Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Conventional PM Materials PDF

Caricato da

Towkir AhmmadDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Conventional PM Materials PDF

Caricato da

Towkir AhmmadCopyright:

Formati disponibili

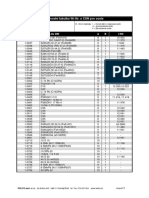

Sintered Steels

Standard References I Typical Properties (References)

Typical Hard-

DIN Density UTS FEL3) YS 0,1 YS 0,2 A2) E

ISO Typical composition1) density ness

SINT- [g/cm3] [MPa] [MPa] [MPa] [MPa] [%] [GPa]

[g/cm3] HB

C 00 6.4 - 6.8 -F-00-100 Fe 6.60 40 130 35 60 75 4 100

C 01 6.4 - 6.8 -F-05-140 Fe-0.5C 6.60 75 250 80 140 160 1.5 100

C 10 6.4 - 6.8 -F-00C2-140 Fe2Cu 6.60 65 230 90 170 185 2 100

D 00 6.8 - 7.2 -F-00-120 Fe 7.00 50 150 45 75 90 10 140

D 00 6.8 - 7.2 -F-00-120 Fe-0.2C 7.00 75 230 70 130 150 5 140

D 01 6.8 - 7.2 -F-05-170 Fe-0.5C 7.00 90 300 95 160 180 3 140

n/a 6.8 - 7.2 -F-08-240 Fe-0.7C 7.00 120 380 120 200 230 2 140

D 10 6.8 - 7.2 -F-00C2-175 Fe2Cu 7.00 85 270 75 210 230 4 140

D 11 6.8 - 7.2 -F-05C2-300 Fe2Cu-0.5C 7.00 140 500 160 300 330 2.5 140

D 11 6.8 - 7.2 -F-05C2-620H Fe2Cu-0.5C 7.00 380 690 240 580 660 <1 140

D 11 6.8 - 7.2 -F-08C2-390 Fe2Cu-0.7C 7.00 170 560 180 370 410 1.5 140

D 30 6.8 - 7.2 n/a Fe1.5Cu1.75Ni0.5Mo-0.2C 7.00 140 470 150 340 360 3.5 140

E 30 > 7.2 n/a Fe1.5Cu1.75Ni0.5Mo-0.2C 7.25 160 500 160 370 390 4 160

D 39 6.8 - 7.2 -FD-05N2C-400 Fe1.5Cu1.75Ni0.5Mo-0.5C 7.00 180 540 185 400 420 2.5 140

D 39 6.8 - 7.2 -FD-05N2C-950H Fe1.5Cu1.75Ni0.5Mo-0.5C 7.00 400 1020 270 760 900 <1 140

E 39 > 7.2 -FD-05N2C-440 Fe1.5Cu1.75Ni0.5Mo-0.5C 7.25 190 570 175 300 340 5 160

D 39 6.8 - 7.2 n/a Fe1.5Cu1.75Ni0.5Mo-0.7C 7.00 210 580 180 340 380 1.5 140

D 30 6.8 - 7.2 n/a Fe1.5Cu4Ni0.5Mo-0.2C 7.00 150 520 170 280 330 3.5 140

E 30 > 7.2 n/a Fe1.5Cu4Ni0.5Mo-0.2C 7.25 170 570 180 290 350 4 160

D 39 6.8 - 7.2 -FD-05N4C-420 Fe1.5Cu4Ni0.5Mo-0.5C 7.00 180 620 200 280 340 2 140

D 39 6.8 - 7.2 -FD-05N4C-930H Fe1.5Cu4Ni0.5Mo-0.5C 7.00 380 1050 300 680 820 <1 140

E 39 > 7.2 -FD-05N4C-450 Fe1.5Cu4Ni0.5Mo-0.5C 7.25 200 700 200 310 370 2.5 160

D 39 6.8 - 7.2 n/a Fe1.5Cu4Ni0.5Mo-0.7C 7.00 230 610 190 320 380 1.5 140

D 31 6.8 - 7.2 n/a Fe2Cu4Ni1.5Mo-0.2C 7.00 160 620 170 390 450 2 140

E 31 > 7.2 n/a Fe2Cu4Ni1.5Mo-0.2C 7.25 190 710 190 400 470 2.5 160

D 32 6.8 - 7.2 n/a Fe2Cu4Ni1.5Mo-0.6C 7.00 300 900 220 500 650 1 140

E 32 > 7.2 n/a Fe2Cu4Ni1.5Mo-0.6C 7.25 330 1050 240 520 670 1.5 160

D 31 6.8 - 7.2 n/a Fe2Cu1.5Mo-0.2C 7.00 150 550 170 320 400 1.5 140

E 31 > 7.2 n/a Fe2Cu1.5Mo-0.2C 7.25 180 600 180 380 450 2 160

D 32 6.8 - 7.2 n/a Fe2Cu1.5Mo-0.6C 7.00 320 850 200 680 800 0.5 140

E 32 > 7.2 n/a Fe2Cu1.5Mo-0.6C 7.25 400 1000 220 800 930 1 160

D 35 6.8 - 7.2 -F-00P05-210 Fe0.45P 7.00 100 380 120 180 230 10 140

n/a 6.8 - 7.2 n/a Fe1Cr1Ni0.85Mo0.6Si-0.6C 7.00 350 950 220 780 900 1 140

n/a 6.8 - 7.2 n/a Fe1Cr1Ni0.85Mo0.6Si-0.6C 7.15 380 1150 250 860 1000 1 150

1) In addition to the elements mentioned, further alloying elements up to 2 % are admitted.

2) Sizing will reduce the elongation.

3) Bending load. 2 x 106 cycles, notch factor αk = 1.0 (ref. 30912 Part 6); R= -1.

4) Austenitized at 900 °C, 60 minutes – oil quenched; tempered at 180 - 220 °C, 60 minutes, air.

5) Sinterhardening is performed in the sinter furnace by gas quenching subsequently to the sintering process. Materials can be

tempered as well at 160 °C – 240 °C for 30 min – 120 min due to requirements.

6) High temperature sintering (HT) is performed at 1200 °C – 1300 °C depending on furnace type.

Chemical Compositions (Standard)1) Standard References II

GKN

C Cu Ni Mo Cr Si P Fe Others

Remark SM Material MPIF

[wt.-%] [wt.-%] [wt.-%] [wt.-%] [wt.-%] [wt.-%] [wt.-%] [wt.-%] [wt.-%]

Code

<0.3 <0.1 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1000C F-0000-15

0.3 - 0.7 <0.1 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1005C F-0005-20

<0.3 1.5 - 2.5 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1020C FC-0200-21

<0.3 <0.1 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1000D F-0000-20

0.1 - 0.5 <0.1 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1002D F-0000-20

0.3 - 0.7 <0.1 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1005D F-0005-25

0.5 - 0.9 <0.1 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1007D F-0008-35

<0.3 1.5 - 2.5 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1020D FC-0200-24

0.3 - 0.7 1.5 - 2.5 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1025D FC-0205-45

quench +

0.3 - 0.7 1.5 - 2.5 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1025D-H1 FC-0205-90HT

temper4)

0.5 - 0.9 1.5 - 2.5 <0.1 <0.1 <0.1 <0.1 <0.1 bal. <1 PMET1027D FC-0208-60

0.1 - 0.5 1.0 - 2.0 1.5 - 2.0 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4602D n/a

0.1 - 0.5 1.0 - 2.0 1.5 - 2.0 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4602E n/a

0.3 - 0.7 1.0 - 2.0 1.5 - 2.0 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4605D FD-0205-55

quench +

0.3 - 0.7 1.0 - 2.0 1.5 - 2.0 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4605D-H1 FD-0205-120HT

temper4)

0.3 - 0.7 1.0 - 2.0 1.5 - 2.0 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4605E FD-0205-65

0.5 - 0.9 1.0 - 2.0 1.5 - 2.0 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4607D FD-0208-60

0.1 - 0.5 1.0 - 2.0 3.5 - 4.5 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4802D n/a

0.1 - 0.5 1.0 - 2.0 3.5 - 4.5 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4802E n/a

0.3 - 0.7 1.0 - 2.0 3.5 - 4.5 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4805D FD-0405-60

quench +

0.3 - 0.7 1.0 - 2.0 3.5 - 4.5 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4805D-H1 FD-0405-130HT

temper4)

0.3 - 0.7 1.0 - 2.0 3.5 - 4.5 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4805E FD-0405-65

0.5 - 0.9 1.0 - 2.0 3.5 - 4.5 0.3 - 0.7 <0.1 <0.1 <0.1 bal. <1 PMET4807D FD-0408-60

0.1 - 0.5 1.5 - 2.5 3.5 - 4.5 1.3 - 1.7 <0.1 <0.1 <0.1 bal. <1 PMET49N2D n/a

0.1 - 0.5 1.5 - 2.5 3.5 - 4.5 1.3 - 1.7 <0.1 <0.1 <0.1 bal. <1 PMET49N2E n/a

sinter

0.4 - 0.8 1.5 - 2.5 3.5 - 4.5 1.3 - 1.7 <0.1 <0.1 <0.1 bal. <1 PMET49N6D FLDN4C2-4908

hardened5)

sinter

0.4 - 0.8 1.5 - 2.5 3.5 - 4.5 1.3 - 1.7 <0.1 <0.1 <0.1 bal. <1 PMET49N6E FLDN4C2-4908

hardened5)

0.1 - 0.5 1.5 - 2.5 <0.1 1.3 - 1.7 <0.1 <0.1 <0.1 bal. <1 PMET49C2D n/a

0.1 - 0.5 1.5 - 2.5 <0.1 1.3 - 1.7 <0.1 <0.1 <0.1 bal. <1 PMET49C2E n/a

sinter

0.4 - 0.8 1.5 - 2.5 <0.1 1.3 - 1.7 <0.1 <0.1 <0.1 bal. <1 PMET49C6D FLDC2-4908

hardened5)

sinter

0.4 - 0.8 1.5 - 2.5 <0.1 1.3 - 1.7 <0.1 <0.1 <0.1 bal. <1 PMET49C6E FLDC2-4908

hardened5)

<0.3 <0.1 <0.1 <0.1 <0.1 <0.1 0.3 - 0.6 bal. <1 PMET10P0D FY-4500-20W

sinter har-

0.4 - 0.8 <0.1 0.5 - 2.5 0.6 - 1.1 0.8 - 1.2 0.4 - 0.8 <0.1 bal. <1 PMET4306D n/a

dened5)

sinter har-

dened5). HT 0.2 - 0.8 <0.1 0.5 - 2.5 0.6 - 1.1 0.8 - 1.2 0.4 - 0.8 <0.1 bal. <1 PMET4306D-HT n/a

sintered6)

UTS: Ultimate Tensile Strength FEL: Fatigue Endurance Limit YS: Yield Strength

A: Fracture Elongation E: Youngs Modulus

Potrebbero piacerti anche

- Uk Intnl Equiv GradesDocumento1 paginaUk Intnl Equiv GradesLLNessuna valutazione finora

- Selection Guide - Mosfet ProductDocumento6 pagineSelection Guide - Mosfet ProductlapiamaNessuna valutazione finora

- Steel FlatDocumento5 pagineSteel Flatચેતન સુથારNessuna valutazione finora

- Zemit - Detail of Pump in StockDocumento1 paginaZemit - Detail of Pump in StockEnergy TechnologyNessuna valutazione finora

- Powder Metallurgy Material MPIF StandardDocumento2 paginePowder Metallurgy Material MPIF Standardidanfri100% (1)

- Material Conversion TableDocumento1 paginaMaterial Conversion Tablemos3ad2006Nessuna valutazione finora

- Man 009 139 PDFDocumento1 paginaMan 009 139 PDFmarceilinus devaluantoNessuna valutazione finora

- Man 009 139 PDFDocumento1 paginaMan 009 139 PDFIgnacio DavilaNessuna valutazione finora

- Tabla de Conversión de MaterialesDocumento1 paginaTabla de Conversión de MaterialesDaniela A. CastroNessuna valutazione finora

- International Comparision of Standards PDFDocumento1 paginaInternational Comparision of Standards PDFwitanto90Nessuna valutazione finora

- Gunnebo Industries - Alloy Steel Rigging Screw No. 801, 802 & 804Documento2 pagineGunnebo Industries - Alloy Steel Rigging Screw No. 801, 802 & 804REDDYNessuna valutazione finora

- Y2 Series: Three Phase Cast Iron MotorDocumento4 pagineY2 Series: Three Phase Cast Iron MotorMark Christian TorresNessuna valutazione finora

- Engine Paramaters Con RodsDocumento1 paginaEngine Paramaters Con RodsCalandrasReyCalandrasreyNessuna valutazione finora

- SG Iron Casting Grades and StandardsDocumento4 pagineSG Iron Casting Grades and Standardsvkhavate100% (1)

- STRG CapacitiesDocumento1 paginaSTRG Capacitiesislam atifNessuna valutazione finora

- Axial Flow FansDocumento3 pagineAxial Flow FansABCDNessuna valutazione finora

- Chapter Viib - Id-455-Banjibohra Li Scheme (DMF)Documento2 pagineChapter Viib - Id-455-Banjibohra Li Scheme (DMF)PRAMODH CHELLURUNessuna valutazione finora

- Material Translation TableDocumento6 pagineMaterial Translation TableFaruk Ekinci100% (3)

- Engine Paramaters Con RodsDocumento1 paginaEngine Paramaters Con RodsАндрей АвраменкоNessuna valutazione finora

- Prevodni Tabulka WR - NR A CSNDocumento12 paginePrevodni Tabulka WR - NR A CSNLukáš TrchalíkNessuna valutazione finora

- Valvula de Balanceo Automatico Tipo KDocumento6 pagineValvula de Balanceo Automatico Tipo Kcarmen hernandezNessuna valutazione finora

- Large Axial Fans: Dimensions (MM)Documento1 paginaLarge Axial Fans: Dimensions (MM)Pradeep JhaNessuna valutazione finora

- Gjs GGG AstmDocumento17 pagineGjs GGG AstmmakmuntohirNessuna valutazione finora

- Samhop MOSFETs Production Selection Guide - Version 2014Documento14 pagineSamhop MOSFETs Production Selection Guide - Version 2014goguNessuna valutazione finora

- QF Series - Metric Compact CylindersDocumento1 paginaQF Series - Metric Compact Cylindersalex araNessuna valutazione finora

- Service SpecificationDocumento69 pagineService SpecificationMirceaNessuna valutazione finora

- Axial Single 1-3.5 Bar SingaflexDocumento2 pagineAxial Single 1-3.5 Bar Singaflexandistwn99Nessuna valutazione finora

- Grade 80 Chain and Accessories: 1210 - Master Link AssemblyDocumento1 paginaGrade 80 Chain and Accessories: 1210 - Master Link AssemblyAlthaf RNessuna valutazione finora

- Tabella Comparativa Acciai Non LegatiDocumento1 paginaTabella Comparativa Acciai Non LegatiCiriaco Di NataleNessuna valutazione finora

- Part ListDocumento2 paginePart Listionescugabriel10Nessuna valutazione finora

- Tab Flange BoltDocumento1 paginaTab Flange Boltsfar yassineNessuna valutazione finora

- Transmital MixerDocumento1 paginaTransmital MixerayavuzbvsNessuna valutazione finora

- FLANGE JIS 16K SS304 & CS Rev 2Documento2 pagineFLANGE JIS 16K SS304 & CS Rev 2Hendrias ari sujarwoNessuna valutazione finora

- Steel W.NR List With Number 1Documento10 pagineSteel W.NR List With Number 1ljnwvobenjqsgpjxmeNessuna valutazione finora

- Chemical Composition and Grades of Ductile Cast IronDocumento7 pagineChemical Composition and Grades of Ductile Cast Ironparth50% (2)

- COMPRESORES ALTERNATIVOS MT - MTM - MTZ - LTZ - Seleccion - Rapida - PistonDocumento10 pagineCOMPRESORES ALTERNATIVOS MT - MTM - MTZ - LTZ - Seleccion - Rapida - PistonAnonymous HrXPSgQ32TNessuna valutazione finora

- HE3455Documento2 pagineHE3455بن سبتي نورهانNessuna valutazione finora

- SG Iron Charts2Documento4 pagineSG Iron Charts2bbaskaran100% (3)

- TOYOFLEXDocumento6 pagineTOYOFLEXriinNessuna valutazione finora

- Drill Pipe Spec SheetDocumento2 pagineDrill Pipe Spec SheetVijay KotiNessuna valutazione finora

- Iron Special Iron Material Spec Finecast Foundry 28.8.20Documento4 pagineIron Special Iron Material Spec Finecast Foundry 28.8.20Lê ChiếnNessuna valutazione finora

- Service Specifications Toyota ProboxDocumento85 pagineService Specifications Toyota ProboxSimon Mwangi kabauNessuna valutazione finora

- Juntas Fluroflex N3 y N4Documento1 paginaJuntas Fluroflex N3 y N4Alberto Alfaro CerdaNessuna valutazione finora

- Service SpecificationsDocumento118 pagineService Specificationsapinya doungsoilNessuna valutazione finora

- LM..UU Series Linear BearingDocumento1 paginaLM..UU Series Linear BearingMikhael Evan SimamoraNessuna valutazione finora

- Product Specifications - Fittings: Eccentric ReducersDocumento1 paginaProduct Specifications - Fittings: Eccentric Reducersreach_arindomNessuna valutazione finora

- Catalog Standard Motor LTS PDFDocumento20 pagineCatalog Standard Motor LTS PDFYogesh BadheNessuna valutazione finora

- Al 000001Documento1 paginaAl 000001Daus AlexandruNessuna valutazione finora

- PH360X3CDocumento1 paginaPH360X3Cأبو زينب المهندسNessuna valutazione finora

- Crelec Technical DataDocumento2 pagineCrelec Technical DataLai Kok ChauNessuna valutazione finora

- JIS Flange STDDocumento10 pagineJIS Flange STD何宗仁Nessuna valutazione finora

- Y Series Motor BearingDocumento7 pagineY Series Motor Bearingduongthetinhqb50% (2)

- MAIN WORKSHOP A2B - Part - List - REV A #05.11.2020Documento6 pagineMAIN WORKSHOP A2B - Part - List - REV A #05.11.2020Ma'arif Nuzul AddibNessuna valutazione finora

- Jis b2220 Flange Standard Dimensions 5kDocumento1 paginaJis b2220 Flange Standard Dimensions 5kSatrio Sigit PurnomoNessuna valutazione finora

- Valvulas MariposaDocumento3 pagineValvulas Mariposadaniel manuel garces davilaNessuna valutazione finora

- POLYMATH Results: Calculated Values of The DEQ VariablesDocumento2 paginePOLYMATH Results: Calculated Values of The DEQ VariablesUlises Wegyf V YtgesudebybNessuna valutazione finora

- Materials Data for Cyclic Loading: Low-Alloy SteelsDa EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsValutazione: 5 su 5 stelle5/5 (2)

- SMART TV Quick Setup Guide: Network SettingsDocumento4 pagineSMART TV Quick Setup Guide: Network SettingsTowkir AhmmadNessuna valutazione finora

- White BronzeDocumento2 pagineWhite BronzeTowkir AhmmadNessuna valutazione finora

- Oem P/No. Meinhard #: Component Descriptions Spectro SOP ICP-OES InstrumentsDocumento1 paginaOem P/No. Meinhard #: Component Descriptions Spectro SOP ICP-OES InstrumentsTowkir AhmmadNessuna valutazione finora

- Compressor Valves For Better Reliability, Higher Efficiency and SafetyDocumento12 pagineCompressor Valves For Better Reliability, Higher Efficiency and SafetyTowkir AhmmadNessuna valutazione finora

- 1 HaberDocumento1 pagina1 HaberTowkir AhmmadNessuna valutazione finora

- (ANSI AIAA) Guide To Reference and Standard ADocumento100 pagine(ANSI AIAA) Guide To Reference and Standard ATowkir AhmmadNessuna valutazione finora

- GALVANIZED STEEL SHEETS (Kobelco)Documento28 pagineGALVANIZED STEEL SHEETS (Kobelco)Towkir AhmmadNessuna valutazione finora

- E Electrical PDF 2011Documento19 pagineE Electrical PDF 2011Towkir AhmmadNessuna valutazione finora

- (ANSI - AWS A5.31-92R) AWS A5 Committee On Filler Metal-Specification For Fluxes For Brazing and Braze Welding-American Welding Society (AWS) (1992) PDFDocumento18 pagine(ANSI - AWS A5.31-92R) AWS A5 Committee On Filler Metal-Specification For Fluxes For Brazing and Braze Welding-American Welding Society (AWS) (1992) PDFTowkir AhmmadNessuna valutazione finora

- (BS en ISO 1520-2006) - Paints and Varnishes. Cupping Test.Documento18 pagine(BS en ISO 1520-2006) - Paints and Varnishes. Cupping Test.Towkir AhmmadNessuna valutazione finora

- MKN Hansdampf Cge12 eDocumento2 pagineMKN Hansdampf Cge12 eRumen PavlovNessuna valutazione finora

- SSG1017E Edition 7Documento14 pagineSSG1017E Edition 7Harold GillNessuna valutazione finora

- Keeara Walji - Fri April 30 - Mon April 3 - Exploration Lesson 2Documento11 pagineKeeara Walji - Fri April 30 - Mon April 3 - Exploration Lesson 2Keeara WaljiNessuna valutazione finora

- Revista Domus 771Documento10 pagineRevista Domus 771Claudia TecuceanuNessuna valutazione finora

- Distance DisplacementDocumento4 pagineDistance DisplacementRuchi Briam James LagitnayNessuna valutazione finora

- AnatoFisio VestibularDocumento17 pagineAnatoFisio VestibularRocío YáñezNessuna valutazione finora

- Jenway 74 76 Series BrochureDocumento6 pagineJenway 74 76 Series BrochureSadik OunisNessuna valutazione finora

- Fiber Optic CatalogueDocumento25 pagineFiber Optic Catalogueapi-3815405100% (2)

- XRF Theory PDFDocumento258 pagineXRF Theory PDFXONΔΡΑΚΗΣ ΓΙΩΡΓΟΣ100% (1)

- Instruction Manual PHE PDFDocumento78 pagineInstruction Manual PHE PDFzniperxNessuna valutazione finora

- Expansion Model Test of Expansive Soil in Different Stress State BDocumento11 pagineExpansion Model Test of Expansive Soil in Different Stress State BHuang BenNessuna valutazione finora

- Cauchy Riemann EquationDocumento6 pagineCauchy Riemann EquationeSinist3rNessuna valutazione finora

- Finite Element Analysis of Steel CordDocumento6 pagineFinite Element Analysis of Steel CordSanjiv Kumar SinghNessuna valutazione finora

- Evo 979 enDocumento2 pagineEvo 979 enSergio Denis UCNessuna valutazione finora

- 4 Hydrates & Hydrate PreventionDocumento26 pagine4 Hydrates & Hydrate PreventionWael Badri100% (1)

- Aeroelastic Tailoring-Theory, Practice, and PromiseDocumento13 pagineAeroelastic Tailoring-Theory, Practice, and Promiservramkumar78Nessuna valutazione finora

- Integration Atmospheric Stability CFD Modeling MeteodynWT For Wind Resource Assessment AEP Validation Real Case Wind FarmDocumento1 paginaIntegration Atmospheric Stability CFD Modeling MeteodynWT For Wind Resource Assessment AEP Validation Real Case Wind FarmMeteodyn_EnergyNessuna valutazione finora

- Ko 2015Documento22 pagineKo 2015Mudavath Babu RamNessuna valutazione finora

- Hsslive Class XII Deleted Topics by Scert 2022Documento17 pagineHsslive Class XII Deleted Topics by Scert 2022Salim ShahulNessuna valutazione finora

- Lutensol TO Types: Technical InformationDocumento15 pagineLutensol TO Types: Technical InformationLjupco AleksovNessuna valutazione finora

- Effect of Specimen Thickness and Stress Ratio On Fatigue Crack Growth After A Single Overload Cycle On Structural SteelDocumento8 pagineEffect of Specimen Thickness and Stress Ratio On Fatigue Crack Growth After A Single Overload Cycle On Structural SteelKamal MankariNessuna valutazione finora

- JIS F 2023 Chain Stopper For Dia.34-36mm Anchor ChainDocumento7 pagineJIS F 2023 Chain Stopper For Dia.34-36mm Anchor ChainusnadiNessuna valutazione finora

- Be & Ca PDFDocumento45 pagineBe & Ca PDFRonimack Trajano de SouzaNessuna valutazione finora

- Disentangling Classical and Bayesian Approaches To Uncertainty AnalysisDocumento19 pagineDisentangling Classical and Bayesian Approaches To Uncertainty Analysiszilangamba_s4535Nessuna valutazione finora

- Lab Test ReportDocumento18 pagineLab Test ReportSumantrra ChattopadhyayNessuna valutazione finora

- PADT TheFocus 35 PDFDocumento18 paginePADT TheFocus 35 PDFDipak BorsaikiaNessuna valutazione finora

- SOALAN BiologiDocumento12 pagineSOALAN BiologiLoong Wai FamNessuna valutazione finora

- Manual PT90Documento68 pagineManual PT90Youssef Sarkis MobarakNessuna valutazione finora

- Mine Machinery-1 SyllabusDocumento3 pagineMine Machinery-1 SyllabusrrathoreNessuna valutazione finora