Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Concrete 2014 PDF

Caricato da

Harf Jucoy MirandaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Concrete 2014 PDF

Caricato da

Harf Jucoy MirandaCopyright:

Formati disponibili

CONCRETE DESIGN

Center for Professional Career Development 59

CONCRETE DESIGN

1. NOMENCLATURE

Notation to be used in the discussion complies with NSCP 2001

Ag = Gross area of section (Ac + As)

Ac = Area of concrete; gross area – area of reinforcing

As = Area of reinforcing

A’s = Area of compressive reinforcement in a doubly reinforced section

Av = Area of shear reinforcement

A1 = Loaded area in bearing

A2 = Gross area of bearing support member

D = Dead loads, or related internal moments and forces

E = Load effects of earthquake, or related internal moments and forces

Ec = Modulus of Elasticity of concrete

Es = Modulus of Elasticity of steel

L = Live loads, or related internal moments and forces

M = Design moment

V = Design shear force

a = Depth of equivalent rectangular stress block (USD)

b = Width of compression face of member

bw = Width of stem in a T-beam

c = Distance from extreme compression fiber to the neutral axis

d = Effective depth, from extreme compression fiber to centroid of tensile reinforcement

e = Eccentricity of a non-axial load, form the centroid of the section to the point of

application of the load

fc = Unit compressive stress in concrete

f’c = Specified compressive strength of concrete

fr = Modulus of rupture of concrete

fs = Stress in reinforcement

fy = Specified yield stress of steel

h = Overall thickness of member; unbraced height of a wall

jd = Length fo internal moment arm (WSD)

kd = Distance from extreme compression fiber ot the neutral axis (WSD)

n = Modular ratio of elasticity: Es/Ec

ρ = Percent of reinforcing with working strength design expressed as a ratio: As/Ag

s = Spacing of stirrups

t = Thickness of solid slab

φ = Strength reduction factor (USD)

60 Center for Professional Career Development

CONCRETE DESIGN

2. MATERIALS AND PROPERTIES OF REINFORCED CONCRETE

2.1 Concrete

CONCRETE

CEMENT WATER AGGREGATES ADMIXTURE

ASTM TYPE I - should be clean and - materials held together by - substances added to

(gen. purpose) free form injurous water-cement paste concrete to improve its

amounts of oil, acid, workability, accelerate

ASTM TYPE III alkali, organic matter its set, harden its

(high-early strength) surface, etc.

ASTM TYPE IV

(low-heat cement)

FINE COARSE

- smaller than 3/8 - larger than 3/8” in

in. in diameter, diameter, includes

includes natural crushed stone, gravel,

d slag

Strength of Concrete at 28th day, f’c

3000 psi 20.685 MPa

4000 psi 27.580 MPa

5000 psi 34.475 MPa

*1 ksi = 6.895 MPa

Modulus of Elasticity for normal weight concrete

E c = 4,700 fc' where f’c is in MPa

2.2 Steel-Reinforcement

Common Grades, fy

Grade 40 40 ksi 275.8 MPa

Grade 60 60 ksi 413.7 MPa

Sizes of Deformed Bars

Bar Diameter

Number

English Metric

3 3/8” 10 mm

4 1/2” 12 mm

5 5/8” 16 mm

6 3/4” 20 mm

8 1” 25 mm

9 9/8” 28 mm

10 1 ¼” 32 mm

***number indicates bar diameter in eights of an inch, 1” = 25 mm

Modulus of Elasticity

Es = 200 GPa = 29,000 ksi

Center for Professional Career Development 61

CONCRETE DESIGN

3. DESIGN METHODS

3.1 Working Stress Design (WSD)

SERVICE LOAD CONDITIONS – no load factors applied

ALLOWABLE STRESSES: fc = 0.45 f’c

fs = 0.5 fy → if not given

3.2 Ultimate Strength Design (USD)

REQUIRED STRENGTH – combination of factored forces

Load Combinations *extracted from NSCP 2001, p. 4-28

Dead Load and Live load: U = 1.4D + 1.7L

Dead Load, Live Load & Wind Load U = 0.75(1.4D + 1.7L +1.7W)

Dead Load and Wind Load U = 0.9D + 1.3W

Dead Load, Live Load & Earthquake U = 1.32D + 1.1(f1)L + 1.1E

f1 = 1.0 for floors of public

assembly, garage live load

and for L > 4.8 kPa

= 0.5 for other live loads

Dead Load & Earthquake U = 0.9D + 1.1E

DESIGN STRENGTH – nominal strength multiplied by strength reduction factor φ

Reduction Factors *extracted from NSCP 2001, p. 4-29

Flexure, without axial (Moment in beams) ……………….. 0.90

Axial compression w/ or w/o Flexure

(Axial load and Moment in Tied columns) ………... 0.70

(Axial load and Moment in Spiral columns)……….. 0.75

Shear and Torsion ………………………………………….. 0.85

Bearing on concrete ………………………………………... 0.70

62 Center for Professional Career Development

CONCRETE DESIGN

4. LOAD ANALYSIS

4.1 SLABS

Sn

4.1.1 ONE WAY SLAB – when m = < 0.5

Ln

Sn

AREA LOAD ON SLAB:

• DEAD LOAD – slab weight and floor fixed loads

D = Wslab + WSDL

D = γ c ⋅ t + WSDL

Ln 1m • LIVE LOAD – depends on type of occupancy

• REQUIRED FLOOR LOAD

o WSD: W = D + L

o USD: Wu = 1.4D + 1.7L

• UNIFORM TRIBUTARY LOAD

w

o WSD: w = W × 1

o USD: wu = Wu × 1

L

1m

B

w w w

Center for Professional Career Development 63

CONCRETE DESIGN

Sn

4.1.2 TWO WAY SLAB – when m = ≥ 0.5

Ln

Sn PANEL abcd

Ln

a b

Ln

d c

4.2 BEAMS

S1 S2

45° 45°

ω2

WS 2

2

WS1 3 − m2

ω1 = L ω1 ω1 ω3 ω3 ω 3 = ω 2

2

2

WS 2

ωb 2 ωb ωb

ω2

45° 45°

WS 2

2

ωb

h−t h TRIBUTARY LOAD

ωb

WS 2

ω2 =

REMAINING BEAM 3

WEIGHT ωb EQUIVALENT UNIFORM

ω b = γ c b (h − t ) TRIBUTARY LOAD

ωb

ω ub = 1.4 ⋅ γ c b (h − t )

64 Center for Professional Career Development

CONCRETE DESIGN

4.3 COLUMNS

A B C D

S1 S2 S3

L1

L2

• REQUIRED LOAD

o WSD: W = D + L

o USD: Wu = 1.4D + 1.7L

• TRIBUTARY COLUMN LOAD PER FLOOR

( )

o WSD: P = W × S × L + ω b × S + L ( )

o USD: ( )

Pu = Wu × S × L + ω ub × S + L ( )

5. GENERAL REQUIREMENTS OF REINFORCED CONCRETE STRUCTURES

5.1 MINIMUM CONCRETE COVER, IN SITU

*based from NSCP 2001, p. 4-20

Exposed to earth (ex. Foundation slab, tie beams)……….………. 75 mm

Exposed to weather (ex .exterior beams and columns)…..………. 50 mm

Not exposed to weather (ex .interior beams and columns)………. 40 mm

Slabs and walls……………………………………………………...… 20 mm

5.2 SPACING OF REINFORCEMENT

5.2.1 SLABS

MAXIMUM SPACING = 3t or 450 mm

S S

20 mm clear cover

Center for Professional Career Development 65

CONCRETE DESIGN

5.2.2 BEAMS

b b

Clear concrete cover

cc ≥ 40 mm

Stirrup or tie

Bars in double layer Bundled bars

vcs ≥ 25 mm

cs ≥ d b and 25 mm cs ≥ d e = n d b

5.2.3 COLUMNS

1.5db but not less than 40mm

5.3 HOOKS AND BENDS

*NSCP, 407

ldb ≥ 150 mm

≥ 8db

Bend diameter:

6db → db is 10 - 25mm

6db 12d

stirrup / tie D = 8db → db is 28 - 32mm

b

10db → db is 36 mm

32mm

ldb ≥ 150 mm

≥ 8db

Bend diameter:

6db → db is 10 - 25mm

D = 8db → db is 28 - 32mm

10db → db is 36

4db

( )

32mm

mm

65mm

min

66 Center for Professional Career Development

CONCRETE DESIGN

6. FLEXURAL BEHAVIOR OF BEAMS

x

x

R1 R2

x b

∑ Fh = 0

C

c C=T

jd V d

N M A

∑ Mx − x = 0

0 = R1(x ) − C( jd )

T R1(x ) = C( jd ) = T( jd )

x

R1

6.1 STAGES OF FAILURE

6.1.1 UNCRACKED STAGE – concrete resists compression and tension with concrete

tensile stress below modulus of rupture, fr = 0.7 f 'c or when moment is less

than cracking moment…

NSCP 2001 PROVISION:

fr ⋅ Ig

6.1.2 CRACKING MOMENT, Mcr =

ct

6.1.3 CRACKED STAGE – member carries bending moment greater than cracking

moment where concrete in tension cracks, steel carries all the tensile force,

stresses are below elastic range

6.1.4 ULTIMATE STRENGTH STAGE (COLLAPSE STAGE) – member collapses

either by crushing of concrete of yielding of steel bars

DISTRIBUTION OF STRESSES

fc fc f’c

C C C

c

c c

NA

d d

NA jd jd

T T T

fct

CRACKED STAGE COLLAPSE STAGE

UNCRACKED STAGE (WORKING STRESS) (ULTIMATE STRENGTH)

Center for Professional Career Development 67

CONCRETE DESIGN

6.2 FLEXURE FORMULA, Working Stress Design (WSD)

Singly Reinforced Rectangular Beam (SRRB)

Straight-line stress distribution (triangular compressive stress block)

Maximum allowable compressive stress of 0.45f’c

Maximum allowable tensile stress on steel of 0.5fy (if not given)

b b

fc x/3

x C

NA

h M d

jd

d-x

As

T

fs

n

BEAM SECTION TRANSFORMED SECTION STRESS DIAGRAM

TRANSFORMED SECTION METHOD

E

Modular Ratio, n= s

Ec

Location of Neutral Axis - ΣMNA = 0 and solve for x

x2

b = nA s (d − x )

2

Moment of Inertia of transformed section – inertia about the N.A.

I NA =

( )

b x3

+ nA s (d − x )2

3

1

Compressive force, C = fc (xb ) → volume of stress block

2

Tensile force, T = A s fs

x x

Resisting Moment, M = C d − = T d −

3 3

M(x )

Extreme concrete stress, fc =

I NA

M(d − x )

Steel bar stress, fs = n

INA

68 Center for Professional Career Development

CONCRETE DESIGN

GENERAL EQUATIONS FOR SRRB.

b

fc kd/3

kd C

NA

h M d

jd

As

T

BEAM SECTION ELASTIC STRESS DIAGRAM

Es

Modular ratio, n=

Ec

As

Steel ratio, ρ=

bd

k= (ρn)2 + 2ρn − ρn

k

j = 1−

3

1

Compressive force, C = fc kdb Resisting Moment, M = Cjd

2

1 2M

Actual concrete stress, M = fc kdb( jd ) → fc =

2 bd2kj

Tensile force, T = A s fs Resisting Moment, M = Tjd

M

Actual Steel Stress, M = A s fs ( jd ) → fs =

A s jd

DESIGN FOR BALANCED SECTION

When there is simultaneous limiting stresses in the concrete and steel

1

kb =

fs

1+

nfc

Balanced steel ratio

kfc

ρbal =

2fs

Center for Professional Career Development 69

CONCRETE DESIGN

LOAD ANALYSIS PROBLEMS:

SIT. A: Reinforced concrete beams DF, BE and EH are 300 mm wide and 500 mm deep below the

slab, spaced 2.5 m on centers. The beams support a monolithic slab 100 mm thick

carrying superimposed dead load of 2 kPa and live load of 4.8 kPa. Concrete weighs 24

kN/m3. Determine the following:

1. Total service floor load.

2. Total factored floor load.

3. The factored uniform load supported by beams BE and EH.

4. The factored uniform load supported by beams DF.

5. The maximum ultimate positive and negative bending moments that must be sustained by

beams BE and EH assuming simple supports at B, E and H.

6. The maximum ultimate positive bending moment that must be sustained by beam DF

assuming simple supports at D and F.

4.5 m 4.5 m

G

A D

2.5 m

B E H

2.5 m

F I

C

SIT. B: A typical floor framing plan of a 4-storey building with roof deck is shown in the following

figure. Reinforced concrete columns are 400 mm square and beams are 300 mm wide and

600 mm deep spaced 2.5 m on centers. The beams support a slab 100 mm thick carrying

superimposed dead load of 3 kPa and live load of 2.9 kPa. Concrete weighs 24 kN/m3.

5.6 m 6m

B C

A

2.5 m

D E F

2.5 m

G H I

2.5 m

J K L

70 Center for Professional Career Development

CONCRETE DESIGN

7. Estimate the axial load carried by column E at the fourth floor from total factored floor load using

tributary area method.

8. Estimate the axial load carried by column E at the ground floor from total factored floor load

using tributary area method.

9. Calculate the factored uniform load on 1-m strip of slab ABED.

10. Calculate the ultimate bending moments for the design of slab ABED by ACI Coefficients

Method.

11. Calculate the factored uniform load on girders DE and EF.

12. Calculate the ultimate bending moments for the design of girder DE and EF by ACI Coefficients

Method.

13. Calculate the shear force at faces of supports for members DE and EF by ACI Coefficients

Method.

NSCP PROVISION : ACI MOMENT COEFFICIENTS

2

POSITIVE MOMENT Mu = Cw uln

End spans

Discontinuous end unrestrained…………………….. 1/11

Discontinuous end integral with support……………… 1/14

Interior spans…………………………………………. 1/16

2

NEGATIVE MOMENT Mu = Cw uln

At exterior face of first interior support

Two spans……………………………………………... 1/9

More than two spans…………………………………. 1/10

At other faces of interior supports…………………….. 1/11

At face of all supports for slabs with spans not exceeding 3 meters; and

beams where ratio of sum of column stiffness to beam stiffness exceeds

eight at each end of the span…………………………………….

1/12

At interior face of exterior support for members built integrally with supports:

Where support is a spandrel beam…………………

1/24

Where support is a column………………………….

1/16

SHEAR

1.15

At face of first interior support …………………… w uln

2

1

At face of all other supports ……………………….. w uln

2

Where C = coefficient

wu = factored floor load

ln = CLEAR span for +M and V;

= AVERAGE adjacent CLEAR span for -M

Center for Professional Career Development 71

CONCRETE DESIGN

BEAM DESIGN AND ANALYSIS BY WSD:

SIT. A: A hollow beam with cross-section given below is simply supported over a span of 4 m. The cracking

moment of the beam is 78 kN·m.

300 mm

150 mm 600 mm

1. Find the maximum uniform load in kN/m the beam can carry without cracking.

2. Calculate the modulus of rupture in MPa of concrete used for the beam.

3. If the hollow part of the beam is replaced with a square of side 200 mm, what is the new cracking

moment in kN·m?

SIT. B: A rectangular beam 300 mm x 500 mm reinforced with 3-φ28 mm bars having its centroid 75 mm

from the bottom edge of the beam. Use f’c = 21 MPa and fy = 275 MPa.

1. Calculate the elastic bending stresses if is to sustain a dead load moment of 30 kN∙m and live load

moment of 40 kN∙m.

2. Calculate the safe bending moment the beam can sustain without exceeding allowable stresses

under working load conditions.

SIT. C: The dimensions of the reinforced concrete T-beam in the figure below are b1 = 500 mm, h1 = 150

mm, b = 250 mm and h = 500 mm. If n = 8 and As = 3300 mm2, determine the following:

1

h1

1. The maximum stress produced in concrete by a positive bending moment of 120 kN-m

2. The maximum stress produced in steel.

3. The maximum bending moment applied without exceeding fc = 12 MPa and fs = 140 MPa.

SIT. D: A rectangular concrete beam of concrete with f’c = 21 MPa and steel reinforcing with fs = 138 MPa

must sustain a total service uniform load of 50 kN/m over a simple span of 5 m. Select the beam

dimensions and the reinforcing for a section with tension reinforcing only. Assume b = 0.56d, db = 20

mm, stirrup diameter = 10 mm.

72 Center for Professional Career Development

CONCRETE DESIGN

6.3 FLEXURE FORMULA, Ultimate Strength Design (USD)

Uniform stress of 0.85f’c replaces the non-linear stress distribution on concrete compression

area from extreme compression fiber to a depth of “a”

Depth of equivalent rectangular stress block, a = c ⋅ β1

β1 = 0.85 → for f'c ≤ 30 MPa

0.05

β1 = 0.85 − (f' c − 30) → for f' c > 30 MPa

7

Linear distribution of strain

Concrete cracks at a maximum strain of concrete, εc = 0.003

fs

Steel strain, ε s =

Es

GENERAL SINGLY REINFORCED BEAM (SRB)

Ac 0.85f’c 0.003

z

c a C

NA

d

d−z

As

Ts εs

STRESS BLOCK STRAIN DIAG

BASIC EQUATIONS OF USD

Compression on Concrete C = 0.85f ' c A c

600(d − c )

Steel tensile stress at εconc = 0.003 fs = < fy

c

Non Yielding Tension on steel, fs < fy ( ) T = A s fs

Yielding Tension on steel, fs ≥ fy( ) T = A s fy

Mn = C ⋅ (d − z )

Nominal Moment Strength

Mn = T ⋅ (d − z )

φMn = 0.9 ⋅ C ⋅ (d − z )

Design Moment Strength

φMn = 0.9 ⋅ T ⋅ (d − z )

Center for Professional Career Development 73

CONCRETE DESIGN

6.3.1 Singly Reinforced Rectangular Beams (SRRB)

b

a/2 0.85f’c εc = 0.003

a C = 0.85f 'c ab c

h d NA

d – a/2

As

T = A s fy

STRESS εs = fs E s

STRAIN

SRRB BASIC EQUATIONS:

A s fy

[C = T] → a =

0.85f 'c b

ρfy d As

1. STATIC EQUILIBRIUM, a= where ρ =

0.85f 'c bd

ωd ρfy

a= where ω =

0.85 f 'c

a

φMn = 0.9 ⋅ C ⋅ d −

2

2. DESIGN MOMENT CAPACITY,

a

φMn = 0.9 ⋅ T ⋅ d −

2

ρfy

FLEXURE EQUATIONS: φMn = 0.9 ⋅ ρfy bd2 1 − 0.59

f 'c

φMn = 0.9 ⋅ bd2 ⋅ f 'c ω ⋅ (1 − 0.59ω)

NSCP 2001 PROVISIONS

MINIMUM TENSION STEEL RATIO

f 'c 1.4

ρmin = but not less than

4fy fy

MAXIMUM TENSION STEEL RATIO

ρmax = 0.75ρbal

74 Center for Professional Career Development

CONCRETE DESIGN

BALANCED CONDITION

When there is simultaneous yielding of concrete and steel

600 ⋅ d

cb =

600 + fy

BALANCED STEEL RATIO

f 'c 600

ρbal = 0.85 ⋅ β1 ×

fy 600 + fy

DETERMINATION OF STEEL AREA

(GIVEN Mu and beam dimensions)

METHOD 1: METHOD 2:

Mu = φMn Mu = φMn

Mu = 1.4MDL + 1.7MLL Mu = 1.4MDL + 1.7MLL

φM = φ0.85f ' ab d − a φMn = φbd f ' c ω ⋅ (1 − 0.59ω)

2

n c

2 CALCULATE ω

CALCULATE a

ωf ' c

ρ=

0.85f 'c ab fy

As =

fy

ρ < ρ min → A s = ρminbd

A s < A s min → A s = A s min = ρminbd ρ ≤ ρmax → A s = ρbd

A s > A s min → redesign as DRB ρ > ρmax → redesign as DRB

DETERMINATION OF MOMENT CAPACITY

(GIVEN beam dimensions and tension steel bars)

METHOD 1: METHOD 2:

[C = T ] ρ=

As

600(d − c ) bd

0.85f ' c (a = cβ1 )b = A s fs =

c ρ fy

ρ < ρbal STEEL YIELDS, ω =

CALCULATE c, fs and check f 'c

fs < fy NON YIELDING STEEL, T = A s fs , a = cβ1 ρfs

ρ > ρbal NON YIELING STEEL, ω =

f 'c

φMn = φA s fs ⋅ (d − a / 2 )

C=T

A s fy 600(d − c )

fs ≥ fy STEEL YIELDS, max T = A s fy , a = 0.85f ' c (a = cβ1 )b = A s fs =

0.85f ' c b c

φMn = φA s fy ⋅ (d − a / 2 ) φMn = φbd2 f ' c ω ⋅ (1 − 0.59ω)

Center for Professional Career Development 75

CONCRETE DESIGN

6.3.2 Doubly Reinforced Beam ( ρSRB > ρmax )

b

0.85f’c εc = 0.003

C’ = A’sf’s

d’ C = 0.85f’cab A’s

A’s a f 's

c ε' s =

Es

d = φMn1 d – a/2 + φMn2 d – d’

Mu

As As1 As2

T1 = As1fy

T2 = As2fy εy = fy Es

DRB SRB STRESS COUPLE

BLOCK BARS STRAIN

MDRB = MSRB + MCouple bars

A’s = compression bars

As = tension bars = As1 + As2

Asmax = ρmaxbd + A’s(fy/f’s)

DESIGN ANALYSIS

(Given Mu, required As & A’s) (Given As & A’s, required φMn )

=

A s A s1 + A s2 φMn = φMn1 + φMn2

A s1 = ρmax bd

a

a A s1fy φMn = φ0.85f 'c ab d − + φA 's f 's ( d − d' )

=

from =

C T: a = c 2

0.85f'c b β1 from C + C' = T

a 0.85f 'c ab + A 's f 's =A s fy → (1)

φMn1 =φA s1fy d −

2

a = cβ1 → ( 2 )

φMn2= Mu − φMn1

from strain diagram

φM= A s2 fy ( d − d' ) → solve A s2

600 ( c − d' )

n2

A 's f 's = A s2 fy =f 's → (3)

c

from strain diagram :

Calculate “c”

0.003 f 's Es

= Check yielding of “f’s”

c c − d'

600 ( c − d' ) f 's < fy , use f 's

f 's =

c f 's ≥ fy , use fy → recalculate "c "

f 's ≥ fy , use fy → A 's = A s2

fy

f 's < fy , use f 's → A 's =

A s2 ***You can also first assume that A’s yielded and

f 's check after.

76 Center for Professional Career Development

CONCRETE DESIGN

6.3.3 T-BEAMS

EFFECTIVE FLANGE WIDTH, bf

Interior Beam bf bf Exterior Beam

b f = 8t t + 8t 2 + b w t1 t2 t3

=

b f 6t 3 + b w

= L/4

= L /12 + b w

S1 + S2

= + bw S3

2 S1 S2 S3 = + bw

bw bw 2

b f = smallest

b f = smallest

NSCP Provision:

5.8.10.1 In T-beam construction, the flange and web shall be built integrally or otherwise effectively bonded

together.

5.8.10.2 Width of slab effective as a T-beam flange shall not exceed one-quarter of the span length of the

beam, and the effective overhanging flange width on each side of the web shall not exceed:

a) eight times the slab thickness, and

b) one-half the clear distance to the next web.

5.8.10.3 For beams with a slab on one side only, the effective overhanging flange width shall not exceed:

a) one-twelfth of the span of the beam,

b) six times the slab thickness, and

c) one-half the clear distance to the next web.

5.8.10.4 Isolated beams, in which the T-shape is used to provide a flange for additional compression area,

shall have a flange thickness not less than one-half the width of web and an effective flange width

not more than four times the width of the web.

Center for Professional Career Development 77

CONCRETE DESIGN

6.3.3.1 WITHOUT T-ACTION, Wide Rectangular Beam

Compression area is within the flange only

The beam behaves as a wide RECTANGULAR beam

a < tf

bf 0.85f’c

a Cf = 0.85f’cabf

tf

d φMn

h d – a/2

As

T = Asfy

T-BEAM STRESS BLOCK

W/o T-action for the Flange

DESIGN ANALYSIS

(Given Mu, required As) (Given As, required φMn )

Assume : a = tf Assume as wide rectangular beam :

t A s fy

φMf =φ0.85f 'c t f b d − f calculate a=

2 0.85f 'c b f

φMf ≥ Mu → design as w/o T - action a ≤ t f → analyze w/o T - action

φMf < Mu → design w/ T - action a > t f → analyze w T - action

a a

Mu =φA s fy d − φMn = φA s fs d −

2 2

A s fy from C = T

a=

0.85f 'c b f A s fs

a=

Calculate As by quadratic formula 0.85f'c b f

Check minimum requirements: from strain diagram:

A 600d a

ρ= s =

c = → calculate fs

bw d 600 + fs β1

ρ > ρmin → ok check : if fs ≥ fy , use fy

ρ ≤ ρmin → A s = ρminb w d if fs < fy , use fs

78 Center for Professional Career Development

CONCRETE DESIGN

6.3.3.2 WITH T-ACTION

Compression area composed of flange and portion of web.

bf

0.85f’c 0.85f’c εc = 0.003

Cw = 0.85f’cabw tf Cf = 0.85f’ctf(bf-bw)

a

tf c

d φMn2

h d – a/2 φMn1 d – tf /2

As

T1 = As1fy T2 = As2fy

εs = fy Es

T-BEAM STRESS BLOCK STRESS BLOCK

with T-action for the Web for the Flange STRAIN

DESIGN ANALYSIS

(Given Mu, required As) (Given As, required φMn )

=

A s A s1 + A s2 φMn = φMn1 + φMn2

φ0.85f 'c t f ( b f − b w )( d − t f 2 )

φMn2 = φ0.85f 'c t f ( b f − b w )( d − t f 2 )

φMn2 =

φA s2 fy ( d − t f 2 )

φMn2 = from Cf = T2

or from Cf = T2 : 0.85f 'c t f ( b f − b w ) =

A s2 fy

0.85f 'c t f ( b f − b w ) =

A s2 fy A=

s1 A s − A s2

φMn1

= Mu − φMn2 a

φMn1 = φA s1fs d −

a 2

φMn2 = φA s1fy d −

2 Check yielding of " A s1 "

from Cw = T1 from Cw = T1

A s1fy A s1fs

a= a= = cβ1

0.85f 'c b w 0.85f 'c b w

Calculate " A s1 " by quadratic formula from strain diagram :

600 ( d − c )

Check “As” for maximum requirements fs =

d

A smax = 0.75A sbal

Calculate “c” simultaneously

From Cf + Cw =

T

Calculate “fs”

0.85f 'c t f ( b f − b w ) + abalb w

A sbal =

fy

= c balβ1

abal

Center for Professional Career Development 79

CONCRETE DESIGN

BEAM DESIGN AND ANALYSIS PROBLEMS:

SIT. E: The service load bending moments on a rectangular beam 250 mm wide are 78.6 kN-m for dead load and

51.5 kN-m for live load. If f’cgv = 27 MPa and fy = 414 MPa, determine the depth of the beam and the required

area of tension reinforcing. Assume ρ = 0.6ρb , db = 20 mm, ds = 10 mm.

SIT. F: A 12 m simply supported beam is provided by an additional support at mid span. A superimposed dead load

of 4.95 kN/m and service live load of 24.57 kN/m is to be carried in addition to the self-weight of the beam.

The beam has a constant rectangular section with b = 300 mm and a total depth h = 450 mm and

reinforcement is to be varied according to requirements. Allow concrete cover to bar centroid of 70 mm, fy =

415 MPa and f’c = 30 MPa. Use 0.75ρb = 0.023 and ρmin = 0.0033

1. Determine the required tensile area for positive bending.

2. Determine the required tensile area for negative bending.

SIT. G: A rectangular concrete beam is 350 mm wide and 700 mm deep. It is reinforced at the bottom with 5-φ32 mm

bars and at the top with 3-φ28 mm bars. Steel covering to bar centroid is 70 mm at the top and at the bottom

of the beam. Use f’c = 21 MPa and fy = 415 MPa

3. Calculate the design moment capacity of the beam section in negative bending.

4. Calculate the design moment capacity of the beam section in positive bending.

5. If the beam is simply supported over a span of 6-m with a 2-m overhang determine the maximum factored

load in kN/m the beam can support.

SIT. H: A rectangular section is limited to a size of b = 350 mm and h = 700 mm to carry a factored moment of 1,500

kN⋅m. Assume that bars in compression will be placed at 70 mm from the compression face and bars in

tension 80 mm from the tension face. Given that f’c = 28 MPa and fy = 415 MPa design the steel requirements

of the cross section.

SIT. I: The typical T-section results from the monolithic construction of the slab and its supporting beams.

Effective flange width bf = 1250 mm

Slab thickness t = 120 mm

Web width bw = 350 mm

Total depth below the slab h = 480 mm

Top reinforcement 3 – ϕ25 mm

Bottom reinforcement 5 – ϕ25 mm

f’c = 20.7 MPa

fy = 415 MPa

Concrete cover to the centroid of reinforcements = 70 mm

Balanced Steel Ratio ρb = 0.021

6. Determine the nominal bending strength for positive moment

7. Find the nominal bending strength for negative moment.

SIT. J: A monolithic floor system consists of 100 mm thick slabs and simply supported beams with a 7.3 m span, 1.2

m on centers. The floor carries a superimposed dead load of 1.15 kPa and live load of 1.9 kPa. Walls

weighing 2.8 kPa and 2.4 m high are directly supported by the beams. Beam dimensions, as determined by

negative moment requirements at supports, are bw = 275 mm and h = 500 mm. Concrete weights 24 kN/m^3.

8. Determine the total factored load to be carried by an interior beam in kN/m.

9. Determine the effective flange width of the interior beam in mm according to NSCP 2001 provisions.

10. Determine the required amount of steel reinforcement at mid-span of a typical interior beam. Use concrete

compressive strength f’c = 21 MPa and steel strength fy = 275 MPa. Assume 20 mm bar diameter for flexure

and 10 mm for stirrups.

80 Center for Professional Career Development

CONCRETE DESIGN

Center for Professional Career Development 81

CONCRETE DESIGN

82 Center for Professional Career Development

CONCRETE DESIGN

Center for Professional Career Development 83

CONCRETE DESIGN

PROBLEMS:

SIT. A: The floor framing plan shown in the figure is to be designed to carry a service live load of 4.8 kPa and dead

load of 1.75 kPa which includes floor finish, ceiling finish, partition and miscellaneous loading. The concrete

slab is 100 mm thick, beams AD, BE and CF are 250 mm wide and 350 mm deep below the slab, beams AC

and DF are 350 mm wide and 450 mm deep below the slab. Concrete weighs 24 kN/m3.

1. Assuming that beam BE is simply supported, calculate the factored shear force at critical section for shear

using concrete cover from tensile bar centroid 70 mm.

2. Determine the required spacing of 10 mm stirrups using f’c = 21 MPa and fy = 275 MPa.

3. At what section from the face of the left support are stirrups not required?

SIT. B: A rectangular beam having b = 300 mm and d = 560 mm, spans 6.1 m face-to-face of simple supports. It is

reinforced for flexure with three 36 mm bars that continue uninterrupted to the ends of the span. It is to carry

service dead load D = 23.8 kN/m (including self-weight), and service live load L = 47.6 kN/m, both uniformly

distributed along the span.

1. Design the shear reinforcement, 10-mm-diameter stirrups, using simplified calculation of shear strength of

concrete. Material strengths are fy = 415 MPa and f’c = 28 MPa.

2. Redesign the shear reinforcement using more detailed calculation of shear strength of concrete.

SIT. C: A column section shown is reinforced with 8-ϕ32 mm bars, with clear concrete cover of 40 mm for the 12 mm

ties. Due to reversal of lateral forces, the design loads due the reversal effect of combined DL, LL and WL

changes as follows:

84 Center for Professional Career Development

CONCRETE DESIGN

1. Determine the nominal shear strength of concrete for the positive x direction using simplified calculation with

concrete strength f’c = 28 MPa and fy = 415 MPa.

2. Determine the nominal shear strength of concrete for the negative x direction using simplified calculation.

3. Recalculate using more detailed calculation.

SIT. D: A rectangular tied column is reinforced as shown in the detail below. Clear cover to the 12 mm ties is 40 mm.

Use f’c = 28 MPa, vertical bars strength fy = 415 MPa and tie bars strength fyh = 278 MPa

1. Calculate the nominal strength of the column against shear along the x-direction if ties and cross-ties are

spaced 100 mm on centers.

2. Calculate the ultimate shear along the y-direction the column can sustain if ties and cross-ties are spaced 100

mm on centers.

3. Calculate the required spacing of transverse reinforcement for a factored shear force Vux = 450 kN if the

allowable nominal concrete shear stress is 0.88 MPa.

4. Calculate the required spacing of transverse reinforcement in accordance with the code for seismic design if

shear is along the x-direction.

5. Calculate the required spacing of transverse reinforcement in accordance with the code for seismic design if

shear is along the y-direction.

Center for Professional Career Development 85

CONCRETE DESIGN

86 Center for Professional Career Development

CONCRETE DESIGN

Center for Professional Career Development 87

CONCRETE DESIGN

88 Center for Professional Career Development

CONCRETE DESIGN

P ROBLEMS:

SIT. E: A rigidly supported beam with cross-section detail shown below supports a uniform service dead

load of 58.38 kN/m and service live load of 87.56 kN/m over its span of 4.3 m. In addition the

beam is also subject to uniform torsional moment due to service dead load of 6.31 kN∙m/m and due

to service live load of 7.57 kN∙m/m over its entire span. Concrete compressive strength f’c = 28

MP. Use 12 mm diameter stirrups with 40 mm clear cover.

1. Calculate the nominal cracking torsion.

2. Calculate the maximum shear stress in the beam due to combined shear and torsion.

3. Calculate the spacing of stirrups required for shear only. Use fy = 415 MPa.

4. Calculate the spacing of stirrups required for torsion only.

5. Calculate the spacing of stirrups required for shear and torsion.

6. Calculate the required additional longitudinal bars for torsion.

Center for Professional Career Development 89

CONCRETE DESIGN

90 Center for Professional Career Development

CONCRETE DESIGN

Center for Professional Career Development 91

CONCRETE DESIGN

92 Center for Professional Career Development

CONCRETE DESIGN

PROBLEMS:

SIT. A: To comply with architectural requirements, a column in a non-sway frame is of T-section as shown.

Given data:

Longitudinal bars: As = 4 – ø28 mm bars

fy = 415 MPa

Lateral ties: dt = ø12 mm bars

fyv = 275 MPa

Clear concrete cover = 40 mm

Concrete: f’c = 27.5 MPa

Consider bending about strong axis. Neglect the concrete area displaced by the steel bars.

1. Determine the location of the plastic centroid of the section from the right face of the column.

2. Determine the bending moment, in kN⋅m, induced by a factored load Pu = 3200 kN acting along x-

axis at 400 mm away from the right face of the column.

SIT. B: A tied column 450 mm square is reinforced with 8-ϕ28 mm equally distributed on its sides. The

unsupported length of the column is 2.6 m and is prevented against sidesway by shear walls. Use

40 mm clear covering to the tie reinforcement with diameter 12 mm, f’c = 20.7 MPa, fy = 415 MPa

and Es = 200 GPa

3. Determine the nominal load in kN that the column could carry.

4. Determine the nominal balanced load in kN using concrete strain of 0.003 and yield strain of steel

εy = fy/Es.

5. Determine the nominal balanced moment capacity of the column.

6. Determine the nominal moment capacity when the factored axial load is 900 kN.

Center for Professional Career Development 93

CONCRETE DESIGN

94 Center for Professional Career Development

CONCRETE DESIGN

Center for Professional Career Development 95

CONCRETE DESIGN

96 Center for Professional Career Development

CONCRETE DESIGN

Center for Professional Career Development 97

CONCRETE DESIGN

98 Center for Professional Career Development

CONCRETE DESIGN

Center for Professional Career Development 99

CONCRETE DESIGN

100 Center for Professional Career Development

CONCRETE DESIGN

Center for Professional Career Development 101

CONCRETE DESIGN

102 Center for Professional Career Development

CONCRETE DESIGN

Center for Professional Career Development 103

CONCRETE DESIGN

PROBLEMS:

SIT. A: A 400 mm square column is supported by rectangular footing 3.0 m by 4.0 m with effective depth 350 mm.

Column Axial Loads: D = 420 kN

L = 360 kN

E = 210 kN

Column Moment due to Earthquake: ME = 160 kN-m (along 4.0 m dimension)

Required Strength: U = 1.32D + 1.1L + 1.1E

1. Calculate the maximum ultimate soil bearing stress.

2. Calculate the maximum nominal beam shear stress in MPa.

3. Calculate the nominal punching shear stress in MPa.

104 Center for Professional Career Development

CONCRETE DESIGN

SIT. B: A wall footing is required for a 350 mm-thick concrete wall carrying uniform dead load of 160 kN/m and

uniform service live load of 200 kN/m. Material properties used are as follows: γc = 24 kN/m3, γs = 16

kN/m3, qa = 170 kPa, f’c = 21 MPa and fy = 275 MPa for bar diameter 16 mm.

1. Calculate the minimum width of the footing slab for a 1-m design strip.

2. Calculate the required thickness of the footing slab.

3. Calculate the spacing of 16 mm longitudinal bars for flexure.

SIT. C: A 400 mm square column shown is supported by square footing on 5 piles 300 mm diameter each. Ultimate

pile capacity of 320 kN.

Column Axial Loads: Due to dead load, D = 420 kN,

Due to live load, L = 360 kN,

Due to earthquake, E = 210 kN

Column Moment due to Earthquake: ME = 160 kN-m

Required Strength: U = 1.32D + 1.1L + 1.1E

P

ME

600 mm

0.75 m

2.00 m

0.75 m

0.75 m 2.00 m 0.75 m

1. Calculate the ultimate critical beam shear stress in MPa on the pile cap.

2. Calculate the ultimate punching shear stress in MPa on the pile cap.

3. Calculate the maximum design moment in kN-m on the pile cap.

Center for Professional Career Development 105

CONCRETE DESIGN

106 Center for Professional Career Development

CONCRETE DESIGN

Center for Professional Career Development 107

Potrebbero piacerti anche

- Ref Nov 17 DesDocumento32 pagineRef Nov 17 DesPrances Pabillore CloribelNessuna valutazione finora

- Sample Problem 1Documento14 pagineSample Problem 1Fritz Luzon100% (1)

- Final PDFDocumento69 pagineFinal PDFKenneth CabarNessuna valutazione finora

- RCD Sample ProblemDocumento3 pagineRCD Sample ProblemRicci Marcelo ÜNessuna valutazione finora

- Maximum Stresses On A Pole Subjected To Combined LoadingsDocumento2 pagineMaximum Stresses On A Pole Subjected To Combined LoadingsShiela GonzalesNessuna valutazione finora

- RCD Slab - Module Take Home Exam AnswersDocumento2 pagineRCD Slab - Module Take Home Exam AnswersAnna Mharize Tano100% (1)

- N M (Joules) FT LB Newton LB M FT: Inhinyero Review CenterDocumento4 pagineN M (Joules) FT LB Newton LB M FT: Inhinyero Review CenterAngelo PlumosNessuna valutazione finora

- Steel Design 1Documento26 pagineSteel Design 1Gracielle NebresNessuna valutazione finora

- MSTEDocumento13 pagineMSTEHann OrillaNessuna valutazione finora

- Ot Online Quiz Ce181Documento8 pagineOt Online Quiz Ce181Chrispin BarnigoNessuna valutazione finora

- Module1 IntroductionDocumento13 pagineModule1 Introductionmarlo ignacioNessuna valutazione finora

- Conc 1 - Nov 2020Documento2 pagineConc 1 - Nov 2020Glenn CalingasanNessuna valutazione finora

- Irrigation Activity No. 1Documento6 pagineIrrigation Activity No. 1Jeiel ValenciaNessuna valutazione finora

- Design and Analysis For ShearDocumento20 pagineDesign and Analysis For Shearhonesto reynaNessuna valutazione finora

- Steel Design INSTRUCTION: Read and Understand Each Problem CarefullyDocumento3 pagineSteel Design INSTRUCTION: Read and Understand Each Problem CarefullyRoma Raquepo RingorNessuna valutazione finora

- Welded ProblemsDocumento6 pagineWelded ProblemsIan BondocNessuna valutazione finora

- UntitledDocumento19 pagineUntitledRojane FloraNessuna valutazione finora

- RCD Reinforced Concrete Design Feu 2019Documento4 pagineRCD Reinforced Concrete Design Feu 2019Josephbraken Balderama Labacanacruz100% (1)

- CE Board Problems in Steel DesignDocumento10 pagineCE Board Problems in Steel DesignVaughn Carlisle BacayonNessuna valutazione finora

- Nov23 Design 01 06 Nov. 2023Documento19 pagineNov23 Design 01 06 Nov. 2023Jayson MariNessuna valutazione finora

- Dhane Kyle Mijares 182-0067 Bsce-3A Problem Set 4 Solve The Following ProblemsDocumento4 pagineDhane Kyle Mijares 182-0067 Bsce-3A Problem Set 4 Solve The Following ProblemsDhane Kyle MijaresNessuna valutazione finora

- M05 - SEC 5 Solution (131331) For FB PostingDocumento11 pagineM05 - SEC 5 Solution (131331) For FB PostingRimar LiguanNessuna valutazione finora

- Moren - MODULE 3 - Beams-ColumnDocumento18 pagineMoren - MODULE 3 - Beams-ColumnJoshua Espanto MorenNessuna valutazione finora

- Refresher Module 04 - M6 - Intermodal Transportation SystemDocumento1 paginaRefresher Module 04 - M6 - Intermodal Transportation SystemKiki Do youNessuna valutazione finora

- 1S1819 Q1 ST1 Set ADocumento1 pagina1S1819 Q1 ST1 Set ALance MendozaNessuna valutazione finora

- Week 4 - Column Interaction DiagramDocumento8 pagineWeek 4 - Column Interaction DiagramMAYHAY, ADRIAN PAULNessuna valutazione finora

- Answer: 250Mm, 0.74mpa, 2.75M: Reinforced Concrete - Lecture03 - August2019Documento5 pagineAnswer: 250Mm, 0.74mpa, 2.75M: Reinforced Concrete - Lecture03 - August2019hazelNessuna valutazione finora

- Steel Design 9 Nov 2020 PDFDocumento1 paginaSteel Design 9 Nov 2020 PDFJustine Ejay MoscosaNessuna valutazione finora

- Inhouse Practice Problems - RCD-Column - Without AnswersDocumento1 paginaInhouse Practice Problems - RCD-Column - Without AnswersAndrea Sochayseng SolijonNessuna valutazione finora

- Tos 2Documento3 pagineTos 2Allyanna Elise DiamNessuna valutazione finora

- CE199 2L 1Q1819 DC 1st TakeDocumento10 pagineCE199 2L 1Q1819 DC 1st TakeJohn Michael Ramos100% (1)

- 5 Design Nov 2013 KeyDocumento6 pagine5 Design Nov 2013 KeyKenneth PadunanNessuna valutazione finora

- Stdl02e Final ExamDocumento6 pagineStdl02e Final ExamPaulo ValderamaNessuna valutazione finora

- Frames Subjected To Lateral Loads (Approximate Analysis) : Structural Theory: Lecture 02Documento6 pagineFrames Subjected To Lateral Loads (Approximate Analysis) : Structural Theory: Lecture 02Michael Christ IcagoyNessuna valutazione finora

- Design Coaching 1 Practice Material and LectureDocumento43 pagineDesign Coaching 1 Practice Material and LectureeklavurNessuna valutazione finora

- Refresher Module 16 (GH8) - Geotechnical Engineering and HydraulicsDocumento1 paginaRefresher Module 16 (GH8) - Geotechnical Engineering and HydraulicsMadelyn OronosNessuna valutazione finora

- Tsu m22 Practice Problems Steel DesignDocumento3 pagineTsu m22 Practice Problems Steel DesignMark Lester Valdoz100% (1)

- Tension Members PDFDocumento21 pagineTension Members PDFMaribeth Salvador50% (2)

- Review - Hydraulics and Geotechnical Engineering Soil MechanicsDocumento4 pagineReview - Hydraulics and Geotechnical Engineering Soil MechanicsPaulyne TuganoNessuna valutazione finora

- Review in Reinforced Concrete Design 1 PDFDocumento113 pagineReview in Reinforced Concrete Design 1 PDFOctavia BlakeNessuna valutazione finora

- Forces On Curved Surfaces 1Documento13 pagineForces On Curved Surfaces 1Yours PamoreNessuna valutazione finora

- Steel Design PDFDocumento207 pagineSteel Design PDFRey Dominique VillarNessuna valutazione finora

- PREBOARD GEO HYDRA WITH ANSWERS NOV 2017 - Set ADocumento2 paginePREBOARD GEO HYDRA WITH ANSWERS NOV 2017 - Set AEngr. HLDCNessuna valutazione finora

- PSAD Refresher October 9 2023Documento4 paginePSAD Refresher October 9 2023Joshua CopianNessuna valutazione finora

- Quiz 12Documento6 pagineQuiz 12John Taylor BernasNessuna valutazione finora

- Quiz 4 Experts - Soil Mech PartDocumento4 pagineQuiz 4 Experts - Soil Mech PartBenjamin Benicarlo Juanillo IIINessuna valutazione finora

- Problem Set 1 With AnsDocumento4 pagineProblem Set 1 With AnsRaine ZaficoNessuna valutazione finora

- Civil Engineering November 2020 Plane & Solid Geometry 1: Review InnovationsDocumento2 pagineCivil Engineering November 2020 Plane & Solid Geometry 1: Review InnovationsKayceeAlcantaraNessuna valutazione finora

- Review Module 44 - RC ONE-WAY SLAB (USD)Documento2 pagineReview Module 44 - RC ONE-WAY SLAB (USD)Hannah BelleNessuna valutazione finora

- Hydro Comprehensive Examination Without SolutionsDocumento3 pagineHydro Comprehensive Examination Without SolutionsPatrik100% (1)

- Assignment - 1Documento3 pagineAssignment - 1chritNessuna valutazione finora

- (Nov2023) PRE-BOARD EXAMINATION (PSAD) - CEBU (A-M) - QuestionsDocumento63 pagine(Nov2023) PRE-BOARD EXAMINATION (PSAD) - CEBU (A-M) - Questionsgt201901573Nessuna valutazione finora

- Policarpio 5 - Refresher SECDocumento2 paginePolicarpio 5 - Refresher SECMigaea100% (1)

- Friction ProblemsDocumento4 pagineFriction ProblemsDaniel PerezNessuna valutazione finora

- Structural ExDocumento14 pagineStructural ExSheryll de Guzman0% (1)

- Steel Design Problem SetxzDocumento35 pagineSteel Design Problem SetxzMiah N. PascualNessuna valutazione finora

- Seac 2 - Strength of Materials (No Answers)Documento6 pagineSeac 2 - Strength of Materials (No Answers)Joshua John Julio100% (1)

- QUESTIONS FinalDocumento15 pagineQUESTIONS FinalkevalNessuna valutazione finora

- Strength Design of Structural Masonry - 2017 10 12Documento70 pagineStrength Design of Structural Masonry - 2017 10 12Ricardo Muñiz DelgadoNessuna valutazione finora

- RCC Design Concept of RCC Members 01.03.2015Documento126 pagineRCC Design Concept of RCC Members 01.03.2015V.m. Rajan100% (1)

- Hec Ras ProjectDocumento15 pagineHec Ras ProjectHarf Jucoy MirandaNessuna valutazione finora

- Kne 773: Advanced Geotechnical Engineering Practicals 2: Two-Dimensional Flow of Water Through SoilDocumento14 pagineKne 773: Advanced Geotechnical Engineering Practicals 2: Two-Dimensional Flow of Water Through SoilHarf Jucoy MirandaNessuna valutazione finora

- Project Phase 2 PDFDocumento14 pagineProject Phase 2 PDFHarf Jucoy MirandaNessuna valutazione finora

- Geo Phase 3 FinalDocumento16 pagineGeo Phase 3 FinalHarf Jucoy MirandaNessuna valutazione finora

- Engineering Geology in Tasmania: A Review: Leaman Geophysics, GPO Box 320, Hobart, Tas. 7001Documento13 pagineEngineering Geology in Tasmania: A Review: Leaman Geophysics, GPO Box 320, Hobart, Tas. 7001Harf Jucoy MirandaNessuna valutazione finora

- Correl 2 Lecture PDFDocumento40 pagineCorrel 2 Lecture PDFHarf Jucoy MirandaNessuna valutazione finora

- Ireview Exam Questions MathDocumento1 paginaIreview Exam Questions MathHarf Jucoy MirandaNessuna valutazione finora

- SENGDocumento1 paginaSENGHarf Jucoy MirandaNessuna valutazione finora

- 1Documento9 pagine1Harf Jucoy MirandaNessuna valutazione finora

- User's Manual: For More Product Details, Please Visit GIGABYTE's WebsiteDocumento41 pagineUser's Manual: For More Product Details, Please Visit GIGABYTE's Websiteasxl113Nessuna valutazione finora

- Sand Trap LouversDocumento7 pagineSand Trap LouversAslam SageerNessuna valutazione finora

- Is 12894: 1990Documento6 pagineIs 12894: 1990mukaslam100% (7)

- Walktrough Amnesia The Machine For PigsDocumento9 pagineWalktrough Amnesia The Machine For PigsErie FailenggoNessuna valutazione finora

- Bullseye Catalog5 FullDocumento64 pagineBullseye Catalog5 FullDAX37100% (1)

- Defects in BrickworkDocumento3 pagineDefects in BrickworksuryakantameNessuna valutazione finora

- Makalah Bahasa Inggris YoviDocumento8 pagineMakalah Bahasa Inggris YoviYovi PransiskaNessuna valutazione finora

- WT Lab Manual PDFDocumento125 pagineWT Lab Manual PDFKiran Dalvi67% (3)

- 2208 Verbena Marketing PackageDocumento7 pagine2208 Verbena Marketing PackageHenry LaraNessuna valutazione finora

- Nagpal 7 Num Rep OrgDocumento67 pagineNagpal 7 Num Rep OrgntnitinNessuna valutazione finora

- High Rise Building Structure SystemDocumento14 pagineHigh Rise Building Structure SystemRobin PratamaNessuna valutazione finora

- The Whole Town Is Sleeping BradburyDocumento8 pagineThe Whole Town Is Sleeping BradburyMendaharin TuskaNessuna valutazione finora

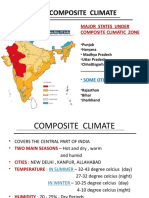

- Composite Climate: Major States Under Composite Climatic ZoneDocumento25 pagineComposite Climate: Major States Under Composite Climatic ZoneSporty Game100% (1)

- 3590 Maintenance InformationDocumento729 pagine3590 Maintenance InformationAlejandro SotoNessuna valutazione finora

- Dbvisit 7 Eleven Case StudyDocumento2 pagineDbvisit 7 Eleven Case StudyKaye Angeline CuyosNessuna valutazione finora

- Continous One Way Slabs With MathCadDocumento18 pagineContinous One Way Slabs With MathCadGiomar OzaitaNessuna valutazione finora

- Cobiax Folder Big5 EDocumento2 pagineCobiax Folder Big5 Emadamarin_21Nessuna valutazione finora

- 1.1 Expansive SoilDocumento9 pagine1.1 Expansive SoilYatin JethiNessuna valutazione finora

- Data Sheet: Fike Engineered Nozzles For Dupont™ Fm-200® or Hfc-227Ea Clean Agent SystemsDocumento2 pagineData Sheet: Fike Engineered Nozzles For Dupont™ Fm-200® or Hfc-227Ea Clean Agent SystemsTiago Levi CardosoNessuna valutazione finora

- Lal-Dora - in The High Court of Delhi at New DelhiDocumento30 pagineLal-Dora - in The High Court of Delhi at New DelhiEva SharmaNessuna valutazione finora

- Fundamentos de Unix PDFDocumento396 pagineFundamentos de Unix PDFRodrigo Guerrero RochaNessuna valutazione finora

- Water Profing Application MethodologyDocumento2 pagineWater Profing Application MethodologyRajarshi KarNessuna valutazione finora

- Dortek Hospital Doors BrochureDocumento10 pagineDortek Hospital Doors BrochureAbdul BaseerNessuna valutazione finora

- Schedule-H Makhu ArifkeDocumento21 pagineSchedule-H Makhu ArifkeKaptan SainiNessuna valutazione finora

- A Tower of Mystery: Jatar Deul: Rangan Datta Freelance WriterDocumento5 pagineA Tower of Mystery: Jatar Deul: Rangan Datta Freelance WriterSayan RoyNessuna valutazione finora

- File Management in SolidWorks PDFDocumento6 pagineFile Management in SolidWorks PDFquiquichina17450Nessuna valutazione finora

- R82 Lean Mix Concrete BaseDocumento94 pagineR82 Lean Mix Concrete BasePavlos ZoulisNessuna valutazione finora

- Mobile Broadband Router: Installation, Operation, and Maintenance GuideDocumento88 pagineMobile Broadband Router: Installation, Operation, and Maintenance Guideaxj42128Nessuna valutazione finora

- AspStoneMastic LRDocumento2 pagineAspStoneMastic LRMohd NasharuddinNessuna valutazione finora

- Spring ReferenceDocumento289 pagineSpring ReferenceALi KaoukabNessuna valutazione finora

- Hero Found: The Greatest POW Escape of the Vietnam WarDa EverandHero Found: The Greatest POW Escape of the Vietnam WarValutazione: 4 su 5 stelle4/5 (19)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureDa EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureValutazione: 5 su 5 stelle5/5 (125)

- The Fabric of Civilization: How Textiles Made the WorldDa EverandThe Fabric of Civilization: How Textiles Made the WorldValutazione: 4.5 su 5 stelle4.5/5 (58)

- Sully: The Untold Story Behind the Miracle on the HudsonDa EverandSully: The Untold Story Behind the Miracle on the HudsonValutazione: 4 su 5 stelle4/5 (103)

- The End of Craving: Recovering the Lost Wisdom of Eating WellDa EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellValutazione: 4.5 su 5 stelle4.5/5 (82)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachDa EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachValutazione: 3.5 su 5 stelle3.5/5 (6)

- The Future of Geography: How the Competition in Space Will Change Our WorldDa EverandThe Future of Geography: How the Competition in Space Will Change Our WorldValutazione: 4 su 5 stelle4/5 (6)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceDa EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceValutazione: 5 su 5 stelle5/5 (5)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDa EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNessuna valutazione finora

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyDa EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNessuna valutazione finora

- System Error: Where Big Tech Went Wrong and How We Can RebootDa EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNessuna valutazione finora

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDa EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestValutazione: 4 su 5 stelle4/5 (28)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreDa EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreValutazione: 4.5 su 5 stelle4.5/5 (33)

- Mini Farming: Self-Sufficiency on 1/4 AcreDa EverandMini Farming: Self-Sufficiency on 1/4 AcreValutazione: 4 su 5 stelle4/5 (76)

- Process Plant Equipment: Operation, Control, and ReliabilityDa EverandProcess Plant Equipment: Operation, Control, and ReliabilityValutazione: 5 su 5 stelle5/5 (1)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDa EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationValutazione: 4.5 su 5 stelle4.5/5 (46)

- The Knowledge: How to Rebuild Our World from ScratchDa EverandThe Knowledge: How to Rebuild Our World from ScratchValutazione: 3.5 su 5 stelle3.5/5 (133)

- Highest Duty: My Search for What Really MattersDa EverandHighest Duty: My Search for What Really MattersNessuna valutazione finora

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDa EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNessuna valutazione finora

- The Book of the Moon: A Guide to Our Closest NeighborDa EverandThe Book of the Moon: A Guide to Our Closest NeighborValutazione: 4.5 su 5 stelle4.5/5 (11)

- The Assassination Complex: Inside the Government's Secret Drone Warfare ProgramDa EverandThe Assassination Complex: Inside the Government's Secret Drone Warfare ProgramValutazione: 4 su 5 stelle4/5 (55)

- Project Management All-in-One For DummiesDa EverandProject Management All-in-One For DummiesValutazione: 5 su 5 stelle5/5 (6)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDa EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerValutazione: 4.5 su 5 stelle4.5/5 (54)

- Reality+: Virtual Worlds and the Problems of PhilosophyDa EverandReality+: Virtual Worlds and the Problems of PhilosophyValutazione: 4 su 5 stelle4/5 (24)