Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

What Is Lopa

Caricato da

guhadebasis0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

83 visualizzazioni5 pagineTitolo originale

WHAT IS LOPA.docx

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

83 visualizzazioni5 pagineWhat Is Lopa

Caricato da

guhadebasisCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

What is LOPA?

LOPA = Layer of Protection Analysis

LOPA is a semi-quantitative methodology that can be used to

identify safeguards that meet the independent protection layer

(IPL) criteria

LOPA provides specific criteria and restrictions for the evaluation

of IPLs

LOPA is limited to a single cause-consequence pair as a

scenario

Layer of Protection analysis (LOPA) is a simplified quantitative tool for analyzing and assessing

risk. LOPA was developed by user organizations during the 1990s as a streamlined risk assessment

tool, using conservative rules and order of magnitude estimates of frequency probability and

consequence severity. When the method was shown to be an efficient means to access risk, several

company published papers describing the driving forces behind their efforts to develop the method,

their experience of LOPA and examples of their use. In particular, the papers and discussions

amount the attendees at the Center for Chemical Process Safety (CCPS) international conference

and workshop on risk analysis in Process safety in 1997 brought agreement that a book describing

the LOPA method should be developed. This led to the publication of the concept book: Layer of

Protection Analysis: simplified Process Risk Assessment (CCPS, LOPA) in 2001.

LOPA has grown greatly in popularity and usefulness since the publication of CCPS LOPA (2001) on

the subject. Guidelines for Initiating Events and Independent Layers of Protection build on LOPA by:

Providing additional examples of initiating events (IE) and

independent protection layers (IPLs)

Provides more guidance for determining the value of each

prospective initiating event frequency (IEF and IPL probibility of

failure on demand (PFD)

Proving more information on the overall management systems as

well as other considerations specific to a particular IE or IPL,

which are needed to support the use of the values provided in

this database.

Basic LOPA Steps

1. Identify the consequence to screen the scenario

2. Select an accident scenario

3. Identify the initiating event & determine the initiating event frequency

4. Identify the IPLs & estimate Probability of Failure on Demand (PFD)

5. Estimate the risk, determine the frequency of the mitigated

consequence by mathematically combining the initiating event

frequency and IPL PFDs

6. Evaluate the risk and see if additional IPL is needed

LOPA Components

Initiating Events

The minimum combination of failures or errors necessary to start the propagation of an incident

sequence.

See Initiating Events

Independent Layer of Protection

An independent protection layer (IPL) is a device, system, or action that is capable of preventing a

scenario from proceeding to its undesired consequence independent of the initiating event or the

action of any other layer of protection associated with the scenario.

See Independent Protection Layers

Conditional Modifier

Probabilistic condition that is not intertwined with the scenario

itself

Probabilities generally associated with the post-release part of an

incident sequence.

Learn about Conditional Modifiers

Enabling Conditions

Enabling conditions are situations which must occur

simultaneous with a given initiating event to allow the specific

cause for a scenario to propagate to a consequence of interest.

Consists of an operation or condition that does not directly cause

the scenario, but that must be present or active in order for the

scenario to proceed to a loss event

Not all LOPA have enabling conditions

Learn about Enabling Conditions

Note: Not every LOPA have enabling condition and conditional Modifiers

CCPS LOPA Initiating Events

You can view the list of LOPA Initiating Events below. If you'd like to see the details, you'll need to

log in as a CCPS member. Learn more about corporate membership.

1. Above ground piping: leak (pipe size ≤ 150 mm, 6 in)

2. Aboveground piping in typical service: full breach failure (pipe

size > 150 mm, 6 in)

3. Aboveground piping: full breach failure (pipe size ≤ 150 mm, 6 in)

4. Aboveground piping: leak (pipe size >150 mm, 6 in)

5. Atmospheric tank: catastrophic failure

6. Atmospheric tank: continuous 10 mm diameter leak

7. BPCS control loop failure

8. Complete primary pump seal failure

9. Failure of double check valves in series

10. Fire-resistant insulation and cladding on vessel

11. Hose failure, leak and rupture

12. Human error during a routine task that is performed >=once per

week

13. Human error during a task that is performed < once per month

14. Human error during a task that is performed between once per

month and once per week

15. Localized loss of power - Single circuit loss of power

16. Premature opening of spring-loaded relief valve

17. Pressure regulator failure

18. Pressure vessel: catastrophic failure

19. Pump seal leak

20. Pump, compressor, fan, or blower failure

21. Screw conveyor failure

22. Screw conveyor overheating of materials

23. Single check valve failure

24. Single circuit loss of power

25. Spurious operation of SCAI

CCPS LOPA Independent Protection

Layers

You can view the list of LOPA IPS below. If you'd like to see the details, you'll need to log in as a

CCPS member. Learn more about corporate membership.

1. Adjustable Movement-Limiting Device

2. Automatic Explosion Suppression System for Process Equipment

3. Automatic Fire Suppression System (within process equipment)

4. Automatic Fire Suppression System for a Room

5. Automatic Fire Suppression System for Local Application

6. Buckling Pin Isolation Valve (BPIV)

7. Buckling Pin Relief Valve

8. Captive Key/Lock System

9. Check Valve

10. Conservation Vacuum and/or Pressure Relief Vent

11. Continuous Pilot

12. Continuous Ventilation with Automated Performance Monitoring

13. Continuous Ventilation without Automated Performance Monitoring

14. Dikes, Berms, and Bunds

15. Drainage to Dikes, Berms, and Bunds with Remote Impoundment

16. Dual Spring-Operated Pressure Relief Valves

17. Emergency Ventilation Initiated by Safety Controls, Alarms, and Interlocks (SCAI)

18. End-of-Line Deflagration Arrestor

19. Excess Flow Valve

20. Explosion Isolation Valve

21. Explosion Panels on Process Equipment

22. Fire-Resistant Insulation and Cladding on Vessel

23. Frangible Roof on Flat-Bottom Tank

24. Gas Balance/Adjustable Set Pressure Surge Relief Valve

25. Human Response to an Abnormal Condition

26. Human Response to an Abnormal Condition with Multiple Indicators…

27. In-Line Deflagration Arrestor

28. In-Line Stable Detonation Arrester

29. In-Line Unstable Detonation Arrester

30. Line Containing a Fluid with the Potential to Freeze

31. Mechanical Overspeed Trip on a Turbine

32. Mechanically Activated Emergency Shutdown/Isolation Device

33. Multiple Mechanical Pump Seal System with Seal Failure Detection and Response

34. Overflow Line Containing a Passive Fluid or with a Rupture Disk

35. Overflow Line with no Impediment to Flow

36. Permanent Mechanical Stop that Limits Travel

37. Personal Protective Equipment (PPE)

38. Pilot-Operated Pressure Relief Valve

39. Pipeline Surge Dampening Vessel

40. Pressure Reducing Regulator

41. Restrictive Flow Orifice

42. Rupture Disk

43. Safety Control Loop

44. Safety Interlock

45. SIS Loop

46. Spring-Operated Pressure Relief Valve

47. Spring-Operated Pressure Relief Valve with Rupture Disk

48. Vacuum Breaker

49. Vent Panels on Enclosures

Conditional Modifiers

Click on any conditional modifier title to see a full description. Learn about when to use and when

not to use conditional modifiers.

List of Conditional Modifiers:

Probability of a hazardous atmosphere

Probability of ignition inside process equipment

Probability of ignition outside process equipment

Probability of uncontrolled reaction initiation

Probability of Dust explosion

Probability of vessel rupture explosion

Probability of vapor cloud explosion

Probability of deflagration to detonation transition

Probability of personnel presence

Probability of injury or fatality

Probability of equipment damage or other financial impact

Appendix A: Simultaneous failure and “double jeopardy”

Double jeopardy

Revealed vs un-revealed failures

Quantifying double jeopardy

When the consideration of the Simultaneous failures is valid

Appendix B: Peak Risk Concepts

Time at Risk Enabling conditions:

Seasonal Risk

Process State Risk

Campaigning Enabling Conditions

Appendix C: Example Rule set for LOPA Enabling conditions

Potrebbero piacerti anche

- NADCA-Introduction To Die Casting PDFDocumento116 pagineNADCA-Introduction To Die Casting PDFMichael Naím Dévora Quintanar100% (6)

- Ооо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RDocumento53 pagineОоо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RSiva baalan50% (2)

- Logic Solver For Tank Overfill Protection: Moore Industries-International, Inc. - 1Documento14 pagineLogic Solver For Tank Overfill Protection: Moore Industries-International, Inc. - 1Ghulam MustafaNessuna valutazione finora

- Crossrunner 250cc Service ManualDocumento228 pagineCrossrunner 250cc Service ManualAnna RyanNessuna valutazione finora

- Risk Acceptance Criteria: Overview of ALARP and Similar Methodologies As Practiced WorldwideDocumento40 pagineRisk Acceptance Criteria: Overview of ALARP and Similar Methodologies As Practiced WorldwidePEP Zona 7Nessuna valutazione finora

- Westfield Company Profile Rev3 May2017 (Web)Documento29 pagineWestfield Company Profile Rev3 May2017 (Web)ifiokdomNessuna valutazione finora

- PSM Compliance ChecklistDocumento18 paginePSM Compliance ChecklistSachin SikkaNessuna valutazione finora

- Ansi Vs API PumpsDocumento4 pagineAnsi Vs API PumpsarcanicrahulNessuna valutazione finora

- Storage Tank Gas Breathing For Purge Gas SizingDocumento3 pagineStorage Tank Gas Breathing For Purge Gas SizingguhadebasisNessuna valutazione finora

- Rotary EquipmentDocumento6 pagineRotary EquipmentVijayaNessuna valutazione finora

- Preliminary Hazard Analysis GuideDocumento40 paginePreliminary Hazard Analysis Guidedroffilcz27100% (2)

- Film Evaporation Technology GuideDocumento12 pagineFilm Evaporation Technology GuideVanessa Denise AguilarNessuna valutazione finora

- Overview of QRA SoftwareDocumento52 pagineOverview of QRA SoftwareMarcus HartfelderNessuna valutazione finora

- Commissioning Air PreheaterDocumento14 pagineCommissioning Air Preheaterarvidkumar87060Nessuna valutazione finora

- 1 1 To Agartala (India) To Akhura (Bangladesh) : Dimension Details of Pile CapDocumento3 pagine1 1 To Agartala (India) To Akhura (Bangladesh) : Dimension Details of Pile CapNilay GandhiNessuna valutazione finora

- DocumentDocumento45 pagineDocumentMuhammad IqmalNessuna valutazione finora

- Iam Opc Security Wp1Documento39 pagineIam Opc Security Wp1Industrial Automation and MechatronicsNessuna valutazione finora

- Correct Hazid ChecklisterDocumento16 pagineCorrect Hazid ChecklisterAkintoye AsaoluNessuna valutazione finora

- Chastainw Advancesinlayerofprotectionanalysis PDFDocumento37 pagineChastainw Advancesinlayerofprotectionanalysis PDFanon_770350620100% (1)

- 2002 07 Beacon English 0Documento1 pagina2002 07 Beacon English 0Eslam HusseinNessuna valutazione finora

- TA Chemicals Guide en LRDocumento24 pagineTA Chemicals Guide en LRYehor HorbatkoNessuna valutazione finora

- PSM 22.1 - Element 17 - Incident Investigation - BSCAT (v2)Documento27 paginePSM 22.1 - Element 17 - Incident Investigation - BSCAT (v2)Ahmed AdelNessuna valutazione finora

- Chapter No. 13: Hazop StudyDocumento9 pagineChapter No. 13: Hazop StudyMudassir HashmiNessuna valutazione finora

- WEB Guidance On Managing Fatigue 16.04.14Documento80 pagineWEB Guidance On Managing Fatigue 16.04.14Wendri PelupessyNessuna valutazione finora

- Flammables, Explosion Risks and DSEARDocumento10 pagineFlammables, Explosion Risks and DSEARTitash Mukherjee SenNessuna valutazione finora

- Managing Double Jeopardy in Process Hazard Analysis - Allison de ManDocumento9 pagineManaging Double Jeopardy in Process Hazard Analysis - Allison de ManJay JayNessuna valutazione finora

- Bowtie Pro MethodologyDocumento12 pagineBowtie Pro MethodologyEfari BahchevanNessuna valutazione finora

- A New Approach to HAZOP of Complex Chemical ProcessesDa EverandA New Approach to HAZOP of Complex Chemical ProcessesNessuna valutazione finora

- A Introduction To Advanced Process Control For ManagersDocumento3 pagineA Introduction To Advanced Process Control For Managerssandeep lalNessuna valutazione finora

- ChE 534 - Module 3Documento34 pagineChE 534 - Module 3Precious JamesNessuna valutazione finora

- Nuclear Radioactive Materials in the Oil and Gas IndustryDa EverandNuclear Radioactive Materials in the Oil and Gas IndustryNessuna valutazione finora

- (Kletz Trevor) Lessons From Disaster-How OrganizatDocumento192 pagine(Kletz Trevor) Lessons From Disaster-How OrganizatAmjad HaniNessuna valutazione finora

- Quantitative Risk Assessment in ChevronDocumento23 pagineQuantitative Risk Assessment in ChevronMani KumarNessuna valutazione finora

- The Data Industry: The Business and Economics of Information and Big DataDa EverandThe Data Industry: The Business and Economics of Information and Big DataNessuna valutazione finora

- Standard Purlins Manual PDFDocumento76 pagineStandard Purlins Manual PDFamazonNessuna valutazione finora

- Simplified Risk Analysis (LOPA)Documento8 pagineSimplified Risk Analysis (LOPA)hmatora72_905124701Nessuna valutazione finora

- Auditorias PSM Hse UkDocumento212 pagineAuditorias PSM Hse UkGustavo AgudeloNessuna valutazione finora

- International Standard: ISO 13702part#Documento12 pagineInternational Standard: ISO 13702part#Deepak DubeyNessuna valutazione finora

- 2 2b Silicon Microfabrication Part 2Documento45 pagine2 2b Silicon Microfabrication Part 2Mạnh HiệpNessuna valutazione finora

- IChemE - LPB 117-1994 - Flixborough 20 Years OnDocumento3 pagineIChemE - LPB 117-1994 - Flixborough 20 Years Onsl1828100% (1)

- Firetrace Report in The Line of FireDocumento18 pagineFiretrace Report in The Line of FireJaam Noman ShafqatNessuna valutazione finora

- FQE Chemicals NORM Decontamination BrochureDocumento4 pagineFQE Chemicals NORM Decontamination BrochureimafishNessuna valutazione finora

- Pigging Simulation For Horizontal Gas-Condensate Pipelines With Low-Liquid LoadingDocumento9 paginePigging Simulation For Horizontal Gas-Condensate Pipelines With Low-Liquid LoadingAnonymous aoNBPi2f1v100% (1)

- Optical Gas Imaging: Infrared Cameras For Gas Leak DetectionDocumento18 pagineOptical Gas Imaging: Infrared Cameras For Gas Leak DetectionFathoni Putra WIjaya100% (1)

- Gas Sweetening Units Risk Assessment Using HAZOP Procedure: Mahdi Goharrokhi Fateme Farahmand Maryam OtadiDocumento5 pagineGas Sweetening Units Risk Assessment Using HAZOP Procedure: Mahdi Goharrokhi Fateme Farahmand Maryam OtadiHani Kirmani50% (2)

- (BS EN 12981 - 2005+A1 - 2009) - Coating Plants. Spray Booths For Application of Organic Powder Coating Material. Safety Requirements.Documento54 pagine(BS EN 12981 - 2005+A1 - 2009) - Coating Plants. Spray Booths For Application of Organic Powder Coating Material. Safety Requirements.Simon ThaonNessuna valutazione finora

- Beacon-Overflow+ignition Source PDFDocumento1 paginaBeacon-Overflow+ignition Source PDFjargiaNessuna valutazione finora

- Seveso Directive Guide InspectionsDocumento26 pagineSeveso Directive Guide InspectionsLau ZamNessuna valutazione finora

- Hazop - Net PDFDocumento9 pagineHazop - Net PDFPalash DeyNessuna valutazione finora

- HAZOP Tutorial: Figure 1. Select Equipment and Process ParameterDocumento9 pagineHAZOP Tutorial: Figure 1. Select Equipment and Process ParameterRangarirai MuswereNessuna valutazione finora

- HSE, HSG53 "Respiratory Protective Equipment at Work, A Practical Guide".Documento65 pagineHSE, HSG53 "Respiratory Protective Equipment at Work, A Practical Guide".Leonora NusblatNessuna valutazione finora

- GAPS Guidelines: Measuring Management of Change PerformanceDocumento2 pagineGAPS Guidelines: Measuring Management of Change PerformanceAsad KhanNessuna valutazione finora

- Wb97-5E0 Outrigger Hydraulic Piping (Con Valvula de Alivio)Documento2 pagineWb97-5E0 Outrigger Hydraulic Piping (Con Valvula de Alivio)ale aleNessuna valutazione finora

- Paper - Arco Channelview Texas Explotion 1990Documento12 paginePaper - Arco Channelview Texas Explotion 1990Ruby0% (1)

- HAZOP Studies GuideDocumento4 pagineHAZOP Studies GuideMRITYUNJOY GUPTANessuna valutazione finora

- HAZOPDocumento8 pagineHAZOPMandar PhadkeNessuna valutazione finora

- Impact of Poor Maintenance!Documento16 pagineImpact of Poor Maintenance!Nimesh Shah100% (1)

- Diagram For Exercise 2: CoolerDocumento6 pagineDiagram For Exercise 2: CoolerJoão AlegretiNessuna valutazione finora

- Gas Cylinders + BLEVEDocumento46 pagineGas Cylinders + BLEVEPintor SiagianNessuna valutazione finora

- Engineers View of Human Error - KletzDocumento53 pagineEngineers View of Human Error - KletzRdW992049RdWNessuna valutazione finora

- Public Report of The Fire and Explosion at Conocophillips RefineryDocumento30 paginePublic Report of The Fire and Explosion at Conocophillips RefineryDragan GasicNessuna valutazione finora

- Lesson From Seveso ItalyDocumento48 pagineLesson From Seveso ItalyBilal ZamanNessuna valutazione finora

- Aac Spec 377005Documento19 pagineAac Spec 377005JakesNessuna valutazione finora

- Chapter Four Risk Assessment of NLNGDocumento8 pagineChapter Four Risk Assessment of NLNGOkePreciousEmmanuelNessuna valutazione finora

- VEGA Level Sensor VEGAFLEX 81 Guided Wave Radar Level Sensor Operating InstructionsDocumento80 pagineVEGA Level Sensor VEGAFLEX 81 Guided Wave Radar Level Sensor Operating InstructionsDavid CoralesNessuna valutazione finora

- F EI Calculation WorkbookDocumento51 pagineF EI Calculation WorkbookWu DangNessuna valutazione finora

- Spe 52157Documento30 pagineSpe 52157budiNessuna valutazione finora

- Risk analysis of a chemical industry using ORA procedureDocumento17 pagineRisk analysis of a chemical industry using ORA procedureUsama NiaziNessuna valutazione finora

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984Da EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984Nessuna valutazione finora

- SummaryDocumento1 paginaSummaryguhadebasisNessuna valutazione finora

- Haz ChemDocumento5 pagineHaz ChemguhadebasisNessuna valutazione finora

- SafetyIntegrityLevel PDFDocumento17 pagineSafetyIntegrityLevel PDFzazaNessuna valutazione finora

- COLLABORATIVEDocumento8 pagineCOLLABORATIVEguhadebasisNessuna valutazione finora

- Form Lopa Summary SheetDocumento1 paginaForm Lopa Summary SheetguhadebasisNessuna valutazione finora

- Waste Treatment and DisposalDocumento2 pagineWaste Treatment and DisposalguhadebasisNessuna valutazione finora

- Two Fa: Interpreting Ure RatesDocumento14 pagineTwo Fa: Interpreting Ure RatesguhadebasisNessuna valutazione finora

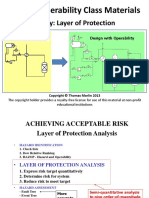

- Safety: Layer of Protection: Process Operability Class MaterialsDocumento48 pagineSafety: Layer of Protection: Process Operability Class MaterialsguhadebasisNessuna valutazione finora

- LT HC ProcessDocumento9 pagineLT HC ProcessguhadebasisNessuna valutazione finora

- Tail Gas Clean UpDocumento2 pagineTail Gas Clean UpguhadebasisNessuna valutazione finora

- Refinery Sweetening Process ExplainedDocumento3 pagineRefinery Sweetening Process ExplainedguhadebasisNessuna valutazione finora

- Catalytic PolymerisationDocumento7 pagineCatalytic PolymerisationguhadebasisNessuna valutazione finora

- 3 PDFDocumento9 pagine3 PDFRaju GummaNessuna valutazione finora

- Light Distillate ProcessDocumento11 pagineLight Distillate ProcessguhadebasisNessuna valutazione finora

- Delayed Coking Process DescriptionDocumento14 pagineDelayed Coking Process DescriptionRaju GummaNessuna valutazione finora

- Guidance Note-Supporting Safety Studies PDFDocumento29 pagineGuidance Note-Supporting Safety Studies PDFFrancesco MonacoNessuna valutazione finora

- 7Documento13 pagine7Raju GummaNessuna valutazione finora

- Crude Oils, Hydrocarbons, and Refinery Products: Petroleum Supply/Demand PictureDocumento13 pagineCrude Oils, Hydrocarbons, and Refinery Products: Petroleum Supply/Demand Pictureul84Nessuna valutazione finora

- 2 PDFDocumento31 pagine2 PDFRaju GummaNessuna valutazione finora

- System Pressure Drop: Cumulative Back Pressure 0.08 Psig 0.00 PsigDocumento5 pagineSystem Pressure Drop: Cumulative Back Pressure 0.08 Psig 0.00 PsigguhadebasisNessuna valutazione finora

- Refinery Economics 2Documento9 pagineRefinery Economics 2guhadebasisNessuna valutazione finora

- Bypass Worksheet: Check The Appropriate BoxDocumento1 paginaBypass Worksheet: Check The Appropriate BoxguhadebasisNessuna valutazione finora

- All in OneDocumento28 pagineAll in OnezakiralitalibNessuna valutazione finora

- Cost of Compressed Air FormulaDocumento1 paginaCost of Compressed Air FormulaguhadebasisNessuna valutazione finora

- 1238-Security Announcement Unexploded Ordnance 10 October 2011Documento2 pagine1238-Security Announcement Unexploded Ordnance 10 October 2011guhadebasisNessuna valutazione finora

- Processsafety Beacon 2011Documento12 pagineProcesssafety Beacon 2011kavehNessuna valutazione finora

- Magnetism Lecture NotesDocumento14 pagineMagnetism Lecture NotesPrashant D BijayNessuna valutazione finora

- Inst Headers Install TitianDocumento3 pagineInst Headers Install TitianhuntersgreenNessuna valutazione finora

- Schapery RA 1962 (PHD Dissertation)Documento182 pagineSchapery RA 1962 (PHD Dissertation)Marcelo MedeirosNessuna valutazione finora

- CFD Analysis of A 15 Stage CompressorDocumento2 pagineCFD Analysis of A 15 Stage Compressoralagarg137691Nessuna valutazione finora

- A Two Phase Model CavitationDocumento11 pagineA Two Phase Model CavitationThePrius0% (1)

- L. Stability Analysis and Design of Structures: Murari GambhirDocumento12 pagineL. Stability Analysis and Design of Structures: Murari GambhirsamuelNessuna valutazione finora

- ID2CNC MachineExplode AllDocumento22 pagineID2CNC MachineExplode AllNixonGarcia100% (1)

- Feejoy BrochureDocumento6 pagineFeejoy BrochureOswaldo HernandezNessuna valutazione finora

- Long Haul / Highway and Regional Drive: Solid Shoulder Drive Tire Stone EjectorsDocumento1 paginaLong Haul / Highway and Regional Drive: Solid Shoulder Drive Tire Stone EjectorsDionicio ChavezNessuna valutazione finora

- Welding Machine Repairing Service in Rajkot Gujarat IndiaDocumento127 pagineWelding Machine Repairing Service in Rajkot Gujarat IndiaSpandan MishraNessuna valutazione finora

- Application of Pump: CentrifugalDocumento8 pagineApplication of Pump: CentrifugalLipika GayenNessuna valutazione finora

- Cypecad Vs Etabs - En1Documento37 pagineCypecad Vs Etabs - En1dskumar49Nessuna valutazione finora

- Part Catalog Yanmar 3TNE78A-ETBYDocumento29 paginePart Catalog Yanmar 3TNE78A-ETBYseptian wahyu widodoNessuna valutazione finora

- Non Circular Pipe FrictionDocumento3 pagineNon Circular Pipe Frictionravi_radanNessuna valutazione finora

- Guideline On Submission of Amendment and Record Piling Plans PDFDocumento9 pagineGuideline On Submission of Amendment and Record Piling Plans PDFBlu SmileyNessuna valutazione finora

- Motor effect concepts and applicationsDocumento2 pagineMotor effect concepts and applicationsIntiser RahmanNessuna valutazione finora

- Numerical Simulations of Interrupted and Conventional Microchannel Heat SinksDocumento12 pagineNumerical Simulations of Interrupted and Conventional Microchannel Heat SinksAnkit LonareNessuna valutazione finora

- Flow 7 DiagramsDocumento12 pagineFlow 7 DiagramsIne Florez PalaciozNessuna valutazione finora

- SECTION Theory&Verification Ver 460Documento137 pagineSECTION Theory&Verification Ver 460A_saravanavelNessuna valutazione finora

- 22년식NMAX125.o 1fsno45dn1l1ni6g1qo71jos14vq8Documento63 pagine22년식NMAX125.o 1fsno45dn1l1ni6g1qo71jos14vq8Jae Man YouNessuna valutazione finora

- Engineering MCQs and D.C. Generators QuestionsDocumento31 pagineEngineering MCQs and D.C. Generators QuestionsNitin MauryaNessuna valutazione finora

- Tcont900 InstallerDocumento24 pagineTcont900 Installerapi-279886039100% (2)

- 5550/5550G Mechanical Vibration Switches DatasheetDocumento8 pagine5550/5550G Mechanical Vibration Switches DatasheetJadid AbdullahNessuna valutazione finora

- Washer - ISO 7093-1-2000Documento9 pagineWasher - ISO 7093-1-2000Corneliu VilcuNessuna valutazione finora