Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Punching, Perforating, Blanking, Nibbling

Caricato da

TtrraanneeOonneeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Punching, Perforating, Blanking, Nibbling

Caricato da

TtrraanneeOonneeCopyright:

Formati disponibili

Page 1 of 2

Punching, perforating, blanking, nibbling

General

The process

Sheet metal is perforated and profiled by a number of specific processes. All rely on shear-fracture of the sheet. In

PUNCHING a circular or shaped hole is punched through the sheet by a hardened die. In PERFORATING an array of

punches operate as one unit, creating a pattern of holes in one operation. In BLANKING a shaped disk is created by

punching from a sheet by a punch with the desired shape mating with a die with the inverse shape. In NIBBLING a

sheet, supported on an anvil, is cut or trimmed to a desired profile by successive bites from a small, hardened punch,

with an action much like that of a sewing machine.

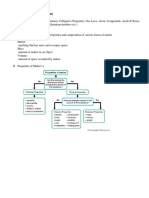

Process schematic

Figure caption

The processes of punching, perforating, blanking and nibbling.

Shape

Flat sheet

Dished sheet

Physical attributes

Range of section thickness 0.1 - 13 mm

Tolerance 0.015 - 0.8 mm

Roughness 0.5 - 12.5 µm

Process characteristics

Primary shaping processes

Secondary shaping processes

Machining processes

Cutting processes

Discrete

Economic attributes

Economic batch size (units) 1e3 - 1e7

Relative equipment cost high

Values marked * are estimates.

No warranty is given for the accuracy of this data

Page 2 of 2

Punching, perforating, blanking, nibbling

Relative tooling cost medium

Labor intensity low

Cost modeling

Relative cost index (per unit) Out Of Range MXN

Parameters: Material Cost = 105MXN/kg, Component Mass = 1kg, Batch Size = 1e3, Overhead Rate = 1.98e3MXN/hr, Capital Write-off Time = 5yrs, Load

Supporting information

Design guidelines

Punching and perforating are used both for functional and for aesthetic purposes. Blanking is the fastest way to make

profiled blanks for further working. It is possible to create raised features called half-shears. These are punched features

that are not fully sheared, giving an upstand which may be used for assembly location of other parts.

Technical notes

The processes can be applied to almost all non-brittle sheet materials provided they are not too hard. Carbon, stainless

and low alloy steels, aluminum alloys, fiberboard, cork, wood, laminated thermosets and cardboard are all cut in this

way.

Typical uses

PUNCHING and PERFORATING: perforated sheet metal, plastic or card.

BLANKING: blanks for pressing, forming and deep drawing, cabinet panels; domestic appliance components; small

machine parts small gears and levers; washers.

NIBBLING: larger, more elaborate sheet shapes often with a complex profile.

The environment

Lubricants and cutting fluids can pose an environmental problem. Special precautions are essential when machining

toxic materials such as beryllium.

Links

MaterialUniverse

Reference

Values marked * are estimates.

No warranty is given for the accuracy of this data

Potrebbero piacerti anche

- BIW Manufacturing Process - BODY in WHITEDocumento4 pagineBIW Manufacturing Process - BODY in WHITEsrinivaschakri0% (1)

- Cat ANeDocumento32 pagineCat ANeUgiezRagielNessuna valutazione finora

- The Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerDa EverandThe Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerValutazione: 4 su 5 stelle4/5 (1)

- Unit Iv Sheet Metal Processes 9Documento45 pagineUnit Iv Sheet Metal Processes 9Mohamed AshikNessuna valutazione finora

- Powder Pressing ProcessesDocumento3 paginePowder Pressing ProcessesThanes WaranNessuna valutazione finora

- Ijresm V2 I6 98 PDFDocumento11 pagineIjresm V2 I6 98 PDFPeterNessuna valutazione finora

- Blanking and PiercingDocumento5 pagineBlanking and PiercingPratap VeerNessuna valutazione finora

- Pressing Processes Sheet MetalDocumento64 paginePressing Processes Sheet MetalAnishMendisNessuna valutazione finora

- Blanking and PiercingDocumento5 pagineBlanking and PiercingSatheesh Sekar100% (1)

- TOPIC 7 Blanking Sheating and TrimmingDocumento19 pagineTOPIC 7 Blanking Sheating and TrimmingmouliNessuna valutazione finora

- 1HSS - Articles - Tooling Tips For High-Speed Stamping - MetalForming MagazineDocumento3 pagine1HSS - Articles - Tooling Tips For High-Speed Stamping - MetalForming MagazineSIMONENessuna valutazione finora

- Unit - Iv Sheet Metal ProcessesDocumento37 pagineUnit - Iv Sheet Metal ProcessesAakunoori GaneshNessuna valutazione finora

- Optimization of Trimming and Piercing Operations by Introducing A New ToolDocumento5 pagineOptimization of Trimming and Piercing Operations by Introducing A New ToolEditor IJTSRDNessuna valutazione finora

- A Circularity Analysis of Different Clearances in The Sheet Metal Punching ProcessDocumento4 pagineA Circularity Analysis of Different Clearances in The Sheet Metal Punching ProcessdesalegnNessuna valutazione finora

- Construction of FLD's On CuZn37 (Brass) Using Single Point Incremental Forming TechniqueDocumento8 pagineConstruction of FLD's On CuZn37 (Brass) Using Single Point Incremental Forming TechniqueInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- IPE 341-Metal Forming Processes - Sheet Metal WorkingDocumento36 pagineIPE 341-Metal Forming Processes - Sheet Metal WorkingMuhshin Aziz KhanNessuna valutazione finora

- Tooling KnowledgeDocumento92 pagineTooling KnowledgeChowkidar Chandru GowdaNessuna valutazione finora

- Turning Process, Defects, EquipmentDocumento7 pagineTurning Process, Defects, Equipmentvinaybaba100% (1)

- Fine BlankingDocumento4 pagineFine BlankingSingh LoveneetNessuna valutazione finora

- IPE 341 Chip Formation MechanismDocumento22 pagineIPE 341 Chip Formation MechanismAsif Bin Syed100% (1)

- A Presentation ON Prototype: Dimensional Accuracy: Dr. D.Y PATIL College of Engineering Akurdi, Pune Maharashtra - 411044Documento10 pagineA Presentation ON Prototype: Dimensional Accuracy: Dr. D.Y PATIL College of Engineering Akurdi, Pune Maharashtra - 411044AkshayJadhavNessuna valutazione finora

- Finite Element Analysis of Rectangular Cup: (2009BPR017) (2009BPR028) 2009BPR601)Documento33 pagineFinite Element Analysis of Rectangular Cup: (2009BPR017) (2009BPR028) 2009BPR601)Enrike GarciaNessuna valutazione finora

- Coin DieDocumento2 pagineCoin DieAnonymous j0aO95fgNessuna valutazione finora

- Fabrication of Flexible Coining Die For Cold Working OperationDocumento2 pagineFabrication of Flexible Coining Die For Cold Working OperationAnonymous j0aO95fgNessuna valutazione finora

- Lecture 4 Metal Cutting ProcessDocumento14 pagineLecture 4 Metal Cutting ProcessDhiraj DhimanNessuna valutazione finora

- Lecture2-Metalcutting 2Documento40 pagineLecture2-Metalcutting 2girma workuNessuna valutazione finora

- Chip Formation: Manufacturing Technology-IiDocumento20 pagineChip Formation: Manufacturing Technology-IiSachin BharadwajNessuna valutazione finora

- 1-Theory of Metal Cutting PDFDocumento144 pagine1-Theory of Metal Cutting PDFNithinArvindNessuna valutazione finora

- Introduction and Classification of Forging Processes: NPTEL - Mechanical Engineering - FormingDocumento8 pagineIntroduction and Classification of Forging Processes: NPTEL - Mechanical Engineering - FormingRashmi DhunganaNessuna valutazione finora

- Forming Limit DiagramsDocumento7 pagineForming Limit DiagramsatseucNessuna valutazione finora

- Design and Simulation of Different Progressive ToolsDocumento8 pagineDesign and Simulation of Different Progressive ToolsAnnaNessuna valutazione finora

- Manufacturing Process - PresentationDocumento15 pagineManufacturing Process - PresentationAnwesha PandaNessuna valutazione finora

- Irjet V6i5557 190928093642Documento6 pagineIrjet V6i5557 190928093642Joel Ramirez SNessuna valutazione finora

- Sheet Metal OperationDocumento17 pagineSheet Metal Operationsekar_scribd60% (5)

- Module 7 Sheet Metal-Forming Lecture 1Documento9 pagineModule 7 Sheet Metal-Forming Lecture 1ettypasewangNessuna valutazione finora

- 776 Dayton's Engineered Clearance-Web PDFDocumento6 pagine776 Dayton's Engineered Clearance-Web PDFMAPROLProjetosNessuna valutazione finora

- ESI Metal Stamping Design Guide v7Documento10 pagineESI Metal Stamping Design Guide v7javad salimiNessuna valutazione finora

- NCM IDocumento23 pagineNCM IAbhishek KumarNessuna valutazione finora

- NCD IcaestDocumento6 pagineNCD IcaestNaresh DeshpandeNessuna valutazione finora

- Design and Analysis of Sheet Metal Die Punch1Documento14 pagineDesign and Analysis of Sheet Metal Die Punch1Myst ToganNessuna valutazione finora

- Piercing DieDocumento5 paginePiercing DieJournalNX - a Multidisciplinary Peer Reviewed JournalNessuna valutazione finora

- Sheet Metal Working: Unit No. VDocumento67 pagineSheet Metal Working: Unit No. VMahesh SalotagiNessuna valutazione finora

- 1 NotesDocumento12 pagine1 NotesNeya SebastianNessuna valutazione finora

- Stamping ProcessDocumento9 pagineStamping ProcessAmp NurarakNessuna valutazione finora

- Basic Mechanical Engineering: Manufacturing ProcessesDocumento49 pagineBasic Mechanical Engineering: Manufacturing Processespritam goleNessuna valutazione finora

- Hard Turning Report En8Documento51 pagineHard Turning Report En8Muthu KumarNessuna valutazione finora

- Abrassive Jet Machining Main FileDocumento34 pagineAbrassive Jet Machining Main FilearjunNessuna valutazione finora

- T&D - Core 4 Tool & DieDocumento44 pagineT&D - Core 4 Tool & Dietisha revillaNessuna valutazione finora

- ICCSME-Conference PaperDocumento8 pagineICCSME-Conference PaperDeepthi Yenuga PNessuna valutazione finora

- Assignment No 6 Shearing Process in Sheet MetalDocumento5 pagineAssignment No 6 Shearing Process in Sheet MetalSameer Ahmed 20 - MCE - 60Nessuna valutazione finora

- 1994 - Precision Forging Straight and Helical Spur GearsDocumento6 pagine1994 - Precision Forging Straight and Helical Spur GearsNguyen Hoang DungNessuna valutazione finora

- Sheet Metal Forming - PpsDocumento26 pagineSheet Metal Forming - PpsNhan LeNessuna valutazione finora

- Experimental Studies On Influence of Milling Parameters On Surface Roughness of Nylon Material Using Taguchi MethodDocumento3 pagineExperimental Studies On Influence of Milling Parameters On Surface Roughness of Nylon Material Using Taguchi MethodIoan PascaNessuna valutazione finora

- Sheet Metal OperationsDocumento33 pagineSheet Metal Operationsziad almnaseerNessuna valutazione finora

- Diecutting and Creasing enDocumento12 pagineDiecutting and Creasing enVaradarajan100% (1)

- Metallic Additive ManufacturingDocumento61 pagineMetallic Additive Manufacturingashok gadewalNessuna valutazione finora

- Built Up Edge in CNC Turning and MillingDocumento2 pagineBuilt Up Edge in CNC Turning and MillingJo MarbeNessuna valutazione finora

- Duplex Nilsson PaperDocumento20 pagineDuplex Nilsson PaperAnky FadharaniNessuna valutazione finora

- CarbonCure Technical Note - Types of Concrete CarbonationDocumento4 pagineCarbonCure Technical Note - Types of Concrete CarbonationSakineNessuna valutazione finora

- Chemistry Investigatory Project: Topic: Preparation of Rayon ThreadDocumento14 pagineChemistry Investigatory Project: Topic: Preparation of Rayon Threadkhushi chelaniNessuna valutazione finora

- Glass Pin Post InsulatorDocumento3 pagineGlass Pin Post InsulatorrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrNessuna valutazione finora

- GRP BoqDocumento44 pagineGRP BoqMikuNessuna valutazione finora

- 10th-C Chapter 12 Re-TestDocumento2 pagine10th-C Chapter 12 Re-TestWasim NawazNessuna valutazione finora

- Heating Torch: The "Hot One" From HarrisDocumento2 pagineHeating Torch: The "Hot One" From HarrisedsngarNessuna valutazione finora

- EBPlate Work ExampleDocumento10 pagineEBPlate Work ExampleVivaCharlesNessuna valutazione finora

- RA Bill AbstractDocumento1 paginaRA Bill AbstractpraveenNessuna valutazione finora

- CyanideDocumento52 pagineCyanideWilliamEliezerClNessuna valutazione finora

- SMD DesolderingDocumento1 paginaSMD Desolderingdavid reyesNessuna valutazione finora

- Journal of Cleaner ProductionDocumento13 pagineJournal of Cleaner ProductionR JNessuna valutazione finora

- SYNOCURE886S70Documento2 pagineSYNOCURE886S70Samuel AgusNessuna valutazione finora

- Chemistry: Classifying MatterDocumento3 pagineChemistry: Classifying MatterMa. Filipina AlejoNessuna valutazione finora

- Oxygen BarrierDocumento20 pagineOxygen BarrierKarina ArdizziNessuna valutazione finora

- Fuel Types and Firing SystemsDocumento80 pagineFuel Types and Firing SystemsIrshad HussainNessuna valutazione finora

- Full Thesis PDFDocumento83 pagineFull Thesis PDFNewaz KabirNessuna valutazione finora

- ELLIPS ESE Lightning ArresterDocumento6 pagineELLIPS ESE Lightning ArresterRuchir Chaturvedi100% (1)

- Coating and CorrosionDocumento76 pagineCoating and CorrosionIntegridad de Equipos y Gestión de Activos Nelcam100% (1)

- Extrusion Die DesignDocumento67 pagineExtrusion Die DesignShubham Chaudhary100% (1)

- NMAT - Must Know-ChemistryDocumento45 pagineNMAT - Must Know-ChemistryElise TraugottNessuna valutazione finora

- ME 6503 DME 2 Marks With AnswerDocumento15 pagineME 6503 DME 2 Marks With AnswerheartyseeNessuna valutazione finora

- CIBSE Pipe Sizing V2.2Documento9 pagineCIBSE Pipe Sizing V2.2Sarmad ShahNessuna valutazione finora

- CHEM 201/L - EXPERIMENT: Elements, Compounds, and Mixture ADocumento2 pagineCHEM 201/L - EXPERIMENT: Elements, Compounds, and Mixture Aroven desuNessuna valutazione finora

- Me301 - FinalDocumento2 pagineMe301 - FinalkhalidNessuna valutazione finora

- Product & Service Datasheet: Medium Voltage (6kV To 36kV) Subsea Power Cable Repair JointDocumento2 pagineProduct & Service Datasheet: Medium Voltage (6kV To 36kV) Subsea Power Cable Repair Jointnader mahfoudhiNessuna valutazione finora

- Acids Bases and Salt Preparations 2 MSDocumento8 pagineAcids Bases and Salt Preparations 2 MSal katerjiNessuna valutazione finora

- Urban Transformers Safety and Environmental ChallengesDocumento8 pagineUrban Transformers Safety and Environmental ChallengesNicodemus Ervino MandalaNessuna valutazione finora

- Alterations and AdditionsDocumento25 pagineAlterations and AdditionsISAAC KIPSEREMNessuna valutazione finora

- SA Ch01Documento9 pagineSA Ch01Mohd AsmawiNessuna valutazione finora