Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bourdon Tube Pressure Gauge, Copper Alloy

Caricato da

Romdhoni Widyo BaskoroCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bourdon Tube Pressure Gauge, Copper Alloy

Caricato da

Romdhoni Widyo BaskoroCopyright:

Formati disponibili

Mechanical

pressure measurement

Bourdon tube pressure gauge, copper alloy

Standard version

Models 111.10, 111.12

WIKA data sheet PM 01.01

for further approvals

see page 3

Applications

■■ For gaseous and liquid media that are not highly viscous

or crystallising and will not attack copper alloy parts

■■ Pneumatics

■■ Heating and air-conditioning technology

■■ Medical engineering

Special features

■■ Reliable and cost-effective

■■ Design per EN 837-1

■■ Nominal size 40, 50, 63, 80, 100 and 160

■■ Scale ranges up to 0 ... 400 bar

Fig. left: Model 111.12, back mount

Fig. right: Model 111.10, lower mount (radial)

Description

The model 111 pressure gauges are based on the proven For mounting in control panels, the pressure gauges can,

Bourdon tube measuring system. On pressurisation, the depending on the process connection, be fitted with a

deflection of the Bourdon tube, proportional to the incident surface mounting flange or with a triangular bezel and

pressure, is transmitted to the movement via a link and mounting bracket.

indicated.

The standard version of the model 111 is manufactured,

The modular design enables a multitude of combinations cost-optimised on modern production lines, in volumes of

of case materials, process connections, nominal sizes and several million instruments per year.

scale ranges. Due to this high variance, the instrument

is suitable for use in a wide range of applications within

industry.

WIKA data sheet PM 01.01 ∙ 06/2017 Page 1 of 5

Data sheets showing similar products:

Panel mounting series; models 111.16, 111.26; see data sheet PM 01.10

With VdS approval; model 111.12.040; see data sheet SP 01.23

Specifications Options

Design ■■ Other process connection

EN 837-1 ■■ Accuracy class 1.6

■■ Steel case, black

Nominal size in mm ■■ Model 111.10: Surface mounting flange

40, 50, 63, 80, 100 (not with NS 40 and 50)

160 only with model 111.10 ■■ Model 111.12: Triangular bezel with mounting bracket

Accuracy class

2.5

Special versions

Scale ranges

0 ... 0.6 to 0 ... 400 bar (NS 160: max. 40 bar) For closed heating systems

or all other equivalent vacuum or combined pressure and NS 63, 80

vacuum ranges with red mark pointer and adjustable green sector, scale

ranges 0 ... 4 bar, red mark at 2.5 or 3 bar

Pressure limitation

Steady: 3/4 x full scale value For refrigeration plants

Fluctuating: 2/3 x full scale value NS 63, 80

Short time: Full scale value with additional temperature scale in °C for refrigerants

Permissible temperature

For water-level indication (hydrometer) and heating

Ambient: -20 ... +60 °C

systems

Medium: +60 °C maximum

NS 80, 100, 160

Scale ranges 0 ... 0.6 to 0 ... 25 bar, with second scale in

Temperature effect

mWS and red mark pointer

When the temperature of the measuring system deviates

from the reference temperature (+20 °C): max. ±0.4 %/10 K

For drinking water installations

of the span

Material suitability of the wetted parts in accordance

with the evaluation criteria for metallic substances of the

Process connection

German federal environmental agency and the “4MS

Copper alloy

Common Composition List”.

For process connections and spanner widths see page 4

Pressure element

Copper alloy

C-type or helical type

Movement

Copper alloy

Dial

NS 40, 50, 63: Plastic, white, with pointer stop pin

NS 80, 100, 160: Aluminium, white, with pointer stop pin

Black lettering, red mark pointer with measuring ranges

0 ... 0.6 to 0 ... 60 bar

Pointer

Plastic, black

NS 160: Aluminium, black

Case

Plastic, black

Model 111.12, NS 100: Steel, black

Model 111.10, NS 160: Steel, black

Window

Plastic, crystal-clear, snap-fitted in case

Model 111.10, NS 160: Instrument glass

Page 2 of 5 WIKA data sheet PM 01.01 ∙ 06/2017

Approvals

Logo Description Country

EU declaration of conformity European Union

Pressure equipment directive

EAC (option) Eurasian Economic Community

Pressure equipment directive

GOST (option) Russia

Metrology, measurement technology

KazInMetr (option) Kazakhstan

Metrology, measurement technology

- MTSCHS (option) Kazakhstan

Permission for commissioning

BelGIM (option) Belarus

Metrology, measurement technology

UkrSEPRO (option) Ukraine

Metrology, measurement technology

- CPA China

Metrology, measurement technology

- CRN Canada

Safety (e.g. electr. safety, overpressure, ...)

Certificates (option)

■■ 2.2 test report per EN 10204 (e.g. state-of-the-art

manufacturing, material proof, indication accuracy)

■■ 3.1 inspection certificate per EN 10204 (e.g. indication

accuracy)

WIKA data sheet PM 01.01 ∙ 06/2017 Page 3 of 5

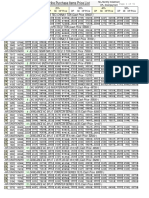

Dimensions in mm

Model 111.10, lower mount (radial)

NS 40, 50, 63 and 160 NS 80 and 100

31132006_2.01

31132006_1.01

NS Dimensions in mm Weight in kg

a b ±0.5 D G h ±1 SW

40 9.5 26 39 G⅛B 36 14 0.08

50 10 27.5 49 G¼B 45 14 0.10

63 9.5 27.5 62 G¼B 53.5 14 0.13

80 11.5 30 79 G½B 72 22 0.18

100 11.5 30.5 99 G½B 83.5 22 0.21

160 15.5 42 160 G½B 115.5 22 0.85

Process connection per EN 837-1 / 7.3

Model 111.12, back mount

NS 40, 50, 63, 80 and 100

31132014.01

NS Dimensions in mm Weight in kg

b1 ±0.5 b2 ±1 D G SW

40 26 42 39 G⅛B 14 0.06

50 29.5 47.5 49 G¼B 14 0.07

63 29 47 62 G¼B 14 0.08

80 32 49 79 G¼B 14 0.11

100 31 49 99 G¼B 14 0.26

Process connection per EN 837-1 / 7.3

Page 4 of 5 WIKA data sheet PM 01.01 ∙ 06/2017

Ordering information

Model / Nominal size / Scale range / Process connection / Options

© 2005 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

WIKA data sheet PM 01.01 ∙ 06/2017 Page 5 of 5

06/2017 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

Potrebbero piacerti anche

- Bourdon Tube Pressure Gauge, Stainless Steel Compact Version, NS 40, 50 and 63 Model 131.11Documento4 pagineBourdon Tube Pressure Gauge, Stainless Steel Compact Version, NS 40, 50 and 63 Model 131.11Parth BhattNessuna valutazione finora

- WIKA Pressure Gauges-DS PM0101 en Co 3997Documento11 pagineWIKA Pressure Gauges-DS PM0101 en Co 3997farhanbaig125319Nessuna valutazione finora

- Capsule Pressure Gauge, Copper Alloy Stainless Steel Case Model 612.20, NS 63, 100 and 160Documento4 pagineCapsule Pressure Gauge, Copper Alloy Stainless Steel Case Model 612.20, NS 63, 100 and 160Akshay SetlurNessuna valutazione finora

- Bourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version, NS 63, 100 and 160 Models 232.30, 233.30Documento4 pagineBourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version, NS 63, 100 and 160 Models 232.30, 233.30Chau TranNessuna valutazione finora

- Capsule Pressure Gauge, Stainless Steel For The Process Industry Models 632.50, 633.50, NS 63, 100, 160Documento4 pagineCapsule Pressure Gauge, Stainless Steel For The Process Industry Models 632.50, 633.50, NS 63, 100, 160Yady SuárezNessuna valutazione finora

- Temp Gauge Ds Tm8101 en CoDocumento8 pagineTemp Gauge Ds Tm8101 en CorahmadhaniNessuna valutazione finora

- Bourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionDocumento3 pagineBourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionChau TranNessuna valutazione finora

- Capsule Pressure Gauge, Stainless Steel For The Process Industry Models 632.50, 633.50, NS 63, 100, 160Documento4 pagineCapsule Pressure Gauge, Stainless Steel For The Process Industry Models 632.50, 633.50, NS 63, 100, 160Joni HartonoNessuna valutazione finora

- Bourdon Tube Pressure Gauge, Copper Alloy Model 113.13, Liquid Filling, Plastic CaseDocumento4 pagineBourdon Tube Pressure Gauge, Copper Alloy Model 113.13, Liquid Filling, Plastic CaseMostafa ShipishlyNessuna valutazione finora

- Manual de Operación Mfi011000200 - SDH-410-0501Documento6 pagineManual de Operación Mfi011000200 - SDH-410-0501Heiner PalaciosNessuna valutazione finora

- Bourdon Tube Pressure Gauge, Copper Alloy For Welding, Cutting and Allied Processes Models 111.11, 111.31Documento7 pagineBourdon Tube Pressure Gauge, Copper Alloy For Welding, Cutting and Allied Processes Models 111.11, 111.31Parth BhattNessuna valutazione finora

- Wika 213.53 Pressure Gauge Catalog PageDocumento4 pagineWika 213.53 Pressure Gauge Catalog PageM MNessuna valutazione finora

- KROHNE Optiflux 2000R11Documento8 pagineKROHNE Optiflux 2000R11janithNessuna valutazione finora

- High-Quality Pressure Transmitter For General Industrial Applications Model S-10Documento8 pagineHigh-Quality Pressure Transmitter For General Industrial Applications Model S-10gliga vasileNessuna valutazione finora

- Differential Pressure Gauge Stainless Steel Version, With Diaphragm Element Model 732.51, All Welded ConstructionDocumento4 pagineDifferential Pressure Gauge Stainless Steel Version, With Diaphragm Element Model 732.51, All Welded ConstructionPaulkumar RamaiahNessuna valutazione finora

- WikaDocumento10 pagineWikasolensa mantenimientoNessuna valutazione finora

- DS PV2101 GB 8017Documento2 pagineDS PV2101 GB 8017josip miskovicNessuna valutazione finora

- DB GB DS21Documento4 pagineDB GB DS21cadhoaNessuna valutazione finora

- Differential Pressure Gauge Model 712.15.160, Copper Alloy Model 732.15.160, Stainless Steel VersionDocumento11 pagineDifferential Pressure Gauge Model 712.15.160, Copper Alloy Model 732.15.160, Stainless Steel VersionNayan DudhatraNessuna valutazione finora

- Wika Pressure Gauge 6 InchDocumento3 pagineWika Pressure Gauge 6 InchsanNessuna valutazione finora

- BMD Plug Gauges Technical GuideDocumento52 pagineBMD Plug Gauges Technical Guidekunalkp88Nessuna valutazione finora

- 7ME65202YJ122AA2-ZDocumento2 pagine7ME65202YJ122AA2-ZElvis AlvarezNessuna valutazione finora

- Level measurement indicator with magnetic displayDocumento24 pagineLevel measurement indicator with magnetic displaymatteo2009Nessuna valutazione finora

- Pressure Sensors: Am Bärenwald 6 87600 Kaufbeuren +49 8341 9505-0Documento20 paginePressure Sensors: Am Bärenwald 6 87600 Kaufbeuren +49 8341 9505-0Guillaume DAVIDNessuna valutazione finora

- DATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsDocumento12 pagineDATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsMirwan MukminNessuna valutazione finora

- Asphalt Pavement Thermal Testing System (TSRST) : StandardDocumento3 pagineAsphalt Pavement Thermal Testing System (TSRST) : StandardSPRANessuna valutazione finora

- Ds pm0215 en CoDocumento7 pagineDs pm0215 en CoMsach RoysNessuna valutazione finora

- Cold Drawn Seamless Steel Tubes For Hydraulic CylindersDocumento8 pagineCold Drawn Seamless Steel Tubes For Hydraulic Cylindersvijayasarathy2013Nessuna valutazione finora

- Variable Area Flow Meter Data Sheet mt3750 enDocumento16 pagineVariable Area Flow Meter Data Sheet mt3750 enaiabbasi9615Nessuna valutazione finora

- P3251 TecsisDocumento4 pagineP3251 TecsisJHONNJANNessuna valutazione finora

- Bourdon Tube Pressure Gauges Model 213.53, Liquid Filling, Stainless Steel CaseDocumento2 pagineBourdon Tube Pressure Gauges Model 213.53, Liquid Filling, Stainless Steel CaseAhrian BenaNessuna valutazione finora

- 43X X6Documento4 pagine43X X6reliableplacementNessuna valutazione finora

- Barton DP GaugeDocumento2 pagineBarton DP GaugeDeji AdesiyanNessuna valutazione finora

- Tradutor Diferencial PD-9 DRUCKDocumento2 pagineTradutor Diferencial PD-9 DRUCKjcbizarretaNessuna valutazione finora

- WIKA - Data Sheet For SnubberDocumento2 pagineWIKA - Data Sheet For Snubberyasser hamzaNessuna valutazione finora

- Endress-Hauser Proline Promag W 300 5W3B enDocumento5 pagineEndress-Hauser Proline Promag W 300 5W3B ennamNessuna valutazione finora

- Optiflux 4000: Electromagnetic Flow SensorDocumento8 pagineOptiflux 4000: Electromagnetic Flow SensoryashNessuna valutazione finora

- Baumer MZ7 EN DSDocumento3 pagineBaumer MZ7 EN DSPablo Gerardo Gil CocaNessuna valutazione finora

- Data Sheet of WikiDocumento2 pagineData Sheet of Wikibcec startNessuna valutazione finora

- RAMC GS01R01B02-00E-E Ed28 Pub22032019Documento24 pagineRAMC GS01R01B02-00E-E Ed28 Pub22032019zaffarNessuna valutazione finora

- Adjustable dead band pressure switch for railways and industriesDocumento1 paginaAdjustable dead band pressure switch for railways and industriesPriyanathan ThayalanNessuna valutazione finora

- Differential Pressure Gauge Model 732.51, Stainless Steel Version, With Diaphragm Element All Welded ConstructionDocumento4 pagineDifferential Pressure Gauge Model 732.51, Stainless Steel Version, With Diaphragm Element All Welded ConstructionClarence AG YueNessuna valutazione finora

- Transmitter SML 10Documento2 pagineTransmitter SML 10alamsyah_syamNessuna valutazione finora

- 1109 Process Pressure Gauge: Data SheetDocumento2 pagine1109 Process Pressure Gauge: Data SheetchienncNessuna valutazione finora

- Product Data Sheet Rosemount Seniorsonic 3414 en 8727396Documento32 pagineProduct Data Sheet Rosemount Seniorsonic 3414 en 8727396Zaki nouiNessuna valutazione finora

- Liquid Turbine Flow Meter Dalian Zero Instrument Technology Co., LTD ChinaDocumento27 pagineLiquid Turbine Flow Meter Dalian Zero Instrument Technology Co., LTD ChinaMichael SunNessuna valutazione finora

- BDT17-08 Clasa 0.25 PDFDocumento2 pagineBDT17-08 Clasa 0.25 PDFvan_dall_2Nessuna valutazione finora

- Ds Uhp Wuc 1x en Us 20710Documento10 pagineDs Uhp Wuc 1x en Us 20710behnamatgNessuna valutazione finora

- Tecsis P3276Documento4 pagineTecsis P3276benNessuna valutazione finora

- Bourdon Tube Pressure Gauges: Solid-Front Turret Style Test Gauge Accuracy + 0.25% of SpanDocumento2 pagineBourdon Tube Pressure Gauges: Solid-Front Turret Style Test Gauge Accuracy + 0.25% of Spanhugo171630Nessuna valutazione finora

- Bimetal Thermometer Model 54, Industrial Series: ApplicationsDocumento7 pagineBimetal Thermometer Model 54, Industrial Series: ApplicationschauNessuna valutazione finora

- General Specifications: Model RAMC Metal Short-Stroke RotameterDocumento20 pagineGeneral Specifications: Model RAMC Metal Short-Stroke RotameterKishore KumarNessuna valutazione finora

- OEM Pressure Transmitter Standard: ApplicationsDocumento3 pagineOEM Pressure Transmitter Standard: ApplicationsTín NhưNessuna valutazione finora

- TECHNIO COMMERCIAL PROPOSAL FOR WELL TEST Trailer PACKAGE R2-AWK Option1 DASDocumento2 pagineTECHNIO COMMERCIAL PROPOSAL FOR WELL TEST Trailer PACKAGE R2-AWK Option1 DASslbclqrkNessuna valutazione finora

- 134 189Documento56 pagine134 189api-208855872Nessuna valutazione finora

- Bourdon Tube Pressure Gauge Stainless Steel Version Models 232.50, 233.50Documento3 pagineBourdon Tube Pressure Gauge Stainless Steel Version Models 232.50, 233.50Karla DelgadoNessuna valutazione finora

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingDa EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNessuna valutazione finora

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesDa EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesValutazione: 4 su 5 stelle4/5 (1)

- Comprehensive Guide to Check Valves, Swing Check Valves, Ball Check Valves and Wafer Check ValvesDocumento12 pagineComprehensive Guide to Check Valves, Swing Check Valves, Ball Check Valves and Wafer Check ValvesdedyNessuna valutazione finora

- Heater Flow DiagramDocumento1 paginaHeater Flow DiagramRomdhoni Widyo BaskoroNessuna valutazione finora

- Essential Guide Shenzhen WebDocumento124 pagineEssential Guide Shenzhen Webjoe9000Nessuna valutazione finora

- Accommodation On Offshore Oil Gas InstallationsDocumento18 pagineAccommodation On Offshore Oil Gas InstallationsRomdhoni Widyo BaskoroNessuna valutazione finora

- Jetty Pipe-Isometric DrawingDocumento16 pagineJetty Pipe-Isometric DrawingRomdhoni Widyo BaskoroNessuna valutazione finora

- EXTWP ARC Digital Twins Process Industries LTR EN LR PDFDocumento21 pagineEXTWP ARC Digital Twins Process Industries LTR EN LR PDFRomdhoni Widyo BaskoroNessuna valutazione finora

- Building Code Requirements For Structural Concrete (ACI 318M-11)Documento53 pagineBuilding Code Requirements For Structural Concrete (ACI 318M-11)MohamedNessuna valutazione finora

- 20 in Iso ContainerDocumento4 pagine20 in Iso ContainerRomdhoni Widyo BaskoroNessuna valutazione finora

- Aci 209.2R-08Documento48 pagineAci 209.2R-08Thanh Vo Phi100% (3)

- New Linde LNG Fuel Station TechnologyDocumento17 pagineNew Linde LNG Fuel Station TechnologyRomdhoni Widyo BaskoroNessuna valutazione finora

- FlameGard 5 MSIR Flame DetectorDocumento4 pagineFlameGard 5 MSIR Flame DetectorRomdhoni Widyo BaskoroNessuna valutazione finora

- FlexSonic AcousticDocumento2 pagineFlexSonic AcousticRomdhoni Widyo BaskoroNessuna valutazione finora

- LS2000 Infrared Hydrocarbon Gas DetectorDocumento2 pagineLS2000 Infrared Hydrocarbon Gas DetectorRomdhoni Widyo BaskoroNessuna valutazione finora

- Traveloka TicketDocumento2 pagineTraveloka TicketRomdhoni Widyo BaskoroNessuna valutazione finora

- Gas BrochureDocumento8 pagineGas BrochureRomdhoni Widyo BaskoroNessuna valutazione finora

- Optical Flame Detection Solutions: The Most Versatile Flame Detectors in The WorldDocumento8 pagineOptical Flame Detection Solutions: The Most Versatile Flame Detectors in The WorldRomdhoni Widyo BaskoroNessuna valutazione finora

- Tds - Wika Pressure GaugeDocumento4 pagineTds - Wika Pressure GaugeSenthil Kumar100% (1)

- PrimaX Gas Transmitter PDFDocumento6 paginePrimaX Gas Transmitter PDFRomdhoni Widyo BaskoroNessuna valutazione finora

- FL4000H Multi-Spectrum Infrared Flame DetectorDocumento2 pagineFL4000H Multi-Spectrum Infrared Flame DetectorRomdhoni Widyo BaskoroNessuna valutazione finora

- Toxgard II Gas MonitorDocumento4 pagineToxgard II Gas MonitorRomdhoni Widyo BaskoroNessuna valutazione finora

- FL3100H and FL3101H UV IR and UV Unitized Flame DetectorsDocumento2 pagineFL3100H and FL3101H UV IR and UV Unitized Flame DetectorsRomdhoni Widyo BaskoroNessuna valutazione finora

- SCH 7 - I-004 PROGRAMMABLE CONTROLLERDocumento12 pagineSCH 7 - I-004 PROGRAMMABLE CONTROLLERRomdhoni Widyo BaskoroNessuna valutazione finora

- S4000CH Data SheetDocumento2 pagineS4000CH Data Sheetgustavohdez2Nessuna valutazione finora

- Money Creation in The Modern Economy Bank EnglandDocumento14 pagineMoney Creation in The Modern Economy Bank Englandbreakingthesilence100% (1)

- Tds - Wika Pressure GaugeDocumento4 pagineTds - Wika Pressure GaugeSenthil Kumar100% (1)

- The Archipelago Economy Unleashing Indonesia's PotentialDocumento3 pagineThe Archipelago Economy Unleashing Indonesia's PotentialRomdhoni Widyo BaskoroNessuna valutazione finora

- Compressor Data Page 1-3Documento3 pagineCompressor Data Page 1-3Romdhoni Widyo BaskoroNessuna valutazione finora

- Lesson 2 Non-Metals and Moles G11Documento61 pagineLesson 2 Non-Metals and Moles G11Jodell CampbellNessuna valutazione finora

- Discharge PrintingDocumento16 pagineDischarge Printingsakshi_mehra123Nessuna valutazione finora

- PipefitterDocumento4 paginePipefitterapi-78684586Nessuna valutazione finora

- Hot Water SupplyDocumento56 pagineHot Water SupplyVismithaNessuna valutazione finora

- Ellingham Diagram UsesDocumento4 pagineEllingham Diagram Usesnanda rizkyNessuna valutazione finora

- Pneumatic StructuresDocumento9 paginePneumatic StructuresMaitreyi YellapragadaNessuna valutazione finora

- Pole Base Foundation Pole Base SpecificationsDocumento10 paginePole Base Foundation Pole Base SpecificationsMuhammad IrfanNessuna valutazione finora

- Salscent (SST) : A Self-Encapsulation Fragrance TechnologyDocumento2 pagineSalscent (SST) : A Self-Encapsulation Fragrance TechnologyRaisha RamadantiNessuna valutazione finora

- Chapter 1-3Documento25 pagineChapter 1-3Janley AresNessuna valutazione finora

- Annexure-A Technical Specifications For Heat Shrinkable Cable Terminations and Joints For 6.6kV, XLPE CablesDocumento4 pagineAnnexure-A Technical Specifications For Heat Shrinkable Cable Terminations and Joints For 6.6kV, XLPE CablesHossam AlzubairyNessuna valutazione finora

- Prevent Water Penetration Brick WallsDocumento4 paginePrevent Water Penetration Brick WallscarmeloNessuna valutazione finora

- Everyday Materials QuizDocumento1 paginaEveryday Materials Quizh4fzzNessuna valutazione finora

- Heavy-Duty Lubricant: FeaturesDocumento2 pagineHeavy-Duty Lubricant: Featuresarjun vsNessuna valutazione finora

- University of Cambridge International Examinations International General Certificate of Secondary EducationDocumento16 pagineUniversity of Cambridge International Examinations International General Certificate of Secondary EducationKim Yen GohNessuna valutazione finora

- Lithium RecoveryDocumento16 pagineLithium RecoverynikitaambeNessuna valutazione finora

- Caterpillar Connecting Rod Bearings Service TrainingDocumento5 pagineCaterpillar Connecting Rod Bearings Service Trainingaudrey100% (40)

- ETAG and ACI DesignDocumento38 pagineETAG and ACI DesigncoolkaisyNessuna valutazione finora

- Piers PDFDocumento3 paginePiers PDFmahmoud elkhedrNessuna valutazione finora

- Rubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method ForDocumento9 pagineRubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method Forسعید اینانلوNessuna valutazione finora

- Corning Gorilla GlassDocumento2 pagineCorning Gorilla GlassCAT MINING SHOVELNessuna valutazione finora

- TAYTAY BID FORM - OdsDocumento42 pagineTAYTAY BID FORM - OdsDavid Raphael CaÑaresNessuna valutazione finora

- HPDocumento51 pagineHPKhan Basit KhanNessuna valutazione finora

- Catalog - Norton Abrasive Product Solutions For The Full Line Stock Industrial Market - 7362 - 2017 BA IndustrialDocumento37 pagineCatalog - Norton Abrasive Product Solutions For The Full Line Stock Industrial Market - 7362 - 2017 BA IndustrialCătălin BăicoianuNessuna valutazione finora

- NADCA Standards 2015Documento272 pagineNADCA Standards 2015mr.nguyenkNessuna valutazione finora

- Disola W MultigradoDocumento1 paginaDisola W MultigradoNibaldo KamelNessuna valutazione finora

- QC Check ListDocumento1 paginaQC Check ListshwayeNessuna valutazione finora

- Testing Facilities: Plain & Reinforced Concrete Laboratory Department of Civil Engineering UET, LHRDocumento1 paginaTesting Facilities: Plain & Reinforced Concrete Laboratory Department of Civil Engineering UET, LHRRana Talal RaziNessuna valutazione finora

- Precoat Supa 30: Bituminous Products Pty LTDDocumento8 paginePrecoat Supa 30: Bituminous Products Pty LTDmacdonaldNessuna valutazione finora

- Yunhong Cheng-2016 PDFDocumento7 pagineYunhong Cheng-2016 PDFJoão AzevedoNessuna valutazione finora

- Building Materials Module 1 PPT NotesDocumento20 pagineBuilding Materials Module 1 PPT NotesmanojNessuna valutazione finora