Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lab 4: An Acyclic Process Objectives

Caricato da

Fnur FatihahTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lab 4: An Acyclic Process Objectives

Caricato da

Fnur FatihahCopyright:

Formati disponibili

LAB 4: AN ACYCLIC PROCESS

Objectives:

1. To install and converge a conversion reactor

2. To simulate a process involving reaction and separation

3. To simulate heat exchanger as cooler using different fluid package.

PART 1:

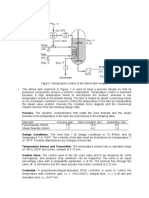

Process:

Toluene is produced from n-heptane by hydrogenation over a Cr2O3 catalyst adsorbed on Al2O3:

C7H16 → C7H8 + 4H2

n-heptane is heated from 65oF to 800oF in a heater at molar flowrate of 100 lbmole/hr and fed to a

catalytic reactor, which operates isothermally and converts 15% of n-heptane to toluene. The effluent is

cooled to 30o F and fed into flash separator to remove all the hydrogen from the liquid stream.

Then, use a separation equipment to separate toluene from excess n-heptane.

Hint:

1. Use Soave-Redlich-Kwong property package.

2. Use adjust operation in HYSYS to achieve the goal

3. Optimize the separation process in the first separator.

Questions:

1. What is the phase of n-heptane at the inlet and outlet of the heater?

2. What is the mole fraction for each component after conversion of 15% n-heptane?

3. What is the phase and temperature of the inlet of separator?

4. Determine the mole fraction for each component at the outlet of the separator.

5. Use a separation equipment to obtain a high purity toluene. Record toluene purity you

PART 2:

Change the cooler to heat exchanger operation, use the simple-weighted type design. Use cooling water

as the cooling medium.

Hint:

1. Use the standard specifications for cooling water.

2. Use separate component list and fluid package for this operation.

Questions:

1. What is the amount of cooling water need to cool the effluent to 30o F?

2. Similarly change the heater, into heat exchanger operation also using the simple-weighted type

design, but use the MP steam as the heating medium. Use ASME Steam package as the fluid

package. What is the amount of steam required to achieve the desired condition?

Potrebbero piacerti anche

- Lab3 3 PDFDocumento1 paginaLab3 3 PDFZana Aza SeiyuuNessuna valutazione finora

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesDa EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNessuna valutazione finora

- Lab 3 An Acyclic ProcessDocumento1 paginaLab 3 An Acyclic ProcessAl FatahNessuna valutazione finora

- Lab 3Documento12 pagineLab 3Paen ZulkifliNessuna valutazione finora

- Lab 3Documento16 pagineLab 3Paen Zulkifli100% (1)

- Acyclic Process (Lab4)Documento6 pagineAcyclic Process (Lab4)sfycNessuna valutazione finora

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersDa EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersValutazione: 4 su 5 stelle4/5 (13)

- NO Index Pages: 1 Procedures 2Documento8 pagineNO Index Pages: 1 Procedures 2Harris EffendiNessuna valutazione finora

- Lab 3 Hysys-AN ACYCLIC PROCESSDocumento7 pagineLab 3 Hysys-AN ACYCLIC PROCESSHikaru MokaNessuna valutazione finora

- Hysys Lab 3Documento7 pagineHysys Lab 3Kangae IlhamNessuna valutazione finora

- For Hysys UsersDocumento5 pagineFor Hysys UsersZohaib RanaNessuna valutazione finora

- Lab 3 HysysDocumento8 pagineLab 3 HysysZulhafizi Kamaruddin100% (2)

- Hydrodealkylation SimulationDocumento8 pagineHydrodealkylation SimulationLívia Lopes100% (2)

- Hysys WorkbookDocumento23 pagineHysys WorkbookDaniloNessuna valutazione finora

- Microsoft Word - Cpci Assignment NewDocumento25 pagineMicrosoft Word - Cpci Assignment NewSaints Burner ChristopherNessuna valutazione finora

- Oel ExperimentDocumento15 pagineOel ExperimentDianah NajeebNessuna valutazione finora

- EvaporationDocumento36 pagineEvaporationPaul Andrew MadlangbayanNessuna valutazione finora

- Literature Survey On 2EH ProductionDocumento3 pagineLiterature Survey On 2EH Productionkilldeadman100% (2)

- Important RegenerationDocumento8 pagineImportant RegenerationrawadNessuna valutazione finora

- HYSYS SIMULATION REPORT Alshaoubka m2Documento16 pagineHYSYS SIMULATION REPORT Alshaoubka m2kaitokidH3MNessuna valutazione finora

- Lecture Three: Process DesignDocumento57 pagineLecture Three: Process DesignAsasira IradNessuna valutazione finora

- Reforming and IsomerizationDocumento17 pagineReforming and Isomerizationhala mrayanNessuna valutazione finora

- Sunway Practical Lab Bicarbonate Decomposition 2012Documento11 pagineSunway Practical Lab Bicarbonate Decomposition 2012venkieeNessuna valutazione finora

- 2.1 Manufacturing Processes and Selection:: 2.1.1 Oxidation ProcessDocumento4 pagine2.1 Manufacturing Processes and Selection:: 2.1.1 Oxidation ProcessLucky9922100% (1)

- Climbing Film EvaporatorDocumento8 pagineClimbing Film EvaporatorPelin Yazgan BirgiNessuna valutazione finora

- Recycle Structure of The FlowsheetDocumento19 pagineRecycle Structure of The FlowsheetSanyog GhoshNessuna valutazione finora

- Catalytic Reforming Unit (Cru)Documento20 pagineCatalytic Reforming Unit (Cru)Ashish RajakNessuna valutazione finora

- Heat ExchangerDocumento4 pagineHeat ExchangerIzwanaRahimiNessuna valutazione finora

- Petroleum Refining Materials and EquipmentDocumento23 paginePetroleum Refining Materials and EquipmentAli AlengineerNessuna valutazione finora

- Aspen For Chem RXN PART 2Documento50 pagineAspen For Chem RXN PART 2hakita86Nessuna valutazione finora

- Production of OlefinsDocumento39 pagineProduction of OlefinsshubhamNessuna valutazione finora

- Full Report Refrigeration UnitDocumento24 pagineFull Report Refrigeration UnitNabil ImranNessuna valutazione finora

- University of Nottingham Butanol Project - Design Guide 1Documento6 pagineUniversity of Nottingham Butanol Project - Design Guide 1Tom HartNessuna valutazione finora

- Hysys Workbook Part-1: By: Eng. Ahmed DeyabDocumento23 pagineHysys Workbook Part-1: By: Eng. Ahmed Deyabahmed atwaNessuna valutazione finora

- Batch Manufacture of Propylene GlycolDocumento6 pagineBatch Manufacture of Propylene Glycolprassna_kamat1573Nessuna valutazione finora

- Lecture - 11 - Gas Processing and PolymerizationDocumento6 pagineLecture - 11 - Gas Processing and Polymerizationrin karinNessuna valutazione finora

- Ethylene UnitsDocumento20 pagineEthylene UnitsLindah Turson100% (3)

- CHEMCAD Models 2Documento33 pagineCHEMCAD Models 2Sheraz FiazNessuna valutazione finora

- Steam Powered Absorption Chiller Installation and Operation Manual TTDocumento44 pagineSteam Powered Absorption Chiller Installation and Operation Manual TTromi_hamdani0% (1)

- TOURTON-páginas-37-124-73-88 PDFDocumento16 pagineTOURTON-páginas-37-124-73-88 PDFJesús David González CañasNessuna valutazione finora

- Crude Distillation Unit & Vacuum Distillation UnitDocumento10 pagineCrude Distillation Unit & Vacuum Distillation Unitsenthilkumarbt100% (1)

- Isomerization TechniqueDocumento14 pagineIsomerization TechniqueharisNessuna valutazione finora

- Methanol From Natural Gas by ICI's FIMDocumento9 pagineMethanol From Natural Gas by ICI's FIMFer MugrabiNessuna valutazione finora

- Process DescriptionDocumento5 pagineProcess DescriptionGurunath EpiliNessuna valutazione finora

- Exp - 7Documento8 pagineExp - 7Ron PascualNessuna valutazione finora

- Ta-Fe-2 231219 080052Documento45 pagineTa-Fe-2 231219 080052MAI NGUYỄN TRẦN THANHNessuna valutazione finora

- Implant Training: Hindustan Organic Chemicals LTDDocumento7 pagineImplant Training: Hindustan Organic Chemicals LTDajin k bobanNessuna valutazione finora

- AbstractDocumento2 pagineAbstractShanice CabrilesNessuna valutazione finora

- EvaporationDocumento50 pagineEvaporationRajNessuna valutazione finora

- Evaporation CrystallizationDocumento53 pagineEvaporation CrystallizationFren R.0% (1)

- Homework 4 - MEEN 2300 - Spring 2015Documento3 pagineHomework 4 - MEEN 2300 - Spring 2015MichaelNessuna valutazione finora

- Control ValveDocumento2 pagineControl ValveNadia KamaNessuna valutazione finora

- Training Report: Rahul Gupta Ammonia PlantDocumento25 pagineTraining Report: Rahul Gupta Ammonia PlantMohit MangalNessuna valutazione finora

- Crude Oil DistillationDocumento34 pagineCrude Oil Distillationfathi100% (2)

- Lecture-3, Practical, 3Documento30 pagineLecture-3, Practical, 3Asasira IradNessuna valutazione finora

- 1 Procedure 10 2 Process Flow Diagram (PFD) 20 3 Workbook/Stream Summary 30 4 Questions & Discussions 40Documento11 pagine1 Procedure 10 2 Process Flow Diagram (PFD) 20 3 Workbook/Stream Summary 30 4 Questions & Discussions 40lynNessuna valutazione finora

- CPE 601 - Polymeric Materials - Week 6-2Documento98 pagineCPE 601 - Polymeric Materials - Week 6-2Ku FaRiezNessuna valutazione finora

- Ent600 BlueprintDocumento22 pagineEnt600 BlueprintFnur Fatihah100% (1)

- Executive SumDocumento1 paginaExecutive SumFnur FatihahNessuna valutazione finora

- Ent600 CSDocumento11 pagineEnt600 CSFnur FatihahNessuna valutazione finora

- Ent600 - Blueprint Guideline & Template - Updated Sept2018Documento14 pagineEnt600 - Blueprint Guideline & Template - Updated Sept2018Fnur FatihahNessuna valutazione finora

- Ent600 CSDocumento11 pagineEnt600 CSFnur FatihahNessuna valutazione finora

- Che692 - Process Modelling and Simulation: Week 6Documento17 pagineChe692 - Process Modelling and Simulation: Week 6Fnur FatihahNessuna valutazione finora

- Week 6 Report g2Documento1 paginaWeek 6 Report g2Fnur FatihahNessuna valutazione finora

- Assignment - Cpe603 - March 2019Documento1 paginaAssignment - Cpe603 - March 2019Fnur FatihahNessuna valutazione finora

- Rotational of Rigid Body (8 Hours) : PhysicsDocumento114 pagineRotational of Rigid Body (8 Hours) : PhysicsFnur FatihahNessuna valutazione finora

- Week 6 - 1hfbDocumento43 pagineWeek 6 - 1hfbFnur FatihahNessuna valutazione finora

- Block Diagram: CPE501 Chemical Process ControlDocumento3 pagineBlock Diagram: CPE501 Chemical Process ControlFnur FatihahNessuna valutazione finora

- Assignment - Cpe603 - March 2019Documento1 paginaAssignment - Cpe603 - March 2019Fnur FatihahNessuna valutazione finora

- Date: . . .Documento1 paginaDate: . . .Madiha ZaimuriNessuna valutazione finora

- Factory and Machinery (Noise Exposure) RegulationsDocumento1 paginaFactory and Machinery (Noise Exposure) RegulationsFnur FatihahNessuna valutazione finora

- Essay Ethics 1Documento24 pagineEssay Ethics 1Fnur FatihahNessuna valutazione finora

- Lab 2 HysysDocumento3 pagineLab 2 HysysFnur FatihahNessuna valutazione finora

- Assignment Ethics 1Documento13 pagineAssignment Ethics 1Fnur Fatihah0% (1)

- Assignment Ethics 1Documento13 pagineAssignment Ethics 1Fnur Fatihah0% (1)

- Wa0016Documento2 pagineWa0016Fnur FatihahNessuna valutazione finora

- HW 03Documento7 pagineHW 03syaquiellaNessuna valutazione finora

- LECTURE 2 W2 Stress - NRR PDFDocumento33 pagineLECTURE 2 W2 Stress - NRR PDFFnur FatihahNessuna valutazione finora

- Industrial Visit FKK UitmDocumento1 paginaIndustrial Visit FKK UitmFnur FatihahNessuna valutazione finora

- Essay Ethics 1Documento24 pagineEssay Ethics 1Fnur FatihahNessuna valutazione finora

- Thermo2 Asgmt 1 GraphDocumento2 pagineThermo2 Asgmt 1 GraphFnur FatihahNessuna valutazione finora

- Lab 6 IntroductionDocumento1 paginaLab 6 IntroductionFnur FatihahNessuna valutazione finora

- Lab6-Tubular Flow ReactorDocumento11 pagineLab6-Tubular Flow ReactorNurtasha Atikah100% (1)

- Block Diagram: CPE501 Chemical Process ControlDocumento3 pagineBlock Diagram: CPE501 Chemical Process ControlFnur FatihahNessuna valutazione finora

- OBJECTIVES - To Determine The Order of Saponification ReactionDocumento2 pagineOBJECTIVES - To Determine The Order of Saponification ReactionFnur FatihahNessuna valutazione finora

- Navien ManualDocumento28 pagineNavien Manualmarathon8caNessuna valutazione finora

- Ficha Técnica LG Giant 11 Kgs - Lavadora y Secadoras-1Documento1 paginaFicha Técnica LG Giant 11 Kgs - Lavadora y Secadoras-1Fernando GonzálezNessuna valutazione finora

- Decoupler RecommendationsDocumento1 paginaDecoupler RecommendationsWaleed FathiNessuna valutazione finora

- Green BuildingsDocumento8 pagineGreen BuildingsMerugu RachanaNessuna valutazione finora

- Building Regulations Pocket Book 2nd EditionDocumento687 pagineBuilding Regulations Pocket Book 2nd Editionthegoonerherd100% (2)

- Compressor - EM2U60HLP (LBP) - DatasheetDocumento4 pagineCompressor - EM2U60HLP (LBP) - DatasheetSamuel OsmagNessuna valutazione finora

- Atlas Copco Face Drilling Rigs: Technical Specification Rocket Boomer L2 CDocumento4 pagineAtlas Copco Face Drilling Rigs: Technical Specification Rocket Boomer L2 CLeonelcito ParedesNessuna valutazione finora

- Presentation On: "Boiler & Auxiliary "Documento47 paginePresentation On: "Boiler & Auxiliary "shivabhaNessuna valutazione finora

- Behr Labor Technik Kjeldahl N Stand enDocumento32 pagineBehr Labor Technik Kjeldahl N Stand enRodrigo Morales VeraNessuna valutazione finora

- Chiller ChecklistDocumento2 pagineChiller Checklistmk saravanan100% (1)

- Steam GeneratorDocumento8 pagineSteam GeneratorRaju SubediNessuna valutazione finora

- NEC RIH-6867 User ManualDocumento25 pagineNEC RIH-6867 User ManualGAPATMNessuna valutazione finora

- The Effect of Artificial Roughness On Performance of Solar Air Heater (SAH) : A Review StudyDocumento19 pagineThe Effect of Artificial Roughness On Performance of Solar Air Heater (SAH) : A Review Studygaith.tw1997Nessuna valutazione finora

- Ceiling Fans As Ventilation Assisting Devices in Buildings A Critical ReviewDocumento17 pagineCeiling Fans As Ventilation Assisting Devices in Buildings A Critical ReviewFakhrizal AkbarNessuna valutazione finora

- Economizer BoilerDocumento38 pagineEconomizer BoilerKvvPrasad0% (1)

- Load Densities For HVAC Calculations (Shubaily)Documento2 pagineLoad Densities For HVAC Calculations (Shubaily)fghabboonNessuna valutazione finora

- TeamTec Incinerator BrochureDocumento9 pagineTeamTec Incinerator BrochureRuslanNessuna valutazione finora

- SANYO MCO 18AIC Incubator ManualDocumento47 pagineSANYO MCO 18AIC Incubator ManualMike LiuNessuna valutazione finora

- Vapour Cycle System PDFDocumento120 pagineVapour Cycle System PDFAishah HanisNessuna valutazione finora

- Keeprite Furnace InstallationDocumento49 pagineKeeprite Furnace InstallationDanny WoodsNessuna valutazione finora

- Passive Design: - Yash Jhawar B.Arch (XTH Sem) P.I.A.D.SDocumento25 paginePassive Design: - Yash Jhawar B.Arch (XTH Sem) P.I.A.D.SyjhawarNessuna valutazione finora

- Ebanks, Peta-Gaye PDFDocumento156 pagineEbanks, Peta-Gaye PDFDiomede PidrancoNessuna valutazione finora

- Mark RMB 15-25 IVR ENG 6999200470Documento6 pagineMark RMB 15-25 IVR ENG 6999200470RUDRA MORENessuna valutazione finora

- Qt-4456-Aster Pharmacy - Halwan - Sharjah - 22.11.2023Documento19 pagineQt-4456-Aster Pharmacy - Halwan - Sharjah - 22.11.2023ipmx16075Nessuna valutazione finora

- Lifeboat EnginesDocumento34 pagineLifeboat EnginesAryl Alfar100% (2)

- Perform Basic BenchworkDocumento45 paginePerform Basic BenchworkrayNessuna valutazione finora

- 102 Cost Concepts and Design Econ 1 PDFDocumento34 pagine102 Cost Concepts and Design Econ 1 PDFcriscab12345Nessuna valutazione finora

- Terminologia OBD2Documento13 pagineTerminologia OBD2Matías LeónNessuna valutazione finora

- Energy ConsumptionDocumento4 pagineEnergy ConsumptionGil DulayNessuna valutazione finora

- Computer Controlled Heat Exchanger Service Module - Ht30XcDocumento12 pagineComputer Controlled Heat Exchanger Service Module - Ht30XcEmonbeifo EfosasereNessuna valutazione finora

- The End of Craving: Recovering the Lost Wisdom of Eating WellDa EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellValutazione: 4.5 su 5 stelle4.5/5 (80)

- Sully: The Untold Story Behind the Miracle on the HudsonDa EverandSully: The Untold Story Behind the Miracle on the HudsonValutazione: 4 su 5 stelle4/5 (103)

- Highest Duty: My Search for What Really MattersDa EverandHighest Duty: My Search for What Really MattersNessuna valutazione finora

- Hero Found: The Greatest POW Escape of the Vietnam WarDa EverandHero Found: The Greatest POW Escape of the Vietnam WarValutazione: 4 su 5 stelle4/5 (19)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDa EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNessuna valutazione finora

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDa EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNessuna valutazione finora

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyDa EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNessuna valutazione finora

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDa EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestValutazione: 4 su 5 stelle4/5 (28)

- The Fabric of Civilization: How Textiles Made the WorldDa EverandThe Fabric of Civilization: How Textiles Made the WorldValutazione: 4.5 su 5 stelle4.5/5 (57)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (242)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterDa EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterValutazione: 5 su 5 stelle5/5 (3)

- The Weather Machine: A Journey Inside the ForecastDa EverandThe Weather Machine: A Journey Inside the ForecastValutazione: 3.5 su 5 stelle3.5/5 (31)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDa EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationValutazione: 4.5 su 5 stelle4.5/5 (46)

- System Error: Where Big Tech Went Wrong and How We Can RebootDa EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNessuna valutazione finora

- Mini Farming: Self-Sufficiency on 1/4 AcreDa EverandMini Farming: Self-Sufficiency on 1/4 AcreValutazione: 4 su 5 stelle4/5 (76)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNessuna valutazione finora

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDa EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerValutazione: 4.5 su 5 stelle4.5/5 (54)

- Pale Blue Dot: A Vision of the Human Future in SpaceDa EverandPale Blue Dot: A Vision of the Human Future in SpaceValutazione: 4.5 su 5 stelle4.5/5 (588)

- The Future of Geography: How the Competition in Space Will Change Our WorldDa EverandThe Future of Geography: How the Competition in Space Will Change Our WorldValutazione: 4.5 su 5 stelle4.5/5 (5)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- Packing for Mars: The Curious Science of Life in the VoidDa EverandPacking for Mars: The Curious Science of Life in the VoidValutazione: 4 su 5 stelle4/5 (1395)

- Reality+: Virtual Worlds and the Problems of PhilosophyDa EverandReality+: Virtual Worlds and the Problems of PhilosophyValutazione: 4 su 5 stelle4/5 (24)

- How to Do Nothing: Resisting the Attention EconomyDa EverandHow to Do Nothing: Resisting the Attention EconomyValutazione: 4 su 5 stelle4/5 (421)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Da Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Valutazione: 4 su 5 stelle4/5 (21)