Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Relationship of Physical Properties of Fats and Oils With Quality Characteristics of Cookie

Caricato da

Mario RatulangiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Relationship of Physical Properties of Fats and Oils With Quality Characteristics of Cookie

Caricato da

Mario RatulangiCopyright:

Formati disponibili

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(A High Impact Factor & UGC Approved Journal)

Website: www.ijirset.com

Vol. 6, Issue 8, August 2017

Relationship of Physical Properties of Fats and

Oils with Quality Characteristics of Cookie

Amita Devi1, B. S. Khatkar2

Ph.D. Scholar, Department of Food Technology, GJUS&T, Hisar, Haryana, India1

Professor, Department of Food Technology, GJUS&T, Hisar, Haryana, India2

ABSTRACT: Six different fats and oils were analyzed for physical characteristics. All the six fats and oils differed

widely in their physicochemical characteristics. The results showed that fats and oils physical properties had

appreciable effects on the spread ratio and breaking strength. Slip melting point (r= -0.990**), creaming power (r= -

0.901**), yield value (r= -0.760**), viscosity (r= -0.729**), and hardness (r= -0.628*) contributed significantly

negatively to cookie spread ratio. These are the factors responsible for superior cookie spread ratio produced by

sunflower oil and groundnut oil. Statistical analysis showed that breaking strength was strongly positively and

negatively correlated to refractive index (r= 0.766**), and slip melting point, creaming power (r= -0. 954**, r= -

0.870**, respectively). Fats and oils with lower slip melting point and creaming power were not desirable for cookies

as they resulted in a stiffer cookie.

KEYWORDS: Fats and oils, Cookie quality, Spread ratio, Breaking strength.

I. INTRODUCTION

Fats and oils are widely used food components. They are the essential ingredients in baked products and influence their

microstructure and physical properties. Fats and oils in baking contribute to product characteristics such as tenderness,

moisture, mouthfeel, lubricity, flavor, structure, and shelf life. Shortenings which are often produced by partial

hydrogenation of oils are commonly used in the baking industry. However, during partial hydrogenation of oil, trans

fatty acids are formed, and research has proved the direct connection of trans fatty acids with many health problems

[1].

The quality and physical properties of many food products strongly depend upon the physical properties of fats and

oils. Physical properties of fats/oils are of critical importance in determining its use. Physical properties of fats and oils

are amongst the most important properties that indicate freshness and quality of the fats and oils as well as their

functionality in food products. Different physical parameters of edible oil were used to monitor the compositional

quality of oils [2, 3]. Physical properties of fats/oils are of critical importance in determining its use. These properties

of fats/oils mainly depend on their fatty acid composition [4]. A higher percentage of saturated fatty acids is related

with the high melting point fats. The melting point of a lipid describes the temperature point at which it changes its

solid states to liquid states. Specific gravity signifies heaviness of fats and oil compared to that of water. The specific

gravity of unsaturated glycerides is higher than the corresponding saturated ones. Refractive index of fats and oils is a

basic value that relates to molecular weight, fatty acid, chain length, the degree of unsaturation and degree of

conjugation. An important functional characteristic required of fat and oil when used in baked products is an ability

when beaten with sugar, to retain air. This ability is referred to as the 'creaming power ' of fat and oil. These properties

assume a noteworthy part in deciding the quality of cookies and other bakery products [5]. Therefore, it is of immense

significance to examine the physical properties of fats and oils. Relatively little work has been done on the relationship

between physical properties of fats and oils and quality characteristics of cookie. The present investigation was

undertaken to investigate the same.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0608034 15767

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(A High Impact Factor & UGC Approved Journal)

Website: www.ijirset.com

Vol. 6, Issue 8, August 2017

II. MATERIALS AND METHODS

A. Materials

Six different types of edible fat and oil samples were examined both from plant and animal origin. Palm oil

was obtained from Ruchi Soya Industries Ltd., Gurgaon. Butter (Amul), hydrogenated fat (Dalda), sunflower

oil (Nature Fresh), groundnut oil (Dhara), and coconut oil (Parachute) were procured from local retailers.

B. Physical Analysis of Fats and Oils

Specific gravity was estimated by the formula: Specific gravity = Density of oil/Density of water. The

viscosity measurement was carried out by Brookfield Viscometer (RV Model). The temperature of samples

was maintained at 25±1˚C throughout the test. Refractive index was determined using an Abbe Refractometer

and white light according to AOAC Standard Method (2000). The slip melting point (SMP) was determined

according to the Official Method of AOCS (1989). A column of fat was tempered at 10±1˚C for 24 h in an

open capillary tube. The tube was then warmed gradually in a water bath until the fat began to ascend because

of hydrostatic pressure. The temperature at which this occurs was determined as SMP using averaging of three

replicates. Consistency was measured by Texture Analyzer TA-XT2 (Stable MicroSystems) controlled by a

computer. Before measurements samples were melted and tempered for 24 hours at room temperature (25˚C).

The compression values were converted to yield value, in accord to Haighton [6]. The hardness of fats and oils

were measured using a double compression test with a Texture Analyser TA-XT2 (Stable MicroSystems). The

hardness of the shortening was indicated by the maximum force detected during compression. The

measurements were performed in triplicate for each sample.

C. Creaming Test

It was performed according to Nor Aini et al. [7] method with slight modifications. A Kenwood Junior mixer

was used with a K beater and a static scraper blade. Icing sugar (72g) and fat/oil (45 g) were mixed using a K

beater for 30s at speed 1, adding water (12g) during that time. Mixing was continued for 2 min at speed 4. The

aerated cream was filled into cups of known volume in duplicate, avoiding the inclusion of void spaces during

filling. The weight of the cup with cream was taken. This process was repeated at 2 min intervals until

creaming time reached 12 min. Creaming power was calculated in terms of specific volume of cream (cm3 g-1).

D. Cookies making

Cookies were prepared according to AACC approved method 10–50D [8] with slight modifications. The

ingredients used were flour (225 g), sugar (130 g), shortening (64 g), dextrose solution (33 ml), sodium

bicarbonate (1.6 g), ammonium bicarbonate (0.9 g), sodium chloride (2.1 g) and distilled water according to

requirement. The dough was prepared and sheeted to a thickness of 5 mm on a dough sheeter, and round

shaped cut was given using a cutter of 50 mm diameter. Cookies were baked in a lightly greased tray in the

baking oven at 205oC for 15 min followed by cooling and subsequently measured for diameter and thickness

and average was calculated. The spread ratio was calculated by dividing diameter (mm) with thickness (mm).

Cookies were prepared in triplicate.

E. Texture analysis

Textural analyzer (Stable Micro Systems TA-XT 2i, U.K.) was used to measure the hardness of the cookie.

The probe used was Knife Edge Insert (HDP/BS) in order to apply braking force required to fracture the

cookies with 5 kg load cell Heavy Duty Platform (HDP/90) at pre-test speed, test speed and post-test speed of

1.5, 2.0 and 10.0 mm/s respectively with a data acquisition rate of 400 pps.

F. Data Analysis

The experimental data collected were analyzed for significant differences with the help of analysis of variance

(ANOVA) conducted using SPSS 16.0 software. The correlation matrix was obtained using SPSS 16.0.

III. RESULTS AND DISCUSSION

Physical Properties of Fats and Oils

Significant variation was observed in the fats and oil physical attributes, such as slip melting point, refractive index,

viscosity, yield value, and hardness. Slip melting point (SMP) of fats and oils ranged from -18 to 38oC. Hydrogenated

fat had the highest SMP while sunflower oil had the lowest SMP owing to its most unsaturated fatty acid composition

[5]. Refractive index of fats and oils, a measure of unsaturated nature, ranged from 1.3294 to 1.3478. It was evaluated

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0608034 15768

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(A High Impact Factor & UGC Approved Journal)

Website: www.ijirset.com

Vol. 6, Issue 8, August 2017

from the observations that the specific gravity was the least for palm oil i.e. 0.9110 g/cm3 while it was maximum for

hydrogenated fat i.e. 0.9219 g/cm3. Viscosity varied from 42.81cP in coconut oil to 82cP in hydrogenated fat. The

maximum yield value was observed in butter (366.73g/cm2) while coconut oil (38.41 g/cm2) had the lowest. The least

hardness value of 0.29N was reported for sunflower oil whereas coconut oil scored a maximum of 41.40N. Results are

in line with [9].

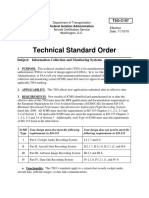

Creaming Power

The capability to trap air is an immensely influential aspect in establishing the significance of fat and oil as a

shortening agent. The volume of air that can be assimilated into a fat-sugar mix when beaten together under standard

conditions can be brought out by measuring the specific volume of the cream, i.e. the volume per unit mass, the value

of which is generally known as the creaming power of the fat and oil. The creaming power ranged from 0.827 to

1.037cm3g-1 after 2 min of beating and from 0.829 to 1.197cm3g-1 after 12 min of beating. Results of the creaming

power test (Fig. 1) indicated that palm oil had the best creaming performance. There was no substantial difference

between creaming performance of palm oil and hydrogenated fat. Sunflower oil and groundnut oil had the poor

creaming power.

1.2

1.15 Palm oil

Creaming Power (Cm3/g)

1.1 Hydrogenat

1.05 ed fat

Butter

1

Coconut oil

0.95

0.9 Groundnut

oil

0.85 Sunflower

oil

0.8

0 2 4 6 8 10 12

Time (Min.)

Fig. 1.Creaming power of fats and oils

Results of the creaming test obtained in this investigation (Fig.1) indicated that palm oil had the best creaming

performance. There is no substantial difference between creaming performance of palm oil and hydrogenated fat.

Although, butter had relatively lower value than palm oil and hydrogenated fat nevertheless in the good range of

creaming performance. Sunflower oil had the poorest creaming power, and groundnut oil had the similar creaming

power to sunflower oil. It might be due to their fatty acid composition and crystal characteristics.

Physical Characteristics of Cookies

The quality of cookie was evaluated in terms of diameter, thickness, spread ratio, and cookie breaking strength.

Cookie quality parameters prepared from different fats and oils differed significantly (Table 1). The diameter of

cookies varied from 55.20 and 62.50 mm, for butter and sunflower oil, respectively. The thickness of cookie ranged

from the lowest of 6.00 mm for cookies made using sunflower oil to the highest of 6.60 mm for cookies prepared using

hydrogenated fat. Higher cookie spread ratio is considered as the desirable quality attributes [10]. Cookie spread was

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0608034 15769

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(A High Impact Factor & UGC Approved Journal)

Website: www.ijirset.com

Vol. 6, Issue 8, August 2017

aligned from 8.45 to 10.42 in increasing orders from hydrogenated fat, followed by butter, palm oil, coconut oil,

groundnut oil, and sunflower oil. Cookies made using palm oil, and butter respectively had similar spread values.

Knightly [11] speculated that the poor spread ratio delivered by cookies containing hydrogenated fat might be due to its

tendency to form beta crystals which do not favour aeration.

The textural property is one of the crucial factors to evaluate the quality of cookies. Hardness, the most imperative

textural characteristics for cookies, measured in terms of breaking strength, as the peak force to snap the cookie.

Cookie breaking strength was significantly affected by different fats and oils. The hardness of cookies ranged from

4982 to 7257 g. Results were in agreement with an earlier investigation done by Barak et al. [12]. The data obtained

(Table 1) showed that the cookies made using the sunflower oil were the hardest, while cookies made using

hydrogenated fat were found the most tender as indicated by their least hardness value. On the other hand, the hardness

of cookies prepared using butter and palm oil was not remarkably different from each other. Cookies made using

sunflower oil resulted in the superior spread but extremely stiff texture; however, cookies made using hydrogenated fat

were tender with lower spread ratio. It was inferred from the data that the cookies containing oils delivered larger

diameter, lower height, higher spread, and stiff texture. Analogous remarks were laid by Mert & Demirkesen [13].

Table 1 Cookie quality characteristics of fats and oils.

Cookie Quality

Fats and oils D (mm) T (mm) SR (D/T) BS (g)

Butter 55.20a 6.30d 8.76b 5050b

Hydrogenated fat 57.75 c 6.60f 8.45a 4982a

Palm oil 58.00d 6.50e 8.92c 5094b

Coconut oil 57.25b 6.25c 9.16d 5221c

Groundnut oil 61.25e 6.20b 9.88e 7146d

Sunflower oil 62.50f 6.00a 10.42f 7257e

Values followed by different letters are significantly different from each other (p≤ 0.05).

D- Diameter; T- Thickness; SR- Spread ratio; BS- Breaking strength.

Relationships among Cookie Quality and Physical Properties of Fats and Oil

Cookie diameter was strongly negatively linked with SMP (r= -0.906**), YV (r= -0.740**), and CP (r= -0.777**).

RI induced significant positive association with cookie diameter (r= 0.844**). Cookie thickness followed the contrary

trend with diameter. The degree of air incorporation also contributes to cookie thickness as indicated by the strong

positive relation with CP (r= 0.856**). Fats and oils that begin melting too early in the baking process are not able to

absorb to the bubbles, which allows air to escape before dough expansion, resulting in bubble rupture and lower cookie

thickness. Similar results sought in this study as slip melting point displayed strong positive relation with cookie

thickness(r= 0.872**). Spread ratio, which is one of the important quality parameters, was significantly negatively

influenced by SMP (r= -0.990**), CP (r= -0.901**), YV (r= -0.760**), and V (r= -0.729**). RI established a positive

relation with SR (r= 0.659*). These are the factors responsible for superior cookie spread ratio produced by sunflower

oil and groundnut oil. Sunflower oil and groundnut oil with lower SMP values melt quickly during baking and yield

cookies with increased spread and decreased thickness. Hardness is an undesirable characteristic of cookie product [14].

Cookie hardness, measured as breaking strength, was significantly negatively related to slip melting point (r= -0.954**),

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0608034 15770

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(A High Impact Factor & UGC Approved Journal)

Website: www.ijirset.com

Vol. 6, Issue 8, August 2017

creaming power (r= -0.870**), and strongly positively associated with RI (r= 0.766**), highlighting tender cookies

delivered by dough formulated with hydrogenated fat, butter, and palm oil. Yield value contributed negatively to

breaking strength (r= -0.657*).

Table 2 Correlation among physical characteristics of fats and oils and cookie quality attributes

Cookie Quality Parameters

Physical Properties of

D T SR BS

Fats and Oils

SMP -0.906** 0.872** -0.990** -0.954**

RI 0.844** -0.355* 0.659* 0.766**

SG ns ns ns ns

V -0.552* 0.776** -0.729** -0.596*

YV -0.740** 0.591* -0.760** -0.657*

HD -0.582* 0.460* -0.628* -0.692*

CP -0.777** 0.856** -0.901** -0.870**

*Correlation is significant at the 0.05 level **Correlation is significant at the 0.01 level. D- Diameter; T- Thickness,

SR- Spread ratio; BS- Breaking strength; SMP- Slip melting point; RI- Refractive index; SG-Specific gravity; V-

Viscosity; YV-Yield value; HD- Hardness; CP-Creaming power; ns- not significant.

Higher the creaming power, more air got incorporated during mixing stage that released during baking resulting in

tender cookies. Lower SMP of fats and oils would melt faster during baking, thus facilitating more gluten interactions

resulting in stiffer cookies. Among the various physical characteristics of fats and oils studied, it was observed that slip

melting point and creaming power were the most important predictors of cookie quality. Specific gravity did not show

any remarkable relation with cookie quality parameters.

IV. CONCLUSION

The study revealed that quality attributes of cookies were significantly affected by physical properties of fats and oils.

The reason for the difference in performance of different fats and oils in cookie making in terms of their physical

properties is far better understood now. Refractive index influenced cookie diameter, spread ratio, and breaking

strength positively, whereas cookie thickness related negatively with it. Sunflower oil possessing the lowest slip

melting point and creaming power produced the cookie with utmost spread and breaking strength.

REFERENCES

[1] Dhaka, V., Gulia, N., Ahlawat, K. S., and Khatkar, B. S., “Trans fats—Sources, Health Risks and Alternative Approach - A Review”,

Journal of Food Science and Technology, Vol.48, pp.534-541, 2011.

[2] Ceriani, R., Paiva, F. R., Gonçalves, C. B., Batista, E. A. C., and Meirelles, A. J. A., “Densities and Viscosities of Vegetable Oils of

nutritional Value”, Journal of Chemical & Engineering Data, Vol.53, pp.1846-1853, 2008.

[3] Mousavi, K., Shoeibi, S., and Ameri, M., “Effects of Storage Conditions and PET Packaging on Quality of Edible Oils in Iran”, Advances

in Environmental Biology, Vol.62, pp.694-701, 2012.

[4] Gunstone, F.D.,” Animal Fats”, Lipid Technology, Vol. 20, pp.72, 2008.

[5] Devi, A., and Khatkar, B. S., “Physicochemical, Rheological and Functional Properties of Fats and Oils in Relation to Cookie Quality: A

Review”, Journal of Food Science and Technology, Vol.53, pp.3633-364, 2016.

[6] Haighton, A.J., “The Measurements of the Hardness of Margarine and Fats with Cone Penetrometers”, Journal of the American Oil

Chemists' Society, Vol.36, pp.345-348, 1959.

[7] Nor Aini, I., Berger, K. G., and Ong, A. S. H., “Evaluation of Shortenings Based on Various Palm Oil Products”, Journal of the Science

of Food and Agriculture, Vol.46, pp.481-493, 1989.

[8] AACC, “Approved methods of the American Association of Cereal Chemists (Vol. 10th)”, St. Paul, MN, USA, American Association of

Cereal Chemists, 2000.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0608034 15771

ISSN(Online): 2319-8753

ISSN (Print): 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(A High Impact Factor & UGC Approved Journal)

Website: www.ijirset.com

Vol. 6, Issue 8, August 2017

[9] Devi, A., and Khatkar, B. S., “Thermo-Physical Properties of Fats and Oils”, International Journal of Engineering and Technical Research,

Vol.7, pp. 45-50, 2017.

[10] Yamamoto, H., Worthington, S. T., Hou, G., and Ng, P., “Rheological Properties and Baking Qualities of Selected Soft Wheats in the

United States”, Cereal Chemistry, Vol.73, pp.215-221, 1996.

[11] Knightly, W. H., “Shortening Systems: Fats, Oils, and Surface-Active Agents- Present and Future”, Cereal chemistry, Vol. 58, pp.171-

174,1981.

[12] Barak, S., Mudgil, D., and Khatkar, B.S., “Effect of Composition of Gluten Proteins and Dough Rheological Properties on the Cookie

Making Quality”, British Food Journal, Vol.115, pp.564-574, 2013.

[13] Mert, B., and Demirkesen, I., “Reducing Saturated Fat with Oleogel/Shortening Blends in a Baked Product”, Food Chemistry, Vol. 199,

pp.809–816, 2016.

[14] Zoulias, E. I., Oreopoulou, V., and Tzia, C., “Textural Properties of Low-Fat Cookies Containing Carbohydrate- or Protein-Based Fat

Replacers”, Journal of Food Engineering, Vol.55, pp.337–34, 2002.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0608034 15772

Potrebbero piacerti anche

- Processing Contaminants in Edible Oils: MCPD and Glycidyl EstersDa EverandProcessing Contaminants in Edible Oils: MCPD and Glycidyl EstersNessuna valutazione finora

- Optimization of Vacuum Frying Condition For ShalloDocumento6 pagineOptimization of Vacuum Frying Condition For ShalloMauricio TorresNessuna valutazione finora

- 2017 Article 2942Documento10 pagine2017 Article 2942Muhammad AbrarNessuna valutazione finora

- Physicochemical, Rheological and Functional Properties of Fats and Oils in Relation To Cookie Quality: A ReviewDocumento10 paginePhysicochemical, Rheological and Functional Properties of Fats and Oils in Relation To Cookie Quality: A ReviewAmita RajanNessuna valutazione finora

- Thermo Physical Properties of Fats and OilsDocumento6 pagineThermo Physical Properties of Fats and OilsFrankPapaNessuna valutazione finora

- Density Viscosity and Surface Tension of Five Vegetable Oils at Elevated Temperatures Measurement and Modeling PDFDocumento18 pagineDensity Viscosity and Surface Tension of Five Vegetable Oils at Elevated Temperatures Measurement and Modeling PDFSnigdha SarmahNessuna valutazione finora

- Dielectric Properties of Edible Oils and Fatty Acids As A Function of Frequency, Temperature, Moisture and CompositionDocumento8 pagineDielectric Properties of Edible Oils and Fatty Acids As A Function of Frequency, Temperature, Moisture and Compositionmasyitah.amat18Nessuna valutazione finora

- Effect of Fat-Type On Cookie Dough and Cookie QualDocumento8 pagineEffect of Fat-Type On Cookie Dough and Cookie QualSHARON TEY YE QIAN / UPMNessuna valutazione finora

- Viscosity of Edible Oils and BlendsDocumento6 pagineViscosity of Edible Oils and BlendsRoberto RebolledoNessuna valutazione finora

- Density, Viscosity, and Surface Tension of Five Vegetable Oils at Elevated Temperatures: Measurement and ModelingDocumento18 pagineDensity, Viscosity, and Surface Tension of Five Vegetable Oils at Elevated Temperatures: Measurement and ModelingMUHAMMAD LUFFINessuna valutazione finora

- Meat Drying Technology and Drying Characteristics of Meat and Meat ProductsDocumento6 pagineMeat Drying Technology and Drying Characteristics of Meat and Meat ProductsShriramNessuna valutazione finora

- 1 s2.0 S0023643820301821 Main Copiar PDFDocumento6 pagine1 s2.0 S0023643820301821 Main Copiar PDFELFER OBISPO GAVINONessuna valutazione finora

- Blending of Oils A Case Study On Storage Stability and Sensory Characteristics of A Ready To Eat Extruded SnackDocumento12 pagineBlending of Oils A Case Study On Storage Stability and Sensory Characteristics of A Ready To Eat Extruded SnackGuisela Carbajal RomeroNessuna valutazione finora

- Process Optimization and Characterization of Cereal Based Ready-To-Eat Extruded Snack FoodDocumento8 pagineProcess Optimization and Characterization of Cereal Based Ready-To-Eat Extruded Snack FoodTJPRC PublicationsNessuna valutazione finora

- Development of Microwave Baked Potato Chips Using Tomato FlavourDocumento15 pagineDevelopment of Microwave Baked Potato Chips Using Tomato FlavourCielo Marie CastroNessuna valutazione finora

- Food Research InternationalDocumento10 pagineFood Research InternationalDewi ArziyahNessuna valutazione finora

- Guerrini2016 PDFDocumento7 pagineGuerrini2016 PDFChris EnriquezNessuna valutazione finora

- MomchilovaDocumento8 pagineMomchilovaEliana ContrerasNessuna valutazione finora

- Karakteristik Food Grade Grease Selama Penyimpanan Dengan Penambahan Antioksidan Alami Ekstrak Buah Pedada (Sonneratia Caseolaris)Documento11 pagineKarakteristik Food Grade Grease Selama Penyimpanan Dengan Penambahan Antioksidan Alami Ekstrak Buah Pedada (Sonneratia Caseolaris)Antonius PrakosaNessuna valutazione finora

- Food Chemistry: A. Kita, G. Lisin Ska, G. GołubowskaDocumento5 pagineFood Chemistry: A. Kita, G. Lisin Ska, G. GołubowskaLina María López RodríguezNessuna valutazione finora

- Rheological Characterization of Animal Fats andDocumento8 pagineRheological Characterization of Animal Fats andnatyquimica100% (2)

- Detection of Adulteration in Market Ghee Using FT-IR SpectrosDocumento8 pagineDetection of Adulteration in Market Ghee Using FT-IR SpectrosIJRASETPublicationsNessuna valutazione finora

- Effect of Antioxidant On Thermal Stability of Vegetable Oils by Using Ultrasonic StudiesDocumento9 pagineEffect of Antioxidant On Thermal Stability of Vegetable Oils by Using Ultrasonic Studieskagasaw023Nessuna valutazione finora

- Zhang - 2020 - Alimentos FrescosDocumento14 pagineZhang - 2020 - Alimentos FrescosagusNessuna valutazione finora

- Textural Melting and Sensory Properties PDFDocumento9 pagineTextural Melting and Sensory Properties PDFYorchitoRCDarkCryNessuna valutazione finora

- Optimization of Production Process and Preservation of Jalebi by Using HeatDocumento12 pagineOptimization of Production Process and Preservation of Jalebi by Using HeatIAEME PublicationNessuna valutazione finora

- 10 1016@j Jcs 2020 103056Documento8 pagine10 1016@j Jcs 2020 103056Sourav GargNessuna valutazione finora

- Renewable Energy: Jerekias Gandure, Clever Ketlogetswe, Abraham TemuDocumento7 pagineRenewable Energy: Jerekias Gandure, Clever Ketlogetswe, Abraham TemuLacramioara Iuliana VladulescuNessuna valutazione finora

- Goma Guar - Fracciones de Aceite (Leer)Documento9 pagineGoma Guar - Fracciones de Aceite (Leer)JOSE DAVID TORRES GONZALEZNessuna valutazione finora

- PROCEEDINGAPTECS2011ITS TheBio FuelPressureStoveFueledbyWasteCookingOil SjaffriadiNugrohoAdiSasongkoDocumento36 paginePROCEEDINGAPTECS2011ITS TheBio FuelPressureStoveFueledbyWasteCookingOil SjaffriadiNugrohoAdiSasongkoJoanna Marie SimonNessuna valutazione finora

- Giacomozzi 2019 - Physical Properties of Monoglycerides Oleogels Modified by Concentration, Cooling Rate and HIUDocumento13 pagineGiacomozzi 2019 - Physical Properties of Monoglycerides Oleogels Modified by Concentration, Cooling Rate and HIUAnabella GiacomozziNessuna valutazione finora

- Development and Evaluation of Shelf Stable Partially Baked Chapatti PDFDocumento8 pagineDevelopment and Evaluation of Shelf Stable Partially Baked Chapatti PDFKrishna KotturiNessuna valutazione finora

- Physio-Chemical Changes During Repeated Frying ofDocumento21 paginePhysio-Chemical Changes During Repeated Frying ofAgustin PodestaNessuna valutazione finora

- Foods: Changes in Physical and Chemical Properties of Thermally and Oxidatively Degraded Sunflower Oil and Palm FatDocumento14 pagineFoods: Changes in Physical and Chemical Properties of Thermally and Oxidatively Degraded Sunflower Oil and Palm FatMehdi KhfifiNessuna valutazione finora

- PROCEEDINGAPTECS2011ITS TheBio FuelPressureStoveFueledbyWasteCookingOil SjaffriadiNugrohoAdiSasongkoDocumento36 paginePROCEEDINGAPTECS2011ITS TheBio FuelPressureStoveFueledbyWasteCookingOil SjaffriadiNugrohoAdiSasongkoVmthreek SecNessuna valutazione finora

- Amany Et Al PDFDocumento8 pagineAmany Et Al PDFArchit AgarwalNessuna valutazione finora

- Densities and Viscosities of Fatty Acid Ethyl EstersDocumento10 pagineDensities and Viscosities of Fatty Acid Ethyl EstersNéia CostaNessuna valutazione finora

- Avec Chrysophyllum 2022Documento11 pagineAvec Chrysophyllum 2022NONVIHO GuévaraNessuna valutazione finora

- Accepted Manuscript: Food ChemistryDocumento20 pagineAccepted Manuscript: Food ChemistryCamila Alejandra DonosoNessuna valutazione finora

- Effect of Coating Material On The Quality of Oil Uptake and PotatoDocumento8 pagineEffect of Coating Material On The Quality of Oil Uptake and PotatoRadwan AjoNessuna valutazione finora

- Shabani2016 - Influence of The Sunflower Oil Content, Cooking Temperature and Cooking Time On The Physical and Sensory Properties of Spreadable Cheese Analogues Based On UF White-Brined CheeseDocumento9 pagineShabani2016 - Influence of The Sunflower Oil Content, Cooking Temperature and Cooking Time On The Physical and Sensory Properties of Spreadable Cheese Analogues Based On UF White-Brined CheeseDinoNessuna valutazione finora

- Tecnologia en ComidasDocumento14 pagineTecnologia en Comidassebastian lopezNessuna valutazione finora

- Study of Fatty Acid Profile in Edible Oil and Used Cooking OilDocumento50 pagineStudy of Fatty Acid Profile in Edible Oil and Used Cooking OilDhanasekar VNessuna valutazione finora

- Laboratory Manual - Fat Rich Dairy Products PDFDocumento74 pagineLaboratory Manual - Fat Rich Dairy Products PDFHeartwin Amaladhas Pushpadass100% (1)

- 1 s2.0 S1877705816309894 MainDocumento6 pagine1 s2.0 S1877705816309894 MainJagathisswary SateeNessuna valutazione finora

- Piyalungka - 2019 - CalabazaDocumento10 paginePiyalungka - 2019 - CalabazaagusNessuna valutazione finora

- 67 2017campagnolDocumento9 pagine67 2017campagnolNguyen Minh TrongNessuna valutazione finora

- Cassava 2Documento8 pagineCassava 2Jenner BaldeoNessuna valutazione finora

- 4caracterización de Películas Comestibles Basadas en SPI Incorporadas Con Aceites Esenciales de Canela o JengibreDocumento8 pagine4caracterización de Películas Comestibles Basadas en SPI Incorporadas Con Aceites Esenciales de Canela o JengibreCamilo Huertas CamposNessuna valutazione finora

- Addition of Olein From Milk Fat Positively Affects The Firmness of ButterDocumento8 pagineAddition of Olein From Milk Fat Positively Affects The Firmness of ButterIra SinagaNessuna valutazione finora

- Internship ProjectDocumento58 pagineInternship ProjectFavour NwaniNessuna valutazione finora

- Articulo Galletas 1Documento8 pagineArticulo Galletas 1ErikaNessuna valutazione finora

- Physico-Chemical Properties of Commercial Semi-Sweet BiscuitDocumento10 paginePhysico-Chemical Properties of Commercial Semi-Sweet Biscuitjoey_vela2002Nessuna valutazione finora

- 2014 - Effect of Radio Frequency Heating On Yoghurt, II - Microstructure and TextureDocumento25 pagine2014 - Effect of Radio Frequency Heating On Yoghurt, II - Microstructure and TextureKthePovedaNessuna valutazione finora

- Research Paper CJASAT 2023Documento11 pagineResearch Paper CJASAT 2023Awadhesh YadavNessuna valutazione finora

- Oil Coating Affects Internal Quality and Sensory Acceptance of Selected Attributes of Raw EggsDocumento7 pagineOil Coating Affects Internal Quality and Sensory Acceptance of Selected Attributes of Raw EggsNafisNessuna valutazione finora

- Aceite de FrituraDocumento8 pagineAceite de FrituraNestor Andres Urbina SuarezNessuna valutazione finora

- Frying Characteristics of Cashew Splits: R. Baby Latha, P. Nagaprabha, K.K. Bhat and Suvendu BhattacharyaDocumento14 pagineFrying Characteristics of Cashew Splits: R. Baby Latha, P. Nagaprabha, K.K. Bhat and Suvendu BhattacharyaTrần Minh ChinhNessuna valutazione finora

- 30220-Article Text-56673-1-10-20200526Documento11 pagine30220-Article Text-56673-1-10-20200526FilipeNessuna valutazione finora

- Turan 2015 HF MethodsDocumento8 pagineTuran 2015 HF Methodsirem emine demirNessuna valutazione finora

- Thesis Topics in Medicine in Delhi UniversityDocumento8 pagineThesis Topics in Medicine in Delhi UniversityBecky Goins100% (2)

- Heisenberg, "Über Den Anschaulichen Inhalt Der Quantentheoretischen Kinematik Und Mechanik"Documento16 pagineHeisenberg, "Über Den Anschaulichen Inhalt Der Quantentheoretischen Kinematik Und Mechanik"Benjamin Crowell0% (1)

- Npad PGP2017-19Documento3 pagineNpad PGP2017-19Nikhil BhattNessuna valutazione finora

- The Global Entrepreneurship and Development Index 2014 For Web1 PDFDocumento249 pagineThe Global Entrepreneurship and Development Index 2014 For Web1 PDFAlex Yuri Rodriguez100% (1)

- CLASS XI (COMPUTER SCIENCE) HALF YEARLY QP Bhopal Region Set-IIDocumento4 pagineCLASS XI (COMPUTER SCIENCE) HALF YEARLY QP Bhopal Region Set-IIDeepika AggarwalNessuna valutazione finora

- Journal Articles: Types of JournalsDocumento4 pagineJournal Articles: Types of JournalsOtieno SteveNessuna valutazione finora

- Mtech Vlsi Lab ManualDocumento38 pagineMtech Vlsi Lab ManualRajesh Aaitha100% (2)

- Ezpdf Reader 1 9 8 1Documento1 paginaEzpdf Reader 1 9 8 1AnthonyNessuna valutazione finora

- Johari WindowDocumento7 pagineJohari WindowSarthak Priyank VermaNessuna valutazione finora

- AYUSH Warli Art 100628Documento10 pagineAYUSH Warli Art 100628adivasi yuva shakti0% (1)

- HUAWEI PowerCube 500Documento41 pagineHUAWEI PowerCube 500soumen95Nessuna valutazione finora

- Enhancing Guest Experience and Operational Efficiency in Hotels Through Robotic Technology-A Comprehensive Review.Documento8 pagineEnhancing Guest Experience and Operational Efficiency in Hotels Through Robotic Technology-A Comprehensive Review.Chandigarh PhilosophersNessuna valutazione finora

- Multi Core Architectures and ProgrammingDocumento10 pagineMulti Core Architectures and ProgrammingRIYA GUPTANessuna valutazione finora

- Lupon National Comprehensive High School Ilangay, Lupon, Davao Oriental Grade 10-Household ServicesDocumento4 pagineLupon National Comprehensive High School Ilangay, Lupon, Davao Oriental Grade 10-Household ServicesJohn Eirhene Intia BarreteNessuna valutazione finora

- 3.2.1 The Role of Market Research and Methods UsedDocumento42 pagine3.2.1 The Role of Market Research and Methods Usedsana jaleelNessuna valutazione finora

- 1Z0-061 Sample Questions AnswersDocumento6 pagine1Z0-061 Sample Questions AnswersLaura JohnstonNessuna valutazione finora

- Singer 900 Series Service ManualDocumento188 pagineSinger 900 Series Service ManualGinny RossNessuna valutazione finora

- What Is Terrorism NotesDocumento3 pagineWhat Is Terrorism NotesSyed Ali HaiderNessuna valutazione finora

- Wall Panel SystemsDocumento57 pagineWall Panel SystemsChrisel DyNessuna valutazione finora

- 1ST Term J1 Fine Art-1Documento22 pagine1ST Term J1 Fine Art-1Peter Omovigho Dugbo100% (1)

- Tso C197Documento6 pagineTso C197rdpereirNessuna valutazione finora

- Ioi Group - Capric Acid 98%Documento7 pagineIoi Group - Capric Acid 98%Wong MjNessuna valutazione finora

- The Consulting Industry and Its Transformations in WordDocumento23 pagineThe Consulting Industry and Its Transformations in Wordlei ann magnayeNessuna valutazione finora

- Demand Determinants EEMDocumento22 pagineDemand Determinants EEMPrabha KaranNessuna valutazione finora

- Wire Rope TesterDocumento4 pagineWire Rope TesterclzagaNessuna valutazione finora

- Acc 106 Account ReceivablesDocumento40 pagineAcc 106 Account ReceivablesAmirah NordinNessuna valutazione finora

- Eco EssayDocumento3 pagineEco EssaymanthanNessuna valutazione finora

- Module 4 How To Make Self-Rescue Evacuation Maps?Documento85 pagineModule 4 How To Make Self-Rescue Evacuation Maps?RejieNessuna valutazione finora

- Encapsulation of Objects and Methods in C++Documento46 pagineEncapsulation of Objects and Methods in C++Scott StanleyNessuna valutazione finora

- One Foot in The Grave - Copy For PlayersDocumento76 pagineOne Foot in The Grave - Copy For Playerssveni meierNessuna valutazione finora