Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) Remarks

Caricato da

BALAJITitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) Remarks

Caricato da

BALAJICopyright:

Formati disponibili

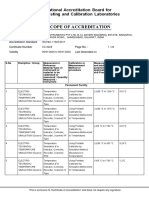

Laboratory Perfect Calibration Centre Pvt. Ltd., No.

84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

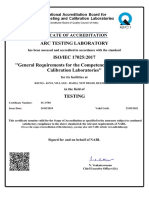

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 1 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

ELECTRO-TECHNICAL CALIBRATION

I. SOURCE

1. Temperature

Simulation$

(Temperature Indicator /

Controller / Recorder/

Scanner)

RTD Type (-) 200°C to 800°C 0.56°C Using Process Calibrator

‘J’ Type Thermocouple (-) 200°C to 1200°C 0.8°C By Direct Method

‘K’ Type Thermocouple (-) 200°C to 1350°C 0.81°C

100°C to 1750°C 1.14°C

‘R’ Type Thermocouple 100°C to 200°C 1.1°C

200°C to 1750°C 0.82°C

‘S’ Type Thermocouple 600°C to 1820°C 0.94°C

B’ Type Thermocouple (-)200°C to 400°C 0.59°C

T’ Type Thermocouple (-) 200°C to 0°C 0.43°C

0°C to 1300°C 0.37°C

‘N’ Type Thermocouple (-) 200°C to 1000°C 0.29°C

‘E’ Type Thermocouple

2. Time Interval (Measure) 1 sec to 1 min 0.08 to 0.13 sec Using Digital Timer

1 min to 24 hr 0.13 to 22 sec by Comparison Method

3. Temperature

Simulation♣

(Temperature Indicator /

Controller / Recorder/

Scanner )

RTD’ Type -200°C to 800°C 0.82°C Using Multifunction

‘J’ Type Thermocouple -200°C to 1200°C 1.45°C Calibrator by Direct

‘K’ Type Thermocouple -200°C to 1350°C 0.96°C Method

‘R’ Type Thermocouple 0°C to 1750° 2.81°C

‘S’ Type Thermocouple 0°C to 1750°C 2.32°C

Vishal Shukla Avijit Das

Convenor Program Director

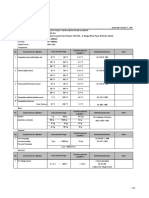

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 2 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

‘B’ Type Thermocouple 600°C to 1820°C 2.88°C

‘T’ Type Thermocouple -200°C to 400°C 0.69°C

‘N’ Type Thermocouple -200°C to 1300°C 0.52°C

‘E’ Type Thermocouple -200°C to 1000°C 0.40°C

4. Time Interval (Measure) 1 sec to 1 min 0.2 to 0.23 sec Using Digital Timer

1 min to 24 hr 0.23 to 22 sec by Comparison Method

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 3 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

FLUID FLOW CALIBRATION

1. Air Flow 0.4 to 20 m/s 7.2%rdg Using Anemometer,

(Anemometer Vane Variable Speed Blower for

Type) Air Supply by Comparison

Method

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 4 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

MECHANICAL CALIBRATION

I. DIMENSION (BASIC MEASURING INSTRUMENT, GAUGE ETC.)

1. Calipers$

(Vernier/Dial/Digital)

L.C:0.01mm 0 to 450mm 18.2 µm Using Slip gauge Set

450 mm to 600mm 18.5 µm Grade ‘0’, Caliper

600 mm to 1000mm 19.5 µm Checker, Length bar &

1000 mm to 1500mm 21.3 µm Slip gauge Accessories.

Comparison Method

L.C:0.02mm 0 to 2000mm 20.2 µm IS :3651(Part 1 & 2)

2. External Micrometer/

Ball Micrometer/

Blade Micrometer/

Disc

Micrometer/Flange

Micrometer/Groove

Micrometer/

Spline Micrometer/

Sheet Metal

Micrometer/

Point

Micrometer/Pitch

Micrometer$

L.C.:0.001mm 0 to 25mm 2.0 µm Using Slip Gauge Set

25 mm to 150mm 5.8 µm Grade ‘0’, Optical Flat &

150 mm to 300mm 6.2 µm Parallels, length bar.

300 mm to 600mm 8.5 µm Comparison Method

600 mm to 1000mm 9.2 µm IS:2967

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 5 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

3. Depth Micrometer$

L.C:0.01mm 0 to 150mm 5.82 µm Using Slip Gauge Set

150 mm to 300 mm 8.2 µm Grade ‘0’, Caliper

Checker & Gauge Block

Accessories by

Comparison Method

BIS:6468

4. Internal Micrometer/

Stick Micrometer$

L.C:0.01mm 0 to 600mm 6.7 µm Using Slip Gauge Set

600 mm to 1000mm 8.5 µm Grade ‘0’, Gauge Block

1000 mm to 2000mm 20.0 µm Accessories Set & Length

bar by Comparison

Method as per IS:2966

5. Plunger Type Dial

Indicator$

L.C:0.001mm 0 to 25mm 2.1 µm Using Length Measuring

25 mm to 50mm 2.1 µm Machine by

Comparison Method as

L.C:0.0005mm ± 0.025mm 2.1 µm per IS:2092

6. Lever Type Dial

Indicators$

L.C:0.01mm 0 to 1.6 mm 5.8 µm Using Length Measuring

L.C:0.001mm 0 to 0.6 mm 2.1 µm Machine by Comparison

L.C:0.002mm 0 to 0.2 mm 2.1 µm Method as per IS:11498

7. Plain Plug Gauge/ Up to 100mm 2.1 µm Using Length Measuring

Width Gauge$ 100 mm to 200mm 2.8 µm Machine by

Comparison Method as

per IS:3455 & IS:7859

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 6 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

8. Snap 3 mm to 200mm 1.4 µm Using Slip gauge Set

Gauge/Adjustable 200 mm to 400mm 1.94 µm Grade ‘0’ by

Snap Gauge, Knife Comparison method as

Edge Gauge, Length per IS:3455, IS:7859 &

Gauge, Height IS:3477

Gauge, Master

Setting Gauge, Gap

Gauge, Distance

Gauge, Depth Gauge,

Bridge Gauge$

9. Dial Depth Gauge$

L.C:0.01mm 0 to 10mm 6.0 µm Using Slip gauge Set

0 to 100mm 6.0 µm Grade ‘0’ by

Comparison method

10. Feeler Gauge$ Upto 1.0mm 2.9 µm Using Digital Micrometer

by Comparison method

as per IS:3179

11. Bore Dial Gauge$

(Only Transmission

movement)

L.C:0.001mm Upto 3mm 2.1 µm Using Length Measuring

Machine by

Comparison Method

12. Dial Thickness

Gauge$ 0 to 50mm 5.9 µm Using Slip gauge Set

L.C:0.01mm Grade ‘0’ by

Comparison method as

perIS:2092

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 7 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

13. Height Gauge$

(Vernier/Digital/Dial)

L.C: 0.01mm 0 to 300mm 14.8 µm Using Caliper Checker by

0 to 1000mm 15.2 µm Comparison method

IS:2921

14 Pistol Caliper$

L.C:0.1mm 0 to 100mm 58.0 µm Using Slip gauge Set

Grade ‘0’ by

Comparison method

IS:2092

15. Depth Caliper $

(Vernier/Dial/Digital)

L.C:0.01mm 0 to 300 mm 9.1 µm Using Slip gauge Set

0 to 600 mm 11.1 µm Grade ‘0’, Gauge Block

Accessories & Caliper

Checker by

Comparison Method

IS:4213

16. Dial Caliper

Gauge/Groove Dial/

Inside Caliper

Gauge$ Using Slip gauge Set

L.C:0.01mm 10 mm to 150mm 5.8 µm Grade ‘0’, & Slip gauge

Accessories by

Comparison Method

17. Cylindrical Upto 25mm 2.1 µm Using Length Measuring

Measuring Pins$ Machine by

(Only Diameter) Comparison Method

IS:11103

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 8 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

18. Cylindrical Upto 100mm 2.1 µm Using Length Measuring

Measuring master$ Machine by

(Only Diameter) Comparison Method

IS:4349

19. Thread Measuring 0.17 mm to 6.35mm 2.1 µm Using Length Measuring

Wires Machine by

Comparison Method

IS:6311

20. Thread Plug gauge$ M2 to M100 3.6 µm Using Length Measuring

M100 to M200 3.6 µm Machine

M2 to M100 5.6 µm Using FCDM, Thread

M100 to M200 5.6 µm Measuring Wire &

Cylindrical Setting Master

by Comparison Method

as per IS 2334, IS 4218

(Part I to IV) ,IS 10216,

IS 8999, ANSI/ASME

B.20.1-1983

21. Taper Thread Ring M2 to M50 5.1 µm Using Length Measuring

Gauge$ M50 to M100 5.1 µm Machine by

Comparison Method

IS 2334, IS 4218 (Part I to

IV) , IS 10216, IS 8999 ,

ANSI/ASME B.20.1-1983

22. Thread Ring Gauge$ M3 to M100 3.6 µm Using Length Measuring

M100 to M 200 3.6 µm Machine & Master Setting

Ring by Comparison

Method as per

IS 4218,IS 2334 ,

ANSI/ASME B.20.1-1983

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 9 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

23. Taper Thread Plug M2 to M100 7.5 µm Using FCDM, Thread

Gauge$ Measuring Wire &

Cylindrical Setting Master

by Comparison Method as

per IS 8999, ANSI/ASME

B.20.1-1983

24. Plain Ring Gauge$ Up to 50mm 3.3 µm Using Length Measuring

50 mm to 100mm 3.3 µm Machine & Master Setting

100 mm to 200mm 3.3 µm Ring by Comparison

200 mm to 300mm 5.7 µm Method as per

IS: 3485

25. Flush Pin Gauge$ Up to 200 mm 2.8 µm Using Slip Gauge Set

Grade ‘0’ , Digital

Micrometer and Plunger

Dial gauge by

Comparison Method

26. Coating Thickness 0.01mm to 2mm 1.79 µm Using Standard Foils by

Gauge$ Comparison Method

27. Foils$ Up to 250 m 1.2 µm Using Length Measuring

0 to 5mm Machine by

Comparison Method

28. Setting Rod / Setting Up to 50mm 3.5 µm Using Slip Gauge Set

Piece$ 50 mm to 100mm 3.5 µm Grade ‘0’, Length bar &

100 mm to 200mm 3.5 µm Electronic comparator by

200 mm to 1000mm 4.7 µm Comparison Method

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 10 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

29. Dial Snap Gauge /

Dial Snap Meter$

L.C:0.001mm 0 to 100mm 0.8 µm Using Slip Gauge Set

(Parallelism of Grade ‘ 0’ by

Measuring faces) Comparison Method as

per IS 3455, IS 7859 &

IS 3477

30. V - Block$ Using Lever Dial gauge,

(Parallelism of (250x 200x180)mm Slip Gauge set Grade “0”,

seating faces, 4.2 µm Bevel Protractor by

Perpendicularity, 3.4 µm Comparison Method as

Angle, 14 min per IS 2949

Axis of the shaft) 1.4 µm

31. Ultrasonic

Thickness gauge$

L.C.: 0.1mm 0 to 100mm 70.2 µm Using slip gauges set

grade“0” by

Comparison Method

32. Comparator Stand$ 300 x 300mm 1.7 µm Using Dial gauge by

( Flatness Only) Comparison method as

per IS 6973

33. Straight edge$ Up to 1000mm 6.0 µm Using Electronic Level &

Dial Gauge by

Comparison Method as

per IS :2220

34. Tri Square$ Up to 500 x 500mm 4.4 µm Using Slip Gauge Set

(Squareness) Up to 500 x 500mm 4.0 µm Grade ‘ 0’, Master

(Parallelism) Square, Plunger dial,

Surface plate by

Comparison Method as

per IS :2103

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 11 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

35. LVDT Probe with

DRO$

L.C:0.1 µm 0 to 10mm 2.5 µm Using Slip Gauge Set

Grade ‘ 0’ by

Comparison Method

36. V- Anvil Micrometer$

L.C: 0.001mm 0 to 100mm 2.1 µm Using Cylindrical setting

master by Comparison

Method

37. Mandrel 100 mm dia 13.4 µm Using Bench centre with

(Run out only) 200 mm Length dial as per IS 2063,

ISO230-1

38. LVDT Probe with

DRO♣

L.C:0.001mm 0 to 25mm 2.5 m Using Slip gauge set

Grade’0’ by

Comparison Method

39. Surface plate♣ 6000 mm X 3000 mm 1.32

√L+W

m Using Electronic level as

150 per IS:7327,IS:2285,

IS:12937

40. Height Measuring

System♣

L.C:0.001 mm 0 to 600 mm 2.8 m Using Slip gauge Set

Grade ‘0’, Length bar by

Comparison Method

41. Microscope♣

Linear

L.C: 0.0001mm 0 to 300 mm 1.1 m Using Graticules scale by

Angle 0 to 360° 3’ Comparison Method

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 12 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

42. Bench Centre Centre height:300 mm 6.0 m Using Mandrel & Dial

Parallelity Admit between Indicator as per

Co- axiality of Centre:750mm IS:5980:2000

centre♣

43. Profile projector /

Video Measuring

Machine♣

Linear

L.C:0.001mm 0 to 300 mm 17.75 m Using Graticules scale ,

Angle L.C:36” 0 to 360 ° 2’ 16” ‘0’ Grade Slip gauge set

Magnification 5X to 100X 2.5% by Comparison Method

44. Gauge Block

Measuring Fixture

with Electronic

System♣

L.C:0.01 m 0 to 100mm 0.09 m Using Grade ‘K’ Pair

Gauge Block by

Comparison Method

45. Tape and Scale

Calibrator♣

L.C:0.001mm 0 to 1000 mm 18.7 m Using Slip Gauge Set

Grade ‘0’, Length Bar,

Lever Dial Gauge by

Comparison Method

II. ACCELERATION & SPEED

1. Tachometer / RPM$

Contact Type 150 rpm to 2500 rpm 0.82% Using RPM Indicator with

Non contact type 150 rpm to 50,000 rpm 0.87% Electric Motor by

Comparison Method

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 13 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

2. Indicator of

Centrifuge / RPM♣

Meter 60 to 25,000 rpm 0.06% of rdg Using Digital Tachometer

Comparison Method

III. ACCOUSTICS

1. Sound Level Meter$ 1kHz Using Sound Level

94 dB & 114 dB 0.8 dB Calibrator by Direct

Method as per

IS:9779:1981

IV. WEIGHTS

1. Mass$ 1 mg 0.013 mg Using E1 Class Standard

(Class F1 accuracy 2 mg 0.013 mg Weights and Electronic

& Coarser) 5 mg 0.013 mg Weighing Balance

10 mg 0.013 mg (Readability : 0.01mg)

20 mg 0.013 mg Substitution method of

weighing and ABBA

weighing cycle based on

OIML R111-1

50 mg 0.02 mg Using E1 Class Standard

100 mg 0.02 mg Weights and Electronic

200 mg 0.02 mg Weighing Balance

500 mg 0.02 mg (Readability: 0.01mg)

1g 0.03 mg Substitution method of

2g 0.04 mg weighing and ABBA

5g 0.04mg weighing cycle based on

10 g 0.05 mg OIML R111-1

20 g 0.06 mg

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 14 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Class F1/M1 50 g 0.09 mg Using E1& F1 Class

accuracy & Coarser 100 g 0.10 mg Standard Weights and

200 g 0.15 mg Electronic Weighing

500 g 0.013 g Balance

1 kg 0.08 g (Readability:

2 kg 0.09 g 0.1mg/10mg)

Substitution method of

weighing and ABBA

weighing cycle based on

OIML R111

5 kg

0.49 g Using F1 Class Standard

10 kg

0.49 g Weights and Electronic

20 kg

1.0 g Weighing Balance

(Readability : 500mg)

Substitution method of

weighing and ABBA

weighing cycle based on

OIML R 111

V. WEIGHING SCALE AND BALANCE

1. Weighing Balance

Calibration of

Electronic Weighing

Balance$

Class II and coarser

Readability : 0.01mg Up to 200 g 0.04 mg Using E1 Class standard

weights, as per OIML R

76-1

Readability : 10 mg Up to 4 kg 0.09 g Using E1 and F1 Class

Standard Weights

as per OIML R 76-1

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 15 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Readability : 500 mg Up to 30 kg 1.30 g Using F1 & M1 Class

Standard Weights as per

OIML R 76-1

2. Calibration of

Electronic Weighing

Balance♣

Class I and coarser

Readability : 0.001 Up to 6.1 g 0.01 mg Using E1 Class Standard

mg Weights as per OIML R

76-1

Readability : 20 g Up to 200 kg 41.0 g

Readability : 50 g Up to 300 kg 50.0 g

VI. VOLUME

1. Micro Pipettes$ 10 l to 50 l 0.11 l Using Precision balance

Readability : 50 l to 100 l 0.11 l and Distilled Water Of

0.01/0.1 mg 100 l to 1000 l 0.27 l Known Density By

1 ml to 5 ml 0.14 l Gravimetric Method as

per ISO 8655-6 & ISO

4787

2. Burette/ Pipette$ Using Precision balance

Readability : 0.01/0.1 1ml to 50 ml 0.14 ml and Distilled Water Of

mg 50 ml to 100 ml 0.14 ml Known Density By

Gravimetric Method as

per ISO 4787

3. Measuring Cylinder/ 100 ml to 200 ml 0.19 ml Using Precision balance

Graduated Jar$ 200 ml to 500 ml 0.63 ml and Distilled Water Of

Readability : 10 mg 500 ml to 1000 ml 0.73 ml Known Density By

& 100 mg 1000 ml to 2000 ml 1.32 ml Gravimetric Method as

2000 ml to 5000 ml 3.1 ml per ISO 4787

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 16 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

4. Volumetric Flask$ 10 ml to 100 ml 0.14 ml Using Precision balance

Readability 100 ml to 200 ml 0.14 ml and Distilled Water By

:0.01mg/ 10 mg/ 200 ml to 500 ml 0.63 ml Gravimetric Method as per

100 mg 500 ml to 1000 ml 0.73 ml ISO 4787

1000 ml to 2000 ml 1.31 ml

2000 ml to 5000 ml 3.1 ml

VI. TORQUE GENERATING DEVICES

1. Torque Wrench / 2 Nm to 20 Nm 2.91% Torque transducer with

Torque Screw 20 Nm to 200 Nm 2.61% Indicator & Fixtures

Driver/Torque 200 Nm to 2000 Nm 1.32% IS/ISO 6789:2003

Spanner

(Type-I & II All

Classes)

VII. UTM, TENSION CREEP AND TORSION TESTING MACHINE

1. Uni- Axial Testing

Machines♣

Compression 5 N to 300 kN 0.8% Using Load cell with

Tension 5 N to 300 kN 0.8% Indicator based on

IS:1828

VIII. HARDNESS TESTING MACHINES

1. Shore Hardness

Tester$

Shore A 0-100 Shore A 0.6 shore A Using Load cell with

Shore D 0-100 Shore D 0.6 shore D Indicator based on ASTM

D 2240-05

2. Verification of HRA 1.0 HRA Using Standard Test

Rockwell Hardness blocks as per IS:1586-

HRB 1.0 HRB

Tester♣ 2:2012 in- by Indirect

HRC 1.0 HRC Method

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 17 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

3. Verification of HBW 2.5/187.5 1.2% Using Standard Test

Brinell Hardness 1.3% blocks as per

HBW 5/750

Tester♣ 1.2% IS:1500-2:2013 IN by

HBW 10/3000

Indirect method

4. Verification of HV 5 1.6% Using Standard Test

Vickers Hardness HV 10 1.6% blocks as per

Tester♣ HV 20 1.6% IS:1501-2:2013 in by

HV 30 1.6%

Indirect Method

HV 50 1.6%

IX. PRESSURE INDICATING DEVICES

1. Pneumatic 0 to 20 bar 0.06%rdg Using Digital Pressure

Hydraulic$ Calibrator DPI 610 and

0 to 700 bar 0.18%rdg

(Pressure Gauge/ External transducer by

Pressure Indicator/ Comparison Method as

Switch/ per DKD-R6-2

Transmitters/

Manometer/

Compound Gauge/

Transducers With

Indicators)

2. Vacuum (-)0.1 bar to (-)0.9 bar 0.7%rdg Using Digital Pressure

Gauge/Switch/ Calibrator DPI 610 by

Transmitters/ Comparison Method as

Transducer With per DKD-R6-1

Indicators/

Compound Gauge$

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 18 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

3. Pressure (-)350 mbar to 350 mbar 0.24 % rdg Using Digital low pressure

Magnehelic Calibrator by Comparison

Gauges / method as per DKD-R6-1

Differential & DKD-R6-2

Pressure Gauge#

4. Pressure Gauge/ 0 to 20 bar 0.33 % rdg Using Digital Pressure

Pressure Indicator / Calibrator by Comparison

0 to 700 bar 0.20 % rdg

Switch/Transmitters Method as per DKD-R6-1

/Manometer/

Compound Gauge/

Transducers with

Indicators♣

5. Vacuum Gauge / (-) 0.1bar to (-) 0.85 bar 0.95 % rdg Using Digital Pressure

Vacuum Indicator/ Calibrator by Comparison

Switch / Method as per DKD-R6-1

Compound Gauge / & ISO: 3567

Transmitters and

Transducer with

Indicator♣

MECHANICAL CALIBRATION – MOBILE

1. Calipers:

(Venire / Dial /

Digital)

L.C:0.01mm 0 to 1000 mm 15.0 µm Using Slip gauge Set

grade ‘0’, Caliper

Checker, Length bar &

Slip gauge Accessories

IS:3651(Part I & II)

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 19 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

2. External

Micrometer/ Ball

Micrometer/ Blade

Micrometer /Disc

Micrometer /Flange

Micrometer/

Groove

Micrometer/Spline

Micrometer /Sheet

Metal

Micrometer/Point

Micrometer/Pitch

Micrometer

L.C:0.001mm 0 to 100mm 1.0 µm Using Slip Gauge Set

100 mm to 600mm 4.5 µm Grade ‘0’, Optical Flat &

Parallels, Length Bar,

Gauge Block Accessories

IS:2967

3. Depth Micrometer

L.C:0.01mm 0 to 300 mm 11.15 µm Using Slip Gauge Set

Grade ‘0’, Caliper

Checker, Gauge Block

Accessories

BIS:6468

4. Internal

Micrometer/ Stick

Micrometer

L.C:0.01 mm 0 to 600 mm 7.1 µm Using Slip Gauge Set

Grade ‘0’, Length Bar &

Gauge Block Accessories

IS:2966

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 20 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

5. Plunger Type Dial

Indicator

L.C:0.001 mm 0 to 25 mm 4.12 µm Using Dial Calibration

Tester IS:2092

6. Lever Type Dial

Indicator

L.C:0.01 mm 0 to 1.6mm 4.86 µm Using Dial Calibration

L.C:0.001mm 0 to 0.6 mm 4.17 µm Tester IS:11498

7. Snap 3 mm to 200 mm 1.74 µm Using Slip Gauge Set

Gauge/Adjustable 200 mm to 400 mm 3.7 µm Grade ‘0’, Slip Gauge

Snap Gauge, Knife Accessories IS: 3455,

Edge Gauge, IS:7859 & IS 3477

Length Gauge,

Height Gauge,

Master Setting

Gauge, Distance

Gauge, Depth

Gauge, Bridge

Gauge

8. Feeler Gauge Up to 1.0 mm 2.78 m Using Digital Micrometer

IS 3179

9. Bore Dial Gauge

( Only

Transmission

Movement)

L.C:0.001mm Up to 2 mm 4.27 m Using Dial Calibration

Tester by Comparison

Method

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 21 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

10. Dial Thickness

Gauge

L.C.: 0.01 mm 0 to 50 mm 5.79 m Using Slip Gauges Set

Grade ‘0’ as per IS 2092

11. Height Gauges

(Vernier/ Digital/

Dial)

L.C:0.01mm 0 to 600 mm 11.1 m Using Caliper Checker

IS 2921

12. Pistol Caliper

L.C.: 0.01 mm 0 to 100 mm 3.7 µm Using Slip Gauge Set

Grade ‘0’ as per IS 2092

13. Depth Vernier

Caliper

L.C.: 0.01 mm 0 to 300 mm 11.6 m Using Slip Gauge Set

Grade ‘ 0’, Gauge Block

Accessories & Caliper

checker as per IS 4213

14. Dial Caliper Gauge/

Groove Dial / Inside

Caliper Gauge

L.C.: 0.01mm 10 mm to 150 mm 3.62 m Using Slip Gauge Set

Grade ‘0’ & Slip Gauge

Accessories by

Comparison Method

15. Flush Pin Gauge Up to 200 mm 2.89 m Using Slip Gauge Set

Grade ‘0’ , Digital

micrometer & Plunger dial

by Comparison Method

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 22 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

16. Coating Thickness 0.01mm to 2 mm 1.79 m Using Standard Foils by

Gauge Comparison Method

17. Foils 0 to 5 mm 1.59 m Using Digital Micrometer

by Comparison Method

18. Measuring Pin 1mm to 20mm 2.83 m Using Slip Gauge Set

Grade ‘ 0’ Electronic

Comparator Stand

IS 11103

19. Dial Snap Gauge /

Dial Snap Meter

(Parallelism of

Measuring faces )

L.C: 0.001mm 0 to 100 mm 0.7 m Using Slip Gauge Set

Grade ‘ 0’ as pwe

IS 3455, IS 7859 & IS

3477

20. Plain Plug Gauge Up to 50 mm 2.83 m Using Slip Gauge Set

Grade ‘ 0’ Electronic

Comparator Stand

IS 3455 & IS 7859

21. Setting Rod Up to 50 mm 0.5 m Using Slip Gauge Set

50 mm to 100 mm 1.19 m Grade ‘ 0’, Length bar &

100 mm to 200 mm 1.32 m Electronic Comparator

200 mm to 600 mm 4.7 m Stand by

Comparison Method

22. Three Point 6 mm to 200mm 2.76 m Using Setting Ring Gauge

Micrometer 200 mm to 250mm 5.95 m by Comparison Method

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 23 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

23. V- Block Parallelism 4.2 m Using Slip Gauge Set

(Parallelism of Perpendicular 3.4 m Grade ‘ 0’, Lever dial

seating faces, Angle 15’ 51” Gauge, Bevel Protractor

Perpendicularity, Axis of Shaft 1.4 m As per IS 2949

Angle, Axis of the

shaft)

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 24 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

THERMAL CALIBRATION

1. TEMPERATURE

1. Liquid in Glass (-) 20 to 150°C 0.20°C Using SPRT with Digital

Thermometers$ Indicator and Low

Temperature Bath.

By Comparison Method

Confirming to IS:6274

2. RTD’s, Thermocouple , (-)80 to 100°C 0.24°C Using SPRT with

Digital Thermometer, 100 °C to 600°C 1.42°C Indicator,

Temperature Indicator 600°C to 1200°C 1.96°C S-type Thermocouple

With Sensor, Baths, with Indicator and Low

Temperature Controllers Temperature Bath/ Dry

With Sensor, Data Black Calibrator & Data

Logger, Transmitters logger by Comparison

With Sensors, Method confirming to

Temperature Gauges & EURAMET cg-8 Ver. 2.1

Temperature Switches$

3. Non – Contact 50 °C to 300°C 2.55°C Using IR Thermometer /

Temperature Calibration 300 °C to 1200°C 3.75°C Pyrometer with Digital

Infrared Thermometer & Indicator Black Body

Pyrometer$ Source by Comparison

Method MSL Technical

Guide & OEM Application

note

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 25 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

4. RTD’s, (-) 80°C to 100°C 0.5°C Using SPRT with Digital

Thermocouple , 100°C to 600°C 1.6°C Indicator and

Digital 600°C to 1200°C 2.1°C S-type Thermocouple

Thermometer, with Indicator and Low

Temperature Temperature Bath/ Dry

Indicator With Black Calibrator & Data

Sensor, Baths, logger By Comparison

Temperature Method confirming to

Controllers With DKD-R-5-1,

Sensor, Data EURAMET

Logger, cg-8,Ver 2.1

Transmitters With

Sensors,

Temperature

Gauges &

Temperature

Switches♣

5. Environment (-)80°C to 100°C 0.9°C Using SPRT with Indicator

Chamber, Cold 100°C to 300°C 1.5°C By Comparison Method,

Chamber, Freezer, based on DKD-R-5-7

Incubator,

Autoclave, Oven♣

( Single Point )

6. Environment (-)80°C to 250°C 0.8 to 1.4 °C Using RTD sensor with

Chamber, Cold Data logger (Multi sensor)

Chamber, Freezer, By Comparison Method,

Incubator, based on DKD-R-5-7.

Autoclave, Oven♣

( Multi Point )

Vishal Shukla Avijit Das

Convenor Program Director

Laboratory Perfect Calibration Centre Pvt. Ltd., No.84 First Floor, Times Corner,

Gengu Reddy Road, Egmore, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2207 (in lieu of C-0399, C-0243,C-0446) Page 26 of 26

Validity 18.06.2017 to 17.06.2019 Last Amended on 01.08.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

7. Furnace♣ 100°C to 600°C 1.39 °C Using SPRT with Indicator

(Single Point) 600°C to 1200°C 1.89 °C R-type Thermocouple

1200°C to1500°C 2.95 °C with Indicator

By Comparison Method,

based on AMS2750E

8. Furnace♣ 100°C to 1200°C 2.79°C Using N - Type

(Multi Point) Thermocouple with Data

logger By Comparison

Method, based on

AMS2750E

II. SPECIFIC HEAT AND HUMIDITY

1. Humidity Indicator 15% to 95% @ 25°C 1.4%RH Using Single Point Probe

of Humidity with Digital Indicator

Chamber / By Comparison Method,

Environment as per DKD – R-5-7

Chamber♣

(Single point)

2. Humidity Chamber / 15% to 95% @ 30°C 1.75%RH to 2.83%RH Using Humidity Sensors

Environment with Digital Indicator

Chamber♣ (Multi point)

(Multi point) By Comparison Method,

as per DKD- R-5-7

* Measurement Capability is expressed as an uncertainty () at a confidence probability of 95%

$

Only in Permanent Laboratory

♣

Only for Site Calibration

#

The laboratory is also capable for site calibration however, the uncertainty at site depends on the

prevailing actual environmental conditions and master equipment used.

Φ

Laboratory can also calibrate instruments/devices of coarser resolution / least count within the

accredited range using same reference standard/ master equipment under the scope of accreditation.

Vishal Shukla Avijit Das

Convenor Program Director

Potrebbero piacerti anche

- Circuit Protective Devices: Learner Work BookDocumento41 pagineCircuit Protective Devices: Learner Work BookChanel Maglinao80% (5)

- Graphite PropertiesDocumento42 pagineGraphite PropertiesAnnisa Puspa MustikaNessuna valutazione finora

- Ugc Model Curriculum Statistics: Submitted To The University Grants Commission in April 2001Documento101 pagineUgc Model Curriculum Statistics: Submitted To The University Grants Commission in April 2001Alok ThakkarNessuna valutazione finora

- Batteries Handling Disposal ProcedureDocumento17 pagineBatteries Handling Disposal ProcedureBALAJINessuna valutazione finora

- V1 N2 1980 RabenhorstDocumento6 pagineV1 N2 1980 Rabenhorstraa2010Nessuna valutazione finora

- Sop Sheet Metal Shear Foot OperatedDocumento2 pagineSop Sheet Metal Shear Foot OperatedBALAJINessuna valutazione finora

- Start Up and Commissioning of Chilled Water PumpsDocumento6 pagineStart Up and Commissioning of Chilled Water PumpsAlaa AnwerNessuna valutazione finora

- Mandatory ProceduresDocumento2 pagineMandatory ProceduresBALAJINessuna valutazione finora

- Calibration Certificate: 140.2223.1019 - 01 Ambre Resort & SpaDocumento2 pagineCalibration Certificate: 140.2223.1019 - 01 Ambre Resort & SpaAkash PraveshNessuna valutazione finora

- DLT Strand Jack Systems - 2.0 - 600 PDFDocumento24 pagineDLT Strand Jack Systems - 2.0 - 600 PDFganda liftindoNessuna valutazione finora

- AccreditationDocumento40 pagineAccreditationWalid BdeirNessuna valutazione finora

- FMEA ExampleDocumento4 pagineFMEA ExampleBALAJINessuna valutazione finora

- Instrument Technology: Measurement of Pressure, Level, Flow and TemperatureDa EverandInstrument Technology: Measurement of Pressure, Level, Flow and TemperatureValutazione: 4 su 5 stelle4/5 (1)

- 00.concrete Mix Design-RailwayDocumento38 pagine00.concrete Mix Design-RailwaySoundar PachiappanNessuna valutazione finora

- Position Sensing: Angle and Distance Measurement for EngineersDa EverandPosition Sensing: Angle and Distance Measurement for EngineersNessuna valutazione finora

- Template ProcedureDocumento3 pagineTemplate ProcedureBALAJINessuna valutazione finora

- MSDS Coffee PDFDocumento3 pagineMSDS Coffee PDFBALAJI100% (2)

- Nozzle Loads - Part 2 - Piping-EngineeringDocumento3 pagineNozzle Loads - Part 2 - Piping-EngineeringShaikh AftabNessuna valutazione finora

- 41.scope Location 1 CC-2792Documento9 pagine41.scope Location 1 CC-2792Ravichandran DNessuna valutazione finora

- 112.scope Location 1 CC-2725Documento10 pagine112.scope Location 1 CC-2725Ravichandran DNessuna valutazione finora

- Model KM 734: Hot Wire Thermal AnemometerDocumento1 paginaModel KM 734: Hot Wire Thermal AnemometerkumarNessuna valutazione finora

- Supplier Global Quality - KanDocumento4 pagineSupplier Global Quality - Kanpyo14Nessuna valutazione finora

- Sri Gokul Cal Lab.Documento4 pagineSri Gokul Cal Lab.VAIBHAV INSTRUMENTATIONNessuna valutazione finora

- 1823-01 - A2la - Iso 17025 - Schope - Cert - 2020-2022 - Rlws - Concord-Ca - RevisedDocumento22 pagine1823-01 - A2la - Iso 17025 - Schope - Cert - 2020-2022 - Rlws - Concord-Ca - RevisedLeandroNessuna valutazione finora

- AvijitDocumento2 pagineAvijitBAlaNessuna valutazione finora

- 75عDocumento3 pagine75عFikry FaradinnaNessuna valutazione finora

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocumento4 pagineSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNessuna valutazione finora

- LK-093-IDN (Temperature, Mass, Pressure, & Length)Documento1 paginaLK-093-IDN (Temperature, Mass, Pressure, & Length)Aries SupiyantoNessuna valutazione finora

- NABL Accredited Calibration Lab As Per ISO/IEC17025:2005 CC - 2715Documento1 paginaNABL Accredited Calibration Lab As Per ISO/IEC17025:2005 CC - 2715arunNessuna valutazione finora

- INTECH Brochure - 2018 PDFDocumento1 paginaINTECH Brochure - 2018 PDFarunNessuna valutazione finora

- CMTI ScopeDocumento13 pagineCMTI ScopeRavichandran DNessuna valutazione finora

- Global Insignia For Technical Services Establishment: This Is To Attest ThatDocumento3 pagineGlobal Insignia For Technical Services Establishment: This Is To Attest ThatAlmansoori MPSNessuna valutazione finora

- CL 222 CertDocumento5 pagineCL 222 CertS SHALUNessuna valutazione finora

- Am50 Velocitor Air Velocity Meter: DM350 Is Encased in A SecondaryDocumento1 paginaAm50 Velocitor Air Velocity Meter: DM350 Is Encased in A SecondaryKevin HuarachaNessuna valutazione finora

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocumento18 pagineSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNessuna valutazione finora

- AVM-04 Metravi Thermo AnemometerDocumento1 paginaAVM-04 Metravi Thermo Anemometerkrishna kumarNessuna valutazione finora

- Bstafm07 DatasheetDocumento1 paginaBstafm07 Datasheetshamroz khanNessuna valutazione finora

- MikronixDocumento3 pagineMikronixrohanmanimaniNessuna valutazione finora

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocumento12 pagineSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNessuna valutazione finora

- G.B.Central Laboratory, TrichyDocumento3 pagineG.B.Central Laboratory, TrichyRavichandran DNessuna valutazione finora

- Scope Location 1 CC-2222Documento24 pagineScope Location 1 CC-2222Ravi Dilawari [Aspire]Nessuna valutazione finora

- CL 221 CertDocumento4 pagineCL 221 CertS SHALUNessuna valutazione finora

- CR1000X 46301Documento2 pagineCR1000X 46301mitziNessuna valutazione finora

- Vibration MeterDocumento2 pagineVibration MeterrajvirsinhjrathodNessuna valutazione finora

- 24.scope Location 1 CC-2833Documento4 pagine24.scope Location 1 CC-2833Ravichandran DNessuna valutazione finora

- 109 JadDocumento24 pagine109 JadLim ChsNessuna valutazione finora

- Item 2. Ficha Tecnica DT-8894Documento2 pagineItem 2. Ficha Tecnica DT-8894Plagiador UnadNessuna valutazione finora

- Onset HOBO UX100 Data LoggersDocumento2 pagineOnset HOBO UX100 Data LoggersIvan BriscoeNessuna valutazione finora

- Vane Thermo-Anemometer: Key PointsDocumento2 pagineVane Thermo-Anemometer: Key Pointsbysquality srlNessuna valutazione finora

- Senso Direct Manual PDFDocumento28 pagineSenso Direct Manual PDFSandra Milena Sanchez RamirezNessuna valutazione finora

- LK-019-IDN (Temperature, Pressure, & Flow)Documento1 paginaLK-019-IDN (Temperature, Pressure, & Flow)Aries SupiyantoNessuna valutazione finora

- Godrej Nabl ScopeDocumento11 pagineGodrej Nabl ScopeRavichandran DNessuna valutazione finora

- VDM 300 ThermoDocumento4 pagineVDM 300 ThermoAmr KonswaNessuna valutazione finora

- Positector Calibration ProcedureDocumento6 paginePositector Calibration ProcedureluigimasterNessuna valutazione finora

- Quantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksDocumento8 pagineQuantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksrohanmanimaniNessuna valutazione finora

- Anemometer (CMM, CFM) Humidity Meter, Light Meter Type K ThermometerDocumento2 pagineAnemometer (CMM, CFM) Humidity Meter, Light Meter Type K ThermometerJose ZamoraNessuna valutazione finora

- LK-067-IDN (Temperature, Mass, & Pressure)Documento2 pagineLK-067-IDN (Temperature, Mass, & Pressure)Aries SupiyantoNessuna valutazione finora

- Temp Bath LowDocumento7 pagineTemp Bath Lowvijay.victorysolutions01Nessuna valutazione finora

- Cat ThermoMETER Infrared en UsDocumento76 pagineCat ThermoMETER Infrared en UsRajatBatishNessuna valutazione finora

- Kimo Ami300Documento4 pagineKimo Ami300Ciresica Sanda CocindauNessuna valutazione finora

- Veksler pH6Con5S400Tx3422TxDocumento3 pagineVeksler pH6Con5S400Tx3422TxShannon HamiltonNessuna valutazione finora

- Reliance 333Documento7 pagineReliance 333Ravichandran DNessuna valutazione finora

- LM-8102 en Manual PDFDocumento16 pagineLM-8102 en Manual PDFBiran AbadiNessuna valutazione finora

- R&D Negative TempDocumento1 paginaR&D Negative Tempvijay.victorysolutions01Nessuna valutazione finora

- 24K Mech Lab-IS ExtDocumento3 pagine24K Mech Lab-IS ExtVikasNessuna valutazione finora

- Northlab HosurDocumento25 pagineNorthlab HosurVikram BillalNessuna valutazione finora

- Hot Wire Anemometer: Model: YK-2005AHDocumento2 pagineHot Wire Anemometer: Model: YK-2005AHAhmad NNessuna valutazione finora

- Digital Vibration Meter 908Documento1 paginaDigital Vibration Meter 908PRAVIN PATELNessuna valutazione finora

- Manual P713 CHDocumento9 pagineManual P713 CHpranjal pandeyNessuna valutazione finora

- 2658Documento7 pagine2658rohanmanimaniNessuna valutazione finora

- SCS - ScopeDocumento22 pagineSCS - ScopeRakesh TrentiyaNessuna valutazione finora

- Va710 User ManualDocumento17 pagineVa710 User ManualSpecial Sicim ProcessesNessuna valutazione finora

- CFM/CMM Thermo-Anemometer + IR Thermometer: Large Display of Airflow or Air VelocityDocumento1 paginaCFM/CMM Thermo-Anemometer + IR Thermometer: Large Display of Airflow or Air VelocityVanHackmanNessuna valutazione finora

- Report of Calibration: 03-03-2022 02-09-2022 05-03-2022 MQS/229001/12 & 02-03-2022 MQS/229001/12/01Documento2 pagineReport of Calibration: 03-03-2022 02-09-2022 05-03-2022 MQS/229001/12 & 02-03-2022 MQS/229001/12/01Yasir Yasir KovanNessuna valutazione finora

- Hazardous Waste Display BoardDocumento3 pagineHazardous Waste Display BoardBALAJINessuna valutazione finora

- Certificate TC 5750 PDFDocumento1 paginaCertificate TC 5750 PDFBALAJINessuna valutazione finora

- 2.7 - Generic Confidentiality Agreement I - v1Documento1 pagina2.7 - Generic Confidentiality Agreement I - v1BALAJINessuna valutazione finora

- GHTF Sg3 n99 8 Guidance On Quality 990629Documento48 pagineGHTF Sg3 n99 8 Guidance On Quality 990629BALAJINessuna valutazione finora

- Misc - Multiple Choice Quiz TemplateDocumento11 pagineMisc - Multiple Choice Quiz TemplateBALAJINessuna valutazione finora

- W304 What Is The Decision RuleDocumento59 pagineW304 What Is The Decision RuleBALAJINessuna valutazione finora

- Emirates Authority For Standardization & Metrology (ESMA) : UAE Draft Standard (DS1)Documento8 pagineEmirates Authority For Standardization & Metrology (ESMA) : UAE Draft Standard (DS1)BALAJINessuna valutazione finora

- FMEA ExampleDocumento4 pagineFMEA ExampleBALAJINessuna valutazione finora

- Tip: To Quickly Find Your Search Term On This Page, Press CTRL+F or - F (Mac) and Use The Find BarDocumento34 pagineTip: To Quickly Find Your Search Term On This Page, Press CTRL+F or - F (Mac) and Use The Find BarBALAJINessuna valutazione finora

- 3323Documento222 pagine3323BALAJINessuna valutazione finora

- Ambient StorageDocumento1 paginaAmbient StorageBALAJINessuna valutazione finora

- Form 8Documento1 paginaForm 8BALAJI100% (1)

- Intercontinental Coffee Trading Inc.: 110 West A Street, Suite 110 San Diego, Ca 92101Documento2 pagineIntercontinental Coffee Trading Inc.: 110 West A Street, Suite 110 San Diego, Ca 92101BALAJINessuna valutazione finora

- Crisis Management Log: Name: Position: Crisis Situation: Time Started: - Time CompletedDocumento1 paginaCrisis Management Log: Name: Position: Crisis Situation: Time Started: - Time CompletedBALAJINessuna valutazione finora

- Nescafe in CupDocumento5 pagineNescafe in CupBALAJINessuna valutazione finora

- Draft Notice Comments Pesticides MRL 08-08-2017Documento46 pagineDraft Notice Comments Pesticides MRL 08-08-2017BALAJINessuna valutazione finora

- Instant Coffee Granules Specification Summary: Coagulase Positive StaphylococciDocumento4 pagineInstant Coffee Granules Specification Summary: Coagulase Positive StaphylococciBALAJINessuna valutazione finora

- Myhaccp Hazard Factsheet: Category: MicrobiologicalDocumento1 paginaMyhaccp Hazard Factsheet: Category: MicrobiologicalBALAJINessuna valutazione finora

- Plate - 3 (FLOT)Documento2 paginePlate - 3 (FLOT)patrick dgNessuna valutazione finora

- Assigment Comouter Science BSCDocumento3 pagineAssigment Comouter Science BSCutkarsh9978100% (1)

- Physics Lab - Detailed - Answer KeyDocumento6 paginePhysics Lab - Detailed - Answer KeyJasdeepSinghNessuna valutazione finora

- API ISCAN-LITE ScannerDocumento4 pagineAPI ISCAN-LITE Scannergrg_greNessuna valutazione finora

- Computer Dictionary PDFDocumento95 pagineComputer Dictionary PDFMarjenneilNessuna valutazione finora

- Switching Power Supply DesignDocumento21 pagineSwitching Power Supply DesignSamuel mutindaNessuna valutazione finora

- Gas Welding Equipment PowerpointDocumento12 pagineGas Welding Equipment PowerpointChristian RexNessuna valutazione finora

- D4304-Syllabus-Neural Networks and Fuzzy SystemsDocumento1 paginaD4304-Syllabus-Neural Networks and Fuzzy Systemsshankar15050% (1)

- ORC - Airbag SystemDocumento13 pagineORC - Airbag SystemGarikoitz FranciscoeneNessuna valutazione finora

- Geared Motors Power Distribution: V V V VDocumento2 pagineGeared Motors Power Distribution: V V V VShamim Ahsan ParvezNessuna valutazione finora

- T8 - Energetics IDocumento28 pagineT8 - Energetics II Kadek Irvan Adistha PutraNessuna valutazione finora

- Naca 4412Documento3 pagineNaca 4412Selva KumarNessuna valutazione finora

- ML Observability Build Vs Buy Download Guide 1689038317Documento31 pagineML Observability Build Vs Buy Download Guide 1689038317rastrol7Nessuna valutazione finora

- FP - ES - 28 - Rindu Grahabhakti Intani - PERMEABLE ENTRY CHARACTERIZATION AT DARAJAT FIELD, WEST JAVA PDFDocumento4 pagineFP - ES - 28 - Rindu Grahabhakti Intani - PERMEABLE ENTRY CHARACTERIZATION AT DARAJAT FIELD, WEST JAVA PDFrindu_intaniNessuna valutazione finora

- Python Unit 1Documento18 paginePython Unit 1Rtr. Venkata chetan Joint secretaryNessuna valutazione finora

- The Kemetic Tree of LifeDocumento1 paginaThe Kemetic Tree of LifeFlorin CiudinNessuna valutazione finora

- Lec1 PDFDocumento12 pagineLec1 PDFtogarsNessuna valutazione finora

- Dawn C. Meredith, Meaning MakingDocumento2 pagineDawn C. Meredith, Meaning MakingMrsriyansyahNessuna valutazione finora

- Assignment - 1 Introduction of Machines and Mechanisms: TheoryDocumento23 pagineAssignment - 1 Introduction of Machines and Mechanisms: TheoryAman AmanNessuna valutazione finora

- Arithmetic Unit: Dr. Sowmya BJDocumento146 pagineArithmetic Unit: Dr. Sowmya BJtinni09112003Nessuna valutazione finora

- Physics Sample Question PaperDocumento9 paginePhysics Sample Question PaperVarsha SharmaNessuna valutazione finora

- Ch-21 Runoff TrianglesDocumento9 pagineCh-21 Runoff TrianglesIsha TachhekarNessuna valutazione finora