Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Safety Services: A Passion For Safety

Caricato da

Sekhar babuTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Process Safety Services: A Passion For Safety

Caricato da

Sekhar babuCopyright:

Formati disponibili

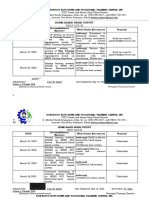

ISO/IEC 17025

Fire & Explosion

Testing Laboratory

Process Safety Services

Process Safety Consultancy

Dust, Gas and Vapour Flammability Testing

Chemical Process Hazard Analysis

Hazard & Risk Awareness Training

Supported Industries

Pharmaceutical

Chemical—Fine—Agro

Oil and Gas

Personal Healthcare

Automotive & Aerospace

Energy / Utilities

Food & Drink Processing

A Passion for Safety

+91 (0)11 4356 5446 safety-india@sigma-hse.com www.sigma-hse.com

Sigma-HSE (India) Pvt Ltd, Office 802, Naurang House, KG Marg, Connaught Place, New Delhi 110001, INDIA

A Passion for Safety

Process Safety Services

Sigma-HSE Engineers and Laboratory Technical staff have many Process Hazard Analysis and Risk

years’ experience in the field of process safety, providing Management

Consultancy and Laboratory data that enable manufacturing plants Hazard Identification Study (HAZID)

to operate safely and meet regulatory compliance.

Hazards & Operability Study (HAZOP)

Quantitative Risk Assessment (QRA)

Fire and Explosion Risk Assessment (FERA)

Process Safety Management Dispersion Analysis

Our core activity is the provision of services relating to PSM which Pre Start-up Safety Review (PSSR)

encompasses comprehensive assessment and analysis of the clients Blast Overpressure Study

manufacturing processes, identifying hazards and risks, reviewing Occupied Building Risk Assessment (OBRA/ BRA)

their safety training and evaluating the organisational safety culture.

Escape, Evacuation and Rescue Analysis (EERA)

Preliminary Process Safety Audit Emergency Systems Survivability Assessment (ESSA)

PSM Gap Analysis, Benchmarking and Implementation Temporary Refuge Impairment Analysis (TRIA)

Process Hazard Analysis Smoke and Gas Ingress Analysis (SGIA)

Quantitative Risk Assessment

Assessment of Safety Awareness, Training and Culture

Safety Management

Assessment Incident Investigation

Sigma-HSE provide assistance and support for manufacturing Emergency Response and Disaster Management Planning

(ERDMP)

industries that need to be compliant with safety legislation either

using OSHA/ CCPS/ Company’s specific guidelines. Such industries

Comprehensive Third Party Safety Audit (as per IS 14489)

include Oil & Gas, Pharmaceuticals & Nutraceuticals, FMCG, Food, Fire Safety Audit

Cement, Agro Commodities, Fertilizers, Paints, Petrochemicals, Gas Dispersion Study

Textile & Dye Stuff, Bulk and Fine Chemicals, etc. Flare Radiation Assessment

Control of Major Accident Hazards (COMAH)

Process Safety Consultancy Functional Safety

Risk(s) to people, assets, revenue and the environment arise from Failure Mode, Effects and Criticality Analysis (FMECA)

engineered systems, procedures, people and surroundings of an Safety Integrity Level (SIL)

organisation’s operations. The modern approach to chemical Layers of Protection Analysis (LOPA)

process safety is to apply risk management systems theory. This

includes recognition of the hazards posed by the process, and a

continual effort to analyse the risks, and to reduce or control them

to the lowest levels practical, while balancing other business

objectives. Process Safety related Legislation require manufacturing

plants to identify if they are working with hazardous substances that

may have a potentially explosible nature and put in place measures

to remove or mitigate the effect of potential fires and explosions.

Industrial Fire and Explosion Hazard

ATEX Assessment

Dust Explosion Risk Assessment

Electrostatic Hazards Assessment

Dust Explosion Vent Calculations & Sizing

Hazardous Area Classification (HAC) and Inspection of Electrical

Assets to BS EN 60079.

Mechanical & Electrical Equipment Ignition Risk Assessment

Audit and Maintaining Compliance Assessments

ISO/IEC 17025 Accredited Laboratory

Email your enquiry to safety-india@sigma-hse.com

Electrical Safety Process Safety

Electrical hazards are a source of continuous risk to safety of people

and property, since they can act as a source of shock and fire.

Laboratory Testing Services

Although in processing areas, electrical sparks are hazardous since ISO/IEC 17025 Accredited

they can act as a source of ignition for flammable atmosphere such Sigma HSE (UK) Laboratories provide accurate test data that can

as vapor, gas, dust cloud dispersed in air in appropriate determine whether a material is flammable or chemically reactive

concentration. However, the same electrical sparks/ short circuiting and if so what test data is required to ensure a risk assessment can

can act as a source of fire in panel rooms, server rooms, battery be performed. Typical test data are:

rooms, cable trays, etc. Fire related to electrical sparks are not only

relevant for processing industry but also for IT, telecommunication, Fire & Explosion Properties

Hospitality, Healthcare and banking industries.

Dust and Powder

Electrical Safety Audit Group A/B Classification or Go-No Go test

Thermography Minimum Ignition Energy (MIE) - with and without inductance

Arc Flash Hazard Analysis Minimum Ignition Temperature - Cloud (MIT)

Relay Coordination Study Layer Ignition Temperature (LIT)

Lightning Risk Assessment Explosion Severity (Pmax, Kst and St Class)

E-HAZOP Minimum Explosive Concentration (MEC)

Limiting Oxygen Concentration (LOC)

Chemical Process Hazards Thermal decomposition for the safe drying of powder

Exothermic chemical reactions are performed by companies as part Burning Behaviour

of their normal manufacturing process for some of their products

and intermediates. These exothermic reactions have the capability Gases and Vapours

to result in devastating effects to life, property and environment, in Flash Point

case of control malfunction leading to uncontrolled or runaway Auto-Ignition Temperature (AIT)

reaction. Flammable Limits (LEL & UEL)

Design Institute of Emergency Relief Sizing (DIERS) vent sizing Heat of Combustion

calculations

Time to Maximum Rate (TMR), Self-accelerating Decomposition Electrostatic Hazards Testing

Temperature (SADT), etc., calculations;

Chemical Reactivity Hazard (CRH) assessment Electrostatic charge build-up, accumulation and discharge can result

Process Hazard Assessment (PHA) for chemical processes

in a variety of concerns from personnel receiving static shocks to

spark discharges that can ignite a dust cloud or vapour cloud,

Consulting on scale-up of chemical processes

resulting in loss of equipment, manufacturing down time, injury or

Computational Fluid Dynamics (CFD) modelling

even fatality. Sigma-HSE can carry out electrostatic assessments and

Engineering Design Services provide test data. Services include:

(CPH Consultancy support is provided directly by our UK Office)

Powder Volume / Surface Resistivity

Charge Relaxation Time for powders, bags (IBC, FIBC), liners etc.

Volume and Surface Resistivity for bags, liners, gloves etc.

Liquid Conductivity

On-site electrostatics testing of pipework, flooring, Operators

(PPE), etc.

Telephone +91 (0)11 4356 5446 to discuss your requirements

A Passion for Safety

ISO/IEC 17025 Accredited Laboratory

Chemical Reaction Hazards Testing

Many industrial processes involve the mixing and blending of materials/chemicals where the

reactions can often produce exothermic energy which has the risk of becoming a runaway

reaction unless appropriate dosing and cooling controls are in place. Sigma-HSE can provide

scale-up and DIERS calculations to ensure your process remains safe or in the event of a

runaway reaction the effects are mitigated. Tests available include:

Adiabatic Calorimetry (VSP2)

Heat Flow Calorimetry (Mettler RC1)

Isothermal Calorimetry (Mettler RC1)

Reaction Calorimetry (Mettler RC1)

Small Scale Screening Tests (DSC, ARC, Carius Tube, VSP, etc.)

Training

Sigma HSE can provide bespoke training packages in all the above areas of concern and can

focus the training on specific levels of management from operator level through to

management/ engineers level.

Fire & Explosion Hazard Training

ATEX Assessment

Dust, Gas and Vapour Fire & Explosion Prevention

Hazardous Area Classification (HAC)

Electrostatic Hazards

PSM & Risk Management

Process Safety Management (PSM)

Hazard & Operability (HAZOP)

Quantitative Risk Assessment (QRA)

SIL/ LOPA

Fire and Gas Mapping

Electrical Safety

Chemical Reaction Hazard Training

ExElect Explosion Demo

Relief Vent Sizing

Safe Process Scale-Up

Specialist Training

CompEx E&I /Mechanical

Inspections of Electrical Equipment to BS EN 60079

Our Locations:

Delhi, India

Mumbai, India

Hyderabad, India

Abu Dhabi, United Arab Emirates

(UAE)

Winchester, United Kingdom

©2018 Sigma-HSE (India) Pvt Ltd

Sigma-HSE (India) Pvt Ltd, Office 802, Naurang House, KG Marg, Connaught Place, New Delhi 110001, INDIA

Potrebbero piacerti anche

- Fire & Explosion Hazard Management: 04 Days TrainingDocumento2 pagineFire & Explosion Hazard Management: 04 Days TrainingMuhammad.SaimNessuna valutazione finora

- A New Approach to HAZOP of Complex Chemical ProcessesDa EverandA New Approach to HAZOP of Complex Chemical ProcessesNessuna valutazione finora

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Guidelines for Defining Process Safety Competency RequirementsDa EverandGuidelines for Defining Process Safety Competency RequirementsValutazione: 3 su 5 stelle3/5 (1)

- Process Safety Management AuditDocumento53 pagineProcess Safety Management AuditKarim EssamNessuna valutazione finora

- EI Middle East Branch: Good Practice Steps To Effective PSMDocumento41 pagineEI Middle East Branch: Good Practice Steps To Effective PSMNicolas TorcheNessuna valutazione finora

- 2002 07 Beacon English 0Documento1 pagina2002 07 Beacon English 0Eslam HusseinNessuna valutazione finora

- The University of Danang Danang University of Science and TechnologyDocumento35 pagineThe University of Danang Danang University of Science and TechnologyLenh LeNessuna valutazione finora

- Employee Participation ProcedureDocumento4 pagineEmployee Participation ProcedureJudy PerryNessuna valutazione finora

- One Day Seminar: A Report ForDocumento5 pagineOne Day Seminar: A Report ForBrijesh100% (1)

- Wyn032 PDFDocumento21 pagineWyn032 PDFWahjudi MuhammadNessuna valutazione finora

- Intro To PSM at UI-WCP Oct 2019 (Workshop)Documento60 pagineIntro To PSM at UI-WCP Oct 2019 (Workshop)Aditya SetiadiNessuna valutazione finora

- Management of Change Procedure - Wyandotte: The Electronic Document Is Controlled. Printed Copies Are UncontrolledDocumento21 pagineManagement of Change Procedure - Wyandotte: The Electronic Document Is Controlled. Printed Copies Are UncontrolledSusin LimNessuna valutazione finora

- LOPA and Risk Graphs For SIL DeterminationDocumento11 pagineLOPA and Risk Graphs For SIL DeterminationShweta181Nessuna valutazione finora

- Hazid Identification Study SampleDocumento1 paginaHazid Identification Study SampleNora Afzam Abd WahabNessuna valutazione finora

- Process Safety Notes 1Documento18 pagineProcess Safety Notes 1Zia AhmadNessuna valutazione finora

- Safety Instrumented System (SIS)Documento8 pagineSafety Instrumented System (SIS)SARFRAZ ALINessuna valutazione finora

- ALARPDocumento7 pagineALARPArgenis José Medina SotilloNessuna valutazione finora

- Compliance Checklist PSMDocumento7 pagineCompliance Checklist PSMTomas Gaviria MartinezNessuna valutazione finora

- Efficient PHA of Non-Continuous Operating ModesDocumento25 pagineEfficient PHA of Non-Continuous Operating ModesShakirNessuna valutazione finora

- Sil PDFDocumento12 pagineSil PDFChandrasekhar ElliahNessuna valutazione finora

- QraDocumento10 pagineQraNakkolopNessuna valutazione finora

- HASILT - An - Intelligent Software Platform For HAZOP - LOPA - SRS and SIL VerificationDocumento9 pagineHASILT - An - Intelligent Software Platform For HAZOP - LOPA - SRS and SIL VerificationRonyNessuna valutazione finora

- What Is Mechanical Integrity and What Are The Requirements of An MI Program - Life Cycle EngineeringDocumento5 pagineWhat Is Mechanical Integrity and What Are The Requirements of An MI Program - Life Cycle EngineeringWisnu HarmawanNessuna valutazione finora

- 07 Biofuels MNGT of ChangeDocumento57 pagine07 Biofuels MNGT of ChangeUkrit ChansodaNessuna valutazione finora

- 06 - Employee Participation WebDocumento7 pagine06 - Employee Participation WebBasil M. IkhleifNessuna valutazione finora

- Pre Safety ReviewDocumento27 paginePre Safety ReviewMagesh KumarNessuna valutazione finora

- HSE Commitment and Policy?Documento6 pagineHSE Commitment and Policy?radhesrikrishnaNessuna valutazione finora

- LOPA and Human Factors 2Documento26 pagineLOPA and Human Factors 2sandhyakasturiNessuna valutazione finora

- Barrier PS ManagementDocumento27 pagineBarrier PS ManagementMarcus HartfelderNessuna valutazione finora

- Process Safety Management: A Legal and Technical Overview: Session No. 526Documento15 pagineProcess Safety Management: A Legal and Technical Overview: Session No. 526Waqas Ahmad KhanNessuna valutazione finora

- A HAZOP AnalysisDocumento2 pagineA HAZOP AnalysisSameer ShekharNessuna valutazione finora

- How To Achieve Zero AccidentDocumento108 pagineHow To Achieve Zero AccidentAjit BhosaleNessuna valutazione finora

- Your Quick Guide To Process Safety ManagementDocumento5 pagineYour Quick Guide To Process Safety ManagementArunachalam AvanashiNessuna valutazione finora

- Paper 2Documento8 paginePaper 2Nitesh Kirnake100% (1)

- Seminar 5 Safety Management System: 6 June 2006Documento114 pagineSeminar 5 Safety Management System: 6 June 2006Latt Minn TharNessuna valutazione finora

- SCS 2019 Presentation-Mark Skelton-Risk Based Decision Making and ALARP-How Low Is Low EnoughDocumento25 pagineSCS 2019 Presentation-Mark Skelton-Risk Based Decision Making and ALARP-How Low Is Low EnoughkhaleedsyedNessuna valutazione finora

- Pha Pro V6 Checklist Index: Comments On Study Worksheet Are Made by ExceptionDocumento36 paginePha Pro V6 Checklist Index: Comments On Study Worksheet Are Made by ExceptionSyed Shiraz AliNessuna valutazione finora

- PSM Course 2014 Day 3Documento102 paginePSM Course 2014 Day 3dcd1980Nessuna valutazione finora

- Fire Explosion Hazard ManagementDocumento11 pagineFire Explosion Hazard ManagementEbenezer AaronNessuna valutazione finora

- Process Safety ManagementDocumento45 pagineProcess Safety ManagementAbbasNessuna valutazione finora

- Is All Safety-Critical Equipment Critical To SafetyDocumento6 pagineIs All Safety-Critical Equipment Critical To SafetyLi QiNessuna valutazione finora

- Layer of Protection AnalysisDocumento6 pagineLayer of Protection Analysishmatora72_905124701Nessuna valutazione finora

- Evolution of Process Hazard Analysis in An Oil & Gas Pipeline Company: From Ad-Hoc To An Enterprise Standard PracticeDocumento10 pagineEvolution of Process Hazard Analysis in An Oil & Gas Pipeline Company: From Ad-Hoc To An Enterprise Standard PracticeMarcelo Varejão CasarinNessuna valutazione finora

- Highlight On "Hazop" For Engineering Safety ReviewDocumento8 pagineHighlight On "Hazop" For Engineering Safety ReviewliamsiNessuna valutazione finora

- Guidance On Performing Transportation Risk Analysis of Hazardous MaterialsDocumento221 pagineGuidance On Performing Transportation Risk Analysis of Hazardous MaterialsDidik SupriyadiNessuna valutazione finora

- Designing Instrumentation and Control For Process SafetyDocumento7 pagineDesigning Instrumentation and Control For Process SafetyAdebamboAinaNessuna valutazione finora

- PSM Course 2014 Day 2Documento86 paginePSM Course 2014 Day 2dcd1980Nessuna valutazione finora

- Operational Risk Management - (Chapter 3 Tools and Techniques) PDFDocumento38 pagineOperational Risk Management - (Chapter 3 Tools and Techniques) PDFMaria MirandaNessuna valutazione finora

- Atul LTD Risk AssessmentDocumento108 pagineAtul LTD Risk AssessmentdevangNessuna valutazione finora

- A Short Course On Process Hazard Analysis (PHA) : For Chemical EngineersDocumento11 pagineA Short Course On Process Hazard Analysis (PHA) : For Chemical EngineersJose AlvarezNessuna valutazione finora

- Managing Double Jeopardy in Process Hazard Analysis - Allison de ManDocumento9 pagineManaging Double Jeopardy in Process Hazard Analysis - Allison de ManJay JayNessuna valutazione finora

- Definition - What Does Hazard Identification Study (HAZID) Mean?Documento2 pagineDefinition - What Does Hazard Identification Study (HAZID) Mean?ShirishNessuna valutazione finora

- Don't Do This!: SafetyDocumento8 pagineDon't Do This!: SafetyJohn AnthoniNessuna valutazione finora

- AI-PS Element Guide No 9Documento8 pagineAI-PS Element Guide No 9rahul kavirajNessuna valutazione finora

- Epsc PSFDocumento23 pagineEpsc PSFKNS GroupNessuna valutazione finora

- Quantitative Risk AssessmentDocumento113 pagineQuantitative Risk AssessmentJay JayNessuna valutazione finora

- HSE Assessment of Explosion Risk Analysis in Offshore Safety CasesDocumento16 pagineHSE Assessment of Explosion Risk Analysis in Offshore Safety CasesMichał MakuchNessuna valutazione finora

- Driving PSM Performance Beyond Kpi Metrics BehieDocumento37 pagineDriving PSM Performance Beyond Kpi Metrics BehieNhut NguyenNessuna valutazione finora

- HAZOP Study MethodologyDocumento5 pagineHAZOP Study MethodologyRonak MotaNessuna valutazione finora

- 28 Psychrometric ProcessesDocumento19 pagine28 Psychrometric ProcessesPRASAD326100% (7)

- 1.TareaParticipacion 2do - ParcialDocumento19 pagine1.TareaParticipacion 2do - ParcialLeonardo EstradaNessuna valutazione finora

- Polymers, Natural Polymers, NaturalDocumento3 paginePolymers, Natural Polymers, NaturalPrem KumarNessuna valutazione finora

- Lincoln Vantage 300 CaracterísticasDocumento8 pagineLincoln Vantage 300 CaracterísticasJean MunozNessuna valutazione finora

- Temperature Measurement Lab Report PDFDocumento13 pagineTemperature Measurement Lab Report PDFSyafiiqahNessuna valutazione finora

- kx0804 PDFDocumento519 paginekx0804 PDFstefan corjuc100% (7)

- Module3 PDFDocumento174 pagineModule3 PDFAhallya JaladeepNessuna valutazione finora

- EFuel ReportDocumento52 pagineEFuel ReportMassimiliano ZocchiNessuna valutazione finora

- Maersk LDocumento12 pagineMaersk LAbhishek Kumar0% (1)

- Light Loss Factor Calculations For LEDsDocumento2 pagineLight Loss Factor Calculations For LEDsErickson AbiolNessuna valutazione finora

- 2002 Physics NQE QuestionsDocumento7 pagine2002 Physics NQE QuestionskarxriNessuna valutazione finora

- 2 Hydraulic Cylinder EKZDocumento25 pagine2 Hydraulic Cylinder EKZthanhNessuna valutazione finora

- 1 Home Base Work March 19-MRCH 31Documento3 pagine1 Home Base Work March 19-MRCH 31Celso AmotoNessuna valutazione finora

- Electrical CircuitsDocumento53 pagineElectrical Circuitssuganyav6Nessuna valutazione finora

- Design and Simulation of A Sine Wave Inverter With PID Control For Nonlinear Load ApplicationsDocumento12 pagineDesign and Simulation of A Sine Wave Inverter With PID Control For Nonlinear Load ApplicationsReno ReoNessuna valutazione finora

- Accident Prevention Program: Thunderstorms - Don't Flirt ... Skirt'EmDocumento5 pagineAccident Prevention Program: Thunderstorms - Don't Flirt ... Skirt'EmLohrasp SuraliwalaNessuna valutazione finora

- TKA MicroPureDocumento4 pagineTKA MicroPureDATA24Nessuna valutazione finora

- PV Cell CharaDocumento40 paginePV Cell CharaBlessy JoyNessuna valutazione finora

- Dryers: DRYERS - Are Equipment Used For Producing A Dry Solid Product From A Wet Feed General Types of DryersDocumento5 pagineDryers: DRYERS - Are Equipment Used For Producing A Dry Solid Product From A Wet Feed General Types of DryersTristan Paul Guerra OrodioNessuna valutazione finora

- High Pressure Drilling Hoses: Fleximak Industrial CatalogueDocumento5 pagineHigh Pressure Drilling Hoses: Fleximak Industrial CatalogueitangNessuna valutazione finora

- OzoneDocumento1 paginaOzonebolsjhevikNessuna valutazione finora

- Barracuda Lite 19 WS RegularDocumento2 pagineBarracuda Lite 19 WS RegularcarlosorizabaNessuna valutazione finora

- TM 9 4935 601 14 3&PDocumento137 pagineTM 9 4935 601 14 3&Pkhaerul jannahNessuna valutazione finora

- General Catalogue: Compressors & Condensing UnitsDocumento88 pagineGeneral Catalogue: Compressors & Condensing UnitsJader Leon100% (1)

- Operation of Fresh Water GeneratorDocumento3 pagineOperation of Fresh Water GeneratoralexdenychenkoNessuna valutazione finora

- BHEL - Agitator Specification PDFDocumento68 pagineBHEL - Agitator Specification PDFRiyaz100% (1)

- Ray Transfer Matrix AnalysisDocumento10 pagineRay Transfer Matrix Analysisabcdefghijklmnopqrstuvwxyz12345678910Nessuna valutazione finora

- Project On Global WarmingDocumento22 pagineProject On Global WarmingHilda DsouzaNessuna valutazione finora

- 5 Feeder Protection & Relay CoordinationDocumento51 pagine5 Feeder Protection & Relay CoordinationSatya VasuNessuna valutazione finora

- The Consumers Guideto Choosinga Heat PumpDocumento11 pagineThe Consumers Guideto Choosinga Heat Pumpmishka123Nessuna valutazione finora