Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

NPT Thread Dimensions PDF

Caricato da

Ramnandan MahtoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

NPT Thread Dimensions PDF

Caricato da

Ramnandan MahtoCopyright:

Formati disponibili

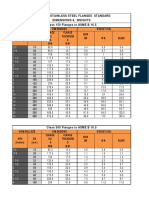

Basic Dimensions, American National Standard Taper Pipe Threads, NPT.

ANSI/ASME B1.20.1-1983 (R1992)

For all dimensions, see corresponding reference letter in table

Angle between sides of thread is 60 degrees. Taper of thread, on diameter, is 3 ⁄4 inch per foot. Angle of taper with center line is 1°47′.

The basic maximum thread height, h, of the truncated thread is 0.8 × pitch of thread. The crest and root are truncated a minimum of 0.033 × pitch for all pitches. For maximum

depth of truncation, see ASME B1-20-1.

Wrench Makeup

Nominal Outside Threads Pitch Pitch Handtight Dia.,a Effective Dia., Length Vanish Overall Nominal Perfect Height Basic Minor

Pipe Dia. of per of Diameter at Engagement E1 Thread, E2 for Internal Thread Thread, Length External Threads d of Dia. at Small

Size Pipe, Inch, Thread, Beginning Length, b Length, c Length, f Dia., (3.47 External Length, Dia., Thread, End of Pipe, e

In. D n p of External L1, mm. L2, mm. L3 E3 thds.), Thread, L5 E5 h K0

Thread, E0 V L4

1/16 7.94 27 0.94 6.89 4.06 7.14 6.63 7.30 2.82 6.71 3.26 9.90 4.75 7.18 0.75 6.14

1/8 10.29 27 0.94 9.23 4.10 9.49 6.70 9.65 2.82 9.06 3.26 9.97 4.82 9.53 0.75 8.48

1/4 13.72 18 1.41 12.13 5.79 12.49 10.21 12.76 4.23 11.86 4.90 15.10 7.38 12.59 1.13 11.00

3/8 17.15 18 1.41 15.55 6.10 15.93 10.36 16.19 4.23 15.28 4.90 15.26 7.54 16.02 1.13 14.42

1/2 21.34 14 1.81 19.26 8.13 19.77 13.56 20.11 5.44 18.92 6.29 19.85 9.93 19.88 1.45 17.81

3/4 26.67 14 1.81 24.58 8.61 25.12 13.86 25.45 5.44 24.24 6.29 20.15 10.23 25.22 1.45 23.13

1 33.40 11 1/2 2.21 30.83 10.16 31.46 17.34 31.91 6.63 30.41 7.66 25.01 12.93 31.63 1.77 29.06

1 1/4 42.16 11 1/2 2.21 39.55 10.67 40.22 17.95 40.67 6.63 39.14 7.66 25.62 13.54 40.40 1.77 37.79

1 1/2 48.26 11 1/2 2.21 45.62 10.67 46.29 18.38 46.77 6.63 45.21 7.66 26.04 13.96 46.49 1.77 43.85

2 60.33 11 1/2 2.21 57.63 11.07 58.33 19.22 58.83 6.63 57.22 7.66 26.88 14.80 58.56 1.77 55.87

g

2 1/2 73.03 8 3.18 69.08 17.32 70.16 28.89 70.88 6.35 68.68 11.02 39.91 22.54 70.49 2.54 66.54

g

3 88.90 8 3.18 84.85 19.46 86.07 30.48 86.76 6.35 84.46 11.02 41.50 24.13 86.36 2.54 82.31

3 1/2 101.60 8 3.18 97.47 20.85 98.78 31.75 99.46 6.35 97.08 11.02 42.77 25.40 99.06 2.54 94.93

4 114.30 8 3.18 110.09 21.44 111.43 33.02 112.16 6.35 109.70 11.02 44.04 26.67 111.76 2.54 107.55

5 141.30 8 3.18 136.92 23.80 138.41 35.72 139.16 6.35 136.53 11.02 46.74 29.37 138.76 2.54 134.38

6 168.28 8 3.18 163.73 24.33 165.25 38.42 166.13 6.35 163.33 11.02 49.43 32.07 165.74 2.54 161.19

8 219.08 8 3.18 214.21 27.00 215.90 43.50 216.93 6.35 213.82 11.02 54.51 37.15 216.54 2.54 211.67

10 273.05 8 3.18 267.85 30.73 269.77 48.90 270.91 6.35 267.45 11.02 59.91 42.55 270.51 2.54 265.31

12 323.85 8 3.18 318.33 34.54 320.49 53.98 321.71 6.35 317.94 11.02 64.99 47.63 321.31 2.54 315.79

14 OD 355.60 8 3.18 349.89 39.67 352.36 57.15 353.46 6.35 349.49 11.02 68.17 50.80 353.06 2.54 347.35

16 OD 406.40 8 3.18 400.37 46.02 403.24 62.23 404.26 6.35 399.97 11.02 73.25 55.88 403.86 2.54 397.83

18 OD 457.20 8 3.18 450.85 50.80 454.03 67.31 455.06 6.35 450.45 11.02 78.33 60.96 454.66 2.54 448.31

20 OD 508.00 8 3.18 501.33 53.98 504.71 72.39 505.86 6.35 500.94 11.02 83.41 66.04 505.46 2.54 498.79

24 OD 609.60 8 3.18 602.30 60.33 606.07 82.55 607.46 6.35 601.90 11.02 93.57 76.20 607.06 2.54 599.76

a

Also pitch diameter at gaging notch (handtight plane).

b

Also length of thin ring gage and length from gaging notch to small end of plug gage.

c

Also length of plug gage.

d The length L5 from the end of the pipe determines the plane beyond which the thread form is imperfect at the crest. The next two threads are perfect at the root. At this

plane the cone formed by the crests of the thread intersects the cylinder forming the external surface of the pipe. L5 = L2 - 2p.

e

Given as information for use in selecting tap drills.

f

Three threads for 2-inch size and smaller; two threads for larger sizes.

g

Military Specification MIL—P—7105 gives the wrench makeup as three threads for 3 in. and smaller. The E 3 dimensions are then as follows: Size 2½ in., 68.48 mm and size 3

in., 84.26 mm.

All dimensions are in mm

by Neil Louis. Taken from ASME B1-20-1 and Machineries Handbook.

Potrebbero piacerti anche

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Torque Values Klingersil Topgraph Topchem (B16.5) PDFDocumento2 pagineTorque Values Klingersil Topgraph Topchem (B16.5) PDFrached100% (2)

- Bolt Pocket ChartDocumento2 pagineBolt Pocket ChartAlex LaraNessuna valutazione finora

- Flange Weight ChartDocumento4 pagineFlange Weight ChartDayo IdowuNessuna valutazione finora

- TEMA FlangesDocumento38 pagineTEMA FlangesAshfaq Anwer100% (1)

- FE410WWA - Equivalent Steel Grades QualitiesDocumento6 pagineFE410WWA - Equivalent Steel Grades QualitiesbkprodhNessuna valutazione finora

- Spiral Wound Gasket Torque Values - Technical Information - Klinger MzansiDocumento3 pagineSpiral Wound Gasket Torque Values - Technical Information - Klinger MzansiHafizi HZnumismaticNessuna valutazione finora

- Pressure Temperature Chart According To ASME B16.34 ASME B PV CodeDocumento5 paginePressure Temperature Chart According To ASME B16.34 ASME B PV CodeDwayne YiiNessuna valutazione finora

- MSS SP 80 PDFDocumento35 pagineMSS SP 80 PDFMuhamed AneeshNessuna valutazione finora

- MRP1000 - Ops ManualDocumento62 pagineMRP1000 - Ops Manualjose abaNessuna valutazione finora

- API 6A Spec Flange Bolt Ring Chart Tap EndDocumento1 paginaAPI 6A Spec Flange Bolt Ring Chart Tap EndKali AbdennourNessuna valutazione finora

- Ensival Moret MP PumpsDocumento6 pagineEnsival Moret MP PumpsBenicio Joaquín Ferrero Brebes100% (1)

- SN398 2008-04 eDocumento4 pagineSN398 2008-04 ewasim_akp9885Nessuna valutazione finora

- Torque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Documento1 paginaTorque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Shijumon Kp100% (2)

- ASME B16.5 - List of Material SpecificationDocumento3 pagineASME B16.5 - List of Material Specificationjr_satish6965Nessuna valutazione finora

- Nominal Pipe Size Chart in Inch and MMDocumento2 pagineNominal Pipe Size Chart in Inch and MMMehman NasibovNessuna valutazione finora

- Victaulic DimensionsDocumento2 pagineVictaulic DimensionsSH1961Nessuna valutazione finora

- Basic Dimensions, American National Standard Taper Pipe Threads, NPT, (ANSI B2.1-1968)Documento2 pagineBasic Dimensions, American National Standard Taper Pipe Threads, NPT, (ANSI B2.1-1968)Adrian Petrascu100% (1)

- Grayloc Product Catalog Woodco Usa PDFDocumento7 pagineGrayloc Product Catalog Woodco Usa PDFDesign2 Department0% (1)

- NPT (Asme B1.20.1)Documento5 pagineNPT (Asme B1.20.1)Afronie Cepoz D'nextNessuna valutazione finora

- Weight For Bolt With Nut PDFDocumento1 paginaWeight For Bolt With Nut PDFRam RajaramanNessuna valutazione finora

- Rubber Gasket (Full Face in Flat Face Flanges) Installation & TorqueDocumento4 pagineRubber Gasket (Full Face in Flat Face Flanges) Installation & Torquecavillalobosb8167Nessuna valutazione finora

- Swivel S135 Explode ViewDocumento1 paginaSwivel S135 Explode ViewingcalderonNessuna valutazione finora

- Type - DH Block: Dimensional ChartDocumento1 paginaType - DH Block: Dimensional ChartHarzanyi MaldonadoNessuna valutazione finora

- Torque Values Graphite Laminate (B16.5)Documento2 pagineTorque Values Graphite Laminate (B16.5)Gonçalo Cortez50% (2)

- 1 - Ring Groove Dimensional ChartDocumento2 pagine1 - Ring Groove Dimensional Chartchau nguyen67% (3)

- Pipe Schedule PDFDocumento1 paginaPipe Schedule PDFSrinivasan SeenuNessuna valutazione finora

- NPT Thread PDFDocumento1 paginaNPT Thread PDFAli BelhaylaNessuna valutazione finora

- Data Sheet of Double Studded Adapter FlangeDocumento3 pagineData Sheet of Double Studded Adapter FlangeAGSMotoVlog 06100% (1)

- Din 580-Lifting Eye Bolts PDFDocumento1 paginaDin 580-Lifting Eye Bolts PDFAntohi CatalinNessuna valutazione finora

- J J Plum Block-PlDocumento6 pagineJ J Plum Block-Plmanoj_doshi_1Nessuna valutazione finora

- ANSI Flange Bolt & Stud ChartDocumento2 pagineANSI Flange Bolt & Stud Chartkh88hmiNessuna valutazione finora

- Check Valve MS and Type R CameronDocumento2 pagineCheck Valve MS and Type R CameronRuben Dario Conde LeonNessuna valutazione finora

- Studding Outlet DimensionDocumento2 pagineStudding Outlet DimensionpandiangvNessuna valutazione finora

- Pipe Flange Torque Summary (Modified by Joan Franco)Documento21 paginePipe Flange Torque Summary (Modified by Joan Franco)Wilmer FigueraNessuna valutazione finora

- Torque Values For Insualtion KitDocumento2 pagineTorque Values For Insualtion KitYasser MahmoudNessuna valutazione finora

- Crochets Combine250TDocumento8 pagineCrochets Combine250TsalemNessuna valutazione finora

- Weld Profile B16.25 - B 16.9Documento2 pagineWeld Profile B16.25 - B 16.9f_riseNessuna valutazione finora

- American National Standard Stub Acme ThreadsDocumento4 pagineAmerican National Standard Stub Acme Threadsjavierpapirico0% (1)

- Tabel MaterialDocumento19 pagineTabel MaterialBang OchimNessuna valutazione finora

- Stainless Steel Square Pipe Price ListDocumento7 pagineStainless Steel Square Pipe Price ListKamlendra SinghNessuna valutazione finora

- Steel ListDocumento11 pagineSteel Listchhay longNessuna valutazione finora

- Weight & Thickness of Schedule Pipe: Sch.80 Sch.160 XS XXS Nominal Sch.5 Sch.10 Sch.40Documento1 paginaWeight & Thickness of Schedule Pipe: Sch.80 Sch.160 XS XXS Nominal Sch.5 Sch.10 Sch.40hisaj4uNessuna valutazione finora

- Stainless Steel Pipe Astm A312 Welded: Schedule 40 Schedule 10Documento32 pagineStainless Steel Pipe Astm A312 Welded: Schedule 40 Schedule 10jsmarksNessuna valutazione finora

- Pipe (Carbon Steel) (OK)Documento1 paginaPipe (Carbon Steel) (OK)Phan Tri ThongNessuna valutazione finora

- 01 Cubes and Cube RootsDocumento4 pagine01 Cubes and Cube Rootskevin muchungaNessuna valutazione finora

- Flow Calculation From A Nozzle Nozzle DischargeDocumento1 paginaFlow Calculation From A Nozzle Nozzle DischargeMohamed Badian TraoreNessuna valutazione finora

- R C CDocumento45 pagineR C CBhupender SinghNessuna valutazione finora

- Exercicios Tendencia CentralDocumento3 pagineExercicios Tendencia CentralmaoriarrudaNessuna valutazione finora

- Aço Tabela 1Documento1 paginaAço Tabela 1Sanlorenzo EngenhariaNessuna valutazione finora

- BPM To Milliseconds ChartDocumento3 pagineBPM To Milliseconds ChartAntoinette PrescottNessuna valutazione finora

- ASTM A1085 Square HSS: Surface Area Design Wall Thickness, T Nominal Wt. Area, Shape TorsionDocumento3 pagineASTM A1085 Square HSS: Surface Area Design Wall Thickness, T Nominal Wt. Area, Shape TorsionamadhubalanNessuna valutazione finora

- H Factor Chart Pg1Documento1 paginaH Factor Chart Pg1Anubhav LakhmaniNessuna valutazione finora

- 4.1 Calculo de Caudal EcologicoDocumento94 pagine4.1 Calculo de Caudal EcologicoDiego VargasNessuna valutazione finora

- POWER Point Daily 20110101 20210331 001d8526S 036d6877e LSTDocumento128 paginePOWER Point Daily 20110101 20210331 001d8526S 036d6877e LSTEdward MainaNessuna valutazione finora

- 90RLARDocumento1 pagina90RLARjody_ariasNessuna valutazione finora

- Estación A: AÑO ENE FEB MAR ABR MAY JUN JULDocumento75 pagineEstación A: AÑO ENE FEB MAR ABR MAY JUN JULjota jotaNessuna valutazione finora

- 4.1 Calculo de Caudal Ecologico 1Documento75 pagine4.1 Calculo de Caudal Ecologico 1Diego VargasNessuna valutazione finora

- Pipe Conversion ChartDocumento7 paginePipe Conversion ChartramyzottyNessuna valutazione finora

- Simulating A M/M/1 Queueing System: Results From One Run: Arrival Rate (Customers/sec) Departure Rate (Custutomers/sec)Documento44 pagineSimulating A M/M/1 Queueing System: Results From One Run: Arrival Rate (Customers/sec) Departure Rate (Custutomers/sec)Dr. Ir. R. Didin Kusdian, MT.Nessuna valutazione finora

- 2nd Grading LAA Grade 10Documento54 pagine2nd Grading LAA Grade 10Urduja Kyle OdiacerNessuna valutazione finora

- Leading The Industry In: Solar Microinverter TechnologyDocumento2 pagineLeading The Industry In: Solar Microinverter TechnologydukegaloNessuna valutazione finora

- Automatic Pneumatic Bumper Mission: International Journal of Pure and Applied Mathematics No. 16 2017, 137-140Documento4 pagineAutomatic Pneumatic Bumper Mission: International Journal of Pure and Applied Mathematics No. 16 2017, 137-140VinayNessuna valutazione finora

- Linux NFS and Automounter Administration (Craig Hunt Linux Library)Documento0 pagineLinux NFS and Automounter Administration (Craig Hunt Linux Library)Bryan BowmanNessuna valutazione finora

- IIM Nagpur Test 1 Version 1 2016Documento6 pagineIIM Nagpur Test 1 Version 1 2016Saksham GoyalNessuna valutazione finora

- Asme Ix Test 1Documento8 pagineAsme Ix Test 1RedzuanNessuna valutazione finora

- ML Observability Build Vs Buy Download Guide 1689038317Documento31 pagineML Observability Build Vs Buy Download Guide 1689038317rastrol7Nessuna valutazione finora

- Ugc Model Curriculum Statistics: Submitted To The University Grants Commission in April 2001Documento101 pagineUgc Model Curriculum Statistics: Submitted To The University Grants Commission in April 2001Alok ThakkarNessuna valutazione finora

- Product Bulletin N 6: Bearing Assemblies - Shaft VariationsDocumento1 paginaProduct Bulletin N 6: Bearing Assemblies - Shaft VariationsRANAIVOARIMANANANessuna valutazione finora

- Essay 1 Weight and BalanceDocumento4 pagineEssay 1 Weight and BalanceHamdan Merchant83% (6)

- Research FinalDocumento29 pagineResearch FinalLaw VesperaNessuna valutazione finora

- Nolte KitchenDocumento44 pagineNolte KitchenGanesh SNessuna valutazione finora

- ORC - Airbag SystemDocumento13 pagineORC - Airbag SystemGarikoitz FranciscoeneNessuna valutazione finora

- Customer DemandDocumento42 pagineCustomer Demandtulika_ajwaniNessuna valutazione finora

- Spelling RulesDocumento5 pagineSpelling RulesvijthorNessuna valutazione finora

- Surface Mount Multilayer Varistor: SC0805ML - SC2220ML SeriesDocumento8 pagineSurface Mount Multilayer Varistor: SC0805ML - SC2220ML SeriesTalebNessuna valutazione finora

- Ijarece Vol 8 Issue 8 141 144Documento4 pagineIjarece Vol 8 Issue 8 141 144Rnav rnavNessuna valutazione finora

- Photo Luminescence of Surfaces and InterfacesDocumento25 paginePhoto Luminescence of Surfaces and InterfacesNick KellerNessuna valutazione finora

- Soiling Rates of PV Modules vs. Thermopile PyranometersDocumento3 pagineSoiling Rates of PV Modules vs. Thermopile PyranometersAbdul Mohid SheikhNessuna valutazione finora

- DLT Strand Jack Systems - 2.0 - 600 PDFDocumento24 pagineDLT Strand Jack Systems - 2.0 - 600 PDFganda liftindoNessuna valutazione finora

- Psychometric Development and Validation of GaslightingDocumento15 paginePsychometric Development and Validation of GaslightingYang ZhangNessuna valutazione finora

- Petrom OMV Norm DEF 2001 Rom Eng Rev.2 2009-06-01Documento61 paginePetrom OMV Norm DEF 2001 Rom Eng Rev.2 2009-06-01luciandu100% (1)

- Italy CasestudyDocumento21 pagineItaly CasestudylozaNessuna valutazione finora

- Aeon7200 Service Manual-V00.01-A4Documento37 pagineAeon7200 Service Manual-V00.01-A4annaya kitaNessuna valutazione finora

- ImmunologyDocumento8 pagineImmunologyማላያላም ማላያላም89% (9)

- ABAP Training PlanDocumento4 pagineABAP Training PlanAhmed HamadNessuna valutazione finora

- C V RamanDocumento8 pagineC V RamanJayesh KomalwarNessuna valutazione finora

- Fluid Mech. 2Documento32 pagineFluid Mech. 2Leslie Owusu MensahNessuna valutazione finora

- FAQs - G7, GRACoL, ISO 12647-2 PDFDocumento5 pagineFAQs - G7, GRACoL, ISO 12647-2 PDFSappiETC50% (2)

- Asm 10Documento4 pagineAsm 10Tukaram ParabNessuna valutazione finora