Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CBC 5202 10KG PDF

Caricato da

shreebalaji140915Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CBC 5202 10KG PDF

Caricato da

shreebalaji140915Copyright:

Formati disponibili

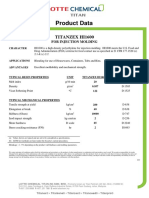

Technical Information Sheet

ESIS the Manufacturers, Exporters and Suppliers of 100% Genuine Solid Epoxy Compound, used for backing wear liners in cone an d gyratory crushers. Epoxy crusher backing compound are highly compressive and have impact strength in nature that facilitates heavy duty crushing.

g Compound

HPG Crusher Backing Compound CBC-5200

100 % solids epoxy compound

High compressive & impact strength

Extreme heavy duty crushing

Excellent volumetric stability

( No formation of gap between backing and liners or main frame )

SALIENT FEATURES APPLICATION (as Backing Compound )

Safe & more economical than molten zinc Cone Crushers

Gyratory Crushers

Simple in application -just mix Resin &

Hardener and pour into a cavity Large gyratory crushers

Minimal amount of filler settlement Mobile Cone Crushers

H P G Crusher Backing

ORDERING INFORMATION

Code Description Package Size

CBC 5202 HP G Crusher Backing Compound 10 KG

PHYSICAL PROPERTIES

Appearance : COLOUR : RED

Viscosity : @ 250 C - 10,000 + 200 cps

Coverage : 170 cubic inches / Gallon.

Curing Time : <= 8 Hours

Maximum operating temp : 121° C

Mixing Ratio By Volume [ R : H ] : 17.8 [ R ] : 1 [ H ]

Compressive strength : 21000 PSI

Tensile strength : 8500 PSI

Hardness : 95 Shore D

Working Time : >= 20 min

Impact Strength : 2.7 ft lbs / inch

SURFACE PREPARATION: It is absolutely necessary that the surface to be coated must be free from oil,

dust, rust, wax, grease and moisture. If the surface is not clean then it affects bonding of product to the metal

substrate.

APPLICATION PROCEDURE : The resin part has to initially be stirred to disperse any settlement. Entire

contents of Hardener to be added slowly to the resin part. Proper stirring helps in proper mixing.. The

mixture has to be poured from one place to fill the cavity and to avoid air gaps.

MATERIAL SAFETY DATA:

• This system is totally solvent free, during application by brush or spray and there is no fog formation. During

application avoid contact with skin or eyes. If still there is contact then clean with fresh tap water.

• Always keep the product away from direct heat.

• Avoid higher quantity of mixing as it will reduce pot life, Change in Hardener ratio will not increase or

decrease the pot life, but it will affect the properties of the final product.

ES Industrial Solutions.,

# 171, Thamini Towers, Subban Chetty Street, Theni - 625531. Tamilnadu, India.

Mobile : 91-9940-83-5257 / 91-9597-50-8138 / +91-9443-23-1113

email : info@esis.net.in website : www.esis.net.in

Potrebbero piacerti anche

- CTS Flexible Benefit PlanDocumento53 pagineCTS Flexible Benefit Plannivasshaan100% (2)

- Dance Lesson Plan Grade 12Documento4 pagineDance Lesson Plan Grade 12api-24976678488% (34)

- Crusher Backing Compound 10 KGDocumento1 paginaCrusher Backing Compound 10 KGshreebalaji140915Nessuna valutazione finora

- JSRNBR eDocumento8 pagineJSRNBR eDevender KumarNessuna valutazione finora

- G 90 Coumarone Indene ResinDocumento2 pagineG 90 Coumarone Indene ResinGorkem TanrıverogluNessuna valutazione finora

- Crusher Backing: Technical InformationDocumento1 paginaCrusher Backing: Technical InformationjohnNessuna valutazione finora

- Resicrete 2118 - TDSDocumento2 pagineResicrete 2118 - TDSPhạm Thanh PhươngNessuna valutazione finora

- Honey KoteDocumento2 pagineHoney KoteVALERIANessuna valutazione finora

- Whitmore Crush-Bac - PDS - EnglishDocumento2 pagineWhitmore Crush-Bac - PDS - EnglishDon HowardNessuna valutazione finora

- HI1600Documento1 paginaHI1600Nawal SahraniNessuna valutazione finora

- Product Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Documento1 paginaProduct Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Joe CruzNessuna valutazione finora

- Mdpe 37120-TDSDocumento1 paginaMdpe 37120-TDSMauricio Alejandro Castillo SorianoNessuna valutazione finora

- PXCF2 F&B (20120912)Documento17 paginePXCF2 F&B (20120912)Jose RojasNessuna valutazione finora

- Chryso Polyflex Epa H (Rv-Ac)Documento2 pagineChryso Polyflex Epa H (Rv-Ac)Sushil RajakNessuna valutazione finora

- Pel BH - Eng - BDDocumento2 paginePel BH - Eng - BDdarmawan listyonoNessuna valutazione finora

- Hilti HIT HY 70 Injection Mortar For MasonryDocumento26 pagineHilti HIT HY 70 Injection Mortar For Masonryantonio gliattaNessuna valutazione finora

- Resicrete 215 - TDSDocumento2 pagineResicrete 215 - TDSPhạm Thanh PhươngNessuna valutazione finora

- Bge Company Profile (2019)Documento13 pagineBge Company Profile (2019)AlsonChin100% (1)

- Sinopec HP-R GreaseDocumento3 pagineSinopec HP-R GreaseYoong TanNessuna valutazione finora

- Material Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFDocumento117 pagineMaterial Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFBikasNessuna valutazione finora

- TamRez 220 TG PDFDocumento2 pagineTamRez 220 TG PDFlim kang hai100% (2)

- Mix Design Request Printing (Pt. Prima Graha Bangun Tunggal)Documento1 paginaMix Design Request Printing (Pt. Prima Graha Bangun Tunggal)fannyNessuna valutazione finora

- Data Sheet 18721Documento1 paginaData Sheet 18721jamartiNessuna valutazione finora

- Litecrete HP: Lightweight Cement Technology For High PressuresDocumento2 pagineLitecrete HP: Lightweight Cement Technology For High PressuresRF CCNessuna valutazione finora

- GGB Datasheet GAR-MAX FRC US-LtrDocumento2 pagineGGB Datasheet GAR-MAX FRC US-LtrWilliam PeeleNessuna valutazione finora

- Carter SH: Synthetic Industrial Gear Lubricant With Long Drain IntervalDocumento2 pagineCarter SH: Synthetic Industrial Gear Lubricant With Long Drain IntervalАлексейNessuna valutazione finora

- Abecote 320: Epoxy Enamel CoatingDocumento2 pagineAbecote 320: Epoxy Enamel Coatingengramir07Nessuna valutazione finora

- Fosroc Renderoc HB: Technical Data SheetDocumento4 pagineFosroc Renderoc HB: Technical Data SheetRJNessuna valutazione finora

- New 1000 CSDocumento2 pagineNew 1000 CSSantiago MonteroNessuna valutazione finora

- Resicrete 218NS - TDSDocumento2 pagineResicrete 218NS - TDSPhạm Thanh PhươngNessuna valutazione finora

- AbraSphere PulvDocumento2 pagineAbraSphere PulverikaNessuna valutazione finora

- 099 033 RZ Web Sany Bro Sy135c enDocumento7 pagine099 033 RZ Web Sany Bro Sy135c en45xtbrvvjpNessuna valutazione finora

- Softening Cation Exchange Resins: Go To MenuDocumento4 pagineSoftening Cation Exchange Resins: Go To Menuedal_108Nessuna valutazione finora

- Cojinete Acero - GGB-SHB-Case-Hardened-Steel-Bearings-DatasheetDocumento2 pagineCojinete Acero - GGB-SHB-Case-Hardened-Steel-Bearings-DatasheetneodymioNessuna valutazione finora

- BXR Large-Size Breaker Series BrochureDocumento7 pagineBXR Large-Size Breaker Series BrochureFahmi R.Nessuna valutazione finora

- Series: Pneumatic PumpDocumento2 pagineSeries: Pneumatic Pumpadrian hernandezNessuna valutazione finora

- 27 - Hofmann - Slew Bearings Brochure - A4Documento2 pagine27 - Hofmann - Slew Bearings Brochure - A4Jorge VillalobosNessuna valutazione finora

- Armorseal Heavy Duty Floor CoatingsDocumento4 pagineArmorseal Heavy Duty Floor CoatingsMohindra PersadNessuna valutazione finora

- Chumacera de Banco DodgeDocumento2 pagineChumacera de Banco Dodgemynor8josh8juarezNessuna valutazione finora

- Axial Excluder Seal HRC1: Extends Service Life by Protecting Wind Turbine Main Shaft Bearings From ContaminantsDocumento3 pagineAxial Excluder Seal HRC1: Extends Service Life by Protecting Wind Turbine Main Shaft Bearings From ContaminantsCesar VasquesNessuna valutazione finora

- Adobe Scan Feb 14, 2021Documento4 pagineAdobe Scan Feb 14, 2021Sudip PatraNessuna valutazione finora

- Dynapac CC122Documento2 pagineDynapac CC122Corona CoronaNessuna valutazione finora

- ANDRITZ - PRENSA COMPACTADORA - 01 - Sludge-And-Reject-Newsletter-Iss4-2-2015-DataDocumento5 pagineANDRITZ - PRENSA COMPACTADORA - 01 - Sludge-And-Reject-Newsletter-Iss4-2-2015-DataClaudinei MayerNessuna valutazione finora

- Hydrotite Brochure Mar08-GreenstreakDocumento4 pagineHydrotite Brochure Mar08-GreenstreakAkshayKadbeNessuna valutazione finora

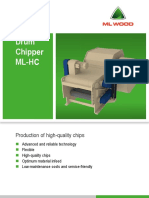

- ML HC 4 Seiter PDFDocumento4 pagineML HC 4 Seiter PDFAlexander MedinaNessuna valutazione finora

- ML HC 4 Seiter PDFDocumento4 pagineML HC 4 Seiter PDFAlexander MedinaNessuna valutazione finora

- Sikafloor 2420Documento3 pagineSikafloor 2420Nguyen Anh TuanNessuna valutazione finora

- LUBCON Lubricants Rail Industry enDocumento7 pagineLUBCON Lubricants Rail Industry enOmin PostingNessuna valutazione finora

- 1609 CO Tire ProductSheet SKS-753 Letter Mixed EN V12 170127 140822 PDFDocumento2 pagine1609 CO Tire ProductSheet SKS-753 Letter Mixed EN V12 170127 140822 PDFAndrés GómezNessuna valutazione finora

- 1500 Pneumatic PumpDocumento1 pagina1500 Pneumatic PumpTien Tran Kha TienNessuna valutazione finora

- Hyperzone Presentation SPE 2019Documento17 pagineHyperzone Presentation SPE 2019phu nghiaNessuna valutazione finora

- CJBrochureDocumento16 pagineCJBrochurejcvf1Nessuna valutazione finora

- HD700 SSDocumento2 pagineHD700 SSD.CORNEILLE100% (1)

- BWT 9000 SCDocumento1 paginaBWT 9000 SCMehdi AcilNessuna valutazione finora

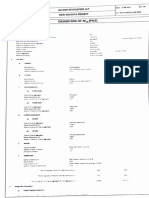

- Concrete Mix Design - Grout Mix (SRC) : Cement Ggbs M.Silica Temp (Fresh Conc-) Mix ClassDocumento1 paginaConcrete Mix Design - Grout Mix (SRC) : Cement Ggbs M.Silica Temp (Fresh Conc-) Mix ClassAlbert NajjarNessuna valutazione finora

- Kuwait Oil Company (K.S.C) New Gathering Centre, Gc-29 in North Kuwait JOB NO: JI-2027Documento2 pagineKuwait Oil Company (K.S.C) New Gathering Centre, Gc-29 in North Kuwait JOB NO: JI-2027Velpandian ManiNessuna valutazione finora

- Asx445 EnglishDocumento16 pagineAsx445 Englisht.meynoldsNessuna valutazione finora

- FRD Blasthole Drill 2017Documento44 pagineFRD Blasthole Drill 2017andiNessuna valutazione finora

- RMT 1240 Product Flyer (RMT)Documento1 paginaRMT 1240 Product Flyer (RMT)Hector OscarNessuna valutazione finora

- En Anderol 5460 Xep 20120328Documento1 paginaEn Anderol 5460 Xep 20120328Shaara NeyNessuna valutazione finora

- MAUS Catalogue PDFDocumento10 pagineMAUS Catalogue PDFCarolina Garcés MoralesNessuna valutazione finora

- Quorum Sensing PDFDocumento9 pagineQuorum Sensing PDFShareenMuneebNessuna valutazione finora

- Lipoma in Submandibular Region - A Case ReportDocumento4 pagineLipoma in Submandibular Region - A Case Reportmaxfac2010Nessuna valutazione finora

- 6 Instrumentation PDFDocumento144 pagine6 Instrumentation PDFWanderley MandruzatoNessuna valutazione finora

- Should Beauty Pageants Be BannedDocumento2 pagineShould Beauty Pageants Be BannedHastin Dilipbhai BagthariyaNessuna valutazione finora

- FBS Q1 WK1Documento4 pagineFBS Q1 WK1Nicole Eve Pelaez-AbarrientosNessuna valutazione finora

- AcuityPDR BrochureDocumento3 pagineAcuityPDR BrochureJulian HutabaratNessuna valutazione finora

- Jokes and Their Relation To The Unconscious: Laurence HenkelmanDocumento3 pagineJokes and Their Relation To The Unconscious: Laurence HenkelmanMilos VisnjicNessuna valutazione finora

- Alcohol Consumption and Related Crime Incident in John Paul CollegeDocumento17 pagineAlcohol Consumption and Related Crime Incident in John Paul Collegejoy mesanaNessuna valutazione finora

- Midas Tutorial Fea 7Documento3 pagineMidas Tutorial Fea 7sasiNessuna valutazione finora

- Total Parenteral NutritionDocumento8 pagineTotal Parenteral NutritionTemiloluwa AdeyemiNessuna valutazione finora

- Basic Electrical Engineering Mcqs Unit 1Documento13 pagineBasic Electrical Engineering Mcqs Unit 1shubha christopherNessuna valutazione finora

- Effects of Various Liquid Organic Solvents On Solvent-Induced Crystallization of Amorphous Poly (Lactic Acid) FilmDocumento11 pagineEffects of Various Liquid Organic Solvents On Solvent-Induced Crystallization of Amorphous Poly (Lactic Acid) FilmqueteimportaNessuna valutazione finora

- LPG PropertiesDocumento2 pagineLPG Propertiesvvk557Nessuna valutazione finora

- Lead and Manage People TTLMDocumento41 pagineLead and Manage People TTLMHenok Mehari100% (1)

- 8-Critical Appraisal of An ArticleDocumento20 pagine8-Critical Appraisal of An ArticleMohmmed Abu MahadyNessuna valutazione finora

- Dental Caries PrevelenceDocumento11 pagineDental Caries PrevelenceSonal KaleNessuna valutazione finora

- English 1 Reading (CVC)Documento27 pagineEnglish 1 Reading (CVC)Angelica ArcangelNessuna valutazione finora

- Good Boys Go To Heaven, Bad Boys Go EverywhereDocumento32 pagineGood Boys Go To Heaven, Bad Boys Go Everywherealcantaravic2006Nessuna valutazione finora

- Machine Design II: Prof. K.Gopinath & Prof. M.M.MayuramDocumento4 pagineMachine Design II: Prof. K.Gopinath & Prof. M.M.Mayurampredrag10Nessuna valutazione finora

- Dingenen 2017Documento14 pagineDingenen 2017pedro.coleffNessuna valutazione finora

- 6 Human Diseases That Cause by VirusesDocumento7 pagine6 Human Diseases That Cause by VirusesJefry JapNessuna valutazione finora

- English: Pst/Jest 1 Weekly Test DATE: 15/02/2021Documento7 pagineEnglish: Pst/Jest 1 Weekly Test DATE: 15/02/2021mastani shahNessuna valutazione finora

- DBM MonetizationDocumento2 pagineDBM MonetizationrsdiamzNessuna valutazione finora

- UNIT-5 International Dimensions To Industrial Relations: ObjectivesDocumento27 pagineUNIT-5 International Dimensions To Industrial Relations: ObjectivesManish DwivediNessuna valutazione finora

- 10.4324 9781315717289 PreviewpdfDocumento179 pagine10.4324 9781315717289 PreviewpdfMahdi GargouriNessuna valutazione finora

- Neicchi 270 ManualDocumento33 pagineNeicchi 270 Manualmits2004Nessuna valutazione finora

- Magicad Heating&Piping and Ventilation Version 2011.11: User'S GuideDocumento285 pagineMagicad Heating&Piping and Ventilation Version 2011.11: User'S GuideCalin CalinNessuna valutazione finora