Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

I-Smi Ti 14e Productqualityreviews PDF

Caricato da

yolaisa riveraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

I-Smi Ti 14e Productqualityreviews PDF

Caricato da

yolaisa riveraCopyright:

Formati disponibili

Product quality reviews

Technical interpretation

Product quality reviews

Document valid from: 07.11.2017

Document number: I-SMI.TI.14 Version no. 05

Classification: Public

Replaced document: I-SMI.TI.14_04 dated: 14.08.2014

Root QMI documents: -

Referenced QMI documents: -

Approval

Date: Signature:

Author: 01.11.2017 Roel op den Camp

Technical verification: 02.11.2017 Christian Schärer

VS-QMI:

(formal verification and release) 07.11.2017 Michelle Scheidegger

Index

1. Purpose and scope .................................................................................................... 3

2. Basis .......................................................................................................................... 3

3. Definitions and abbreviations ..................................................................................... 3

4. Interpretation .............................................................................................................. 3

4.1 Content of the PQR .................................................................................................... 3

4.2 Responsibilities for the PQR ...................................................................................... 4

4.2.1 Responsibility for establishing the PQR...................................................................... 4

4.2.2 Responsibility for evaluating the PQR ........................................................................ 5

4.3 Review period of the PQR .......................................................................................... 5

SMI-Ident: I-SMI.TI.14e / V05 / ocr / scg / smi / 07.11.2017 1/6

Ausgedruckt am 07.11.17

Product quality reviews

Technical interpretation

4.4 Timelines for establishing and evaluating the PQR .................................................... 5

4.5 Products in co-marketing ........................................................................................... 5

5. Changes to the previous version ................................................................................ 6

6. Appendixes ................................................................................................................ 6

SMI-Ident: I-SMI.TI.14e / V05 / ocr / scg / smi / 07.11.2017 2/6

Ausgedruckt am 07.11.17

Product quality reviews

Technical interpretation

1. Purpose and scope

The importance and requirements for performing annual Product Quality Reviews (PQRs) are

described and defined in the Guide to Good Manufacturing Practice for medicinal products, part

I and part II, PIC/S document PE 009 respectively Eudralex volume 4. The PQR is considered a

key document for verifying the consistency of the existing production process.

This technical interpretation describes the minimal expectations as well as recommendations for

establishing and evaluating a PQR, that inspectors of the competent regulatory authority can

have when assessing compliance with the guidance during an inspection of a manufacturer of

medicinal products, a manufacturer of Active Pharmaceutical Ingredients (APIs) for medicinal

products or a marketing authorisation holder, in order to assure a harmonized conduct of in-

spections.

2. Basis

AMBV/OAMéd art. 7 para. 1a and 3a

AMBV/OAMéd art. 10 para. 3b

AMBV/OAMéd attachment 1 para. 1c and 1d

Guide to GMP, PIC/S PE 009, part I chapter 1.10 and 1.11 (product quality review for fin-

ished products)

Guide to GMP, PIC/S PE 009, part II chapter 2.6 (product quality review for Active Pharma-

ceutical Ingredients)

3. Definitions and abbreviations

API Active Pharmaceutical Ingredient

Product Quality Review (PQR) Documented regular periodic or rolling quality reviews of all

licensed medicinal products or APIs with the objective of ver-

ifying the consistency of the existing manufacturing process

to highlight any trends and to identify product and process

improvements or weaknesses. For licensed medicinal prod-

ucts the appropriateness of current specifications for both

starting materials and finished products is included

4. Interpretation

The PQR must be written in a defined language which can be understood by all involved parties

(manufacturer, marketing authorisation holder, competent regulatory authorities).

4.1 Content of the PQR

The Guide to GMP requires conducting PQRs for APIs and for all licensed medicinal products

(including export only products) and lists the topics, which need to be taken into account (for fin-

ished products in the Guide to GMP, part I and for APIs in the Guide to GMP, part II).

It is expected that all topics listed in the Guide to GMP are explicitly addressed in the PQR. The

extent (i.e. selection of the parameters to be reviewed, e.g. critical in-process controls) and

depth of data review for each of these topics should be defined in a risk based way and should

be suitable to highlight any trends in relevant quality characteristics and enable to identify the

necessity for product and/or process improvements. The justification for the chosen extent and

SMI-Ident: I-SMI.TI.14e / V05 / ocr / scg / smi / 07.11.2017 3/6

Ausgedruckt am 07.11.17

Product quality reviews

Technical interpretation

depth should be science based and documented. The justification can be described in a sepa-

rate document.

In general, the PQR has to cover all products and all the batches of a product produced during

the review period. Grouping of products is acceptable but a scientific justification for the group-

ing must be part of the PQR.

To be able to verify the consistency of the existing production process, the number of batches

produced should be as large as possible. Therefore, the PQR should include all the batches of

a product produced and not only the batches supplied to one customer. For example, if a cer-

tain product is registered in several countries or produced for multiple customers (this means

the products has multiple marketing authorisations), but the production process, the in process

controls and finished product specifications are the same, only one PQR covering all batches

should be established and made accessible to all customers.

If a product is registered in several countries (multiple marketing authorisations) or produced for

multiple customers, and the production process is essentially the same, with only minor varia-

tions in process controls and finished product specifications, only one PQR based on the most

stringent criteria may be established and made accessible to all customers.

Normally, the PQR should not contain endless lists with single data (raw data) but should con-

tain overviews, graphs or tables summarising the raw data. The PQR should contain a review

and interpretation of the raw data followed by a condensed summary including an assessment

and conclusion.

They PQR should consider conclusions and preventive and/or corrective actions from previous

reviews.

4.2 Responsibilities for the PQR

4.2.1 Responsibility for establishing the PQR

Where several companies are involved in the manufacture or analysis and where the marketing

authorisation holder is different from the manufacturer, it is expected that one overall PQR is es-

tablished. If the overall PQR refers to PQRs, which are covering parts of the manufacturing ac-

tivities, the conclusions from these partial PQRs should be included in the overall PQR.

There should be one overall responsible person/organisation for establishing the PQR. This can

be either the manufacturer technically releasing the API and/or finished products (and being re-

sponsible for final batch certification) or, in case of finished products, the marketing authorisa-

tion holder releasing the finished product for the (Swiss) market. Technical agreements should

be established between all parties involved, defining who will take the overall responsibility for

establishing the PQR and the way, the extent and the responsibility for providing data for the

PQR. Such agreements must comply with chapter 7 of the Guide to GMP part I or chapter 16 of

the Guide to GMP part II.

It is expected that the overall responsible person/organisation as well as all involved manufac-

turers establish procedures (SOPs) for establishing the relevant part of the PQR. These proce-

dures should ensure that the content of the PQR is appropriate and that the necessary conclu-

sions are drawn out of the reviewed data and documented in the PQR.

SMI-Ident: I-SMI.TI.14e / V05 / ocr / scg / smi / 07.11.2017 4/6

Ausgedruckt am 07.11.17

Product quality reviews

Technical interpretation

4.2.2 Responsibility for evaluating the PQR

Both, the manufacturer, and in case of finished products, the marketing authorisation holder,

should evaluate the results of the PQR and both should make an assessment of whether cor-

rective and preventative action or any revalidation should be undertaken. The evaluation should

involve the upper management and the responsible person of the companies involved.

The marketing authorisation holder should verify whether the product consistently fulfils the re-

quirements as specified in the marketing authorisation. The process for the evaluation of the

PQR and for the follow up of defined actions should be described in a SOP. The SOP of the

marketing authorisation holder should include at least the following aspects:

a) a verification, that the reviews as defined in the Guide to GMP have been conducted

b) an evaluation of the conclusions drawn in the PQR, including a review of the trendings

c) a verification of being in compliance with the marketing authorisation

d) review of country-specific aspects like recalls, returns, complaints, quality defects, devia-

tions or marketing authorisation variations

e) review and follow up of previously defined actions.

Documented evidence for having evaluated the PQR should be available.

4.3 Review period of the PQR

The PQR should be established at least annually. The yearly periods may be set independently

from the calendar year, i.e. not necessarily from January to December.

Where only 1 batch or very few batches were produced during the year, the review period might

be longer than 1 year. The chosen review period for such cases should include at least 5

batches or should be performed after 5 years if at least 3 batches have been produced. If after 5

years less than 3 batches have been produced, a PQR should be established as soon as 3

batches have been produced. For products with very few batches produced during a review pe-

riod, a reasonable grouping with other products might be considered.

In case of recalls, quality-related returns or a relative high number of complaints the establish-

ment of a PQR, even if only few batches have been produced, is recommended.

4.4 Timelines for establishing and evaluating the PQR

The PQR should be established in a timely manner. “Timely” is considered as within 6 months

after the end of the review period.

An evaluation of the results and an assessment of potential actions should be performed within

3 months after the establishment of the PQR. The evaluation and assessment of the PQR

should be completed at the latest before the end of the next review period or at the latest 12

months after the end of the reviewed period (e.g. in case of a discontinued production).

4.5 Products in co-marketing

The marketing authorisation holder of a product in co-marketing (VAZV/OASMéd art. 34 - art.

38), in principle, has the same responsibilities as a marketing authorisation holder of a basic

product. However, the co-marketing authorisation holder is not able to verify whether the prod-

uct consistently fulfils the requirements as specified in the marketing authorisation because he

does not have access to the marketing authorisation. Therefore, different requirements to the

PQR are applicable.

The co-marketing authorisation holder should secure or at least verify that the marketing author-

isation holder of the basic product establishes a PQR. Co-marketing-product specific aspects

SMI-Ident: I-SMI.TI.14e / V05 / ocr / scg / smi / 07.11.2017 5/6

Ausgedruckt am 07.11.17

Product quality reviews

Technical interpretation

like recalls, returns, complaints, quality defects or deviations must be integrated in the PQR of

the basic product and must, therefore, be made available by the co-marketing authorisation

holder to the marketing authorisation holder.

If the marketing authorisation holder does not establish a PQR, including co-marketing product

specific aspects, the co-marketing holder is obliged to establish an adapted PQR (in line with

this technical interpretation), which contains all the activities as defined in the Guide to GMP,

part I, for which the co-marketing holder is responsible (e.g. primary and/or secondary packag-

ing, changes, recalls, returns, complaints, quality defects, deviations or contractual arrange-

ments).

The exchange of information between the marketing authorisation holder and the co-marketing

authorisation holder (e.g. complaint data) should be defined in a technical agreement.

5. Changes to the previous version

Chapter 2, 4.1 and 4.5: correction of the referenced chapters in the GMP Guidelines

Chapter 4.2.2: correction of a typing error

6. Appendixes

None

SMI-Ident: I-SMI.TI.14e / V05 / ocr / scg / smi / 07.11.2017 6/6

Ausgedruckt am 07.11.17

Potrebbero piacerti anche

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionDa EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionValutazione: 4.5 su 5 stelle4.5/5 (10)

- I Smi - Ti.14 - 04 Swiss Medic PQRDocumento6 pagineI Smi - Ti.14 - 04 Swiss Medic PQRSundar GanesanNessuna valutazione finora

- Guidance For Industry - PQR - 201312 PDFDocumento9 pagineGuidance For Industry - PQR - 201312 PDFAshok LenkaNessuna valutazione finora

- Product and Systems Development: A Value ApproachDa EverandProduct and Systems Development: A Value ApproachNessuna valutazione finora

- WHO - PQS - Standard Operating Procedures PDFDocumento208 pagineWHO - PQS - Standard Operating Procedures PDFLenin Fernandez ArellanoNessuna valutazione finora

- Certifiable Software Applications 3: Downward CycleDa EverandCertifiable Software Applications 3: Downward CycleNessuna valutazione finora

- RD of CBD ProductsDocumento13 pagineRD of CBD ProductsUmair ShekhaniNessuna valutazione finora

- Pharma Questions PDFDocumento71 paginePharma Questions PDFDipesh BardoliaNessuna valutazione finora

- Guidance For Industry PQR 201312Documento9 pagineGuidance For Industry PQR 201312Trung NamNessuna valutazione finora

- Most Frequently Asked Questions: Page 1 of 6Documento66 pagineMost Frequently Asked Questions: Page 1 of 6shanmukha2007Nessuna valutazione finora

- Standard Operting Procedures For Immunization Devices - 06!12!2021Documento254 pagineStandard Operting Procedures For Immunization Devices - 06!12!2021Judith HerreraNessuna valutazione finora

- Stephen Galvin Biotech Process Validation Master PlanDocumento14 pagineStephen Galvin Biotech Process Validation Master PlanTanChantreaNessuna valutazione finora

- Procedure For Internal AuditingDocumento4 pagineProcedure For Internal AuditingQuality Unit 1 Ajay Pandey67% (3)

- Quality Assurance Question BankDocumento72 pagineQuality Assurance Question BankMuhammad Noman bin FiazNessuna valutazione finora

- Pi 021 2 Aide Memoire On GMP GCPDocumento10 paginePi 021 2 Aide Memoire On GMP GCPIsmail MathakiyaNessuna valutazione finora

- Pharmaceutical Interview QuestionsDocumento74 paginePharmaceutical Interview QuestionsDr usama El Shafey100% (4)

- PR18 Procedure On RNDDocumento7 paginePR18 Procedure On RNDShahariar ShahadatNessuna valutazione finora

- Pe 008 4 Site Master File Copy1 PDFDocumento8 paginePe 008 4 Site Master File Copy1 PDFCamilo SuárezNessuna valutazione finora

- Product Quality Review or Annual Product Review-1Documento6 pagineProduct Quality Review or Annual Product Review-1nataarajan praveen100% (1)

- Global Supplier Manual Appendix M - Suzuki Customer Specific Requirements For SuppliersDocumento4 pagineGlobal Supplier Manual Appendix M - Suzuki Customer Specific Requirements For Suppliersnkrish21856Nessuna valutazione finora

- (NORMA) Request For Quality MetricsDocumento14 pagine(NORMA) Request For Quality MetricsJhovanaNessuna valutazione finora

- Annual Product Quality Review TemplateDocumento9 pagineAnnual Product Quality Review Templateyasinpapers.datasNessuna valutazione finora

- Production Part Approval ProcessDocumento6 pagineProduction Part Approval ProcessleonardoNessuna valutazione finora

- Annual Product Quality Review APQR FormatDocumento9 pagineAnnual Product Quality Review APQR FormatDr.Sivakumar Selvaraj100% (1)

- DHF Index-ElsmarDocumento13 pagineDHF Index-Elsmarisrael afolayan mayomiNessuna valutazione finora

- Production Part Approval Process: PurposeDocumento6 pagineProduction Part Approval Process: Purposefabroto88Nessuna valutazione finora

- IATF 16949-2016 Intro and Clauses PDFDocumento274 pagineIATF 16949-2016 Intro and Clauses PDFneetuyadav2250% (2)

- Q5E Guideline PDFDocumento16 pagineQ5E Guideline PDFJosé Carlos Solís SuárezNessuna valutazione finora

- Annual Product Quality Review APQR FormatDocumento9 pagineAnnual Product Quality Review APQR Formatqc jawa100% (6)

- Quality Manual ExampleDocumento15 pagineQuality Manual ExampleHagit Givati100% (1)

- FNGP Supplier Manual Rev9 10-1-2007Documento21 pagineFNGP Supplier Manual Rev9 10-1-2007davidalejandrotorresNessuna valutazione finora

- Guidance For Industry PQR 201312Documento9 pagineGuidance For Industry PQR 201312Roman SmishkoNessuna valutazione finora

- VMPDocumento29 pagineVMPj.k.kumar100% (2)

- Annula Product Review Standared Operation ProcedureDocumento4 pagineAnnula Product Review Standared Operation ProcedureSolomon GamanuelNessuna valutazione finora

- Production Part Approval Process PPAPDocumento4 pagineProduction Part Approval Process PPAPtintucinNessuna valutazione finora

- The GCC Data Requirments For The Renewal of Marketing Authorizations version12GCC-ENDocumento9 pagineThe GCC Data Requirments For The Renewal of Marketing Authorizations version12GCC-ENiliyasNessuna valutazione finora

- BRSM Form 009 Qms MDD - TJDocumento15 pagineBRSM Form 009 Qms MDD - TJAnonymous q8lh3fldWMNessuna valutazione finora

- Validation Master Plan Example - LongDocumento31 pagineValidation Master Plan Example - LongJayesh kolheNessuna valutazione finora

- Process Performance Qualification ProtocolDocumento7 pagineProcess Performance Qualification Protocolsandeep sharmaNessuna valutazione finora

- SOP - Control of Quality RecordsDocumento11 pagineSOP - Control of Quality Recordshimawan setyarsoNessuna valutazione finora

- 2.PR-GM 02 Document Control ProcedureDocumento8 pagine2.PR-GM 02 Document Control ProcedureFULGENCE RUHARARANessuna valutazione finora

- Ifs BP.080 FPM Sta-Final2Documento48 pagineIfs BP.080 FPM Sta-Final2Yuda PrawiraNessuna valutazione finora

- ICH Q8 Q9 Q10 Implementation Quality - IWG - PtCR2 - 6dec2011Documento20 pagineICH Q8 Q9 Q10 Implementation Quality - IWG - PtCR2 - 6dec2011Calderón DaniiNessuna valutazione finora

- SWGDRUG Recommendations 6Documento72 pagineSWGDRUG Recommendations 6Maria CamilaNessuna valutazione finora

- The Pharma Professionals Interview Guide PDFDocumento48 pagineThe Pharma Professionals Interview Guide PDFAjit Lonkar100% (1)

- A Product Which Has Completed All Stages of Manufacture, Including Final PackagingDocumento4 pagineA Product Which Has Completed All Stages of Manufacture, Including Final Packagingom shankar JhaNessuna valutazione finora

- Pivp - mnl-00 Usp Ivp-Api Manual For Participants - Docxjan202024071555Documento68 paginePivp - mnl-00 Usp Ivp-Api Manual For Participants - Docxjan202024071555Angel FloresNessuna valutazione finora

- CT18-1 API Spec Q2 Toolkit DemoDocumento25 pagineCT18-1 API Spec Q2 Toolkit Demomhmmad alahmad100% (1)

- Introduction To Production Part Approval Process (PPAP)Documento7 pagineIntroduction To Production Part Approval Process (PPAP)VigneshNessuna valutazione finora

- Pharma M&A Due DiligenceDocumento43 paginePharma M&A Due DiligencePraveen KumarNessuna valutazione finora

- IPRP QWG Guidance For Q Assessors DP 2020 0528Documento36 pagineIPRP QWG Guidance For Q Assessors DP 2020 0528Cati JurcaNessuna valutazione finora

- Process For Control of Non-Conforming ProductDocumento8 pagineProcess For Control of Non-Conforming ProductselvamuthukumarNessuna valutazione finora

- Global Supplier Standards Manual Quality Expectations SectionDocumento18 pagineGlobal Supplier Standards Manual Quality Expectations Sectionamhosny64Nessuna valutazione finora

- APIC Quick Guide For API SourcingDocumento8 pagineAPIC Quick Guide For API SourcingBNPARIKHNessuna valutazione finora

- Quality Manual ExampleDocumento32 pagineQuality Manual ExamplesaiaviNessuna valutazione finora

- Applying ICH Q8 (R2), Q9, and Q10 Principles To CMC ReviewDocumento5 pagineApplying ICH Q8 (R2), Q9, and Q10 Principles To CMC Reviewvg_vvgNessuna valutazione finora

- PPAP Submission PDFDocumento15 paginePPAP Submission PDFRabi Chhetri UpadhyayNessuna valutazione finora

- Production Part Approval Process (PPAP) Submission AssessmentDocumento15 pagineProduction Part Approval Process (PPAP) Submission Assessmentffppxxzz100% (1)

- A Report On Square Pharmaceuticals LTDDocumento45 pagineA Report On Square Pharmaceuticals LTDrakib_001171% (14)

- Life Aveda - All ProductsDocumento64 pagineLife Aveda - All ProductsChetanNessuna valutazione finora

- Vendor QualificationDocumento2 pagineVendor QualificationDharmesh PatelNessuna valutazione finora

- Zoka Coffee FDA Warning LetterDocumento4 pagineZoka Coffee FDA Warning LetterDoug LevyNessuna valutazione finora

- Healthcare Pharmaceuticals LTDDocumento26 pagineHealthcare Pharmaceuticals LTDNafiz NiazNessuna valutazione finora

- Audit Final Report 2023 NaveedDocumento20 pagineAudit Final Report 2023 Naveednaveed100% (1)

- PHSS - Clarity - in - GMP - Guidance - Barrier - Isolator - Technology - Leak Integrity Classes - v1Documento12 paginePHSS - Clarity - in - GMP - Guidance - Barrier - Isolator - Technology - Leak Integrity Classes - v1AkuWilliamsNessuna valutazione finora

- Richard C. Fries - Handbook of Medical Device Design (2001, CRC Press)Documento795 pagineRichard C. Fries - Handbook of Medical Device Design (2001, CRC Press)Grimmy GrimNessuna valutazione finora

- The Arab GMPDocumento68 pagineThe Arab GMPAhmad RamahiNessuna valutazione finora

- Oxytocin Quality: Evidence To Support Updated Global Recommendations On Oxytocin For Postpartum HemorrhageDocumento13 pagineOxytocin Quality: Evidence To Support Updated Global Recommendations On Oxytocin For Postpartum HemorrhageAndreaNessuna valutazione finora

- How Ethical Is The Pharmaceutical Industry in IndiaDocumento5 pagineHow Ethical Is The Pharmaceutical Industry in IndiaKeerthi NarayananNessuna valutazione finora

- 1426144337wpdm - WHO - TRS - 908-Annex9 GSP PDFDocumento12 pagine1426144337wpdm - WHO - TRS - 908-Annex9 GSP PDFYuly YusNessuna valutazione finora

- Module - 1Documento25 pagineModule - 1vijayns_250355172Nessuna valutazione finora

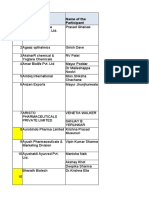

- 한-인도 제약산업 웨비나 인도측 B2B 참석자Documento35 pagine한-인도 제약산업 웨비나 인도측 B2B 참석자Baria VirenNessuna valutazione finora

- National Drug PolicyDocumento14 pagineNational Drug PolicyAlam SherNessuna valutazione finora

- SQF Manufacturing Ed8.1Checklist With DeskDocumento353 pagineSQF Manufacturing Ed8.1Checklist With DeskLuis GallegosNessuna valutazione finora

- FDA Academy Course Calendar 2013Documento4 pagineFDA Academy Course Calendar 2013Johnny ManahanNessuna valutazione finora

- Process Validation From An FDA Perspective - Part 2Documento4 pagineProcess Validation From An FDA Perspective - Part 2Darren Tan100% (1)

- ISO 22716 GMP For CosmeticsDocumento5 pagineISO 22716 GMP For CosmeticsDenySidiqMulyonoChtNessuna valutazione finora

- Degradation of Pharmaceutical SolidsDocumento23 pagineDegradation of Pharmaceutical SolidsakramuddaulaNessuna valutazione finora

- Cosmetics RegulationDocumento112 pagineCosmetics RegulationChiNessuna valutazione finora

- Manufacturing Practice Audit: (GMP Audit - Check List)Documento31 pagineManufacturing Practice Audit: (GMP Audit - Check List)Sandra100% (1)

- HCPL Company PresentationDocumento16 pagineHCPL Company Presentationgaurav gupteNessuna valutazione finora

- FFSQ ProspectusDocumento94 pagineFFSQ ProspectusArun CelestinNessuna valutazione finora

- US Vs Real Water: ComplaintDocumento19 pagineUS Vs Real Water: ComplaintTony OrtegaNessuna valutazione finora

- Risk-Based Food Inspection Manual PDFDocumento92 pagineRisk-Based Food Inspection Manual PDFNicolae Boţan100% (1)

- Annual Product Quality ReviewDocumento6 pagineAnnual Product Quality ReviewwondwossengNessuna valutazione finora

- Abbreviations Used in The Pharmaceutical IndustryDocumento8 pagineAbbreviations Used in The Pharmaceutical Industryatul8295Nessuna valutazione finora

- PQE Group Guidelines To EU GMP Annex 1 Draft 2020Documento12 paginePQE Group Guidelines To EU GMP Annex 1 Draft 2020António Ferreira100% (1)

- Guidance On Good Manufacturing PracticeDocumento153 pagineGuidance On Good Manufacturing PracticeOanh NguyễnNessuna valutazione finora

- Obviously Awesome: How to Nail Product Positioning so Customers Get It, Buy It, Love ItDa EverandObviously Awesome: How to Nail Product Positioning so Customers Get It, Buy It, Love ItValutazione: 4.5 su 5 stelle4.5/5 (152)

- $100M Leads: How to Get Strangers to Want to Buy Your StuffDa Everand$100M Leads: How to Get Strangers to Want to Buy Your StuffValutazione: 5 su 5 stelle5/5 (19)

- $100M Offers: How to Make Offers So Good People Feel Stupid Saying NoDa Everand$100M Offers: How to Make Offers So Good People Feel Stupid Saying NoValutazione: 5 su 5 stelle5/5 (23)

- Summary: $100M Leads: How to Get Strangers to Want to Buy Your Stuff by Alex Hormozi: Key Takeaways, Summary & Analysis IncludedDa EverandSummary: $100M Leads: How to Get Strangers to Want to Buy Your Stuff by Alex Hormozi: Key Takeaways, Summary & Analysis IncludedValutazione: 3 su 5 stelle3/5 (6)

- The Catalyst: How to Change Anyone's MindDa EverandThe Catalyst: How to Change Anyone's MindValutazione: 4.5 su 5 stelle4.5/5 (274)

- Fascinate: How to Make Your Brand Impossible to ResistDa EverandFascinate: How to Make Your Brand Impossible to ResistValutazione: 5 su 5 stelle5/5 (1)

- Ca$hvertising: How to Use More than 100 Secrets of Ad-Agency Psychology to Make Big Money Selling Anything to AnyoneDa EverandCa$hvertising: How to Use More than 100 Secrets of Ad-Agency Psychology to Make Big Money Selling Anything to AnyoneValutazione: 5 su 5 stelle5/5 (114)

- Understanding Digital Marketing: Marketing Strategies for Engaging the Digital GenerationDa EverandUnderstanding Digital Marketing: Marketing Strategies for Engaging the Digital GenerationValutazione: 4 su 5 stelle4/5 (22)

- Jab, Jab, Jab, Right Hook: How to Tell Your Story in a Noisy Social WorldDa EverandJab, Jab, Jab, Right Hook: How to Tell Your Story in a Noisy Social WorldValutazione: 4.5 su 5 stelle4.5/5 (18)

- Invisible Influence: The Hidden Forces that Shape BehaviorDa EverandInvisible Influence: The Hidden Forces that Shape BehaviorValutazione: 4.5 su 5 stelle4.5/5 (131)

- Summary: Dotcom Secrets: The Underground Playbook for Growing Your Company Online with Sales Funnels by Russell Brunson: Key Takeaways, Summary & Analysis IncludedDa EverandSummary: Dotcom Secrets: The Underground Playbook for Growing Your Company Online with Sales Funnels by Russell Brunson: Key Takeaways, Summary & Analysis IncludedValutazione: 5 su 5 stelle5/5 (2)

- Dealers of Lightning: Xerox PARC and the Dawn of the Computer AgeDa EverandDealers of Lightning: Xerox PARC and the Dawn of the Computer AgeValutazione: 4 su 5 stelle4/5 (88)

- Visibility Marketing: The No-Holds-Barred Truth About What It Takes to Grab Attention, Build Your Brand, and Win New BusinessDa EverandVisibility Marketing: The No-Holds-Barred Truth About What It Takes to Grab Attention, Build Your Brand, and Win New BusinessValutazione: 4.5 su 5 stelle4.5/5 (7)

- Yes!: 50 Scientifically Proven Ways to Be PersuasiveDa EverandYes!: 50 Scientifically Proven Ways to Be PersuasiveValutazione: 4 su 5 stelle4/5 (153)

- How to Read People: The Complete Psychology Guide to Analyzing People, Reading Body Language, and Persuading, Manipulating and Understanding How to Influence Human BehaviorDa EverandHow to Read People: The Complete Psychology Guide to Analyzing People, Reading Body Language, and Persuading, Manipulating and Understanding How to Influence Human BehaviorValutazione: 4.5 su 5 stelle4.5/5 (33)

- Pre-Suasion: Channeling Attention for ChangeDa EverandPre-Suasion: Channeling Attention for ChangeValutazione: 4.5 su 5 stelle4.5/5 (278)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessDa EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNessuna valutazione finora

- 100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziDa Everand100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziNessuna valutazione finora

- Summary: The Intelligent Investor: The Definitive Book on Value Investing by Benjamin Graham: Key Takeaways, Summary & AnalysisDa EverandSummary: The Intelligent Investor: The Definitive Book on Value Investing by Benjamin Graham: Key Takeaways, Summary & AnalysisValutazione: 4 su 5 stelle4/5 (4)

- Summary: Traction: Get a Grip on Your Business: by Gino Wickman: Key Takeaways, Summary, and AnalysisDa EverandSummary: Traction: Get a Grip on Your Business: by Gino Wickman: Key Takeaways, Summary, and AnalysisValutazione: 5 su 5 stelle5/5 (10)

- The Power of Why: Breaking Out In a Competitive MarketplaceDa EverandThe Power of Why: Breaking Out In a Competitive MarketplaceValutazione: 4 su 5 stelle4/5 (5)

- The Myth of the Rational Market: A History of Risk, Reward, and Delusion on Wall StreetDa EverandThe Myth of the Rational Market: A History of Risk, Reward, and Delusion on Wall StreetNessuna valutazione finora

- 46 Consumer Reporting Agencies Investigating YouDa Everand46 Consumer Reporting Agencies Investigating YouValutazione: 4.5 su 5 stelle4.5/5 (6)

- Marketing Made Simple: A Step-by-Step StoryBrand Guide for Any BusinessDa EverandMarketing Made Simple: A Step-by-Step StoryBrand Guide for Any BusinessValutazione: 5 su 5 stelle5/5 (203)

- Brand Identity Breakthrough: How to Craft Your Company's Unique Story to Make Your Products IrresistibleDa EverandBrand Identity Breakthrough: How to Craft Your Company's Unique Story to Make Your Products IrresistibleValutazione: 4.5 su 5 stelle4.5/5 (48)

- Summary: Influence: The Psychology of Persuasion by Robert B. Cialdini Ph.D.: Key Takeaways, Summary & AnalysisDa EverandSummary: Influence: The Psychology of Persuasion by Robert B. Cialdini Ph.D.: Key Takeaways, Summary & AnalysisValutazione: 5 su 5 stelle5/5 (4)

- Create Once, Distribute Forever: How Great Creators Spread Their Ideas and How You Can TooDa EverandCreate Once, Distribute Forever: How Great Creators Spread Their Ideas and How You Can TooNessuna valutazione finora

- The Power of Experiments: Decision-Making in a Data Driven WorldDa EverandThe Power of Experiments: Decision-Making in a Data Driven WorldNessuna valutazione finora