Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

G6400 LCMS Site Preparation Checklist

Caricato da

Atul SharmaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

G6400 LCMS Site Preparation Checklist

Caricato da

Atul SharmaCopyright:

Formati disponibili

Agilent 6400 Series Triple Quad LC/MS

Site Preparation Checklist

Thank you for purchasing an Agilent instrument. To get you started and to assure a successful and

timely installation of your Agilent software, please refer to this specification or set of requirements.

Correct site preparation is the key first step in ensuring that your instruments and software systems

operate reliably over an extended lifetime. This document is an information guide and checklist

prepared for you that outlines the supplies, consumables, space and utility requirements for your

equipment.

Customer Responsibilities

Make sure your site meets the following specifications before the installation date. For

details, see specific sections within this checklist, including:

The computing environment and the necessary space is made available.

The number & location of electrical outlets for your instruments, computer systems, and peripherals

are planned.

That your site meets the software, hardware and networking specifications below locate your sales

order information, software authorization codes and/or software licenses/certificates.

The necessary software media, disks etc are available including upgrade/update disks that a suitable

backup solution is identified for your software.

Availability of a system/network administrator as needed to connect to your intranet please consult

Other/Special Requirements section below for other product-specific information.

If Agilent is delivering installation and familiarization services, users of the system should be present

throughout these services; otherwise, they will miss important operational, maintenance and safety

information.

Complete Final Check: Software Site Preparation Tool.

The proper pressure, capacity, and purity of nitrogen gases for instruments and peripherals are

planned.

The adequate exhaust ventilation for instruments and peripherals are planned.

The necessary customer supplied chemicals for instruments and peripherals are provided.

Important Customer Information

1. If you have questions or problems in providing anything described as a Customer Responsibility

above, please contact your local Agilent or partner support/service organization for assistance

prior to delivery. In addition, Agilent and/or it's partners reserve the right to reschedule the

installation dependent upon the readiness of your laboratory.

2. Should your site not be ready for whatever reasons, please contact Agilent as soon as possible to

re-arrange any services that have been purchased.

3. Other optional services such as additional training, operational qualification (OQ) and

consultation for user-specific applications may also be provided at the time of installation when

ordered with the system, but should be contracted separately.

Issued: 17-Mar-2016, Revision: 03 Copyright1 2016 Agilent Technologies

Page 1 of 10

Agilent 6400 Series Triple Quad LC/MS

Site Preparation Checklist

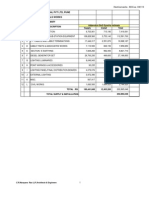

Dimensions and Weight

Identify the laboratory bench space before your system arrives based on the table below. Pay special

attention to the total height and total weight requirements for all system components you have ordered

and avoid bench space with overhanging shelves.

Special Notes

1. The 6400 Series Triple Quad LC/MS dimensions represent the maximum cabinet dimensions with

a Spray Chamber installed.

2. At least 30 cm (1 ft.) to the left (source end) and right of the instrument must be added to the

dimensions to provide adequate instrument access and ventilation.

3. The supporting surface must be relatively vibration free and capable of supporting the combined

weight of the Triple Quad system.

Instrument/Spray Weight Height Depth Width

Chamber/Foreline Pump

Model Kg lbs cm in cm in cm in

G6410A QQQ LC/MS 107.5 236.5 47 18.5 66 26 111 43.5

G6410B QQQ LC/MS 107.5 236.5 47 18.5 66 26 111 43.5

G6420A QQQ LC/MS 107.5 236.5 47 18.5 66 26 111 43.5

G6430A QQQ LC/MS 115 255 47 18.5 66 26 111 43.5

G6460A QQQ LC/MS 115 255 48 18.8 66 26 111 43.5

G6460C QQQ LC/MS 115 255 48 18.8 66 26 111 43.5

G6470A QQQ LC/MS 115 255 47 18.5 76 30 84 33

G6490A QQQ LC/MS 115 255 47 18.5 76 30 84 33

G6495A QQQ LC/MS 115 255 47 18.5 76 30 84 33

G1948B Electrospray

1.7 3.8 17 6.8 9.5 3.7 18 7.1

Source

G1947B APCI Source 1.7 3.8 23 9.2 13.0 5.1 18 7.1

G1971B APPI Source 1.7 3.8 23 9.2 13.0 5.1 18 7.1

G1978B Multimode Source 2.29 5.05 23 9.2 13.0 5.1 18 7.1

Agilent Jet Stream 1.7 3.8 23 9.2 11.5 4.5 18 7.1

G4240A HPLC-Chip Cube 14 31 36 14.1 30 11.7 35 13.7

Issued: 17-Mar-2016, Revision: 03 Copyright2 2016 Agilent Technologies

Page 2 of 10

Agilent 6400 Series Triple Quad LC/MS

Site Preparation Checklist

E2M28 Foreline Pump 40.0 88.2 28 11 58.3 23.0 17 7.1

MS40+ Foreline Pump 33.0 72.7 22.8 9.0 41.8 16.5 29.7 11.7

Identify the laboratory bench space before your system arrives based on the table below. Pay special

attention to the total height and total weight requirements for all system components you have ordered

and avoid bench space with overhanging shelves.

Environmental Conditions

Operating your instrument within the recommended temperature ranges insures optimum instrument

performance and lifetime.

Special Notes

1. Performance can be affected by sources of heat & cold e.g. direct sunlight, heating/cooling from

air conditioning outlets, drafts and/or vibrations.

2. The site’s ambient temperature conditions must be stable for optimum performance.

3. The Agilent 6400 Series Triple Quad LC/MS is specified for operation under the following

conditions:

a. Indoor use.

b. Constant temperature (< +/-3°C from calibration temperature).

c. Non-condensing, non-corrosive atmosphere.

d. Altitude: Not to exceed 3,300 m up to 35°C, not to exceed 3,700 m up to 30°C.

Operating temp range Operating Heat Dissipation

Instrument Model C (F) humidity range (%) (BTU)

6400 Series QQQ LC/MS (all

15 - 35 °C (59 - 95 °F) < 85% RH @ 35 °C < 4500 BTU/hr

models)

Power Consumption

Special Notes

1. If a computer system is supplied with your instrument, be sure to account for those electrical

outlets.

2. The LC/MS electrical outlet(s) must have an isolated, noise-free electrical ground that is

connected to the main earth ground for the facility.

3. Mains supply voltage tolerances must be between +10% and -5% of nominal line voltage.

4. Models utilizing the E2M28 foreline pump must be ordered specifying installation site voltage.

Issued: 17-Mar-2016, Revision: 03 Copyright3 2016 Agilent Technologies

Page 3 of 10

Agilent 6400 Series Triple Quad LC/MS

Site Preparation Checklist

5. Electrical power for the 6400 Series Triple Quad LC/MS may be delivered in either single-phase

or 208- Wye configuration:

Configuration Measurement Nominal Voltage

Line to neutral 200, 220, 230 or 240 VAC

Singe Phase Line to ground 200, 220, 230 or 240 VAC

Ground to neutral < 0.5 V rms

Line to line (phase A to phase B) 208, 220 VAC

208-Wye Line to ground (phase A to ground) 120, 127 VAC

Line to ground (phase B to ground) 120, 127 VAC

Instrument Line Voltage & Frequency Supply Circuit Number of Maximum Power

Model (V, Hz) Rating (A) Outlets Consumption (VA)

G6410A 200 - 240 VAC @ 50/60 Hz 15 A 1 2500

G6410B

G6420A

200 - 240 VAC @ 50/60 Hz 15 A 1 2700

G6430A

G6460A

G6460C 200 - 240 VAC @ 50/60 Hz 15 A 2 2850

G6470A 200 - 240 VAC @ 50/60 Hz 15 A 2 2850

G6490A

200 - 240 VAC @ 50/60 Hz 15 A 2 2850

G6495A

Main Nitrogen Gas Supply Requirements

Special Notes

1. For information on Agilent consumables, accessories and laboratory operating supplies, please

visit: http://www.chem.agilent.com/en-US/Products/consumables/Pages/default.aspx.

2. Impurities from LN2 Dewar being oxygen only.

3. "Hydrocarbon free" means < 0.1 PPM hydrocarbons with the remaining gas being oxygen and

trace argon.

4. Nitrogen Pressure as measured at the LC/MS inlet (not the supply side).

Issued: 17-Mar-2016, Revision: 03 Copyright4 2016 Agilent Technologies

Page 4 of 10

Agilent 6400 Series Triple Quad LC/MS

Site Preparation Checklist

5. Minimum Nitrogen Flow required at all times to prevent air from entering the instrument.

6. Main Nitrogen Supply fittings are 1/4" Swagelok.

Model Nitrogen Source Nitrogen Purity Pressure Flow

G6410A ≥ 99.5% and

LN2 Dewar ≤ 18 L/min

G6410B hydrocarbon free

Maximum

G6420A 5.5 - 6.8 bar

( ≤ 1080 L/hour)

G6430A ≥ 95.0% and (80 - 100 PSI)

Nitrogen Generator > 3 L/min

G6460A#100 hydrocarbon free

Minimum

G6460C#100

≥ 99.5% and ≤ 30 L/min

LN2 Dewar

hydrocarbon free Maximum

G6460A 5.5 - 6.8 bar

( ≤ 1800 L/hour)

G6460C ≥ 95.0% and (80 - 100 PSI)

Nitrogen Generator > 3 L/min

hydrocarbon free

Minimum

≥ 99.5% and ≤ 50 L/min

LN2 Dewar

hydrocarbon free Maximum

G6490A 5.5 - 6.8 bar

( ≤ 3000 L/hour)

G6495A ≥ 95.0% and (80 - 100 PSI)

Nitrogen Generator > 9 L/min

hydrocarbon free

Minimum

≥ 95% hydrocarbon ≤ 30 L/min

LN2 Dewar

Free Maximum

5.5 - 6.8 bar

G6470A Maximum ( ≤ 1800 L/hour)

≥ 95% and (80 - 100 PSI)

Nitrogen Generator > 3 L/min

Hydrocarbon free

Minimum

Collision Cell Nitrogen Gas Supply Requirements

Special Notes

1. For information on Agilent consumables, accessories and laboratory operating supplies, please

visit http://www.chem.agilent.com/en-US/Products-Services/Parts-

Supplies/Pages/BuyAndTry.aspx.

2. Nitrogen is the only supported Collision Cell gas.

3. Splitting the Main Nitrogen Gas supply for use with the collision cell is not supported due to

nitrogen purity requirements.

4. Collision Cell gas supply fittings are 1/8" Swagelok.

Issued: 17-Mar-2016, Revision: 03 Copyright5 2016 Agilent Technologies

Page 5 of 10

Agilent 6400 Series Triple Quad LC/MS

Site Preparation Checklist

Instrument Model Nitrogen Source Nitrogen Purity Pressure Flow

≥ 99.999% and

6400 Series QQQ High Pressure hydrocarbon free 1 - 2 bar ≤ 0.001 L/min

LC/MS (all models) Cylinder (< 0.1 PPM (15 - 30 PSI) ( ≤ 0.006 L/hour)

hydrocarbons)

Compressed Air Requirements - HPLC-Chip Cube equipped

systems only

Special Notes

1. For information on Agilent consumables, accessories and laboratory operating supplies, please

visit http://www.chem.agilent.com/en-US/Products/consumables/Pages/default.aspx.

2. Compressed Air is required for HPLC-Chip Cube equipped systems only.

3. Air source must be able to deliver air at a constant pressure.

4. Inlet gas pressure for air must be equal to or slightly higher than the pressure used for the Main

Nitrogen Gas supply.

5. Compressed Air supply fittings are 1/4" Swagelok.

Instrument Model Air Source Air Purity Pressure Flow

G6410B

G6420A G6430A High Pressure Air ≥ 99.99% and 6.8 - 6.9 bar ≤ 4 L/min Maximum

G6460A G6460C source hydrocarbon free (100 - 120 PSI) ( ≤ 240 L/hour)

G6470A

G6490A High Pressure Air ≥ 99.99% and 6.8 - 6.9 bar ≤ 10 L/min Maximum

G6495A source hydrocarbon free (100 - 120 PSI) ( ≤ 600 L/hour)

Exhaust Venting

For information on Agilent consumables, accessories and laboratory operating supplies, please

The LC/MS generates exhaust fumes from the foreline pump(s) and drain bottle (from the spray

chamber) that must be properly vented for supported instrument operation and compliance with

laboratory safety requirements.

Issued: 17-Mar-2016, Revision: 03 Copyright6 2016 Agilent Technologies

Page 6 of 10

Agilent 6400 Series Triple Quad LC/MS

Site Preparation Checklist

Special Notes

1. Exhaust must be vented according to local Environmental Health and Safety regulations.

2. Exhaust gases contain traces of solvent, sample and hydrocarbon pump fluid.

3. Venting Rate is commensurate with Nitrogen consumption rate.

4. Two independent, negative pressure vents must be available with one for each of the exhaust

sources: foreline pump(s) and Spray Chamber. If only 1 vent is available, the exhaust line(s) from

the foreline pump(s) required must extend beyond the exhaust line from the spray chamber.

5. If a negative pressure vent is not available, the length of the tubing from the foreline pump(s) and

the drain bottle to the vent should each not exceed 460 cm (15 ft).

6. Exhaust tubing is 1/2" interior diameter (I.D.).

Instrument Model Combined Exhaust Venting Rate (Continuous)

G6410A G6410B

≤ 20 L/min Maximum

G6420A G6430A

( ≤ 1080 L/hour)

G6460A#100

> 3 L/min Minimum

G6460C#100

G6460A ≤ 30 L/min Maximum

G6460C ( ≤ 1800 L/hour)

G6470A > 3 L/min Minimum

≤ 50 L/min Maximum

G6490A

( ≤ 3000 L/hour)

G6495A

> 9 L/min Minimum

Note:

Failure to vent the foreline pump and spray chamber separately will void the warranty for the 6400

Series Triple Quad LC/MS. Agilent service representatives will not install an Agilent 6400 Series Triple

Quad LC/MS until an adequate exhaust system is present and functioning.

Required Operating Supplies by Customer

Special Notes

1. For information on Agilent consumables, accessories and laboratory operating supplies, please

visit http://www.chem.agilent.com/en-US/Products/consumables/Pages/default.aspx.

2. For detailed information on Operating Supplies, please refer to the Site Preparation Guide.

Issued: 17-Mar-2016, Revision: 03 Copyright7 2016 Agilent Technologies

Page 7 of 10

Agilent 6400 Series Triple Quad LC/MS

Site Preparation Checklist

Item Description Vendor’s Part Number Recommended

(including dimensions etc) (if applicable) Quantity

Agilent Triple Quad LC/MS Site Preparation Guide G2571-90010 1

Tuning Calibrant – Dependent on LC/MS model and

Source

Electrospray (ESI) Calibrant G2431A 1

APCI/APPI Calibrant G2432A 1

ESI-Low Calibrant G1969-85000 1

APCI-Low Calibrant G1969-85010 1

Performance Standard – Electrospray/APCI Positive G2423A 1

Ion

Performance Standard – ES Negative Ion (Acid Red G2424A 1

4)

Performance Standard - ES Negative Ion 5190-0591 1

(Chloramphenicol)

Performance Standard – APCI Negative Ion G2525A 1

Performance Standard – Multimode LC Demo G1978-85000 1

Sample

Performance Standard – Electrospray LC Demo 59987-20033 1

Sample

Ammonium Formate G1946-85021 1

Formic Acid – Reagent Grade G2453-85060 2

HPLC Flushing Solvent (500 mL) G1969-85026 1

Methanol, High Purity (1 L) 8500-1867 3

Acetonitrile, High Purity (1 L) G2453-85050 2

Water, High Purity (4 L) 8500-2236 1

Pipette, 1 mL 9301-1423 3

Volumetric Flask, 50 mL 9301-1424 1

Volumetric Flask, 100 mL 9301-1433 2

Vials, 2 mL Screw Top, Wide Opening, Amber 5182-0716 1

(100/pk)

Vial Caps, Blue, PTFE/red silicone septa (100/pk) 5182-0717 1

Issued: 17-Mar-2016, Revision: 03 Copyright8 2016 Agilent Technologies

Page 8 of 10

Agilent 6400 Series Triple Quad LC/MS

Site Preparation Checklist

Recommended Configurations

Agilent recommends 2 standard stacking configurations for your new system depending on the number

and type of included modules. Please use these notes and figures as reference for HPLC and LC/MS

configurations.

Special Notes

Stacking the entire HPLC modules on top of the 6400 Series QQQ LC/MS is not supported.

Issued: 17-Mar-2016, Revision: 03 Copyright9 2016 Agilent Technologies

Page 9 of 10

Agilent 6400 Series Triple Quad LC/MS

Site Preparation Checklist

Other Important Customer Web Links

For additional information about our solutions, please visit our web site at

http://www.agilent.com/home

Need to get information on your product?

Literature Library - http://www.agilent.com/en-us/library/

Need to know more?

Customer Education – http://www.agilent.com/crosslab/university/

Need technical support, FAQs? – http://www.agilent.com/home

Need supplies? – http://www.agilent.com/en-us/products/lab-supplies

Issued: 17-Mar-2016, Revision: 03 Copyright10 2016 Agilent Technologies

Page 10 of 10

Potrebbero piacerti anche

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Electrical Works - Package 2B Addendum BoQ Synefra EstimateDocumento46 pagineElectrical Works - Package 2B Addendum BoQ Synefra Estimatemsdixit2006100% (4)

- Overhead Water Tank Structural AnalysisDocumento28 pagineOverhead Water Tank Structural Analysiscollins unanka100% (3)

- Operational Amplifier Circuits: Analysis and DesignDa EverandOperational Amplifier Circuits: Analysis and DesignValutazione: 4.5 su 5 stelle4.5/5 (2)

- Ceiling Fan Laboratory Guidance ManualDocumento35 pagineCeiling Fan Laboratory Guidance ManualSsdssddNessuna valutazione finora

- Th255, Th255c Axle Cat ServiceDocumento280 pagineTh255, Th255c Axle Cat ServiceKevine KhaledNessuna valutazione finora

- 1260 HPLC Site Preparation ChecklistDocumento9 pagine1260 HPLC Site Preparation ChecklistlruizdeoNessuna valutazione finora

- 345KV Autotransformer Spec (08.29.2012)Documento56 pagine345KV Autotransformer Spec (08.29.2012)Dante FilhoNessuna valutazione finora

- Op Amps: Design, Application, and TroubleshootingDa EverandOp Amps: Design, Application, and TroubleshootingValutazione: 5 su 5 stelle5/5 (2)

- Summit 325E - Service ManualDocumento40 pagineSummit 325E - Service ManualPhuong le Dinh100% (1)

- SEM 3037E Tower Piping.Documento52 pagineSEM 3037E Tower Piping.Kodali Naveen KumarNessuna valutazione finora

- 6RA70 V3.1 Operating InstructionsDocumento736 pagine6RA70 V3.1 Operating InstructionsŞaban ŞekerNessuna valutazione finora

- Valleylab Force FX-8c Electrosurgical Generator - Service Manual PDFDocumento218 pagineValleylab Force FX-8c Electrosurgical Generator - Service Manual PDFElias AuccapiñaNessuna valutazione finora

- CA3080Documento12 pagineCA3080yusufwpNessuna valutazione finora

- Calibration Procedure For Clamp Meters Fluke Models 333, 334, 335, 336 and 337 - Tb-9-6625-2408-24Documento15 pagineCalibration Procedure For Clamp Meters Fluke Models 333, 334, 335, 336 and 337 - Tb-9-6625-2408-24luroguita100% (1)

- Datasheet 8V1010002-ACOPOS 1010Documento20 pagineDatasheet 8V1010002-ACOPOS 1010Umut ÖnalNessuna valutazione finora

- Subject and Content NotesDocumento52 pagineSubject and Content NotesJoe Carl CastilloNessuna valutazione finora

- Gen Sizing Guide-SiemensDocumento16 pagineGen Sizing Guide-Siemensdinesh_kp7647Nessuna valutazione finora

- Fusing Equipment: Dual Sensing Bay-O-Net Fuse LinkDocumento6 pagineFusing Equipment: Dual Sensing Bay-O-Net Fuse Linksaniya_mirza4Nessuna valutazione finora

- Astm D5127-2013 (2018)Documento2 pagineAstm D5127-2013 (2018)Atul Sharma0% (1)

- Filter Integrity Test MachineDocumento4 pagineFilter Integrity Test MachineAtul SharmaNessuna valutazione finora

- Certification HandbookDocumento21 pagineCertification Handbookedk34Nessuna valutazione finora

- Destination Phrasal Verbs @destination - b1 - b2 - c1Documento25 pagineDestination Phrasal Verbs @destination - b1 - b2 - c1Samira GulomovaNessuna valutazione finora

- Exposure Control MatrixDocumento37 pagineExposure Control MatrixAtul SharmaNessuna valutazione finora

- EtomDocumento1 paginaEtomarthryxNessuna valutazione finora

- 1220Infinity-Infinity2-LC Site Preparation ChecklistDocumento5 pagine1220Infinity-Infinity2-LC Site Preparation ChecklistYudi - PT. Laborindo SaranaNessuna valutazione finora

- Cga Svx01b en 0404 TraneDocumento32 pagineCga Svx01b en 0404 TraneFrancisco Rodriguez HuertasNessuna valutazione finora

- 01200-90600 HW1200SitePreparationDocumento11 pagine01200-90600 HW1200SitePreparationManickam EllampoorananNessuna valutazione finora

- Sivacon 4RB PowerQualitySolution Pi enDocumento56 pagineSivacon 4RB PowerQualitySolution Pi enkiderilke100% (1)

- Fuji MC SelectionDocumento14 pagineFuji MC SelectionmasakpNessuna valutazione finora

- Low Voltage Change-over and Transfer Switches GuideDocumento116 pagineLow Voltage Change-over and Transfer Switches GuideCarolina Alicia Bravo VillegasNessuna valutazione finora

- MOIen-LEFM 280C Rev 03-1 PDFDocumento76 pagineMOIen-LEFM 280C Rev 03-1 PDFDav HdzNessuna valutazione finora

- Instructions For The 15kV VCP-W 25-63ka Simple Manual Ground and Test DeviceDocumento19 pagineInstructions For The 15kV VCP-W 25-63ka Simple Manual Ground and Test Devicevanhalenfernando123Nessuna valutazione finora

- Manual Supplement: © 2006-2015 Fluke Corporation. All Rights ReservedDocumento4 pagineManual Supplement: © 2006-2015 Fluke Corporation. All Rights ReservedFaouzi TlemcenNessuna valutazione finora

- Customer ResponsibilitiesDocumento5 pagineCustomer ResponsibilitiesPedro LopesNessuna valutazione finora

- GTFM4 ManualDocumento26 pagineGTFM4 ManualRobert MeglicNessuna valutazione finora

- Simoreg PDFDocumento734 pagineSimoreg PDFRogerio Henrique SilveiraNessuna valutazione finora

- Atv31h Installation Manual en v3 PDFDocumento17 pagineAtv31h Installation Manual en v3 PDFp_inesNessuna valutazione finora

- Manual Instalacion ATV31HDocumento17 pagineManual Instalacion ATV31HJWVANessuna valutazione finora

- Agilent 6890n DatasheetDocumento5 pagineAgilent 6890n DatasheetMayar SayedNessuna valutazione finora

- FXDQ-NBVE Technical Data PDFDocumento13 pagineFXDQ-NBVE Technical Data PDFLuis CarlosNessuna valutazione finora

- Customer Responsibilities: "Agilent GC, GC/MS, and Automatic Liquid Sampler (ALS) Site Preparation Guide"Documento15 pagineCustomer Responsibilities: "Agilent GC, GC/MS, and Automatic Liquid Sampler (ALS) Site Preparation Guide"محمد محمودNessuna valutazione finora

- ATV31C Installation Manual en 1624729 04Documento18 pagineATV31C Installation Manual en 1624729 04Muhammad AkbarNessuna valutazione finora

- Agilent GC, MSD, and ALS: Site Preparation ChecklistDocumento14 pagineAgilent GC, MSD, and ALS: Site Preparation ChecklistHamidNessuna valutazione finora

- 6RA70 Operating Instruction - Total-Rev10Documento728 pagine6RA70 Operating Instruction - Total-Rev10Laur IriNessuna valutazione finora

- Laboratorios Tabasco - A - 03072017 - 1544 03 de JULIODocumento9 pagineLaboratorios Tabasco - A - 03072017 - 1544 03 de JULIOantonio lopezNessuna valutazione finora

- BCM184E - Technical Data SheetDocumento8 pagineBCM184E - Technical Data Sheet3efooNessuna valutazione finora

- Sola Transformer SelectionDocumento6 pagineSola Transformer SelectionchandruhbkkNessuna valutazione finora

- Service: ManualDocumento54 pagineService: ManualElseven AkifNessuna valutazione finora

- Allen Bradley - PowerFlex 400Documento28 pagineAllen Bradley - PowerFlex 400Marcos José Nuñez YsseleNessuna valutazione finora

- JPI FS450InstallManualDocumento9 pagineJPI FS450InstallManualMaicon FrancaNessuna valutazione finora

- VF MicroVLT DanfossDocumento102 pagineVF MicroVLT DanfossJose Arley Gil Machado100% (1)

- Mitsubishi A500 Series VFD BrochureDocumento8 pagineMitsubishi A500 Series VFD BrochureMROstop.comNessuna valutazione finora

- Ds Acopos1022 1045 1090Documento19 pagineDs Acopos1022 1045 1090Simon DrumsNessuna valutazione finora

- VRVSelectionReport Ciacova 6-11-2019!1!23 PMDocumento22 pagineVRVSelectionReport Ciacova 6-11-2019!1!23 PMCristi NechiforNessuna valutazione finora

- HS-3,4,6,7 (R) Ec-Series Installation: Important! Refer To Local Code Requirements Before Wiring MachinesDocumento53 pagineHS-3,4,6,7 (R) Ec-Series Installation: Important! Refer To Local Code Requirements Before Wiring MachinesEdwilson ReisNessuna valutazione finora

- Mill EV 5W.10W.15W Pre-Install Guide - Laser - MilllenniaDocumento10 pagineMill EV 5W.10W.15W Pre-Install Guide - Laser - MilllenniaLetalis IraNessuna valutazione finora

- Sony Hcd-s550, s880Documento138 pagineSony Hcd-s550, s880boroda2410100% (2)

- 6RA7018 6DS22 0 SiemensDocumento736 pagine6RA7018 6DS22 0 Siemensduccuong2004Nessuna valutazione finora

- BCM184H - Technical Data SheetDocumento8 pagineBCM184H - Technical Data Sheet3efooNessuna valutazione finora

- AP01200003E - Fault Current - Coordination CalculatorDocumento13 pagineAP01200003E - Fault Current - Coordination CalculatorVíctor RojasNessuna valutazione finora

- 50PJ350Documento70 pagine50PJ350jghdzmx50% (2)

- CL60A - Version 1.5 (Core Loss)Documento34 pagineCL60A - Version 1.5 (Core Loss)Asencios MiguelNessuna valutazione finora

- Agilent Models 6690A-6692A System DC Power Supply: Data SheetDocumento5 pagineAgilent Models 6690A-6692A System DC Power Supply: Data Sheetdhavala2858Nessuna valutazione finora

- TC CatalogDocumento79 pagineTC Catalogpayolin77100% (1)

- Model Predictive Control of High Power Converters and Industrial DrivesDa EverandModel Predictive Control of High Power Converters and Industrial DrivesNessuna valutazione finora

- The Requirements For Manufacturing Highly Active or Sensitising Drugs Comparing Good Manufacturing PracticesDocumento12 pagineThe Requirements For Manufacturing Highly Active or Sensitising Drugs Comparing Good Manufacturing PracticesCatrinescu OanaNessuna valutazione finora

- Phase 4 KaveriDocumento72 paginePhase 4 KaveriAtul SharmaNessuna valutazione finora

- 1 .2 Ultrapure Fittings: Fittings With Either Tri-Weld® For Orbital Welding Connections. Line in Compliance CurrentDocumento41 pagine1 .2 Ultrapure Fittings: Fittings With Either Tri-Weld® For Orbital Welding Connections. Line in Compliance CurrentAtul SharmaNessuna valutazione finora

- AminesDocumento1 paginaAminesAtul SharmaNessuna valutazione finora

- Containment Solutions: Engineered For ExcellenceDocumento11 pagineContainment Solutions: Engineered For ExcellenceAtul SharmaNessuna valutazione finora

- Detector TubeDocumento1 paginaDetector TubeAtul SharmaNessuna valutazione finora

- Fundamentals of Depth FiltrationDocumento2 pagineFundamentals of Depth FiltrationAtul SharmaNessuna valutazione finora

- Chinese GMP 2010Documento115 pagineChinese GMP 2010Atul SharmaNessuna valutazione finora

- AmmoniaDocumento1 paginaAmmoniaAtul SharmaNessuna valutazione finora

- 70Documento1 pagina70Atul SharmaNessuna valutazione finora

- Detector TubeDocumento1 paginaDetector TubeAtul SharmaNessuna valutazione finora

- Acid GasesDocumento1 paginaAcid GasesAtul SharmaNessuna valutazione finora

- AcetoneDocumento1 paginaAcetoneAtul SharmaNessuna valutazione finora

- AcetyleneDocumento1 paginaAcetyleneAtul SharmaNessuna valutazione finora

- Acetic AcidDocumento1 paginaAcetic AcidAtul SharmaNessuna valutazione finora

- AmmoniaDocumento1 paginaAmmoniaAtul SharmaNessuna valutazione finora

- AcetaldehydeDocumento1 paginaAcetaldehydeAtul SharmaNessuna valutazione finora

- API Regulatory-Starting-MaterialsDocumento4 pagineAPI Regulatory-Starting-MaterialsAtul SharmaNessuna valutazione finora

- Z-Value Calculation: August 18, 1999Documento9 pagineZ-Value Calculation: August 18, 1999atul110045Nessuna valutazione finora

- New Motor Vehicles Act ProvisionsDocumento7 pagineNew Motor Vehicles Act ProvisionsExpress Web86% (7)

- Qualification and Validation OverviewDocumento16 pagineQualification and Validation OverviewAtul SharmaNessuna valutazione finora

- 109AD - Oil - InstructionsDocumento2 pagine109AD - Oil - InstructionsAtul SharmaNessuna valutazione finora

- Bacterial-Endotoxins QAS11-452 FINAL July12 PDFDocumento13 pagineBacterial-Endotoxins QAS11-452 FINAL July12 PDFsherylqueridaNessuna valutazione finora

- BEAMEX Calibration in Regulatory EnvironmentsDocumento5 pagineBEAMEX Calibration in Regulatory Environmentsbertan dağıstanlıNessuna valutazione finora

- ISO 90012015 - Understanding The International Standard White PaperDocumento8 pagineISO 90012015 - Understanding The International Standard White PaperSanthosh MuruganNessuna valutazione finora

- Studying Supply and Demand of Software Maintenance and Evolution ServicesDocumento6 pagineStudying Supply and Demand of Software Maintenance and Evolution ServicesJorge Arturo Moreno VeasNessuna valutazione finora

- U1L2 - Definitions of 21st Century LiteraciesDocumento19 pagineU1L2 - Definitions of 21st Century LiteraciesJerry Glenn Latorre CastilloNessuna valutazione finora

- GCSE H3 02g4 02 3D TrigonometryDocumento2 pagineGCSE H3 02g4 02 3D TrigonometryAndrei StanescuNessuna valutazione finora

- Design and Simulation of Programmable AC-DC Converter Using Pulse Width Modulation (PWM) Techniques in MATLABDocumento5 pagineDesign and Simulation of Programmable AC-DC Converter Using Pulse Width Modulation (PWM) Techniques in MATLABJeannot MpianaNessuna valutazione finora

- Non-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesDocumento2 pagineNon-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesveeramalaiNessuna valutazione finora

- Republic of The Philippines Iba, Zambales: President Ramon Magsaysay State UniversityDocumento3 pagineRepublic of The Philippines Iba, Zambales: President Ramon Magsaysay State UniversityErika Joy EscobarNessuna valutazione finora

- Antenna SpecificationsDocumento2 pagineAntenna SpecificationsRobertNessuna valutazione finora

- Margin Philosophy For Science Assessment Studies: EstecDocumento11 pagineMargin Philosophy For Science Assessment Studies: EstecFeyippNessuna valutazione finora

- Individual Moving Range (I-MR) Charts ExplainedDocumento18 pagineIndividual Moving Range (I-MR) Charts ExplainedRam Ramanathan0% (1)

- RB450G Trouble ShootingDocumento9 pagineRB450G Trouble Shootingjocimar1000Nessuna valutazione finora

- Demand Performa For Annual DemandDocumento10 pagineDemand Performa For Annual DemandpushpNessuna valutazione finora

- 6.1.3 Final Exam - Exam (Exam)Documento8 pagine6.1.3 Final Exam - Exam (Exam)parker3poseyNessuna valutazione finora

- 21st Century Literature Exam SpecsDocumento2 pagine21st Century Literature Exam SpecsRachel Anne Valois LptNessuna valutazione finora

- Comparison of Waste-Water Treatment Using Activated Carbon and Fullers Earth - A Case StudyDocumento6 pagineComparison of Waste-Water Treatment Using Activated Carbon and Fullers Earth - A Case StudyDEVESH SINGH100% (1)

- The Influence of Teleworking On Performance and Employees Counterproductive BehaviourDocumento20 pagineThe Influence of Teleworking On Performance and Employees Counterproductive BehaviourCHIZELUNessuna valutazione finora

- Mock PPT 2023 TietDocumento22 pagineMock PPT 2023 Tiettsai42zigNessuna valutazione finora

- Amber ToolsDocumento309 pagineAmber ToolshkmydreamsNessuna valutazione finora

- Plenaristas León 2022xDocumento6 paginePlenaristas León 2022xGloria MontielNessuna valutazione finora

- Lesson Element Baron-Cohen Et Al. (1997) : Instructions and Answers For TeachersDocumento10 pagineLesson Element Baron-Cohen Et Al. (1997) : Instructions and Answers For TeachersSyed SumaiyahNessuna valutazione finora

- Guimaras State CollegeDocumento5 pagineGuimaras State CollegeBabarianCocBermejoNessuna valutazione finora

- Transportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDocumento11 pagineTransportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDaniel Juan De Dios OchoaNessuna valutazione finora

- Understanding Otdr Understanding-otdr-po-fop-tm-aePo Fop TM AeDocumento1 paginaUnderstanding Otdr Understanding-otdr-po-fop-tm-aePo Fop TM AeAgus RiyadiNessuna valutazione finora

- TCBE - Conversation Skills TemplateDocumento10 pagineTCBE - Conversation Skills TemplateAryoma GoswamiNessuna valutazione finora

- Materials For Oxygen ServicesDocumento4 pagineMaterials For Oxygen Services陳0鴻Nessuna valutazione finora