Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

18EXCHGR

Caricato da

howard herreraCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

18EXCHGR

Caricato da

howard herreraCopyright:

Formati disponibili

Section 18

Heat Exchangers

GENERAL

A heat exchanger or interchanger is a device which transfers heat from one fluid to another

through a container wall. In a typical process industry application, a heat exchanger may be a

vessel in which an outgoing processed hot liquid transfers some of its heat to an incoming cold

liquid about to be processed. The amount of heat transferred is therefore not lost and can be

used again.

Heat exchangers can also be used to cool process fluids. For example, an outgoing cold gas

may take up part of the heat from an incoming warmer gas, as in a liquid-air plant.

Double Pipe Exchangers

As shown in Figure 18-1, a double pipe or fintube exchanger consists of two pipes, one inside

another. The inner tube is usually finned to provide a larger surface for heat transfer. Double

pipe exchangers are used where flow and necessary temperature transfer are rather small.

1. SHELL ASSEMBLY 8. FINTUBE STUB END FLANGE 15. SHELL NOZZLE BOLTING 16.

2. TUBE ASSEMBLY 9. TUBE RETURN BEND CONNECTOR 17. BRACKET BOLTS

3. COVER PLATE 10. TUBE RETURN BEND CONNECTOR 18. COVER GASKET

4. COMPRESSION FLANGE 11. TUBE RETURN BEND CONNECTOR 19. FINTUBE GASKET

5. SEALING RING 12. SHELL NOZZLE COMPANION FLANGE 20. SHELL NOZZLE GASKET

6. SPLIT RING 13. COVER PLATE BOLTING 21. NAMEPLATE

7. FINTUBE FITTING FLANGE 14. TUBESIDE BOLTING

FIGURE 18- - DOUBLE PIPE EXCHANGER

Fintube exchangers are generally used when one fluid is gaseous, viscous, or of small quantity.

They are particularly desirable for high pressure services because their small diameter is

conducive to low cost construction. Their modular design assures maximum flexibility of

application since sections can be stacked vertically or horizontally to attain desired heat transfer.

It is also easy to reuse these units in other services since one or more sections may be used as

needed. The fins can be welded to the tube to form a unit. Fins can also be formed by an

extrusion process. For special applications they may be on the inside or on both inside and

outside of the parent pipe.

© 1996 Bechtel Corp. Piping/Mechanical Handbook 18-1

Section 18 Heat Exchangers

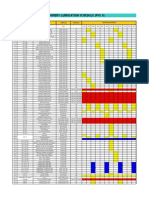

FIGURE 18- - TEMA SHELL AND TUBE EXCHANGER TYPES

18-2 Piping/Mechanical Handbook 1996:Rev.2

Heat Exchangers Section 18

FIGURE 18- - TYPICAL SHELL AND TUBE HEAT EXCHANGER

1. PASS PARTITION 12. IMPINGEMENT BAFFLE 23. GASKET

2. BLIND FLANGE 13. TUBE 24. BACK-UP RING

3. LIFTING RING 14. TIE ROD 25. SPLIT-KEY RING

4. CHANNEL FLANGE 15. SPACER 26. VENT CONNECTION

5. CHANNEL CYLINDER 16. SHELL CYLINDER 27. SHELL COVER CYLINDER

6. CHANNEL NOZZLE 17. TRAVERSE BAFFLE 28. SHELL COVER HEAD

7. CHANNEL FLANGE 18. SUPPORT PLATE 29. FLOATING HEAD COVER

8. STATIONARY TUBE SHEET 19. STUD 30. FLOATING TUBE SHEET

9. SHELL FLANGE (CHANNEL END) 20. HEX NUT 31. DRAIN CONNECTION

10. INSTRUMENT CONNECTION 21. SHELL FLANGE (COVER END) 32. SUPPORT SADDLES

11. SHELL NOZZLE 22. SHELL COVER FLANGE

The shell side is furnished with companion flanges so that piping can be connected to a beveled

end. Tubeside connections are supplied with a flanged assembly to allow the tube hairpin to be

disconnected from the piping. The tube or hairpin section will be pulled from the return bend

housing end.

These units are almost always installed as multiple modules. They are normally spoken of in

multiples such as "3 wide by 2 high" which refers to 6 modules installed in 2 layers, 3 side by side

units. Support saddles are provided with bolt holes on all four sides for modular bolting and are

not fixed to the shell assembly, leaving foundation spacing. Sometimes one or two units are

bolted to vertical steel columns.

Shell and Tube Exchangers

Shell and tube type exchangers of the type shown in Figure 18-3 are most commonly specified

for process plants. These exchangers are designed in accordance with the TEMA (Tubular

1996:Rev.2 Piping/Mechanical Handbook 18-3

Section 18 Heat Exchangers

FIGURE 18- - TEMA TYPES AES SHELL AND TUBE EXCHANGER

Exchanger Manufacturers Association) code. Figure 18-2 lists typical TEMA shell and tube heat

exchanger types. TEMA also specifies exchanger part types in a letter code.

Referring to the type AES exchanger shown in Figure 18-4, flow entering the nozzle, Item 6, at

the channel or tubeside end meets the pass partition, Item 1, and is diverted into the tubes. The

tubes, Item 13, route flow to the other end and back to the channel outlet nozzle. Shell side fluid

enters nozzle, Item 11, and makes contact with the outside of the tubes. Transverse baffles, Item

17, are located so that they force the fluid to flow up and down, making the most efficient tube

contact and attaining maximum heat transfer on its way to the outlet nozzle.

The tube bundle is comprised of the tubesheet, Item 8, and the tubes attached to the tubesheet.

By removing the channel section, the entire tube bundle can be pulled out from the exchanger for

cleaning, repairs or total replacement. Not all exchangers have removable tube bundles.

Nonremovable tube bundle exchangers are called fixed tubesheet types.

18-4 Piping/Mechanical Handbook 1996:Rev.2

Heat Exchangers Section 18

FIGURE 18- - TEMA KETTLE TYPE SHELL AND TUBE EXCHANGER

1. CHANNEL COVER 7. SHELL NOZZLE 13. SHELL FLANGE

2. CHANNEL FLANGE 8. LIQUID LEVEL CONNECTION 14. SUPPORT

3. INSTRUMENT CONNECTION 9. SHELL COVER 15. TIE RODS AND SPACERS

4. CHANNEL NOZZLE 10. WEIR 16. SUPPORT PLATES

5. PASS PARTITION 11. CHANNEL 17. TUBES

6. SHELL 12. TUBESHEET

Kettle Type Exhangers

In the kettle type exchanger shown in Figure 18-5, the heating fluid always enters the channel top

nozzle, Item 4, and exits via the bottom channel nozzle. The main purpose of the shell side is to

vaporize liquid entering the shell nozzle, Item 7, near the shell flange, Item 13. Vapor exits

through the shell nozzle, Item 7, at the top of the exchanger shell. The weir, Item 10, is a dam

designed to keep the tube bundle covered with liquid at all times. Surplus liquid overflows the

weir and into the shell cover area. A level controller is piped to the Liquid Level Connections, Item

8, and maintains liquid level in this section at about half the weir height. Surplus liquid exits via

the shell nozzle, Item 7, in this section. Normally a level gage allows visual examination of the

liquid level behind the weir.

1996:Rev.2 Piping/Mechanical Handbook 18-5

Section 18 Heat Exchangers

FIGURE 18- - INDUCED DRAFT AIR COOLED HEAT EXCHANGER

Air Cooled Heat Exchangers

Air cooled heat exchangers are those in which the cooling is done by blowing or drawing air

across finned tubes. Air cooled exchangers may be either induced draft as shown in Figure 18-6

or forced draft as shown in Figure 18-7 which means that the fans may either be mounted above

the tube sections, drawing the air up through the tubes and exhausting to the atmosphere, or the

fans may be mounted below the tube sections, drawing the air from the atmosphere and forcing it

up through the sections. The commodity temperature from the coolers can be controlled by:

· The use of two speed fans

· Adjustable louvers

· A combination of the two

Two speed fans have the definite advantage of conserving horsepower and are usually provided.

The range of control gained by this means is obviously limited and, for this reason, adjustable

louvers are quite often provided where more precise control is required such as in extremely cold

climates. The louvers may be manually or automatically controlled by the commodity outlet

temperature. The fans may also have adjustable pitch blades for further temperature control.

This is usually done automatically through a hydraulic drive.

18-6 Piping/Mechanical Handbook 1996:Rev.2

Heat Exchangers Section 18

FIGURE 18- - FORCED DRAFT AIR COOLED HEAT EXCHANGER

A significant feature of the dry coolers is the finned tubes. It is necessary that the tubes have

these fins to increase the surface in contact with the air where the heat transfer rate is usually

quite low. Since these fins must be relied on to conduct the bulk of the heat from the commodity

inside the tubes to the air outside, it is important that they maintain a good thermal bond with the

tubes at all times.

There are several different types of fin construction. The best and most durable type is that in

which the fins are an integral part of the tube itself and are formed by extrusion of the tube

through a die. This type of tube, however, is usually rather expensive. At least one manufacturer

attaches the fins by routing a groove in the tube wall and forcing the fin tightly into this groove. In

some cases, the fin is wrapped around the tube and then soldered to the tube. This provides a

very high thermal efficiency. In some cases, the fins are wound in a tight helix about the tube and

soldered at each end. This design depends on pressure to hold the fin against the tube and air

gaps between the fin and tube reduce the thermal transfer.

1996:Rev.2 Piping/Mechanical Handbook 18-7

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- BMW Climate Control ComponentsDocumento59 pagineBMW Climate Control Componentsgraig27100% (3)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Wing Fan CatalogueDocumento6 pagineWing Fan CatalogueMarcinNessuna valutazione finora

- Homemade HRV, PDF, Jan 2004Documento39 pagineHomemade HRV, PDF, Jan 2004JohnNessuna valutazione finora

- Servicemanual Electrolux Dishwasher PDFDocumento32 pagineServicemanual Electrolux Dishwasher PDFmvgonzalez2020100% (3)

- Air-Cooled Heat ExchangersDocumento8 pagineAir-Cooled Heat Exchangersmohamed abd eldayemNessuna valutazione finora

- Problems of PET BlowingDocumento14 pagineProblems of PET BlowingMohamedHassan100% (3)

- ESA Instruction Manual English 1.01Documento18 pagineESA Instruction Manual English 1.01Stephany Sucerquia100% (1)

- Ge Tome 1Documento81 pagineGe Tome 1Adetunji Taiwo100% (1)

- Glbe3025-2 2425GR PDFDocumento540 pagineGlbe3025-2 2425GR PDFMihail Kolish100% (2)

- Peugeot 306 Cooling Fan Operation PrincipleDocumento7 paginePeugeot 306 Cooling Fan Operation PrincipleawangddNessuna valutazione finora

- Final Report of Dry CoolerDocumento43 pagineFinal Report of Dry CoolerHailemariam WeldegebralNessuna valutazione finora

- GP170501 Human Factors in Plant Design PDFDocumento27 pagineGP170501 Human Factors in Plant Design PDFegfernandez21100% (1)

- Fans and Blowers Research ReportDocumento14 pagineFans and Blowers Research ReportRibhanshu RajNessuna valutazione finora

- Cooling Tower Project ReportDocumento35 pagineCooling Tower Project Reportdilliprout.caplet2016Nessuna valutazione finora

- Shine Dew Water Equiment Co., LTD.: Chapter 1 - Project Basic DataDocumento17 pagineShine Dew Water Equiment Co., LTD.: Chapter 1 - Project Basic Dataardhendu1Nessuna valutazione finora

- Solar Dryer IFRJDocumento18 pagineSolar Dryer IFRJdzaki ramadhanNessuna valutazione finora

- Nirolisting248049453720123211626252888761 2017330222740 507030 1Documento188 pagineNirolisting248049453720123211626252888761 2017330222740 507030 1Ganesh IngaleNessuna valutazione finora

- Fuji E11 CatalogueDocumento24 pagineFuji E11 CatalogueShujhat AhmedNessuna valutazione finora

- Lube Oil Plan PVC2Documento10 pagineLube Oil Plan PVC2daxNessuna valutazione finora

- Catalogo de Partes Cocina Figidaire Manual de FabricaDocumento14 pagineCatalogo de Partes Cocina Figidaire Manual de Fabricaalexis paulino cedeño rivera100% (1)

- Appendix 2.17 - SPAIN - Madrid - M30-Río-TUNNELDocumento6 pagineAppendix 2.17 - SPAIN - Madrid - M30-Río-TUNNELAnonymous CoidT1yNessuna valutazione finora

- API Standards: Pumps Api STD Edition Year PublishedDocumento3 pagineAPI Standards: Pumps Api STD Edition Year PublishedSlbcar LoogingNessuna valutazione finora

- Operation Manual Panduan Pengoperasian: ModelDocumento32 pagineOperation Manual Panduan Pengoperasian: ModelHong HuyNessuna valutazione finora

- R&AC Lab ManualDocumento29 pagineR&AC Lab ManualPARAMESHNessuna valutazione finora

- Frecon Plus SeriesDocumento4 pagineFrecon Plus SeriesacjsystemsNessuna valutazione finora

- Ahu Low Res PDFDocumento52 pagineAhu Low Res PDFmo farawelaNessuna valutazione finora

- I HtgMKTGLiteraturePDFsModine7-115 0Documento24 pagineI HtgMKTGLiteraturePDFsModine7-115 0huron11Nessuna valutazione finora

- Carrier 39Lx03-25 PDFDocumento44 pagineCarrier 39Lx03-25 PDFDanNessuna valutazione finora

- Saudi Fan Industries: Technical ProjectDocumento12 pagineSaudi Fan Industries: Technical ProjectMohamad MhannaNessuna valutazione finora

- Midea Rooftop Package UnitDocumento15 pagineMidea Rooftop Package Unithany mohamedNessuna valutazione finora