Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

46-01 Horizontal Machining

Caricato da

David BumbaloughCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

46-01 Horizontal Machining

Caricato da

David BumbaloughCopyright:

Formati disponibili

46-01 Horizontal Machining

In this simple project for horizontal machining, the objective is to make a circular groove on each of the four

sides of a cubical stock (600L ´ 400W ´ 500H). X0Y0 is the center of pocket, Z0 is the front of each face.

ò To develop a CNC program, follow these conditions:

1. Use Æ20 mm end mill to full depth of each groove at 1500 r/min

2. Start each groove at 0° degrees (3 o’clock position), in the CCW direction

3. Program only one block for each full circle tool motion

4. Use functions M78 to CLAMP and M79 to UNCLAMP the indexing table

600 400

50

00

Ø3

Ø2

500

FRONT - G54 - B0.0 R-SIDE - G55 - B90.0

Z-10.0 GROOVE DEPTH Z-7.0 GROOVE DEPTH

75

00

Ø2

Ø2

500

BACK - G56 - B180.0 L-SIDE - G57 - B270.0

Z-5.0 GROOVE DEPTH Z-3.0 GROOVE DEPTH

Peter Smid CNC Programming Handbook 46-01 [ 1 ]

Potrebbero piacerti anche

- Bollard details for 9000DWT bargeDocumento1 paginaBollard details for 9000DWT bargeGoh Boon TiongNessuna valutazione finora

- SY3 5 7 9000 Ventil Magnet 5 Porte PDFDocumento212 pagineSY3 5 7 9000 Ventil Magnet 5 Porte PDFDhika Bagus SetiawanNessuna valutazione finora

- Project:: Pile Cap LayoutDocumento12 pagineProject:: Pile Cap LayoutSara NuonNessuna valutazione finora

- Online Game Objects 0216fDocumento15 pagineOnline Game Objects 0216fMayank DeshpandeNessuna valutazione finora

- 9 M6X Ya 00005Documento30 pagine9 M6X Ya 00005Mohamad ShafeyNessuna valutazione finora

- Lowara z8 z10 z12 Technical Datasheet PDFDocumento108 pagineLowara z8 z10 z12 Technical Datasheet PDFArif MahendraNessuna valutazione finora

- 7579-301 Assignment - 2Documento14 pagine7579-301 Assignment - 2roburecam88Nessuna valutazione finora

- Reporte Viga ADocumento15 pagineReporte Viga AjosNessuna valutazione finora

- 4PileCapDesign - Bending Theory Method PDFDocumento2 pagine4PileCapDesign - Bending Theory Method PDFisholaoladimejiNessuna valutazione finora

- Analisa StrukturDocumento6 pagineAnalisa StrukturPrameswari Wed DingNessuna valutazione finora

- Linear actuator Econom 01 guideDocumento6 pagineLinear actuator Econom 01 guideDanyini IniNessuna valutazione finora

- 01-R0-Reinf - Details of Column Starter Bars.-1Documento1 pagina01-R0-Reinf - Details of Column Starter Bars.-1yasirjurabaNessuna valutazione finora

- CJ615零件手册Documento18 pagineCJ615零件手册harber2958Nessuna valutazione finora

- E-0002514-173-04415 Rev. 0 - IFC (Equipment Installation Detail Drawing Cooling Tower)Documento39 pagineE-0002514-173-04415 Rev. 0 - IFC (Equipment Installation Detail Drawing Cooling Tower)Rully SaputraNessuna valutazione finora

- MY-031599 - 7M Monolith (MY-160) (V4) Deli2go - Costa Coffee - VP - Shell SELECT - 24JAMDocumento1 paginaMY-031599 - 7M Monolith (MY-160) (V4) Deli2go - Costa Coffee - VP - Shell SELECT - 24JAMxer tieNessuna valutazione finora

- Ходовые редукторы Bonfiglioli серии 700C (гусеничные)Documento10 pagineХодовые редукторы Bonfiglioli серии 700C (гусеничные)MortariosNessuna valutazione finora

- 5M. Polygonal: Hot Dip Galvanized Pole Model: TUGDocumento1 pagina5M. Polygonal: Hot Dip Galvanized Pole Model: TUGDumitrache IulianNessuna valutazione finora

- C D B A: First Floor Beam On Axis 1 (300x400) (300X200) A-B STAIRDocumento1 paginaC D B A: First Floor Beam On Axis 1 (300x400) (300X200) A-B STAIRmetsihafeNessuna valutazione finora

- Pile Hammer Requirement: NO Item Drawing NoDocumento12 paginePile Hammer Requirement: NO Item Drawing NoMuhammadArismunndarPNessuna valutazione finora

- Design of Reinforced Concrete Elements: UsingDocumento62 pagineDesign of Reinforced Concrete Elements: UsingISsa Qafa'itiNessuna valutazione finora

- Bar DetailsDocumento1 paginaBar Detailssagnik bhattacharjeeNessuna valutazione finora

- Tugas BalokDocumento12 pagineTugas Balokilham kartikoNessuna valutazione finora

- Drawing 3Documento4 pagineDrawing 3Nesreen Ahmed NaoumNessuna valutazione finora

- Problems: Gineering, Vol. 45, No. 9, Pp. 81-85, 1990. Skovde Plant, Gothenberg, SwedenDocumento13 pagineProblems: Gineering, Vol. 45, No. 9, Pp. 81-85, 1990. Skovde Plant, Gothenberg, SwedenAustin EdwinNessuna valutazione finora

- York - AHU - Selection PDFDocumento172 pagineYork - AHU - Selection PDFAhmed NabilNessuna valutazione finora

- Nictoro Brochure Cabinet FanDocumento12 pagineNictoro Brochure Cabinet FanFaquruddinNessuna valutazione finora

- Main frame assembly drawingDocumento1 paginaMain frame assembly drawingFuad EfendiNessuna valutazione finora

- Ejemplos de Partes A Reparar o FabricarDocumento4 pagineEjemplos de Partes A Reparar o FabricarmauriciotrochesaNessuna valutazione finora

- NCS catalog(0)Documento27 pagineNCS catalog(0)minhdoan00Nessuna valutazione finora

- ArmBushingConvDocumento2 pagineArmBushingConvporter1980Nessuna valutazione finora

- WD500-3 Parts CatalogDocumento493 pagineWD500-3 Parts Catalogkit101Nessuna valutazione finora

- FAHU-1 External Static Pressure CalculationDocumento2 pagineFAHU-1 External Static Pressure CalculationMUBASHIRNessuna valutazione finora

- Flat Slab Punching Shear Check r1Documento5 pagineFlat Slab Punching Shear Check r1Usama ChauguleNessuna valutazione finora

- Design of Columns Attanagalla Water Supply Pump Station - Column - Z1Documento11 pagineDesign of Columns Attanagalla Water Supply Pump Station - Column - Z1Amila KulasooriyaNessuna valutazione finora

- Amphenol Militar Connectors MS3106Documento4 pagineAmphenol Militar Connectors MS3106Stefan OlianoNessuna valutazione finora

- WAREHOUSEDocumento9 pagineWAREHOUSEcontentaibasedNessuna valutazione finora

- Transportation Problem HWDocumento5 pagineTransportation Problem HWChelsea Dela TorreNessuna valutazione finora

- Enc-Cv5-Bbs-00008 (PCS Sump Z-1-001) Rev.02Documento18 pagineEnc-Cv5-Bbs-00008 (PCS Sump Z-1-001) Rev.02Norwahyu TeknikoNessuna valutazione finora

- Side ViewDocumento3 pagineSide ViewAjayNessuna valutazione finora

- PS 7500na Bom DrawingDocumento1 paginaPS 7500na Bom DrawingEmanuel VidalNessuna valutazione finora

- 210ton Sumitomo - PLATENDocumento1 pagina210ton Sumitomo - PLATENcountzeroaslNessuna valutazione finora

- PRO Gate Valves Catalog 101116cDocumento5 paginePRO Gate Valves Catalog 101116cMounica PallaNessuna valutazione finora

- S550 Hand Brake Assy STN 190 Riveter: Drawing List For: 132630-190Documento52 pagineS550 Hand Brake Assy STN 190 Riveter: Drawing List For: 132630-190juan carlosNessuna valutazione finora

- Eaton 713-0091-032Documento1 paginaEaton 713-0091-032JustinNessuna valutazione finora

- Katalog BMC 2019Documento48 pagineKatalog BMC 2019ben bilmemNessuna valutazione finora

- Katalog BMC 2019Documento48 pagineKatalog BMC 2019ben bilmemNessuna valutazione finora

- Stand Engine HD785-7Documento2 pagineStand Engine HD785-7dody mirsyaNessuna valutazione finora

- 3721 MM 5485 MM: 5CB16:Elevation (Scale 1:75)Documento1 pagina3721 MM 5485 MM: 5CB16:Elevation (Scale 1:75)manarajNessuna valutazione finora

- PM42M048Documento1 paginaPM42M048Lendry NormanNessuna valutazione finora

- Brueninghaus Hydromatik Rexroth A2FO Pump & A2FM Motor: Open and Closed CircuitsDocumento11 pagineBrueninghaus Hydromatik Rexroth A2FO Pump & A2FM Motor: Open and Closed CircuitsCHRISTIAN LOPEZ FLOREZ100% (1)

- Polyslab Technical Manual Brochure Ilovepdf Compressed1Documento28 paginePolyslab Technical Manual Brochure Ilovepdf Compressed1Ayodele DinaNessuna valutazione finora

- ABN103 CDocumento1 paginaABN103 CSergio FelipeNessuna valutazione finora

- Shanghai Cone CrusherDocumento5 pagineShanghai Cone CrushernaniturkNessuna valutazione finora

- DX2.ipbDocumento1 paginaDX2.ipbMike DailyNessuna valutazione finora

- Backward CurvedDocumento1 paginaBackward CurvedNARENDER NIMMANessuna valutazione finora

- SES 50 (Imp Dia 254mm)Documento1 paginaSES 50 (Imp Dia 254mm)Jaeni GilangNessuna valutazione finora

- This Little Weed Is One of The Most Useful Medicines On The PlanetDocumento6 pagineThis Little Weed Is One of The Most Useful Medicines On The PlanetDavid BumbaloughNessuna valutazione finora

- How To Become Untrackable - Part 1 - SurvivopediaDocumento12 pagineHow To Become Untrackable - Part 1 - SurvivopediaDavid Bumbalough100% (1)

- Providers - PrivacytoolsDocumento7 pagineProviders - PrivacytoolsDavid BumbaloughNessuna valutazione finora

- Feedrate Q+A: # Answer 1Documento2 pagineFeedrate Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- Tomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDocumento11 pagineTomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDavid BumbaloughNessuna valutazione finora

- 15-01 Reference Points - MillDocumento1 pagina15-01 Reference Points - MillDavid BumbaloughNessuna valutazione finora

- Gun Control and The Founding Fathers Intent - The - Truth - and - JusticeDocumento9 pagineGun Control and The Founding Fathers Intent - The - Truth - and - JusticeDavid BumbaloughNessuna valutazione finora

- 12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDocumento21 pagine12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDavid BumbaloughNessuna valutazione finora

- The Complete Guide To Growing Corn in Containers - Garden and HappyDocumento17 pagineThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNessuna valutazione finora

- Exercises After Abdominal SurgeryDocumento5 pagineExercises After Abdominal SurgeryDavid BumbaloughNessuna valutazione finora

- HK94, MP5, Parts KitsDocumento6 pagineHK94, MP5, Parts KitsDavid BumbaloughNessuna valutazione finora

- Tortort Manufacturing 80% Milled Receivers AK47Documento6 pagineTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNessuna valutazione finora

- Scaling Exercise: Use T01 Ø20 End MillDocumento1 paginaScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNessuna valutazione finora

- Scaling Function Q+A: # Answer 1Documento2 pagineScaling Function Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- 49-01 Documenting Programs Q+A PDFDocumento1 pagina49-01 Documenting Programs Q+A PDFDavid BumbaloughNessuna valutazione finora

- 49-01 Documenting Programs Q+ADocumento1 pagina49-01 Documenting Programs Q+ADavid BumbaloughNessuna valutazione finora

- Verifying Programs Q+A: # Answer 1Documento2 pagineVerifying Programs Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- 44-01 Machining With TailstockDocumento1 pagina44-01 Machining With TailstockDavid BumbaloughNessuna valutazione finora

- CNC Machining Q+A: Major Criteria for Running First PartDocumento2 pagineCNC Machining Q+A: Major Criteria for Running First PartDavid BumbaloughNessuna valutazione finora

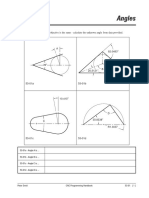

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDocumento1 paginaAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNessuna valutazione finora

- Calculating XY Points of a Blend Arc Dimensioned to its CenterDocumento1 paginaCalculating XY Points of a Blend Arc Dimensioned to its CenterDavid BumbaloughNessuna valutazione finora

- 53-02 Locators PDFDocumento1 pagina53-02 Locators PDFDavid BumbaloughNessuna valutazione finora

- Unknown Radius: Chine Shop MagazineDocumento1 paginaUnknown Radius: Chine Shop MagazineDavid BumbaloughNessuna valutazione finora

- Calculate Contour Change Points 1Documento1 paginaCalculate Contour Change Points 1David BumbaloughNessuna valutazione finora

- Calculating XY Points of a Blend Arc Dimensioned to its CenterDocumento1 paginaCalculating XY Points of a Blend Arc Dimensioned to its CenterDavid BumbaloughNessuna valutazione finora

- 20-02 Rapid Motion FormulasDocumento2 pagine20-02 Rapid Motion FormulasDavid BumbaloughNessuna valutazione finora

- 53-04 Contour Points 2Documento1 pagina53-04 Contour Points 2David BumbaloughNessuna valutazione finora

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDocumento1 paginaTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNessuna valutazione finora

- 19-01 Tool LengthDocumento1 pagina19-01 Tool LengthDavid BumbaloughNessuna valutazione finora