Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

44-01 Machining With Tailstock

Caricato da

David BumbaloughDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

44-01 Machining With Tailstock

Caricato da

David BumbaloughCopyright:

Formati disponibili

44-01 Machining with Tailstock

In barfeeding operations, it is often necessary to extend the bar stock a certain distance from the chuck or collet face.

For this purpose, a bar stopper is usually mounted in the turret and brought to the Z position to which the bar should be

extended. If the bar extension is relatively short, for example, 2:1 or 3:1 ratio between the extended length and the bar

diameter, the subsequent machining can usually take place without a tailstock support. For a bar that extends farther

from the chuck/collet face, for example 5:1 ratio or higher, the tailstock support is required, which also means using a

center drilling operation, often done on a CNC lathe as well.

The objective of this special lathe project is to face and center drill a bar stock extended to a certain length from the

chuck or collet face, then apply the tailstock before actual machining of the external contour.

ò To develop the part program, follow the following conditions:

1. T08 serves as both the bar stopper and the center drill (see illustration bellow for dimensions)

2. T03 is a 35° turning tool (such as a VNMG type, with 0.8 nose radius)

3. The bar stock is Æ25 mm, precut to 250 mm lengths

4. The selected bar extension for facing and center drilling is 50 mm from the chuck face

5. The selected bar extension for the OD turning is 200 mm from the chuck face

6. Both the bar stock and the tailstock quill are handled manually (no programmable functions)

T08

Z-offset

+ The illustration on the left shows the relationship between

X-offset

the setting for offset 08 (tip of the center drill), and the tool

corner that will be used as the bar stopper reference point.

T08

In the program, this difference must be included.

Wear offset cannot be used, because the offset amount

17

would exceed the allowable range.

16 SHIFT POINT FOR STOPPER

180

165

15

R2000

1x45°

Ø24

ALUMINUM BAR- Ø25x250 LENGTH

Peter Smid CNC Programming Handbook 44-01 [ 1 ]

Potrebbero piacerti anche

- 4L80E Modifications Guide v2Documento36 pagine4L80E Modifications Guide v2sonyaNessuna valutazione finora

- How To Become Untrackable - Part 1 - SurvivopediaDocumento12 pagineHow To Become Untrackable - Part 1 - SurvivopediaDavid Bumbalough100% (1)

- Rotary Table ZP-375 Ó ÷Documento13 pagineRotary Table ZP-375 Ó ÷Gabriel IbarraNessuna valutazione finora

- Tortort Manufacturing 80% Milled Receivers AK47Documento6 pagineTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNessuna valutazione finora

- Time Series Forecasting - Project ReportDocumento68 pagineTime Series Forecasting - Project ReportKhursheedKhan50% (2)

- HK94, MP5, Parts KitsDocumento6 pagineHK94, MP5, Parts KitsDavid BumbaloughNessuna valutazione finora

- Torque Vs Tension Interpretation Instructions Rev 6Documento25 pagineTorque Vs Tension Interpretation Instructions Rev 6Kurt Kandora MontroneNessuna valutazione finora

- The Complete Guide To Growing Corn in Containers - Garden and HappyDocumento17 pagineThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNessuna valutazione finora

- Swing CheckDocumento3 pagineSwing CheckSuresh RamanujaluNessuna valutazione finora

- Ar Cutting OperationDocumento7 pagineAr Cutting OperationNandakrishnan S LNessuna valutazione finora

- Broaching Operations Guide for Rotary BroachingDocumento2 pagineBroaching Operations Guide for Rotary BroachingpeterNessuna valutazione finora

- Mounting, Maintenance & Repair of Cardanshafts - GEWESDocumento5 pagineMounting, Maintenance & Repair of Cardanshafts - GEWESHesham MahdyNessuna valutazione finora

- SRP 2020Documento25 pagineSRP 2020waleedyehiaNessuna valutazione finora

- Measure radial throw swing check valuesDocumento2 pagineMeasure radial throw swing check valuesfcof123237483% (6)

- 11 EngineDocumento556 pagine11 Enginerumen80100% (3)

- Permit Part-2 Process-Oriented Permit in SAPDocumento13 paginePermit Part-2 Process-Oriented Permit in SAPsachinWebDNessuna valutazione finora

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Tool and Cutter PDFDocumento15 pagineTool and Cutter PDFKiwishooter50% (4)

- Making A Spur GearDocumento9 pagineMaking A Spur GearHaraprasad DolaiNessuna valutazione finora

- MS For The Access Control System Installation and TerminationDocumento21 pagineMS For The Access Control System Installation and Terminationwaaji snapNessuna valutazione finora

- Biax Electronic Scraper and AccessoriesDocumento16 pagineBiax Electronic Scraper and AccessoriesPaisaje Silencioso100% (1)

- G1975 - Instruction ManualDocumento36 pagineG1975 - Instruction ManualLeon GalindoNessuna valutazione finora

- Tapping ChucksDocumento14 pagineTapping ChucksDHAMODHARANNessuna valutazione finora

- EIA GuidelineDocumento224 pagineEIA GuidelineAjlaa RahimNessuna valutazione finora

- Resharpening & Inspection Cutting Tools PDFDocumento10 pagineResharpening & Inspection Cutting Tools PDFHeineken Ya PraneetpongrungNessuna valutazione finora

- Alignment of Turbine Generator SetDocumento31 pagineAlignment of Turbine Generator SetRajendra Singh50% (2)

- Energy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefDocumento8 pagineEnergy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefSalomonlcNessuna valutazione finora

- Garments & Tailoring Business: Submitted byDocumento6 pagineGarments & Tailoring Business: Submitted bykartik DebnathNessuna valutazione finora

- CNC Taper Pin Metric ProgrammingDocumento1 paginaCNC Taper Pin Metric ProgrammingDavid BumbaloughNessuna valutazione finora

- Aircontrol Ace Control de Movimiento Amortiguadores Rotativos Rotacion Parcial AjustableDocumento2 pagineAircontrol Ace Control de Movimiento Amortiguadores Rotativos Rotacion Parcial AjustableAraceli CaihuaraNessuna valutazione finora

- Euronorm Slewing Rings Manual (ENG)Documento8 pagineEuronorm Slewing Rings Manual (ENG)Gladwin JesNessuna valutazione finora

- wiac.info-pdf-ciac-4-operationamp-maintenance-pr_8f2094fc84644dbb53fd1e798e0e6483Documento24 paginewiac.info-pdf-ciac-4-operationamp-maintenance-pr_8f2094fc84644dbb53fd1e798e0e6483LisandroNessuna valutazione finora

- Ring FederDocumento12 pagineRing Federarvi_vinNessuna valutazione finora

- Alignment Instruction for York Refrigeration Screw CompressorsDocumento8 pagineAlignment Instruction for York Refrigeration Screw CompressorsManuel perezNessuna valutazione finora

- PENTACUT - MMDocumento4 paginePENTACUT - MMphạm minh hùngNessuna valutazione finora

- User'S Manul: 3Gp Series Steam Boiler Feed PumpDocumento25 pagineUser'S Manul: 3Gp Series Steam Boiler Feed PumpEdinsonUribeTorresNessuna valutazione finora

- Dobladores de TubingDocumento19 pagineDobladores de TubingJuan Chan CanulNessuna valutazione finora

- Technical Section RYCO HydraulicDocumento50 pagineTechnical Section RYCO Hydraulicedhy_03100% (1)

- Installation Cautions for 50mm Rotary EncodersDocumento1 paginaInstallation Cautions for 50mm Rotary Encodersesau hernandezNessuna valutazione finora

- Mini Milling/Drilling Machine Instruction ManualDocumento19 pagineMini Milling/Drilling Machine Instruction ManualAnonymous f6goFflg3T100% (1)

- Assembly of brake cylinderDocumento4 pagineAssembly of brake cylinderyongjun xiaNessuna valutazione finora

- Know GD&T Symbols Start Your Design Engineering Career With A Bang!Documento3 pagineKnow GD&T Symbols Start Your Design Engineering Career With A Bang!NB BC12Nessuna valutazione finora

- Code of The Cardan Shaft: Series Size Structural MouldDocumento4 pagineCode of The Cardan Shaft: Series Size Structural Mouldscr1bdu5rNessuna valutazione finora

- XTR DHDocumento1 paginaXTR DHTimour BIARTNessuna valutazione finora

- The specialists for high-accuracy continuous-path processesDocumento4 pagineThe specialists for high-accuracy continuous-path processesAsim PedicNessuna valutazione finora

- A8PO Bent Axis Pumps - IsODocumento21 pagineA8PO Bent Axis Pumps - IsOAttral HONessuna valutazione finora

- Worm Gear Sets enDocumento30 pagineWorm Gear Sets enDimas Dwi HNessuna valutazione finora

- Taper Turning TechniquesDocumento15 pagineTaper Turning TechniquesKher Bee A. PingolNessuna valutazione finora

- Index of ISO Hole and Shaft tolerances pagesDocumento2 pagineIndex of ISO Hole and Shaft tolerances pagesNgoc BangNessuna valutazione finora

- COP 1838 ME - HE Technical SpecificationDocumento2 pagineCOP 1838 ME - HE Technical SpecificationAlexNessuna valutazione finora

- Straight Spur Gears and RACKSDocumento10 pagineStraight Spur Gears and RACKSIRONSAVIORNessuna valutazione finora

- 88 PDFDocumento1 pagina88 PDFNandu KrishNessuna valutazione finora

- BOP Stack Organization and BOP Stack ArrangementDocumento2 pagineBOP Stack Organization and BOP Stack ArrangementAgung Doank Yess0% (1)

- Before Placement of ModuleDocumento3 pagineBefore Placement of Modulezohrehmm2004Nessuna valutazione finora

- Series of Pressure Relief Device For Transformers User's ManualDocumento6 pagineSeries of Pressure Relief Device For Transformers User's ManualwondNessuna valutazione finora

- Mechanical Drawing Fits and TolerancesDocumento36 pagineMechanical Drawing Fits and TolerancesMohamed MoawedNessuna valutazione finora

- GMN2Documento24 pagineGMN2maqvereNessuna valutazione finora

- Echnical Information: Oncept and Main ApplicationsDocumento15 pagineEchnical Information: Oncept and Main ApplicationsJózek JózekNessuna valutazione finora

- Worm Wheel HobsDocumento7 pagineWorm Wheel HobsRaul PerezNessuna valutazione finora

- Fucntional DatumDocumento13 pagineFucntional Datumavinash babu50% (2)

- 00 CINCINNATI No 2 Radius Grinding AttachmentDocumento4 pagine00 CINCINNATI No 2 Radius Grinding AttachmentGilberto GarciaNessuna valutazione finora

- TC3700 Tire Changer BrochureDocumento4 pagineTC3700 Tire Changer Brochuredionisio emilio reyes jimenezNessuna valutazione finora

- Feeds SpeedsDocumento4 pagineFeeds SpeedschrisNessuna valutazione finora

- Flyer Robot AR1440 E 09.2020Documento2 pagineFlyer Robot AR1440 E 09.2020Elmer MuruaNessuna valutazione finora

- Radial Piston Pump, Fi Xed DisplacementDocumento8 pagineRadial Piston Pump, Fi Xed DisplacementDIEGO MOYANessuna valutazione finora

- Rotary actuator-RHADocumento10 pagineRotary actuator-RHAmkt mechoceanNessuna valutazione finora

- Pequea Turbo Tedder TT4100 & TT4101 Operator's ManualDocumento23 paginePequea Turbo Tedder TT4100 & TT4101 Operator's Manualfarid said errahmaniNessuna valutazione finora

- Pump CatalogueDocumento123 paginePump Cataloguemohammed sallemNessuna valutazione finora

- 12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDocumento21 pagine12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDavid BumbaloughNessuna valutazione finora

- Tomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDocumento11 pagineTomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDavid BumbaloughNessuna valutazione finora

- This Little Weed Is One of The Most Useful Medicines On The PlanetDocumento6 pagineThis Little Weed Is One of The Most Useful Medicines On The PlanetDavid BumbaloughNessuna valutazione finora

- Gun Control and The Founding Fathers Intent - The - Truth - and - JusticeDocumento9 pagineGun Control and The Founding Fathers Intent - The - Truth - and - JusticeDavid BumbaloughNessuna valutazione finora

- Feedrate Q+A: # Answer 1Documento2 pagineFeedrate Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- Providers - PrivacytoolsDocumento7 pagineProviders - PrivacytoolsDavid BumbaloughNessuna valutazione finora

- Exercises After Abdominal SurgeryDocumento5 pagineExercises After Abdominal SurgeryDavid BumbaloughNessuna valutazione finora

- 15-01 Reference Points - MillDocumento1 pagina15-01 Reference Points - MillDavid BumbaloughNessuna valutazione finora

- Scaling Function Q+A: # Answer 1Documento2 pagineScaling Function Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- 49-01 Documenting Programs Q+ADocumento1 pagina49-01 Documenting Programs Q+ADavid BumbaloughNessuna valutazione finora

- 46-01 Horizontal MachiningDocumento1 pagina46-01 Horizontal MachiningDavid BumbaloughNessuna valutazione finora

- 49-01 Documenting Programs Q+A PDFDocumento1 pagina49-01 Documenting Programs Q+A PDFDavid BumbaloughNessuna valutazione finora

- Unknown Radius: Chine Shop MagazineDocumento1 paginaUnknown Radius: Chine Shop MagazineDavid BumbaloughNessuna valutazione finora

- Scaling Exercise: Use T01 Ø20 End MillDocumento1 paginaScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNessuna valutazione finora

- 53-02 Locators PDFDocumento1 pagina53-02 Locators PDFDavid BumbaloughNessuna valutazione finora

- CNC Machining Q+A: Major Criteria for Running First PartDocumento2 pagineCNC Machining Q+A: Major Criteria for Running First PartDavid BumbaloughNessuna valutazione finora

- Verifying Programs Q+A: # Answer 1Documento2 pagineVerifying Programs Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- Calculating XY Points of a Blend Arc Dimensioned to its CenterDocumento1 paginaCalculating XY Points of a Blend Arc Dimensioned to its CenterDavid BumbaloughNessuna valutazione finora

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDocumento1 paginaTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNessuna valutazione finora

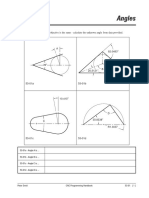

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDocumento1 paginaAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNessuna valutazione finora

- Calculate Contour Change Points 1Documento1 paginaCalculate Contour Change Points 1David BumbaloughNessuna valutazione finora

- Calculating XY Points of a Blend Arc Dimensioned to its CenterDocumento1 paginaCalculating XY Points of a Blend Arc Dimensioned to its CenterDavid BumbaloughNessuna valutazione finora

- 53-04 Contour Points 2Documento1 pagina53-04 Contour Points 2David BumbaloughNessuna valutazione finora

- 19-01 Tool LengthDocumento1 pagina19-01 Tool LengthDavid BumbaloughNessuna valutazione finora

- 20-02 Rapid Motion FormulasDocumento2 pagine20-02 Rapid Motion FormulasDavid BumbaloughNessuna valutazione finora

- Apple Led Cinema Display 24inchDocumento84 pagineApple Led Cinema Display 24inchSantos MichelNessuna valutazione finora

- Statement of Purpose Lanka Venkata Raghava Ravi TejaDocumento2 pagineStatement of Purpose Lanka Venkata Raghava Ravi TejaRavi Teja LvrNessuna valutazione finora

- Rural Perception of SUV CarsDocumento29 pagineRural Perception of SUV CarsritusinNessuna valutazione finora

- In Gov cbse-SSCER-191298202020 PDFDocumento1 paginaIn Gov cbse-SSCER-191298202020 PDFrishichauhan25Nessuna valutazione finora

- NURKSE's Balanced GrowthDocumento7 pagineNURKSE's Balanced GrowthArnab MutsuddyNessuna valutazione finora

- Holmes 1993Documento8 pagineHolmes 1993Rumaisa KrubaNessuna valutazione finora

- Speaking Telephone RoleplaysDocumento2 pagineSpeaking Telephone RoleplaysremimiguelNessuna valutazione finora

- Tabel Condenstatori SMDDocumento109 pagineTabel Condenstatori SMDAllYn090888Nessuna valutazione finora

- Alcalel-Lucent WLAN OmniAcces StellarDocumento6 pagineAlcalel-Lucent WLAN OmniAcces StellarJBELDNessuna valutazione finora

- What is a Server ClusterDocumento2 pagineWhat is a Server Clusterfikru tesefayeNessuna valutazione finora

- Circuit Project Electronic: Simple Pulse Generator by IC 555 TimerDocumento1 paginaCircuit Project Electronic: Simple Pulse Generator by IC 555 TimerM Usman RiazNessuna valutazione finora

- Dhabli - 1axis Tracker PVSYSTDocumento5 pagineDhabli - 1axis Tracker PVSYSTLakshmi NarayananNessuna valutazione finora

- BurhanresumeDocumento1 paginaBurhanresumeAbdul Rangwala0% (1)

- Daa M-4Documento28 pagineDaa M-4Vairavel ChenniyappanNessuna valutazione finora

- Interpretation 1Documento17 pagineInterpretation 1ysunnyNessuna valutazione finora

- Wizard's App Pitch Deck by SlidesgoDocumento52 pagineWizard's App Pitch Deck by SlidesgoandreaNessuna valutazione finora

- EffectofObligations PDFDocumento0 pagineEffectofObligations PDFÄnne Ü KimberlieNessuna valutazione finora

- Tds Uniqflow 372s enDocumento1 paginaTds Uniqflow 372s enm daneshpourNessuna valutazione finora

- Lifetime Physical Fitness and Wellness A Personalized Program 14th Edition Hoeger Test BankDocumento34 pagineLifetime Physical Fitness and Wellness A Personalized Program 14th Edition Hoeger Test Bankbefoolabraida9d6xm100% (27)

- Chemistry1207 Lab 4Documento2 pagineChemistry1207 Lab 4Kayseri PersaudNessuna valutazione finora

- SUTI Report - Metro ManilaDocumento87 pagineSUTI Report - Metro ManilaIvan Harris TanyagNessuna valutazione finora

- Microsoft Windows 98 Second Edition README For Tips and Tricks, April 1999Documento8 pagineMicrosoft Windows 98 Second Edition README For Tips and Tricks, April 1999scriNessuna valutazione finora

- Office of The Controller of Examinations Anna University:: Chennai - 600 025Documento4 pagineOffice of The Controller of Examinations Anna University:: Chennai - 600 025M.KARTHIKEYANNessuna valutazione finora