Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tool Checklist en

Caricato da

peterjkeller100%(1)Il 100% ha trovato utile questo documento (1 voto)

2K visualizzazioni5 pagineTitolo originale

Tool Checklist En

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

XLS, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

2K visualizzazioni5 pagineTool Checklist en

Caricato da

peterjkellerCopyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

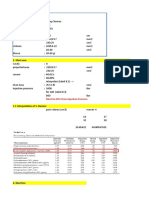

Buy Off Checklist

Customer: Part Description: Date: Type of tool: □Progression;□Manufacture

VT Tool No.: Part Number:

Assemble QC

Checklist OK NOK N/A OK NOK N/A

Comments

1 All die steels must be demagneted

2 Cuting clearence at 10%

3 Parts falling off die freely

4 4 Post die set

5 Die shoe minimun 80mm thick

6 All non functional edges champfered

7 Part & scrap fall off die seperatelly

8 Part/scrap chutes designed

9 Fork lift free access

10 2mm slots on bottoming blocks

11 No blind dowel holes

12 Dowel pins slide fit in die plates and sections

13 Dowel pins press fit in die set

14 Dowel pins engage 2 times deeps of diameter.

15 Does dowel pin go to die shoe 2 times diameter deep?

16 Screws and bolts below die surface

17 Bolt fastened 1.5-2 times deeps aginest diameter

18 counterbored bolts (1/3 of section height)

19 set screw fastened over 5mm.

VT Metal Technologies Co.,Ltd. 1

Buy Off Checklist

Customer: Part Description: Date: Type of tool: □Progression;□Manufacture

VT Tool No.: Part Number:

Assemble QC

Checklist OK NOK N/A OK NOK N/A

Comments

20 Details stamped with detail no & steel type

21 cuting steel meet customer requirement

22 forming steel meet customer requirement

23 sections over 25KG need lifting holes.

24 No shims in die

25 No welding in die

26 engineering change records

27 correct feeder heigh

28 no blind pilot holes

29 All stations piloted

30 Material feeding smoothly

31 Material guides capture material correctly

32 Is there any venting holes for springs?

33 correct length for compression spring

34 All springs captured

35 Strip stoper designed

36 stripper are guided

37 Fixed guild rail with dowled and harden steel.

38 Form parts raised surfficently

VT Metal Technologies Co.,Ltd. 2

Buy Off Checklist

Customer: Part Description: Date: Type of tool: □Progression;□Manufacture

VT Tool No.: Part Number:

Assemble QC

Checklist OK NOK N/A OK NOK N/A

Comments

39 miss feed sensors and part off sensor installed?

40 Stripper equipped with leveling pads

41 Does one of the guide pins offset?

42 coating of forming punchs/inserts if customer required

43 No rust on die

44 Paint meet customer requirement

45 does die parallar with ram ans bolsters of press, is there any gaps when die in the press?

46 Ledgend plate filled out & mounted

47 Does nitrogen used for forming, if required by customer

48 spare parts list to customer

49 does cuting punches staged?

50 Are stopers on pallars?

51 Is there transportation bar on top and bottom die?

52 Does die packaging meet standard?

53 Does CAM applied with positive return?

54 Cams & slides self lubricated

55 Is there ejector pins in the punch?

56 Form blocks ajustable?

57 does gas spring are covered.

VT Metal Technologies Co.,Ltd. 3

Buy Off Checklist

Customer: Part Description: Date: Type of tool: □Progression;□Manufacture

VT Tool No.: Part Number:

Assemble QC

Checklist OK NOK N/A OK NOK N/A

Comments

58 Is there feed direction on die shoe?

59 No preload on nitrogen springs

60 Is there any gap between stripper and die plate during shipment?

61 Does punch holder hold puch tight enough?

62 Does clearance between stripper and punches meet customer requirement?

63 Top die screws painted white

64 Does spring guided?

65 Customer's prints

66 Customer's check fixture

67 Customer's samples

68 Checking fixture

69 Detailed drawings:□ hard prints & data in DISC ;□E-mail

70 Provide tool steel certificate

71 Provide heat treatment report

72 Provide tryout report

73 Provide last samples inspection report

74 Provide BOM of purchased components

75 Final strip with the die.

76 First stop pin for all tools.

77 Any tryout material remained?

VT Metal Technologies Co.,Ltd. 4

Buy Off Checklist

Customer: Part Description: Date: Type of tool: □Progression;□Manufacture

VT Tool No.: Part Number:

Assemble QC

Checklist OK NOK N/A OK NOK N/A

Comments

78 Did scraps be clearned from low die?

Tool maker: Tool making manager:

Inspector: QC Manager:

Designer: Sales: Project manager:

Tooling acceptable□ Tooling not acceptable□

Remark:

Form No:V&T-RF-82-09-B Project dept.keep this file.

VT Metal Technologies Co.,Ltd. 5

Potrebbero piacerti anche

- Form Tooling List Approval Tooling (002) Rev 4Documento3 pagineForm Tooling List Approval Tooling (002) Rev 4Kalista BettiNessuna valutazione finora

- Die Design ChecklistDocumento3 pagineDie Design ChecklistLương TuấnNessuna valutazione finora

- Mold ChecklistDocumento5 pagineMold ChecklistSelvaraj BalasundramNessuna valutazione finora

- 02injection Moulding MachineDocumento31 pagine02injection Moulding MachineS Karthick KeyanNessuna valutazione finora

- The Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SDocumento6 pagineThe Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SSanjay KumarNessuna valutazione finora

- Instructions For Completion of Piece Cost Breakdown WorksheetDocumento9 pagineInstructions For Completion of Piece Cost Breakdown WorksheetfranciscoNessuna valutazione finora

- Supplier Tooling Cost Breakdown Form: (Dies and Molds)Documento1 paginaSupplier Tooling Cost Breakdown Form: (Dies and Molds)rtsultanNessuna valutazione finora

- Mold SpecificationDocumento1 paginaMold SpecificationVictor Villouta LunaNessuna valutazione finora

- Partcost With Freight Table Rev. 7Documento3 paginePartcost With Freight Table Rev. 7RJLockNessuna valutazione finora

- Injctmld F03Documento2 pagineInjctmld F03prasad_kcpNessuna valutazione finora

- Lathe and VMC Cycle Time CalculatorDocumento5 pagineLathe and VMC Cycle Time CalculatorDhanus KodiNessuna valutazione finora

- Mould Maintenance A KumarDocumento40 pagineMould Maintenance A KumarprashanthNessuna valutazione finora

- Stamping Blank and Tonnage CalculatorDocumento10 pagineStamping Blank and Tonnage CalculatorDhanus KodiNessuna valutazione finora

- Program Name: CE's APQP and Product Launch System (APLS)Documento2 pagineProgram Name: CE's APQP and Product Launch System (APLS)Janaka MangalaNessuna valutazione finora

- CTM Mold Design Standards PDFDocumento43 pagineCTM Mold Design Standards PDFDini ViruNessuna valutazione finora

- Mold Springs CalculationDocumento2 pagineMold Springs Calculationmeve646Nessuna valutazione finora

- KSS713 - Die Casting Tool Standard - Rev.03Documento17 pagineKSS713 - Die Casting Tool Standard - Rev.03Adrian Doru100% (2)

- Investment Casting Cycle TimeDocumento12 pagineInvestment Casting Cycle TimemaheshNessuna valutazione finora

- Methodology of Die Design For HPDCDocumento8 pagineMethodology of Die Design For HPDCruben6286Nessuna valutazione finora

- Mold Design Fundamental Calculation BATTERY COVERDocumento7 pagineMold Design Fundamental Calculation BATTERY COVERrgrao85Nessuna valutazione finora

- Calculation of Hourly Rate For Laser Cutting Machine - 500W Input of Data Calculations. Yearly Work Capacity 4800Documento2 pagineCalculation of Hourly Rate For Laser Cutting Machine - 500W Input of Data Calculations. Yearly Work Capacity 4800Susheel ShuklaNessuna valutazione finora

- Presentation On Bandsaw MachineDocumento15 paginePresentation On Bandsaw MachineInotech GroupNessuna valutazione finora

- CNC Machining Cycle Time CalculationDocumento4 pagineCNC Machining Cycle Time CalculationRathnakrajaNessuna valutazione finora

- D10369520ADocumento4 pagineD10369520AQUALITY ControlNessuna valutazione finora

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocumento8 pagineMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNessuna valutazione finora

- Tool Design Calculation: Cutting ForceDocumento4 pagineTool Design Calculation: Cutting ForceRaja SathishNessuna valutazione finora

- Costing FormatDocumento3 pagineCosting FormatdavNessuna valutazione finora

- Presstool Design Tutorial - MisumiDocumento166 paginePresstool Design Tutorial - Misumiazadsingh1Nessuna valutazione finora

- Lab10 Final Progressive Die PDFDocumento7 pagineLab10 Final Progressive Die PDFSyed Asif Bukhari100% (1)

- Tooling Standard (Die Casting)Documento39 pagineTooling Standard (Die Casting)Kmilo GiraldoNessuna valutazione finora

- 86 Mould Base Series 16 & 20 Individual Plate PricesDocumento21 pagine86 Mould Base Series 16 & 20 Individual Plate PricesAmitava DattaNessuna valutazione finora

- Die CalculationsDocumento13 pagineDie CalculationsDhinakaran R100% (1)

- Costing Format - Press ToolDocumento6 pagineCosting Format - Press ToolVineet Pandey Vlogs67% (3)

- Instructions:: Any ExceptionsDocumento3 pagineInstructions:: Any ExceptionsAkhmad FathoniNessuna valutazione finora

- FES MTG Welding Fixture F7222910Documento11 pagineFES MTG Welding Fixture F7222910Sekar NaikNessuna valutazione finora

- WI Mold HandlingDocumento5 pagineWI Mold HandlingAnonymous dS56HONessuna valutazione finora

- MHR Calculation 1Documento13 pagineMHR Calculation 1RamNessuna valutazione finora

- Production ProblemDocumento2 pagineProduction ProblemSaqib RehmanNessuna valutazione finora

- Automotive Door Trim Bezel Mold DesignDocumento17 pagineAutomotive Door Trim Bezel Mold DesignagniflameNessuna valutazione finora

- Workflow of Injection Molding Simulation & Verification: Ffinno-Technologies-Co-LtdDocumento6 pagineWorkflow of Injection Molding Simulation & Verification: Ffinno-Technologies-Co-Ltdluan_ba100% (1)

- Mold Design ChecklistDocumento2 pagineMold Design ChecklistWerner SchrammelNessuna valutazione finora

- HPDC Design DetailsDocumento15 pagineHPDC Design Detailspatiltushar79Nessuna valutazione finora

- Cost BreakupDocumento6 pagineCost Breakuppiyush sharma100% (1)

- Tooln Die Design Part OneDocumento14 pagineTooln Die Design Part Oneazizmaarof100% (2)

- Injection Molding: Part Cost EstimatorDocumento3 pagineInjection Molding: Part Cost EstimatorpchakkrapaniNessuna valutazione finora

- Automotive Parts InfoDocumento38 pagineAutomotive Parts Inforahul srivastavaNessuna valutazione finora

- Shot Area: Must Be 50% From Injection PressureDocumento7 pagineShot Area: Must Be 50% From Injection PressureAri Wibowo NugrohoNessuna valutazione finora

- New Operator Training ManualDocumento35 pagineNew Operator Training ManualBharat ChakravartinNessuna valutazione finora

- Mold Design ChecklistDocumento10 pagineMold Design ChecklistRamesh RaoNessuna valutazione finora

- Mold Spec Guidelines Jun 08revisedDocumento27 pagineMold Spec Guidelines Jun 08revisedDirk HenningNessuna valutazione finora

- PQ TOS555 How To Check PQ Amplifier (During Pump Run)Documento3 paginePQ TOS555 How To Check PQ Amplifier (During Pump Run)mike100% (1)

- Mould Change, Storage and Maintenance ProcedureDocumento10 pagineMould Change, Storage and Maintenance ProcedureTechnicians SIM100% (1)

- Gears Cutting and GrindingDocumento8 pagineGears Cutting and GrindingАлександар ВујаковићNessuna valutazione finora

- Mold Inspection SpecificationDocumento6 pagineMold Inspection SpecificationNaukowyDrpNessuna valutazione finora

- Die Casting Design PDFDocumento38 pagineDie Casting Design PDFPrabagarane Ramachandran100% (2)

- Generic: Process Step Illustration 1.3Documento4 pagineGeneric: Process Step Illustration 1.3idenbelleNessuna valutazione finora

- 03 - SIPOC Diagram - 2009-06-11Documento1 pagina03 - SIPOC Diagram - 2009-06-11Anand RajaNessuna valutazione finora

- Bluskies Engineering PVT LTD: Acp Panel Inpection ReportDocumento7 pagineBluskies Engineering PVT LTD: Acp Panel Inpection ReportRavi Shankar KolluruNessuna valutazione finora

- PDI Inspection ReportDocumento2 paginePDI Inspection ReportIsmail BiradarNessuna valutazione finora

- After Cooler InspectionAE3Documento1 paginaAfter Cooler InspectionAE3boy qsiNessuna valutazione finora

- Configuration Diagrams: Group 80ADocumento20 pagineConfiguration Diagrams: Group 80ALuis Guillermo Ledezma CastroNessuna valutazione finora

- DatasheetDocumento2 pagineDatasheetStuxnetNessuna valutazione finora

- Scalar Control of Ac DrivesDocumento38 pagineScalar Control of Ac Drivessureshy-ee213Nessuna valutazione finora

- Cooliing System TTLM PR - by S-DDocumento142 pagineCooliing System TTLM PR - by S-DElias WeldeyohansNessuna valutazione finora

- CEPU TOA Price ListDocumento5 pagineCEPU TOA Price ListJoglo SoloNessuna valutazione finora

- Cec l-109-14Documento5 pagineCec l-109-14metaNessuna valutazione finora

- Tda 8175Documento4 pagineTda 8175miniecateNessuna valutazione finora

- FIC 486-Vip-Io Manual PDFDocumento15 pagineFIC 486-Vip-Io Manual PDFryan cooperNessuna valutazione finora

- Technical Education and Skills Development AuthorityDocumento5 pagineTechnical Education and Skills Development AuthorityRenniel DingcongNessuna valutazione finora

- Light Axle Parts For Jeep Applications: June 2011 Supersedes X510-6 Dated August 2005Documento120 pagineLight Axle Parts For Jeep Applications: June 2011 Supersedes X510-6 Dated August 2005Aguss SalimNessuna valutazione finora

- Instructor's or Course Coordinator's Name: Harpreet SinghDocumento3 pagineInstructor's or Course Coordinator's Name: Harpreet SinghNandini GuptaNessuna valutazione finora

- Despiece Hidrojet K310 1.994-680.0 PDFDocumento12 pagineDespiece Hidrojet K310 1.994-680.0 PDFjose velascoNessuna valutazione finora

- RR RD5700SDocumento1 paginaRR RD5700ShugoamendozaNessuna valutazione finora

- Sirocco 1000w HTI: Versatile Lighting BalloonDocumento2 pagineSirocco 1000w HTI: Versatile Lighting BalloonSiding BarroNessuna valutazione finora

- Jade Thermal Massage Bed: Camilla Térmica JadeDocumento8 pagineJade Thermal Massage Bed: Camilla Térmica JadeEugeniaLeca-BurceaNessuna valutazione finora

- Valvula Control Herion 80265Documento2 pagineValvula Control Herion 80265Base SistemasNessuna valutazione finora

- Parts Manual: B30D & B25D 6X6 MKV AdtDocumento150 pagineParts Manual: B30D & B25D 6X6 MKV AdtTeknik MakinaNessuna valutazione finora

- TH420 Operating Manual EnglishDocumento64 pagineTH420 Operating Manual EnglishLeofler Laureta Aguinaldo0% (1)

- Slotnotes (Repaired) PDFDocumento159 pagineSlotnotes (Repaired) PDFTecnicos ArequipaNessuna valutazione finora

- Arduino Based Object SortingDocumento4 pagineArduino Based Object SortingIJIERT-International Journal of Innovations in Engineering Research and TechnologyNessuna valutazione finora

- 3412C EMCP II+ For PEEC Engines Electrical SystemDocumento4 pagine3412C EMCP II+ For PEEC Engines Electrical Systemविशाल पुडासैनी100% (1)

- Pressure Gauge Dan Diff Gauge Datasheet - Rev.ADocumento20 paginePressure Gauge Dan Diff Gauge Datasheet - Rev.Asugeng wahyudiNessuna valutazione finora

- Vibration Meter Circuit Using LED Driver IC LM3915 - GadgetronicxDocumento4 pagineVibration Meter Circuit Using LED Driver IC LM3915 - GadgetronicxK. RAJA SEKARNessuna valutazione finora

- 04.CH430-03 Operators Instructions S223.1111-01 en-USDocumento44 pagine04.CH430-03 Operators Instructions S223.1111-01 en-USAtef YagoubiNessuna valutazione finora

- Microondas Manual Americano en EspañolDocumento52 pagineMicroondas Manual Americano en EspañolAlan SotoNessuna valutazione finora

- ZVC Power ResonatorDocumento7 pagineZVC Power Resonatorsaid3232Nessuna valutazione finora

- Rate List of Plumbing Work180208Documento1 paginaRate List of Plumbing Work180208Kiran KDzNessuna valutazione finora

- LIT 11626 22 71 - Zuma125 - 1663 PDFDocumento88 pagineLIT 11626 22 71 - Zuma125 - 1663 PDFMatius Ger CharrysNessuna valutazione finora

- Types of MemoryDocumento3 pagineTypes of MemoryVenkatareddy Mula0% (1)

- Baker - 690981 PDFDocumento24 pagineBaker - 690981 PDFAsep SuhermanNessuna valutazione finora