Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cat

Caricato da

Muhammad IshfaqCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cat

Caricato da

Muhammad IshfaqCopyright:

Formati disponibili

® 287 bkW / 385 bhp

C13 ACERT ™

2100 rpm

Industrial

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore....................................................... 130.0 mm (5.12 in)

Stroke.................................................... 157.0 mm (6.18 in)

Displacement............................................ 12.5 L (762.8 in3)

Aspiration................................... Turbocharged Aftercooled

Compression Ratio.................................................... 17.3:1

Rotation (from flywheel end).................... Counterclockwise

Weight, Net Dry (approximate kg, lb).......... 939 kg, 2070 lb

Image shown may not reflect

actual engine

FEATURES

Emissions Full Range of Attachments

Meets Tier 3, Stage IIIA emission requirements. Tier 3 Wide range of bolt-on system expansion attachments,

refers to EPA (U.S.) standards. Stage IIIA refers to factory designed and tested.

European standards.

Unmatched Product Support Offered Through

Worldwide Supplier Capability Worldwide Caterpillar Dealer Network

Caterpillar More than 1,500 dealer outlets.

- Casts engine blocks, heads, and cylinder liners. Caterpillar factory-trained dealer technicians service

- Machines critical components every aspect of your industrial engine.

- Assembles complete engine 99.7% of parts orders filled within 24 hours worldwide.

Ownership of these manufacturing processes enables Caterpillar parts and labor warranty.

Caterpillar to produce high quality, dependable product. Preventive maintenance agreements available for repair

Factory-designed systems built at Caterpillar ISO before failure options.

certified facilities.

Scheduled Oil Sampling program matches your oil

Testing sample against Caterpillar set standards to determine:

- internal engine component condition

Prototype testing on every model: - presence of unwanted fluids

- proves computer design - presence of combustion by-products

- verifies system torsional stability

- tests functionality on every model

Web Site

Every Caterpillar engine is dynamometer tested under For all your industrial power requirements, visit

full load to ensure proper engine performance. www.cat-industrial.com.

13 December 2007 10:36 AM

®

C13 ACERT ™ INDUSTRIAL ENGINE

287 bkW (385 bhp)

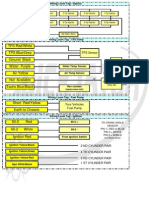

STANDARD ENGINE EQUIPMENT

Air Inlet System Fuel System

Air to air aftercooled (ATAAC) MEUI injection

Turbocharged Fuel filter, secondary (2 micron high performance)

Fuel transfer pump

Control System Fuel priming pump

ACERT™ Technology

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation Lube System

Power compensation for fuel temperature Crankcase breather

Programmable low and high idle and total engine limit Oil cooler

Electronic diagnostics and fault logging Oil filler

Engine monitoring system Oil filter

J1939 Broadcast (diagnostic and engine status) Oil pan front sump

ADEM™ A4 Oil dipstick

Oil pump (gear driven)

Cooling System

Thermostats and housing, vertical outlet General

Jacket water pump, centrifugal Paint, Caterpillar Yellow

Water pump, inlet Vibration damper

Lifting eyes

Exhaust System

Exhaust manifold, dry

Optional exhaust outlet

Flywheels and Flywheel Housing

SAE No. 1 Flywheel housing

2 13 December 2007 10:36 AM

®

C13 ACERT ™ INDUSTRIAL ENGINE

287 bkW (385 bhp)

PERFORMANCE CURVES

IND - A (Continuous) - DM7685-02

Engine English

Torque lb•ft

Engine

Power bhp

BSFC

lb/bhp-hr

Engine Speed rpm

Engine Speed Engine Power Engine Torque BSFC lb/bhp-hr Fuel Rate

rpm bhp lb•ft gal/hr

2100 385 963 .355 19.5

2000 385 1011 .351 19.3

1900 385 1064 .348 19.2

1800 385 1124 .346 19.0

1700 381 1177 .343 18.7

1600 373 1224 .340 18.1

1500 361 1266 .340 17.5

1400 346 1298 .339 16.8

1300 317 1281 .339 15.3

1200 286 1252 .338 13.8

3 13 December 2007 10:36 AM

®

C13 ACERT ™ INDUSTRIAL ENGINE

287 bkW (385 bhp)

RATINGS AND CONDITIONS

IND - A (Continuous) Continuous heavy duty service Engine Performance Diesel Engines — 7 liter and

where the engine is operated at maximum power and higher All rating conditions are based on SAE J1995,

speed up to 100% of the time without interruption or inlet air standard conditions of 99 kPa (29.31 in. Hg) dry

load cycling. barometer and 25°C (77°F) temperature. Performance

measured using a standard fuel with fuel gravity of 35°

API having a lower heating value of 42,780 kJ/kg

(18,390 btu/lb) when used at 29° C (84.2° F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length 47.35 in Note: Do not use for installation design. See

general dimension drawings for detail

(2) Width 39.81 in (Drawing # 2588857 ).

(3) Height 46.67 in

Performance Number: DM7685-02 © 2007 Caterpillar

Feature Code: C13DI00 Arr. Number: 2413804 All rights reserved.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

11692820 CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of Caterpillar

and may not be used without permission.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Marine and Industrial qsk60Documento10 pagineMarine and Industrial qsk60Muhammad IshfaqNessuna valutazione finora

- Vibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsDocumento23 pagineVibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsMuhammad Ishfaq100% (1)

- 005-012 Fuel Injection Pumps, In-Line: InstallDocumento14 pagine005-012 Fuel Injection Pumps, In-Line: InstallMuhammad Ishfaq100% (3)

- 003-004 Overhead Set: General InformationDocumento12 pagine003-004 Overhead Set: General InformationMuhammad IshfaqNessuna valutazione finora

- qsk23 Data SheetDocumento2 pagineqsk23 Data SheetMuhammad IshfaqNessuna valutazione finora

- qst30 System SpecificationsDocumento24 pagineqst30 System SpecificationsMuhammad IshfaqNessuna valutazione finora

- Power House 1Documento2 paginePower House 1Muhammad IshfaqNessuna valutazione finora

- 243 New-EnDocumento4 pagine243 New-Enjaskaran singhNessuna valutazione finora

- Cyl. Head Unit No. 6 PmeDocumento5 pagineCyl. Head Unit No. 6 PmeMuhammad IshfaqNessuna valutazione finora

- Cat 3516Documento4 pagineCat 3516Muhammad IshfaqNessuna valutazione finora

- Module 4 - Ignition Systems - QSK60GDocumento18 pagineModule 4 - Ignition Systems - QSK60GMuhammad Ishfaq100% (1)

- Hybrid Varieties and Saving Seed - Archives - Aggie HorticultureDocumento3 pagineHybrid Varieties and Saving Seed - Archives - Aggie HorticultureMuhammad IshfaqNessuna valutazione finora

- Loctite 577™: Technical Data SheetDocumento4 pagineLoctite 577™: Technical Data SheetCristian SerbovNessuna valutazione finora

- CPGS - Power House PDFDocumento2 pagineCPGS - Power House PDFMuhammad IshfaqNessuna valutazione finora

- QSK60G Temp Control GuidelinesDocumento4 pagineQSK60G Temp Control GuidelinesMuhammad IshfaqNessuna valutazione finora

- Top 40 Reasons For Motor Oil Consumption PDFDocumento6 pagineTop 40 Reasons For Motor Oil Consumption PDFMuhammad IshfaqNessuna valutazione finora

- Fiji Power ServiceDocumento2 pagineFiji Power ServiceMuhammad IshfaqNessuna valutazione finora

- 1000-0099B enDocumento3 pagine1000-0099B enMuhammad Ishfaq100% (2)

- Cummins 161110083846 PDFDocumento18 pagineCummins 161110083846 PDFMuhammad IshfaqNessuna valutazione finora

- QSK60 Over Head Valve Setting PerformaDocumento2 pagineQSK60 Over Head Valve Setting PerformaMuhammad Ishfaq100% (1)

- Aftercooler Parts For Qsk60 Gas EngineDocumento3 pagineAftercooler Parts For Qsk60 Gas EngineMuhammad IshfaqNessuna valutazione finora

- QSV Oil Analysis Guidelines, Rev. 02Documento7 pagineQSV Oil Analysis Guidelines, Rev. 02Muhammad IshfaqNessuna valutazione finora

- Fuel Consumption CalculationDocumento4 pagineFuel Consumption CalculationTariqMaqsoodNessuna valutazione finora

- QSK60 Maintenance ScheduleDocumento11 pagineQSK60 Maintenance ScheduleMuhammad Ishfaq100% (4)

- Exhaust Temp K394Documento1 paginaExhaust Temp K394Muhammad IshfaqNessuna valutazione finora

- Cucumber Hybrid Seed Production (Hilights)Documento8 pagineCucumber Hybrid Seed Production (Hilights)Muhammad IshfaqNessuna valutazione finora

- Farm RecordsDocumento22 pagineFarm RecordsMuhammad IshfaqNessuna valutazione finora

- Tomato Paste PulpDocumento26 pagineTomato Paste PulpYousef TahnonNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- SAE Published - 2022-01-5067Documento9 pagineSAE Published - 2022-01-5067이태의Nessuna valutazione finora

- Quincy Qr25Documento8 pagineQuincy Qr25vearasNessuna valutazione finora

- Spesifikasi AlatDocumento5 pagineSpesifikasi AlatFranz AnggiNessuna valutazione finora

- 32-40 IMO Tier II - MarineDocumento450 pagine32-40 IMO Tier II - MarineDaniel AlvarezNessuna valutazione finora

- Piston Displacement Vs Crankshaft AngleDocumento2 paginePiston Displacement Vs Crankshaft AngleMurali KrishnaNessuna valutazione finora

- TURBOCHARGERDocumento5 pagineTURBOCHARGERAnand Raju100% (1)

- Racing Gas Engine: Building A Twin CylinderDocumento12 pagineRacing Gas Engine: Building A Twin Cylinder2n Tv100% (1)

- BK117C2 B1 ED2REV4 06 Power Plant 14.06.2016 eDocumento163 pagineBK117C2 B1 ED2REV4 06 Power Plant 14.06.2016 eЕвгений Касьянов100% (2)

- Engine Control Avanza SDocumento3 pagineEngine Control Avanza SMurham MunirNessuna valutazione finora

- Dongfeng Cummins Engine Parts Catalog: AD 9003ZZDocumento79 pagineDongfeng Cummins Engine Parts Catalog: AD 9003ZZАнтон ШестаковNessuna valutazione finora

- 2tz Fze 1 1Documento21 pagine2tz Fze 1 1andypress100% (1)

- Quincy QR-25 Series Model 390: Parts Manual Record of Change 108Documento32 pagineQuincy QR-25 Series Model 390: Parts Manual Record of Change 108SergeyNessuna valutazione finora

- Operating Instructions OM904LA OM926LADocumento122 pagineOperating Instructions OM904LA OM926LAmnydinex100% (5)

- DicktaorDocumento1 paginaDicktaorMario JL BorgesNessuna valutazione finora

- Upto91 PDFDocumento143 pagineUpto91 PDFjorge dazaNessuna valutazione finora

- Gold Cup Motors Model Number Sheet: M11 R - 2 N 1 - 9A 5 - B 0 0 - B 0 Motor DisplacementDocumento2 pagineGold Cup Motors Model Number Sheet: M11 R - 2 N 1 - 9A 5 - B 0 0 - B 0 Motor DisplacementmecambNessuna valutazione finora

- Suzuki Shogun Arashi 125 Rextor Adjustable Cdi Manual enDocumento1 paginaSuzuki Shogun Arashi 125 Rextor Adjustable Cdi Manual enPaksi JolodoroNessuna valutazione finora

- Turbine + CompressorsDocumento3 pagineTurbine + CompressorsRiyadh SalehNessuna valutazione finora

- Air Compressors NotesDocumento11 pagineAir Compressors NotesHafizuddin RazakNessuna valutazione finora

- Elantra 2004 2.0LDocumento277 pagineElantra 2004 2.0LJohan7880Nessuna valutazione finora

- Common Rail Fuel Injection SystemDocumento56 pagineCommon Rail Fuel Injection SystemMarcos Maciel100% (1)

- G3512 SpecDocumento4 pagineG3512 SpecnunkpNessuna valutazione finora

- Lect 23Documento23 pagineLect 23Anvesh KadimiNessuna valutazione finora

- 50 5Documento4 pagine50 5MontaserNessuna valutazione finora

- Cylinder Lub Oil Sampling MethodDocumento4 pagineCylinder Lub Oil Sampling MethodRathne AbeynayakeNessuna valutazione finora

- Abstract For Camless EngineDocumento1 paginaAbstract For Camless EngineVamsi KrishnaNessuna valutazione finora

- Volvo - L70EDocumento730 pagineVolvo - L70EThiago FredyNessuna valutazione finora

- 2006 Scion Engine ManualDocumento2 pagine2006 Scion Engine ManualTopBritish David100% (1)

- A 6 VM 107 HD 1 D 63 WVZB 020 BDocumento16 pagineA 6 VM 107 HD 1 D 63 WVZB 020 BAgus Yulfizar0% (1)

- Massey Harris Pony11 ManuelDocumento18 pagineMassey Harris Pony11 ManuelRobert MoreauNessuna valutazione finora