora

- Maryhill College, Inc.: A Business Plan of Wrap Eat UpDocumento6 pagineMaryhill College, Inc.: A Business Plan of Wrap Eat UpSofia VeluzNessuna valutazione finora

- Black Forest Gateau Recipe by Eric Lanlard - Sainsbury's MagazineDocumento2 pagineBlack Forest Gateau Recipe by Eric Lanlard - Sainsbury's MagazinelebbomareNessuna valutazione finora

- Apricot and Gouda Scones: IngredientsDocumento4 pagineApricot and Gouda Scones: IngredientsAbi CatacutanNessuna valutazione finora

- India Ingredients Substitution ChartDocumento1 paginaIndia Ingredients Substitution Chartsachinsaklani23Nessuna valutazione finora

- LM - GRADE 6 - DLP 10 - Following Series of DirectionsDocumento11 pagineLM - GRADE 6 - DLP 10 - Following Series of DirectionsAllan Ronulo0% (1)

- Practice About Adverbs of Frequency Activities Promoting Classroom Dynamics Group Form - 72210Documento2 paginePractice About Adverbs of Frequency Activities Promoting Classroom Dynamics Group Form - 72210Dalya Maritzza Silva B100% (1)

- Corn Manchurian Fried Rice - Corn Recipes - Indian Chinese RecipesDocumento8 pagineCorn Manchurian Fried Rice - Corn Recipes - Indian Chinese RecipesChakradhar DNessuna valutazione finora

- Granola Bar: Type - Energy Bar - Diet Bar - Nutricious Bar - Vitamin C BarDocumento12 pagineGranola Bar: Type - Energy Bar - Diet Bar - Nutricious Bar - Vitamin C BarFakhrul AkulafakNessuna valutazione finora

- Kontakt Lista Za IvozDocumento15 pagineKontakt Lista Za Ivozostojicv100% (1)

- Gastronomy 2018 PDFDocumento24 pagineGastronomy 2018 PDFVasileios KozakidisNessuna valutazione finora

- Amy Kim - Capstone MindmapDocumento1 paginaAmy Kim - Capstone Mindmapapi-690574008Nessuna valutazione finora

- Keto Work BookDocumento8 pagineKeto Work BookMiteshNessuna valutazione finora

- El Fuego Food Menu OnlineDocumento10 pagineEl Fuego Food Menu OnlinedavemacbrainNessuna valutazione finora

- PDF Rex Digestive Anti - Refluxdiet PDFDocumento1 paginaPDF Rex Digestive Anti - Refluxdiet PDFJenniferNessuna valutazione finora

- Signature Burgers: SmokeyDocumento4 pagineSignature Burgers: SmokeyMichelleNessuna valutazione finora

- Gastronomy Quiz With Present PerfectDocumento3 pagineGastronomy Quiz With Present PerfectXiomara DiosaNessuna valutazione finora

- Lesson 1: Master cake decorating techniquesDocumento9 pagineLesson 1: Master cake decorating techniquesaileen sarmientoNessuna valutazione finora

- FAB Midterm Study GuideDocumento4 pagineFAB Midterm Study Guidesotos5Nessuna valutazione finora

- SITHKOP005 Student LogbookDocumento177 pagineSITHKOP005 Student LogbookRamesh Adhikari100% (1)

- Authentic Chettinad Pepper chicken recipeDocumento10 pagineAuthentic Chettinad Pepper chicken recipejey011Nessuna valutazione finora

- Roduct Atalog: Food Preparation Machines - Made in SwedenDocumento19 pagineRoduct Atalog: Food Preparation Machines - Made in SwedenMahmmoud MoattyNessuna valutazione finora

- Group 5 Integrative Survival Restaurant Budget PlanDocumento24 pagineGroup 5 Integrative Survival Restaurant Budget PlanRifkah IqbalNessuna valutazione finora

- English Form 3 Units 2Documento6 pagineEnglish Form 3 Units 2Miera MijiNessuna valutazione finora

- BQT Table Setup - BuffetDocumento2 pagineBQT Table Setup - BuffetVivekanand SinghNessuna valutazione finora

- Analisis Kadar Alkohol Pada Tape Ubi Yang Difermentasikan Selama 3 Hari Dan 6 Hari Yang Dijual Pada Pasar Boro Kecamatan Rumbia Kabupaten JenepontoDocumento6 pagineAnalisis Kadar Alkohol Pada Tape Ubi Yang Difermentasikan Selama 3 Hari Dan 6 Hari Yang Dijual Pada Pasar Boro Kecamatan Rumbia Kabupaten JenepontoAdinda MahardikaNessuna valutazione finora

- F&F Recipe BookDocumento51 pagineF&F Recipe BookJohnNessuna valutazione finora