Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tme BX: Technical Data Sheet

Caricato da

Enrique HortaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tme BX: Technical Data Sheet

Caricato da

Enrique HortaCopyright:

Formati disponibili

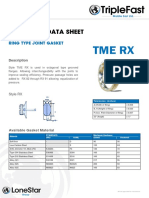

TECHNICAL DATA SHEET

STYLE BX

RING TYPE JOINT GASKET

TME BX

Description

All BX energized gaskets manufactured to API 6A

incorporate a pressure passage hole, allowing

equalization of pressure between grooves.

Style BX

23°

Tolerances: (Inches)

A (Width of Ring) + 0.008, - 0.000

D (Hole Size) ± 0.002

H H (Height of Ring) + 0.008, - 0.000

OD (OD of Ring) + 0.000, - 0.006

23°(Angle) ± ¼°

OD

Available Gasket Material

STANDARD Maximum Hardness

Material

UNS ASME Brinell Rockwell

Soft Iron - D 90 56

Low Carbon Steel - S 120 68

4-6% Chrome ½% Moly (F5) K42544 F5 130 72

Type 304 Stainless Steel S30400 S304 160 83

Type 316 Stainless Steel S31600 S316 160 83

Alloy 321 S32100 S321 217 95

Alloy 625 N06625 INC625 200 93

Alloy 825 N08825 IN825 160 83

API 6A approved for manufacture.

D

23º ± 0º 15’

23º ± 0º 15’ G

R R 23º ± 0º 15’

TECHNICAL DATA SHEET H

E

X

N

a

R 0.03

≤X0.006 x 45º

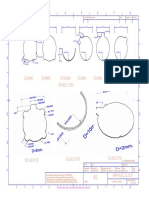

STYLE BX RING DIMENSIONS R C

A

R

ODT X

OD

Ring No. Pipe sizes & pressure class rating Outside Height of Width of Diam eter of Width of flat Hole size Depth of Outside Width of Weight

for type BX ring gaskets diameter of ring ring flat groove diameter of groove

ring groove

OD Hb Ab ODT C D E G N Lbs

API (PSI)

0 +0.008 +0.008 ±0.002 +0.006 ±0.02 +0.02 +0.004 +0.004

-0.006 0 0 0 0 0 0

2000 3000 5000 10000 15000 20000 Dimensions in inches

BX-150 … … … 1-11/16" 1-11/16" … 2.842 0.366 0.366 2.790 0.314 0.06 0.22 2.893 0.450 0.30

BX-151 … … … 1-13/16" 1-13/16" 1-13/16" 3.008 0.379 0.379 2.954 0.325 0.06 0.22 3.062 0.466 0.34

BX-152 … … … 2-1/16" 2-1/16" 2-1/16" 3.334 0.403 0.403 3.277 0.346 0.06 0.23 3.395 0.498 0.42

BX-153 … … … 2-9/16" 2-9/16" 2-9/16" 3.974 0.448 0.448 3.910 0.385 0.06 0.27 4.046 0.554 0.63

BX-154 … … … 3-1/16" 3-1/16" 3-1/16" 4.600 0.488 0.488 4.531 0.419 0.06 0.30 4.685 0.606 0.88

BX-155 … … … 4-1/16" 4-1/16" 4-1/16" 5.825 0.560 0.560 5.746 0.481 0.06 0.33 5.930 0.698 1.22

BX-156 … … … 7-1/16" 7-1/16" 7-1/16" 9.367 0.733 0.733 9.263 0.629 0.12 0.44 9.521 0.921 4.14

BX-157 … … … 9" 9" 9" 11.593 0.826 0.826 11.476 0.709 0.12 0.50 11.774 1.039 6.55

BX-158 … … … 11" 11" 11" 13.860 0.911 0.911 13.731 0.782 0.12 0.56 14.064 1.149 9.60

BX-159 … … … 13-5/8" 13-5/8" 13-5/8" 16.800 1.012 1.012 16.657 0.869 0.12 0.62 17.033 1.279 14.41

BX-160 … … 13-5/8" … … … 15.850 0.938 0.541 15.717 0.408 0.12 0.56 16.063 0.786 6.75

BX-161 … … 16-3/4" … … … 19.347 1.105 0.638 19.191 0.482 0.12 0.67 19.604 0.930 11.50

BX-162 … … 16-3/4" 16-3/4" 16-3/4" … 18.720 0.560 0.560 18.641 0.481 0.06 0.33 18.832 0.705 5.00

BX-163 … … 18-3/4" … … … 21.896 1.185 0.684 21.728 0.516 0.12 0.72 22.185 1.006 14.50

BX-164 … … … 18-3/4" 18-3/4" … 22.463 1.185 0.968 22.295 0.800 0.12 0.72 22.752 1.290 21.50

BX-165 … … 21-1/4" … … … 24.595 1.261 0.728 24.417 0.550 0.12 0.75 24.904 1.071 19.00

BX-166 … … … 21-1/4" … … 25.198 1.261 1.029 25.020 0.851 0.12 0.75 25.507 1.373 27.50

BX-167 26-3/4" … … … … … 29.896 1.412 0.516 29.696 0.316 0.06 0.84 30.249 0.902 17.00

BX-168 … 26-3/4" … … … … 30.128 1.412 0.632 29.928 0.432 0.06 0.84 30.481 1.018

BX-169 … … … 5-1/8" … … 6.831 0.624 0.509 6.743 0.421 0.06 0.38 6.955 0.666 1.76

BX-170 … … … 6-5/8" 6-5/8" … 8.584 0.560 0.560 8.505 0.481 0.06 0.33 8.696 0.705 2.23

BX-171 … … … 8-9/16" 8-9/16" … 10.529 0.560 0.560 10.450 0.481 0.06 0.33 10.641 0.705

BX-172 … … … 11-5/32" 11-5/32" … 13.113 0.560 0.560 13.034 0.481 0.06 0.33 13.225 0.705

BX-303 30" 30" … … … … 33.573 1.494 0.668 33.361 0.457 0.06 0.89 33.949 1.078

Radius R shall be 8% to 12% of the gasket height H. One pressure-passage hole required per gasket on centerline.

a

Break sharp corner on inside diameter of groove.

b

A plus tolerance of 0.088 in for width of A and height H is permitted, provided the variation in width or height of any ring does not exceed 0.004 in throughout its

entire circumference

API 6A approved for manufacture.

Potrebbero piacerti anche

- RX Ring Gasket Technical Data SheetDocumento3 pagineRX Ring Gasket Technical Data SheetEnrique HortaNessuna valutazione finora

- Database Management Systems: Understanding and Applying Database TechnologyDa EverandDatabase Management Systems: Understanding and Applying Database TechnologyValutazione: 4 su 5 stelle4/5 (8)

- Tme R: Technical Data SheetDocumento5 pagineTme R: Technical Data SheetEnrique HortaNessuna valutazione finora

- 1597 KI Avant Tone Horn S140 HELLA ENDocumento2 pagine1597 KI Avant Tone Horn S140 HELLA ENUlyses MorataNessuna valutazione finora

- K 5Documento44 pagineK 5Ricardo Rincon Vega100% (1)

- Bus Bar Spec SheetDocumento1 paginaBus Bar Spec SheetandhikabpNessuna valutazione finora

- Iso DJ Milling InsertsDocumento21 pagineIso DJ Milling InsertsalphatoolsNessuna valutazione finora

- Opening Lintels Details Schedule: Section G-GDocumento1 paginaOpening Lintels Details Schedule: Section G-GMohammad AlkahteebNessuna valutazione finora

- Iso Turning InsertsDocumento37 pagineIso Turning InsertsalphatoolsNessuna valutazione finora

- A2 Mybmrchuc: VDP-1507-G0011-D01-01Documento1 paginaA2 Mybmrchuc: VDP-1507-G0011-D01-01tênchỉđểgọiNessuna valutazione finora

- P Gleason Locator 22.3Documento1 paginaP Gleason Locator 22.3VikramNessuna valutazione finora

- ToolingBox Solid CBN Inserts Brochure-2022Documento24 pagineToolingBox Solid CBN Inserts Brochure-2022ToolingBoxNessuna valutazione finora

- Block Mill Pass Profile PDFDocumento1 paginaBlock Mill Pass Profile PDFAmit RayNessuna valutazione finora

- Circular MeasureDocumento7 pagineCircular MeasureaffendeNessuna valutazione finora

- AJ Sai Clock Ver2-Layout1SketchyDocumento1 paginaAJ Sai Clock Ver2-Layout1Sketchynoonot126Nessuna valutazione finora

- Furnace Coil DrawingDocumento1 paginaFurnace Coil DrawingpurNessuna valutazione finora

- Motor Handle For Manual Rotating RBSDocumento1 paginaMotor Handle For Manual Rotating RBSIrfhan FebrianNessuna valutazione finora

- Joggling Cutter - Inner Group Upper RollerDocumento1 paginaJoggling Cutter - Inner Group Upper RollerEngr. Imran Hasan PathanNessuna valutazione finora

- S-1 Open Cabinet With RailingsDocumento1 paginaS-1 Open Cabinet With RailingsVeni Rigel BallesterosNessuna valutazione finora

- P.O. Bc23-00002 Drawing For Approval r.0Documento1 paginaP.O. Bc23-00002 Drawing For Approval r.0Hadjer BouchlaghemNessuna valutazione finora

- Kerosene StripperDocumento10 pagineKerosene StripperToni100% (1)

- Ilovepdf Merged PDFDocumento18 pagineIlovepdf Merged PDFRahul BaroNessuna valutazione finora

- Critical Load Cases: L/C 44: 1.2DL + 1.2FL + 0.8LL (C+Z)Documento3 pagineCritical Load Cases: L/C 44: 1.2DL + 1.2FL + 0.8LL (C+Z)John Carlo AmodiaNessuna valutazione finora

- VNT Brochure NewDocumento5 pagineVNT Brochure Newda vin ciNessuna valutazione finora

- Features: Switching RegulatorDocumento7 pagineFeatures: Switching RegulatorCesar GastaldiNessuna valutazione finora

- Electrodes passage assembly drawingDocumento1 paginaElectrodes passage assembly drawingtututasNessuna valutazione finora

- Licad86061000013 L14Documento1 paginaLicad86061000013 L14Sakeel WagirkhanNessuna valutazione finora

- E60H Series: Rotary EncoderDocumento1 paginaE60H Series: Rotary EncoderkopihitammorningbakeryNessuna valutazione finora

- Baffle Support, Non Discharge SideDocumento1 paginaBaffle Support, Non Discharge SideCông NguyênNessuna valutazione finora

- Catalog of Milling Solution 2020Documento31 pagineCatalog of Milling Solution 2020vedrenne92Nessuna valutazione finora

- Semiconductor KRA221S KRA226S: Technical DataDocumento5 pagineSemiconductor KRA221S KRA226S: Technical Datahanzhio elNessuna valutazione finora

- Drw. Surface Texture: 1. Break All Edges. 2Documento1 paginaDrw. Surface Texture: 1. Break All Edges. 2Ruslan BayramovNessuna valutazione finora

- The Flow Characteristic (Hydraulic Cylinder)Documento18 pagineThe Flow Characteristic (Hydraulic Cylinder)Eng-CalculationsNessuna valutazione finora

- OL-388.8-Hitachi 20211203184635.614 XDocumento1 paginaOL-388.8-Hitachi 20211203184635.614 XWilson AlvesNessuna valutazione finora

- lever2Documento1 paginalever2mohamed.hassan031Nessuna valutazione finora

- MDSD AIRPORT INFODocumento20 pagineMDSD AIRPORT INFOPablo SuredaNessuna valutazione finora

- DRW - 12 156484651Documento1 paginaDRW - 12 156484651k koradiaNessuna valutazione finora

- Helix 13625-15500-0.870-SPDocumento1 paginaHelix 13625-15500-0.870-SPtibismtxNessuna valutazione finora

- SH KSK 60236 G39 03Documento1 paginaSH KSK 60236 G39 03Ashkan AsefiNessuna valutazione finora

- Building ReferencesDocumento266 pagineBuilding Referencesaya maapNessuna valutazione finora

- 0.12 A 0.25 A 0.16 A 0.12 0.25 A 0.12 A 0.12 0.16 A 0.25 A 0.16 A 0.25 A Ra 1.63 Ra 0.63 Ra 80 Ra 0.63 Ra 1.25Documento1 pagina0.12 A 0.25 A 0.16 A 0.12 0.25 A 0.12 A 0.12 0.16 A 0.25 A 0.16 A 0.25 A Ra 1.63 Ra 0.63 Ra 80 Ra 0.63 Ra 1.25José Antonio Quispealaya HernándezNessuna valutazione finora

- Bearing Cap - 84B559583-ALL PDFDocumento1 paginaBearing Cap - 84B559583-ALL PDFSivaprakash KrishnasamyNessuna valutazione finora

- Utstøpingsring 3: Plate 50x240x250 KokillerammeDocumento1 paginaUtstøpingsring 3: Plate 50x240x250 KokillerammezsmithNessuna valutazione finora

- Winstar 2021 Cutting Tools CatalogueDocumento702 pagineWinstar 2021 Cutting Tools CataloguegkhnNessuna valutazione finora

- THORWESTEN - TT800UniSLDocumento1 paginaTHORWESTEN - TT800UniSLgldiasNessuna valutazione finora

- Sbfi Rwy-15-33 Vac 20211104Documento1 paginaSbfi Rwy-15-33 Vac 20211104Fábio KastelamaryNessuna valutazione finora

- Doc 01 RO 20210722134755Documento2 pagineDoc 01 RO 20210722134755alex7vnNessuna valutazione finora

- Manual New Hidden FixationsDocumento2 pagineManual New Hidden FixationsjosepNessuna valutazione finora

- NHD-24064WG-ATMI-VZ#: Graphic Liquid Crystal Display ModuleDocumento11 pagineNHD-24064WG-ATMI-VZ#: Graphic Liquid Crystal Display ModuleMiguel VanegasNessuna valutazione finora

- Grua JofreDocumento1 paginaGrua JofreandresNessuna valutazione finora

- Rooster RandDocumento1 paginaRooster Randapi-371028301Nessuna valutazione finora

- XL120RFS Ex3 Revision DanielHuberDocumento1 paginaXL120RFS Ex3 Revision DanielHuberBigPantsNessuna valutazione finora

- Ultrasonic Testing of Materials 133Documento1 paginaUltrasonic Testing of Materials 133joNessuna valutazione finora

- Full LayoutDocumento2 pagineFull Layoutabdelrahmansamir.engNessuna valutazione finora

- Penstock Block 3Documento28 paginePenstock Block 3Mani ShresthaNessuna valutazione finora

- Rod Seal TS22PDocumento1 paginaRod Seal TS22Pfrançois MNessuna valutazione finora

- Bottom 020201Documento1 paginaBottom 020201Rajkumar PalNessuna valutazione finora

- Pitch 1 Diamond Knurling: Pt. Sugih Instrumendo AbadiDocumento1 paginaPitch 1 Diamond Knurling: Pt. Sugih Instrumendo AbadiagusNessuna valutazione finora

- РазверткиDocumento10 pagineРазверткиСергей РыбаковNessuna valutazione finora

- Cameron Manual Type F FCDocumento7 pagineCameron Manual Type F FCEnrique HortaNessuna valutazione finora

- Tme S: Technical Data SheetDocumento1 paginaTme S: Technical Data SheetEnrique HortaNessuna valutazione finora

- RMRS Style DictionaryDocumento120 pagineRMRS Style DictionaryEnrique HortaNessuna valutazione finora

- Cameron Manual Gate Valve FLDocumento2 pagineCameron Manual Gate Valve FLEnrique HortaNessuna valutazione finora

- Lone StarDocumento1 paginaLone StarEnrique HortaNessuna valutazione finora

- Comandos Del Java CompiladorDocumento2 pagineComandos Del Java CompiladorEnrique HortaNessuna valutazione finora

- Cameron Manual Type F FCDocumento7 pagineCameron Manual Type F FCEnrique HortaNessuna valutazione finora

- Catalog 2Documento44 pagineCatalog 2Enrique HortaNessuna valutazione finora

- Spiral Wound Gaskets Guide Seals FlangesDocumento3 pagineSpiral Wound Gaskets Guide Seals FlangesEnrique HortaNessuna valutazione finora

- FlexSuite User English PDFDocumento38 pagineFlexSuite User English PDFEnrique HortaNessuna valutazione finora

- Ram-Type BOPs U BOP at BULLET UII BOP UL PDFDocumento24 pagineRam-Type BOPs U BOP at BULLET UII BOP UL PDFEnrique HortaNessuna valutazione finora

- Cameron Manual Gate Valve FLDocumento2 pagineCameron Manual Gate Valve FLEnrique HortaNessuna valutazione finora

- Flexmark User English PDFDocumento49 pagineFlexmark User English PDFEnrique HortaNessuna valutazione finora

- Tme Si: Technical Data SheetDocumento1 paginaTme Si: Technical Data SheetEnrique HortaNessuna valutazione finora

- 2a33687 Exl Back Pressure Relief ValveDocumento19 pagine2a33687 Exl Back Pressure Relief ValveEnrique HortaNessuna valutazione finora

- Weco Butterfly ValvesDocumento16 pagineWeco Butterfly ValvesAdan Olvera HernandezNessuna valutazione finora

- A 487Documento6 pagineA 487arockia1977100% (2)

- 2a33687 Exl Back Pressure Relief Valve PDFDocumento51 pagine2a33687 Exl Back Pressure Relief Valve PDFEnrique HortaNessuna valutazione finora

- Tme CS: Technical Data SheetDocumento1 paginaTme CS: Technical Data SheetEnrique HortaNessuna valutazione finora

- wellServicingTools PDFDocumento47 paginewellServicingTools PDFEnrique HortaNessuna valutazione finora

- MCM Catalog Rev 16Documento31 pagineMCM Catalog Rev 16Enrique HortaNessuna valutazione finora

- IWNT MembershipDocumento2 pagineIWNT MembershipEnrique HortaNessuna valutazione finora

- NDT STDDocumento1 paginaNDT STDEnrique HortaNessuna valutazione finora

- Ta MismatchunionDocumento8 pagineTa MismatchunionChristian MatteoNessuna valutazione finora

- EquipmentDocumento38 pagineEquipmentEnrique HortaNessuna valutazione finora

- BTC Gate ValvesDocumento26 pagineBTC Gate ValvesCamilo Sanchez VanegasNessuna valutazione finora

- DocumentDocumento20 pagineDocumentEnrique HortaNessuna valutazione finora

- IIW - International Institute of WeldingDocumento3 pagineIIW - International Institute of WeldingNilesh MistryNessuna valutazione finora

- ATCO Gas STOPAQ-Vinylester Procedure Rev0Documento45 pagineATCO Gas STOPAQ-Vinylester Procedure Rev0mkash028Nessuna valutazione finora

- Elements Compounds MixturesDocumento55 pagineElements Compounds MixturesFatima ?Nessuna valutazione finora

- SY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchDocumento3 pagineSY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchLYKA ANTONETTE ABREGANANessuna valutazione finora

- Plastics: Name: Taaha Muzaffar Imam ROLL NO.: 19011AA002 Sem/Sec: Ii/A Branch: B.Arch College: Spa' JnafauDocumento5 paginePlastics: Name: Taaha Muzaffar Imam ROLL NO.: 19011AA002 Sem/Sec: Ii/A Branch: B.Arch College: Spa' JnafauTaaha Muzaffar ImamNessuna valutazione finora

- Merck Chemicals - Advantages For The EnvironmentDocumento4 pagineMerck Chemicals - Advantages For The EnvironmentMerck ChemicalsNessuna valutazione finora

- T.9.2.7 Reinforcing For Shear - EUROCODE2: RAPT User ManualDocumento16 pagineT.9.2.7 Reinforcing For Shear - EUROCODE2: RAPT User Manualtailieuxaydung2019Nessuna valutazione finora

- Computer Code For Monte Carlo MarchingDocumento78 pagineComputer Code For Monte Carlo MarchingJacob H. (Jack) LashoverNessuna valutazione finora

- ATP Production From Carbs Protein FatsDocumento16 pagineATP Production From Carbs Protein Fatshuraira bhattiNessuna valutazione finora

- Materials and Design: Sumrerng Rukzon, Prinya ChindaprasirtDocumento6 pagineMaterials and Design: Sumrerng Rukzon, Prinya ChindaprasirthenryNessuna valutazione finora

- Abzymes and Its ApplicationsDocumento36 pagineAbzymes and Its ApplicationsKritika Verma100% (2)

- OVERVIEW (4 Points) : CH116 General and Organic Principles LabDocumento4 pagineOVERVIEW (4 Points) : CH116 General and Organic Principles Labapi-557329548Nessuna valutazione finora

- Lesson 1 - Reactions Energy WorksheetDocumento4 pagineLesson 1 - Reactions Energy WorksheetAvakoalaNessuna valutazione finora

- Experiment 2: Brinell Hardness TestDocumento5 pagineExperiment 2: Brinell Hardness TestseifNessuna valutazione finora

- Unirub Techno India PVT 7Documento7 pagineUnirub Techno India PVT 7BalajiYachawadNessuna valutazione finora

- Journal of Controlled Release: Alexander Wei, Jonathan G. Mehtala, Anil K. PatriDocumento11 pagineJournal of Controlled Release: Alexander Wei, Jonathan G. Mehtala, Anil K. Patriprakush_prakushNessuna valutazione finora

- Organic Chemistry Carbonyl CompoundsDocumento34 pagineOrganic Chemistry Carbonyl CompoundsLovely Joysweet100% (2)

- CMTDocumento284 pagineCMTAaron R. AllenNessuna valutazione finora

- Energetics Lab - ChemDocumento5 pagineEnergetics Lab - Chemvaibhav100% (1)

- Analisis de Gas de Aceite de Transformador Utilizando Una Columna de Separacion Astm d3612 KasalabDocumento2 pagineAnalisis de Gas de Aceite de Transformador Utilizando Una Columna de Separacion Astm d3612 KasalabJohnatan HernándezNessuna valutazione finora

- List of Steel Products Made in The UK PDFDocumento120 pagineList of Steel Products Made in The UK PDFAntonio MarrufoNessuna valutazione finora

- Coal To LiquidsDocumento44 pagineCoal To LiquidsSukaran Singh100% (1)

- Effects of CN Ratios and Turning Frequencies On The Composting Process of Food Waste and Dry LeavesDocumento8 pagineEffects of CN Ratios and Turning Frequencies On The Composting Process of Food Waste and Dry LeavesJonathan SotoNessuna valutazione finora

- Coal Conversion StatisticsDocumento2 pagineCoal Conversion StatisticsPaulo BarraNessuna valutazione finora

- Psma411-Prelim ReviewerDocumento82 paginePsma411-Prelim ReviewerRebekah EquizNessuna valutazione finora

- Characterizing Synthetic Dyes by 2D LC-MSDocumento18 pagineCharacterizing Synthetic Dyes by 2D LC-MSM BustamanteNessuna valutazione finora

- PFOA Factsheet (Revised)Documento8 paginePFOA Factsheet (Revised)AngshumanNessuna valutazione finora

- Du Et Al 2020Documento12 pagineDu Et Al 2020Deise Dalazen CastagnaraNessuna valutazione finora

- Dwnload Full Chemistry in Context 9th Edition Amer Solutions Manual PDFDocumento35 pagineDwnload Full Chemistry in Context 9th Edition Amer Solutions Manual PDFezrak2martin100% (9)

- ThermodynamicsDocumento12 pagineThermodynamicsWasif RazzaqNessuna valutazione finora