Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ABB Review Q3 2015 - Transformer Health in The Real World en

Caricato da

Ushma V PatelTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ABB Review Q3 2015 - Transformer Health in The Real World en

Caricato da

Ushma V PatelCopyright:

Formati disponibili

Transformer health in

the real world

Maximizing transformer JOHN VINES, BERNARD BANH, CRAIG STIEGEMEIER, POORVI PATEL, LUIZ V.

CHEIM – Many companies that utilize transformers are seeing significant

reliability on a budget reductions in maintenance budgets and expert resources, as well as

new, tougher regulatory requirements and higher expectations from

shareholders. This new reality requires a fresh approach to equipment

management – instead of maintaining the status quo, different method-

ologies must be implemented. Many transformer maintenance method-

ologies are currently time-based. Because some units simply do not

need as much maintenance as others this approach can result in

unnecessary maintenance. The answer is the much more efficient

approach of condition-based maintenance. With this method, the units

that need maintenance are prioritized based on risk and importance,

and money is spent where it is needed most. So what techniques are

used to make sure the maintenance is properly prioritized? The answer

lies in data analytics.

1 2 ABB review 3|15

1 Outdoor equipment is especially prone to power system and environmental stresses.

C

ompanies tend to rely on the

same equipment experts year

after year to keep assets run-

ning ➔ 1. However, many of

these experts are reaching retirement

age and are not being replaced. This re-

duction in manpower is part of an overall

cost reduction trend that is also seeing

maintenance budgets decreased.

essential for transformer operation and with parameters whose weights are

Many companies would like to rely on health. A weight is given to each item on low.

monitoring and data analysis to fill these the list to indicate

knowledge gaps. However, the amount its relative impor-

and complexity of the data quickly over- tance. It is then a The ideal system includes a

whelms even the best-intentioned orga- matter of assess-

nizations. This has initiated a search for a ing the condition determination of the relative

way to handle the large amounts of data

involved and compensate for the loss of

of each parameter

and assigning a

importance of the asset and

expertise. score (eg, between the risk of failure.

zero and 100), mul

Transformer health index reliability tiplying individual

issues weights by the respective scores, and − A robust sensitivity analysis is typically

One option available is the transformer dividing the result by the sum of all lacking – most approaches do not

health index calculation. There are sev- weights times the maximum score per stress test the proposed solution to a

eral approaches to this concept, the ma- individual parameter. point where real-life cases are tested

jority of which utilize a list of technical and compared with the output of the

parameters that experts may classify as This approach has its disadvantages: procedure.

− The weights chosen by the experts − Strangely enough, the method

are subjective and different experts described will render the same output

Title picture may propose different weights. for any given selection of weights as

Approaching transformer maintenance in an − Poorly-chosen weights may easily long as all scores are at their maxi-

intelligent way can reduce outlays and make better

overshadow the importance of other mum.

use of the dwindling numbers of experts. How can

data analytics be exploited to achieve the best parameters or functions, consequent-

result? ly underestimating eventual problems

Transformer health in the real world 1 3

It is important that 2 As available data increases, so does the confidence level of the assessment.

the system pro- 100

vides recommen- 90

dations and risk-

Confidence in risk assessment (%)

80

70

mitigating advice 60

to help keep the 50

40

transformer 30

healthy. 20

10

0

Available data quantity (a.u.)

Level 1 Level 2 Level 3 Level 4 Level 5

An ideal solution would be able to gather spects of the transformer, along with

a

and analyze large amounts of data from taking a view of the entire picture.

many different sources. Flexibility is key

here as data would come from many dif- As a start, the following data should be

ferent types of sensors, monitors and collected:

systems. Whether it is hourly, daily, − Nameplate information, dissolved gas

monthly or yearly, the data needs to be analysis (DGA) and oil quality param-

captured. Once organized, it should then eters

be analyzed using expert algorithms that − Loading, transformer turns ratio (TTR)

look at the system as a whole, not just at and insulation power factor

its individual parts. − Bushing – capacitance and power

factor, porcelain condition, thermal

Regular checkups scan, oil level, and type and vintage

Comparing a person’s year-to-year health − Load tap changer – type, mainte-

checkups helps to spot any poor health nance data, DGA and condition

developments and maintain well-being.

The same approach has proven to be

very effective for transformers. A trans- To handle the

former’s condition needs to be assessed

– information is collected, evaluated and constantly chang-

compared with previous data in order to

identify condition trends, then a diagno-

ing data, ABB

sis is made. The ideal system also deter- developed the

mines the relative importance of the

a sset and the risk of failure. It is also

Dynamic Trans-

i mportant that the system provides

recommendations and risk-mitigating

former Manage-

advice to help keep the transformer in ment Program.

good condition.

Confidence level − Cooling system and oil preservation

The initial condition assessment must be system condition, tank oil level, and

very thorough and result in a risk-of-fail- age of accessories

ure calculation for the unit ➔ 2. Rather − Tank integrity, leaks, rust, paint, main

than simply creating a health index view cabinet condition and controls

of individual features and then adding − Protection (Buchholz relay, arresters,

them up, a better approach is to take pressure relief, etc.) and product history.

a dvantage of transformer subject matter − Sister unit failure data, design and

experts (SMEs) to assess functional reclosing practice

1 4 ABB review 3|15

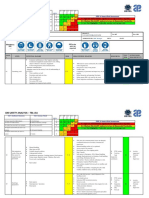

3 Mature Transformer Management Program approach based on functionality

The algorithms

employed by the

Mechanical Dielectric DTMProgram are

–

–

Faults

Design

Parameters a, b, c, ... able to analyze

–

–

Load

... each of the func-

Thermal

Transformer

Management Output = risk of failure

tional aspects of a

Program

transformer then

aggregate these

into the five func-

Miscellaneous Accessories

tional areas used by

the MTMProgram.

− Special test results such as furan data is added, the risk of failure and

testing, degree of polymerization maintenance or operation recommenda-

(DP), field-induced voltage test, tions need to be updated daily. To handle

sweep frequency response analysis the constantly changing data, ABB de-

(SFRA), dielectric frequency response veloped the Dynamic Transformer Man-

(DFR), etc. agement Program (DTMProgram™). The

− Geomagnetically induced currents algorithms employed by the DTMProgram

(GIC) are able to analyze each of the functional

aspects of a transformer then aggregate

The data collected can be analyzed these into the five functional areas used

by ABB’s Mature Transformer Manage- by the MTMProgram. An expert system

ment Program (MTMProgram™). The algorithm is then able to look at a trans-

MTMProgram groups data into five func- former as a whole instead of at its indi-

tional groups – thermal, mechanical, di- vidual components, as a health index

electric, accessories and miscellaneous would ➔ 5. This expert system operates

– to provide a complete condition as- on a fleet-wide basis and is also capable

sessment ➔ 3 – 4. Reliability improvement of looking for cross-correlations among

recommendations are made for individu- any issues found on the transformer.

al transformers. The main transformer

functions covered include typical stress- ABB SMEs have also created algorithms

es, network solicitation, and short-cir- for batteries and breakers using an ap-

cuit, thermal and dielectric capabilities. proach similar to that described above.

Many more algorithms are under devel-

The approach establishes a close con- opment to support other critical assets

nection between the most stressed con- throughout the industry. The key to the

ditions, the requirements for each indi- success of these algorithms is the utiliza-

vidual transformer and the contribution of tion of SMEs during the design phase.

individual parameters to achieve that The transformer algorithms are very flex-

functionality. It then calculates the risk of ible and can be integrated into multiple

failure for each of the specified transform- software platforms. No matter what the

ers in the fleet. After more than a decade data sources and existing software sys-

and close to 10,000 transformers as- tems are, there is a solution to support a

sessed globally, this program has proven condition-based maintenance approach.

to have benefits for many end users of

transformers in different applications. Asset Health Center – further solutions

One of these further solutions is Asset

The program provides a one-time snap- Health Center (AHC), which incorporates

shot of the transformer’s overall health. ABB operational technology (OT) subject

Therefore, as conditions change or new matter expertise and ABB information

Transformer health in the real world 1 5

4 Dynamic analysis of transformer data

Off-the-shelf online

sensors

Data from transformer fleet

User’s headquarters

24/7:

– Flag/report events

SCADA – Update risk of failure

– Recommend actions

DTMP

Field service

technology (IT) software knowledge to indicators (green, yellow and red) users

An expert system provide the latest online offering in fleet can quickly identify the units or areas that

condition monitoring. need more attention so maintenance

algorithm is then

able to look at a After a baseline as-

sessment, the soft- ABB subject matter experts

transformer as a ware uses online

have created algorithms for

sensor data and/or

whole instead of manually entered tra-

batteries and breakers and

at its individual ditional offline test

data to perform au- many more algorithms are

components, as a tomated condition

under development to support

assessments on a

health index would. daily basis, and pro-

other critical assets through-

vide expert recom-

mendations based out the industry.

on that analysis. Also

included are condi-

tion monitoring, risk of failure, trend analy- budgets and resources can be allocated

sis, family comparisons, email and SMS to where they are most needed. Most im-

alerts, reporting options and fleet scalabil- portantly, this helps avoid unplanned out-

ity inputs. ages. The interface allows the user to drill

further down into the information – down

Straightforward and easy-to-use dash- to a single transformer’s sensor informa-

boards allow users to see the transformer tion – if needed. When conditions start to

fleet health at a glance. Using traffic light deteriorate past a predefined point, users

1 6 ABB review 3|15

5 Example of an online performance model

B1 Flag 4 – Sum current above 6%

No

Update percentiles Calculate last

Get last 30 days’ No 30 days trend with

and look for outliers Latest data set

worth of magnitude 95% confidence interval Level < 6%

(magnitude only) is an outlier?

and angle readings of the slope

6% Yes

4%

Phase Flag 1 – statistical outlier phase… Yes

ID

∆t ≤ 5 days

No Trend may lead Yes

Return Update phasor chart to 4% in less than Level < 4%

5 days?

Yes

Phase Flag 2 – trend may lead to No

Calculate time to 4%, t4%

ID 4% in t4% days

Yes Trend may lead

Flag 3 – trend may lead to

Calculate time to 6%, t6% to 6% in less than

4% to 6% in ... days

5 days?

No

B2 Flag 5 – Sum current above 4%

can be automatically notified of the issues on transformer assets by ensuring high

via email or SMS alerts. reliability, reduced life-cycle costs and The key to the

optimized overall performance. The re-

Aging assets, rising energy demand and sult of this data analysis helps create a success of these

the critical need to avoid unplanned out-

ages are challenging utilities and indus-

prioritized list of maintenance actions for

the entire fleet. Avoiding unnecessary

algorithms is the

tries around the world. While financial service on assets in good condition and utilization of subject

constraints are reducing maintenance focusing attention on more risky assets

budgets and expert resources, demand with higher importance will satisfy share- matter experts

for increased return on investment is un-

diminished. Maintenance managers fac-

holders and support adherence to new

regulatory requirements.

during the design

ing these demands should utilize assess- phase.

ments, sensors, data analytics and soft-

ware to adapt to condition-based main-

tenance planning. These methodologies

can provide a much better understand-

ing of asset risk and strengthen the con-

fidence level of the actual condition as

power equipment ages.

Avoid failures, increase asset

reliability and predictability John Vines

The ABB DTMProgram expert system Bernard Banh

a lgorithm provides recommendations to Craig Stiegemeier

optimize the maintenance and operation Poorvi Patel

of transformers. By prioritizing mainte- Luiz V. Cheim

nance, budgets can be concentrated ABB Power Transformers

where needed. Failure avoidance and St. Louis, MO, United States

risk mitigation with condition-based john.a.vines@us.abb.com

maintenance, structured and prioritized bernard.banh@us.abb.com

replacement plans, and the use of sen- craig.stiegemeier@us.abb.com

sors for near real-time data delivery all poorvi.patel@us.abb.com

allow the industry to maximize the return luiz.v.cheim@us.abb.com

Transformer health in the real world 1 7

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Power Systems Notes For GATE and Competitive Exams !Documento137 paginePower Systems Notes For GATE and Competitive Exams !satishfactory93% (28)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- 2012 Electric Load Forecast ReportDocumento113 pagine2012 Electric Load Forecast Reportshree_rs81Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Power System Stability Vol III KimbarkDocumento330 paginePower System Stability Vol III KimbarkShashidhar Kasthala89% (18)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Large Power Transformer Reliability Improvement in Eskom DistributionDocumento4 pagineLarge Power Transformer Reliability Improvement in Eskom DistributionUshma V PatelNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Transformer Reliability and Condition AssessmentDocumento6 pagineTransformer Reliability and Condition AssessmentUshma V PatelNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Smart Grids - Challenges and Ongoing Activities: KumarDocumento0 pagineSmart Grids - Challenges and Ongoing Activities: KumarUshma V PatelNessuna valutazione finora

- Power System Analysis-IiDocumento115 paginePower System Analysis-IiSrinivasReddy100% (2)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Development of An Independent Type of Hybrid Power Generation SystemDocumento6 pagineDevelopment of An Independent Type of Hybrid Power Generation SystemUshma V PatelNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Power System Analysis-IiDocumento115 paginePower System Analysis-IiSrinivasReddy100% (2)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Reliability Evaluation of Engineering Systems by Roy BillintonDocumento13 pagineReliability Evaluation of Engineering Systems by Roy BillintonUshma V Patel20% (10)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- GK Capsule Nicl RbiDocumento16 pagineGK Capsule Nicl RbiZiaur RahmanNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Equations of Kinetics 3Documento29 pagineEquations of Kinetics 3Ushma V PatelNessuna valutazione finora

- Billinton Allan Excerpt Reliability Evaluation of Engineering Systems by Roy BillintonDocumento11 pagineBillinton Allan Excerpt Reliability Evaluation of Engineering Systems by Roy BillintonUshma V Patel100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Equations of Kinetics 3Documento29 pagineEquations of Kinetics 3Ushma V PatelNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Power Quality Improvement Using FACTS Power Filter Compensation SchemeDocumento11 paginePower Quality Improvement Using FACTS Power Filter Compensation SchemeUshma V PatelNessuna valutazione finora

- Paper Battery-A Promising Energy Solution For IndiaDocumento4 paginePaper Battery-A Promising Energy Solution For IndiaUshma V Patel100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Power Quality Improvement Using FACTS Power Filter Compensation SchemeDocumento11 paginePower Quality Improvement Using FACTS Power Filter Compensation SchemeUshma V PatelNessuna valutazione finora

- Paper Battery-A Promising Energy Solution For IndiaDocumento4 paginePaper Battery-A Promising Energy Solution For IndiaUshma V Patel100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Power Quality Improvement Using FACTS Power Filter Compensation SchemeDocumento11 paginePower Quality Improvement Using FACTS Power Filter Compensation SchemeUshma V PatelNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Paper Battery-A Promising Energy Solution For IndiaDocumento4 paginePaper Battery-A Promising Energy Solution For IndiaUshma V Patel100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Basic Research Needs For Electrical Energy Storage PDFDocumento186 pagineBasic Research Needs For Electrical Energy Storage PDFlgmartellNessuna valutazione finora

- Paper Battery-A Promising Energy Solution For IndiaDocumento4 paginePaper Battery-A Promising Energy Solution For IndiaUshma V Patel100% (1)

- 10 1 1 62Documento4 pagine10 1 1 62Ushma V PatelNessuna valutazione finora

- Power Quality Improvement Using FACTS Power Filter Compensation SchemeDocumento11 paginePower Quality Improvement Using FACTS Power Filter Compensation SchemeUshma V PatelNessuna valutazione finora

- AT89 Series Hardware DescriptionDocumento33 pagineAT89 Series Hardware Descriptiongray0132Nessuna valutazione finora

- Chanakya Niti - Some Quotes by Arya ChanakyaDocumento2 pagineChanakya Niti - Some Quotes by Arya ChanakyaUshma V PatelNessuna valutazione finora

- Chanakya Niti - Some Quotes by Arya ChanakyaDocumento2 pagineChanakya Niti - Some Quotes by Arya ChanakyaUshma V PatelNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Chanakya Niti - Some Quotes by Arya ChanakyaDocumento2 pagineChanakya Niti - Some Quotes by Arya ChanakyaUshma V PatelNessuna valutazione finora

- Schedule Risk AnalysisDocumento40 pagineSchedule Risk Analysisemilio_ndl5360Nessuna valutazione finora

- Case Home DepotDocumento53 pagineCase Home DepotFayaza Rahman Eva100% (6)

- Brett Steenbarger Overcoming Market PanicDocumento3 pagineBrett Steenbarger Overcoming Market Panicmansam1100% (3)

- IPC PL 14 04 Issue 4Documento27 pagineIPC PL 14 04 Issue 4saladinNessuna valutazione finora

- Insurance OperationsDocumento12 pagineInsurance OperationsIsunni AroraNessuna valutazione finora

- Grade 11.1 - 2nd Semester Final Exam WorksheetDocumento2 pagineGrade 11.1 - 2nd Semester Final Exam WorksheetyasirNessuna valutazione finora

- Bangladesh Bank Defined Sector Specific Environmental & Social Due Diligence (ESDD) ChecklistDocumento23 pagineBangladesh Bank Defined Sector Specific Environmental & Social Due Diligence (ESDD) ChecklistMohammad Shafiqul Islam RoneeNessuna valutazione finora

- Unit II-Project Identification, Selection, PlanningDocumento76 pagineUnit II-Project Identification, Selection, PlanningRohit GhulanavarNessuna valutazione finora

- A Cyber Mission Impact Assessment ToolDocumento7 pagineA Cyber Mission Impact Assessment ToolНиколай ДомуховскийNessuna valutazione finora

- 03 Cyber Security Testing Guideline - HKMA - 20161221 (FromDoman)Documento4 pagine03 Cyber Security Testing Guideline - HKMA - 20161221 (FromDoman)anna leeNessuna valutazione finora

- The Sociology of Food Eating and The Place of Food in Society - CompressedDocumento299 pagineThe Sociology of Food Eating and The Place of Food in Society - CompressedDedy IsmailNessuna valutazione finora

- Guidelines For Classifying The Hazard Potential of DamsDocumento206 pagineGuidelines For Classifying The Hazard Potential of DamsSalim BhaldarNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocumento5 pagineJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriNessuna valutazione finora

- Chapter I, Ii, Ii, IvDocumento222 pagineChapter I, Ii, Ii, IvArtemio Jr A LonzagaNessuna valutazione finora

- Temperature Excursion Management - A Novel Approac PDFDocumento8 pagineTemperature Excursion Management - A Novel Approac PDFPharmacist100% (1)

- Project Reprot On Working Capital & Inventory Management at TATA STEELDocumento103 pagineProject Reprot On Working Capital & Inventory Management at TATA STEELAvik Roy96% (23)

- PMP Prep Exam 1Documento21 paginePMP Prep Exam 1Serges Fokou100% (1)

- Iogp590 201702 PDFDocumento286 pagineIogp590 201702 PDFningzhiheNessuna valutazione finora

- Risk Management NotesDocumento18 pagineRisk Management Noteswww.pubg4.co.inNessuna valutazione finora

- A Dynamic Fault Tree PDFDocumento9 pagineA Dynamic Fault Tree PDFJosé MéndezNessuna valutazione finora

- Actualtests: Topping Certification Exam Prep, Test Dumps Materials - ActualtestsitDocumento8 pagineActualtests: Topping Certification Exam Prep, Test Dumps Materials - ActualtestsitFaim HasanNessuna valutazione finora

- Xods G8D1Documento75 pagineXods G8D1om cncNessuna valutazione finora

- Comprehensive Security Master PlanDocumento17 pagineComprehensive Security Master PlanBrenda AndersonNessuna valutazione finora

- Guidebook ISO 14001 GBDocumento32 pagineGuidebook ISO 14001 GBarielNessuna valutazione finora

- Review of Literature Empirical Research On Corporate GovernanceDocumento5 pagineReview of Literature Empirical Research On Corporate GovernanceaflsjizafNessuna valutazione finora

- 7 Steps To Build A GRC FrameworkDocumento29 pagine7 Steps To Build A GRC FrameworkAnkush Markandey50% (2)

- Bus 206 Sample Questions Chapters 5-8Documento24 pagineBus 206 Sample Questions Chapters 5-8Mochamad Rizky Pradana Muharam100% (1)

- BSEE Steel Catenary Riser Integrity Management ReportDocumento26 pagineBSEE Steel Catenary Riser Integrity Management ReportEyoma EtimNessuna valutazione finora

- Procedure For Handling of Deviations PDFDocumento5 pagineProcedure For Handling of Deviations PDFSaeed EbrahimiNessuna valutazione finora

- Case # 3 - Home Inspection Co.Documento9 pagineCase # 3 - Home Inspection Co.Ahmad RafiqNessuna valutazione finora