Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Zeron 100 PDF

Caricato da

NAVANEETHTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Zeron 100 PDF

Caricato da

NAVANEETHCopyright:

Formati disponibili

METRODE

A133

WELDING CONSUMABLES

25%Cr SUPERDUPLEX - ZERON® 100

Alloy type Microstructure

25%Cr superduplex ferritic-austenitic stainless steels Multipass welds in the as-welded condition consist of a

matching the proprietary Zeron® 100 alloy. duplex austenite-ferrite microstructure with an

approximate 30-60% ferrite level, depending on heat

Materials to be welded input/cooling conditions.

Matching

Welding guidelines

wrought: cast:

UNS S32760 UNS J93380, DIN 1.4508 Preheat not generally required. Interpass temperature

DIN 1.4501 ASTM A890 6A, 150°C max. Heat input in the range 1.0–2.0 kJ/mm

ASTM A182 F55 ACI CD3MWCuN (depending on material thickness) should be acceptable

but most codes restrict the max to 1.5 or 1.75kJ/mm.

Other superduplex, including

wrought: PWHT

UNS S32750, 2507 (Sandvik/Avesta), UR47N (CLI)

Although welds in wrought duplex stainless steels are

UNS S32550, S32520, UR52N+ (CLI), Ferralium

almost always left in the as-welded condition, major

SD40 (Meighs)

repairs to castings are generally specified in the solution

UNS S39274, DP3W (Sumitomo), UNS S32950, 7-Mo

treated condition. Experience has indicated good

Plus (Carpenter)

cast:

properties following 1120°C/3-6h + water quench.

UNS J93404, DIN 1.4469

ASTM A890 5A, ACI CE3MN Additional information

Further information on the welding of Zeron® 100 is

Applications available in the Metrode Technical Profile on duplex

®

Zeron 100 has an exceptional combination of strength and superduplex.

and resistance to corrosion and erosion in a wide range

of aggressive media. The presence of Cu+W provides Related alloy groups

superior resistance to sulphuric and hydrochloric acids 2507 superduplex (data sheet B-62) and matching

when compared to similar alloys without these consumables for casting repair (solution annealed)

additions. Offshore applications exploit the high applications.

resistance to pitting and stress-corrosion cracking in

seawater. It is also highly resistant to caustic alkalis and Products available

phosphoric acid. Service temperature range is usually

limited to –50°C to 280°C, the upper limit owing to Process Product Specification

thermal instability ("450°C" and sigma embrittlement). MMA ®

Zeron 100XKS BS EN E25 9 4 NLB

®

It is widely used in oil and gas production and process TIG/MIG/SAW Zeron 100X BS EN 25 9 4 NL

pipework, risers, manifolds, pressure vessels, valves, SAW flux SSB BS EN SA AF 2

pumps, desalination plant, systems for flue-gas LA491 BS EN SA FB 2

desulphurisation (FGD) and also in the mining, Supercore

FCW --

chemical and pharmaceutical industries. Zeron® 100 Z100XP

wires are also used for joining supermartensitic stainless

steels.

TEL : +609-567 4662 FAX : +609-566 4459

NET-LITE

EMAIL : sales@netlite.com.my

METRODE

A134

WELDING CONSUMABLES

General Data for all Zeron® 100 MMA Electrodes

Storage 3 hermetically sealed ring-pull metal tins per carton, with unlimited shelf life. Direct use from tin is satisfactory

for longer than a working shift of 8h. Excessive exposure of electrodes to humid conditions will cause some

moisture pick-up and increase the risk of porosity.

For electrodes that have been exposed:

Redry 200 – 300°C/1-2h to restore to as-packed condition. Maximum 400° C, 3 cycles, 10h total.

Storage of redried electrodes at 50 – 200°C in holding oven or heated quiver: no limit, but maximum 6 weeks

recommended. Recommended ambient storage conditions for opened tins (using plastic lid): < 60% RH, > 18°C.

Fume data Fume composition, wt % typical:

Fe Mn Ni Cr Cu Mo V F OES (mg/m3)

7 6 1 7 0.5 0.2 <0.1 28 0.7

ZERON® 100XKS Basic pipe-welding electrode for superduplex

Product description Basic coated all-positional MMA electrode for welding Zeron® 100 and other superduplex alloys for service in the

as-welded condition. This electrode is overmatching with respect to nickel content to achieve correct austenite-

ferrite microstructural phase balance. It is designed for the most demanding vertical and overhead welding

positions such as fixed pipework qualified in the ASME 6G position.

Fully alloyed matching Zeron® 100 core wire including W and Cu. Moisture resistant flux technology.

Recovery is about 105% with respect to core wire, 65% with respect to whole electrode.

Specifications AWS A5.4 E2595-15

BS EN 1600 E 25 9 4 N L B 4 2

Weir Materials MDS 12809/08

Approvals ABS, DNV

ASME IX Qualification QW432 F-No 5, QW442 A-No 8

Composition C Mn Si S P Cr Ni Mo W Cu N PREN PREW

(weld metal wt %) min -- -- -- -- -- 24.0 9.0 3.5 0.5 0.5 0.2 40 40

max 0.03 1.0 1.0 0.01 0.03 26.0 10.0 4.0 1.0 1.0 0.3 -- --

typ 0.025 0.9 0.5 0.005 0.02 25 9.3 3.6 0.7 0.7 0.23 41 42

Pitting resistance equivalent PREN = Cr + 3.3Mo + 16N

Pitting resistance equivalent PREW = Cr + 3.3Mo + 1.65W + 16N

All-weld mechanical As welded min typical

properties Tensile strength MPa 760 800-950

0.2% Proof stress MPa 550 650-750

Elongation on 4d % 15 30

Elongation on 5d % 20 22-27

Reduction of area % -- 40-45

Impact energy - 20°C J -- > 55

- 50°C J -- > 40

Hardness HV -- 270-320

Operating parameters DC +ve

ø mm 2.5 3.2 4.0 5.0

min A 50 70 100 130

max A 75 95 155 210

Packaging data ø mm 2.5 3.2 4.0 5.0

length mm 300 350 350 350

kg/carton 12.0 14.1 13.5 13.5

pieces/carton 696 360 270 172

TEL : +609-567 4662 FAX : +609-566 4459

NET-LITE

EMAIL : sales@netlite.com.my

METRODE

A135

WELDING CONSUMABLES

ZERON® 100X Solid welding wire for superduplex

Product description Solid wire for TIG, MIG and SAW.

For applications where Zeron® 100X wire is to be used for welding supermartensitic stainless steels it is possible

for wire to be supplied with a total hydrogen content of 3ppm maximum.

Specifications AWS A5.9 ER2594

BS EN ISO 14343-A 25 9 4 N L (prefix W=TIG, G=MIG, S=SAW)

Weir Materials MDS 12809/07

Approvals ABS, DNV (TIG and SAW in conjunction with SSB flux)

ASME IX Qualification QW432 F-No 6, QW442 A-No 8

Composition C Mn Si S P Cr Ni Mo W Cu N PRE PRE

N W

(wire wt %) min -- -- -- -- -- 24.0 9.0 3.5 0.5 0.5 0.2 40 40

max 0.03 1.0 1.0 0.01 0.03 26.0 10.0 4.0 1.0 1.0 0.3 -- --

typ 0.015 0.7 0.4 0.002 0.02 25 9.3 3.7 0.6 0.7 0.23 41 42

All-weld mechanical Typical values as welded min TIG MIG SAW TIG +160°C

properties Tensile strength MPa 760 870 860 885 769

0.2% Proof stress MPa 550 695 645 700 523

Elongation on 4d % 15 36 25 26 39

Elongation on 5d % 20 32 23 24 34

Reduction of area % -- 68 28 48 72

Impact energy -50°C J -- 130 60 40 --

-75°C J -- >100 -- -- --

Hardness cap/mid HV -- 290 290 290 --

Typical operating TIG MIG SAW

parameters Shielding Argon Ar/He/CO2 SSB flux

Current DC- pulsed DC+

Diameter 1.6/2.4mm 1.2mm 1.6mm

Voltage 100A, 12V 180A, 28V 350A, 30V

Packaging data ø mm TIG MIG SAW

0.8 -- To order --

1.0 -- To order --

1.2 -- To order --

1.6 2.5kg tube -- 25kg coil

2.0 2.5kg tube -- --

2.4 2.5kg tube -- 25kg coil

3.2 2.5kg tube -- --

Fume data MIG fume composition (wt %) (TIG and SAW fume negligible)

Fe Mn Cr3 Ni Mo Cu OES (mg/m3)

28 10 22 8 2 1.3 2.3

TEL : +609-567 4662 FAX : +609-566 4459

NET-LITE

EMAIL : sales@netlite.com.my

METRODE

A136

WELDING CONSUMABLES

SSB FLUX Sub-arc flux

Product description Agglomerated basic non-alloying flux for submerged arc welding.

Specifications DIN 32522 BFB6 63353 DC8M

BS EN 760 SA AF2 DC

ASME IX Qualification QW432 F-No -, QW442 A-No -

Composition C Mn Si S P Cr Ni Mo Cu W N

(typical) Zeron® 100X wire 0.015 0.7 0.4 0.002 0.023 25 9.3 3.7 0.7 0.7 0.23

Deposit 0.02 0.6 0.4 0.002 0.02 24.5 9.3 3.6 0.7 0.7 0.21

All-weld mechanical Typical values as welded min SAW

properties with Tensile strength MPa 750 890

®

Zeron 100X wire 0.2% Proof stress MPa 550 700

Elongation on 4d % -- 25

Elongation on 5d % 20 24

Reduction of area % -- >40

Impact energy - 50°C J -- 40

Hardness HV -- 290

Operating parameters Current: DC +ve ranges as below:

ø mm amp-volt range typical stickout

1.6 200-350A, 27-31V 300A, 28V 20-25mm

2.4 250-450A, 28-32V 350A, 29V 20-25mm

Packaging data Metrode SSB Flux is supplied in sealed moisture resistant 20kg metal drums. Preferred storage conditions for

opened drums: < 60%RH, > 18°C. If the flux has become damp or has been stored for a long period, it should be

redried in the range 250-400°C/1-3h.

LA491 FLUX Sub-arc flux

Product description Agglomerated fluoride-basic non-alloying flux for submerged arc welding.

Specifications DIN 32522 B FB 6 55455 AC 8

BS EN 760 SA FB 255 AC

ASME IX Qualification QW432 F-No -, QW442 A-No -

Composition C Mn Si S P Cr Ni Mo Cu W N

(typical) Zeron® 100X 0.015 0.7 0.4 0.002 0.02 25 9.3 3.7 0.7 0.7 0.23

wire

Deposit 0.02 0.6 0.4 0.002 0.02 24.5 9.3 3.6 0.7 0.7 0.21

All-weld mechanical Typical values as welded min SAW

properties with Tensile strength MPa 750 890

®

Zeron 100X wire 0.2% Proof stress MPa 550 700

Elongation on 4d % -- 25

Elongation on 5d % 20 24

Reduction of area % -- >40

Impact energy - 50°C J -- 40

Hardness HV -- 290

Operating parameters Current: DC +ve ranges as below:

ø mm amp-volt range typical stickout

1.6 200-350A, 27-31V 300A, 28V 20-25mm

2.4 250-450A, 28-32V 350A, 29V 20-25mm

Packaging data Metrode LA491 Flux is supplied in sealed moisture resistant 20kg metal drums. Preferred storage conditions for

opened drums: < 60%RH, > 18°C. If the flux has become damp or has been stored for a long period, it should be

redried in the range 300-350°C/1-3h.

TEL : +609-567 4662 FAX : +609-566 4459

NET-LITE

EMAIL : sales@netlite.com.my

METRODE

A137

WELDING CONSUMABLES

SUPERCORE Z100XP Rutile flux cored wire for superduplex stainless steel

Product description Flux cored wire made with an alloyed stainless steel sheath and rutile flux system. Supercore Z100XP combines

easy operability, high deposit quality for both positional pipework and downhand welding. Metal recovery is

about 90% with respect to the wire.

Specifications There are no national specifications for this wire.

ASME IX Qualification QW432 F-No --, QW442 A-No --

Composition C Mn Si S P Cr Ni Mo Cu W N PRE PREW

N

(weld metal wt %) min -- -- -- -- -- 24.0 8.5 3.5 0.5 0.5 0.2 40 40

max 0.04 1.5 1.0 0.01 0.03 26.0 10.0 4.0 1.0 1.0 0.3 -- --

typ 0.03 1.0 0.5 0.005 0.02 24.5 9.1 3.7 0.6 0.6 0.22 41 42

Pitting resistance equivalent PREN = Cr + 3.3Mo + 16N

Pitting resistance equivalent PREW = Cr + 3.3Mo + 1.65W + 16N

All-weld mechanical As welded min typical

properties Tensile strength MPa 750 880

0.2% Proof stress MPa 550 690

Elongation on 4d % -- 27

Elongation on 5d % 20 25

Reduction of area % -- 33

Impact energy -20°C J -- 40

-50°C J -- 32

Hardness HV -- 280

HRC -- 26

Operating parameters Shielding gas: 80%Ar-20%CO2 at 20-25l/min. Proprietary gases may be used but argon should not exceed 85%.

Current: DC+ve ranges as below for Ar-20%CO2:

ø mm amp-volt range typical stickout

1.2 120 – 250A, 22 – 34V 180A, 29V 15 – 20mm

Packaging data Spools vacuum-sealed in barrier foil with cardboard carton: 15kg

The as-packed shelf life is virtually indefinite.

Resistance to moisture absorption is high, but to maintain the high integrity of the wire surface and prevent any

possibility of porosity, it is advised that part-used spools are returned to polythene wrappers.

Where possible, preferred storage conditions are 60% RH max, 18°C min.

Fume data Fume composition (wt %)

Fe Mn Ni Cr3 Cr6 Cu F OES (mg/m3)

14 10 1.5 5 5 <1 5 1.0

TEL : +609-567 4662 FAX : +609-566 4459

NET-LITE

EMAIL : sales@netlite.com.my

Potrebbero piacerti anche

- Aluminum 5083Documento2 pagineAluminum 5083razormebackNessuna valutazione finora

- MonevaDocumento15 pagineMonevaKurt Lester Moneva100% (1)

- 1.4462 PropertiesDocumento1 pagina1.4462 PropertiesutreshwarmiskinNessuna valutazione finora

- Welder Job DescriptionDocumento2 pagineWelder Job DescriptionNAVANEETHNessuna valutazione finora

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesDa EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNessuna valutazione finora

- Duplex Stainless Steel WeldingDocumento25 pagineDuplex Stainless Steel WeldingcfcshakerNessuna valutazione finora

- Esab DublexDocumento8 pagineEsab DublexSuphi YükselNessuna valutazione finora

- Study Materials Level 3Documento6 pagineStudy Materials Level 3Krishna Vacha50% (2)

- Simple Physical Models For Foundation DynamicsDocumento43 pagineSimple Physical Models For Foundation DynamicsJORGRULESNessuna valutazione finora

- Atlas 3CR12 DatasheetDocumento3 pagineAtlas 3CR12 DatasheettridatylNessuna valutazione finora

- High Temperature Brazing AlloysDocumento0 pagineHigh Temperature Brazing AlloysvkmsNessuna valutazione finora

- Graphene InfomationDocumento5 pagineGraphene InfomationbillyboyclydeNessuna valutazione finora

- Calculation of pitting resistance equivalent numbers (PRENDocumento7 pagineCalculation of pitting resistance equivalent numbers (PRENVivi OktaviantiNessuna valutazione finora

- Utico FZC Safe Work Procedure Manual Bending RollsDocumento2 pagineUtico FZC Safe Work Procedure Manual Bending RollsNAVANEETHNessuna valutazione finora

- Metrode Welding Duplex & Superduplex Stainless SteelsDocumento18 pagineMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- Utico FZC WPS & PQR ListDocumento1 paginaUtico FZC WPS & PQR ListNAVANEETH100% (1)

- Welding Consumables For Hydro Power StationsDocumento16 pagineWelding Consumables For Hydro Power StationsMohamed FaragNessuna valutazione finora

- Utico FZC Work Instruction Manual Drilling MachineDocumento2 pagineUtico FZC Work Instruction Manual Drilling MachineNAVANEETHNessuna valutazione finora

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Documento2 pagineSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.Nessuna valutazione finora

- Understand Contacts - Midas NFX PDFDocumento10 pagineUnderstand Contacts - Midas NFX PDFdzejziNessuna valutazione finora

- 6 InertingDocumento9 pagine6 InertingHasan CosalevNessuna valutazione finora

- Zeron SmawDocumento4 pagineZeron SmawJoe FizzoNessuna valutazione finora

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocumento7 pagine22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNessuna valutazione finora

- Super Duplex Stainless Steel: Excellent Engineering SolutionsDocumento3 pagineSuper Duplex Stainless Steel: Excellent Engineering SolutionsshyamNessuna valutazione finora

- Alloy 625 ConsumablesDocumento4 pagineAlloy 625 ConsumablesRodrigo CarneiroNessuna valutazione finora

- 3CR12 Data Sheet 2021Documento1 pagina3CR12 Data Sheet 2021Elcio VilanculoNessuna valutazione finora

- Matching Alloy 625 Welding ConsumablesDocumento5 pagineMatching Alloy 625 Welding Consumablesharan2000Nessuna valutazione finora

- 253 MA-NF AC/DC: Covered ElectrodesDocumento1 pagina253 MA-NF AC/DC: Covered ElectrodesElMacheteDelHuesoNessuna valutazione finora

- 11⁄4Cr-1⁄2Mo Steel Welding Electrodes Data SheetDocumento7 pagine11⁄4Cr-1⁄2Mo Steel Welding Electrodes Data Sheetanon_928750560Nessuna valutazione finora

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocumento3 pagineStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNessuna valutazione finora

- Table A3 Typical Storage and Drying Conditions For Covered Arc Welding ElectrodesDocumento1 paginaTable A3 Typical Storage and Drying Conditions For Covered Arc Welding Electrodesravi00098Nessuna valutazione finora

- Product Data Sheet for FabCO 811N1 Flux Cored Gas Shielded WireDocumento2 pagineProduct Data Sheet for FabCO 811N1 Flux Cored Gas Shielded WireAlejandroAcuñaMaureiraNessuna valutazione finora

- 22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESDocumento7 pagine22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESNguyen Anh TuanNessuna valutazione finora

- Zeron 100 Data SheetDocumento2 pagineZeron 100 Data SheetMorgan PalmaNessuna valutazione finora

- Railrod: Data SheetDocumento1 paginaRailrod: Data Sheetmohamed AdelNessuna valutazione finora

- Electrode Booklet F Web 100Documento1 paginaElectrode Booklet F Web 100satnamNessuna valutazione finora

- B-62 2507 Rev 06Documento5 pagineB-62 2507 Rev 06Shaik ShahNessuna valutazione finora

- SS 6mo - 1.4547Documento1 paginaSS 6mo - 1.4547f_riseNessuna valutazione finora

- 1.4462 SpecificationDocumento2 pagine1.4462 SpecificationSergeyNessuna valutazione finora

- High Strength Low Alloy Welding ConsumablesDocumento5 pagineHigh Strength Low Alloy Welding Consumablesmohamed AdelNessuna valutazione finora

- Datasheet-Sandvik-254-Smo-Esr-En-V2019-11-21 11 - 42 Version 1Documento7 pagineDatasheet-Sandvik-254-Smo-Esr-En-V2019-11-21 11 - 42 Version 1KashishNessuna valutazione finora

- Properties and Welding Procedure For Grade 91 Alloy Steel: Siddharth Pant and Swati BhardwajDocumento6 pagineProperties and Welding Procedure For Grade 91 Alloy Steel: Siddharth Pant and Swati BhardwajArvind ShuklaNessuna valutazione finora

- Improving The Corrosion Resistance of Duplex Stainless Steel WeldsDocumento29 pagineImproving The Corrosion Resistance of Duplex Stainless Steel WeldsRaghuram BathulaNessuna valutazione finora

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Documento2 pagineAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNessuna valutazione finora

- P91 - Modified 9crmo: Alloy TypeDocumento7 pagineP91 - Modified 9crmo: Alloy TypeHanLe DuyNessuna valutazione finora

- Data Sheet A-10: Alloy TypeDocumento3 pagineData Sheet A-10: Alloy Typemohamed AdelNessuna valutazione finora

- Advanced welding electrode for aluminium bronzesDocumento1 paginaAdvanced welding electrode for aluminium bronzesAris WicaksonoNessuna valutazione finora

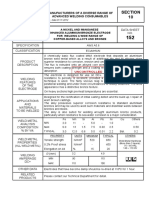

- Manufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6Documento1 paginaManufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6yadi_baeNessuna valutazione finora

- Duplex Stainless Steel 329 Round Bars ManufacturerDocumento2 pagineDuplex Stainless Steel 329 Round Bars Manufacturertien100% (1)

- Hoja de Especificaciones Del Acero T-410Documento2 pagineHoja de Especificaciones Del Acero T-410cristobal_tl2277Nessuna valutazione finora

- .Au-Aluminium Alloy 3003Documento5 pagine.Au-Aluminium Alloy 3003ali alhamilNessuna valutazione finora

- Uns s32760Documento3 pagineUns s32760NitinNessuna valutazione finora

- CuW Sintered E USDocumento5 pagineCuW Sintered E USanuragsngNessuna valutazione finora

- EN1.4462-0509 Original EngDocumento2 pagineEN1.4462-0509 Original Eng4455jappNessuna valutazione finora

- Ferritic 9Cr1Mo Alloy Selected for PFBR Steam Generator TubesDocumento4 pagineFerritic 9Cr1Mo Alloy Selected for PFBR Steam Generator TubesrkukgNessuna valutazione finora

- Duplex 1.4662 UKDocumento2 pagineDuplex 1.4662 UKtienNessuna valutazione finora

- 301 Stainless SteelDocumento1 pagina301 Stainless SteelDanielNessuna valutazione finora

- Rogers Corp Product Selector GuideDocumento3 pagineRogers Corp Product Selector GuideGeorgios SarrisNessuna valutazione finora

- High Quality Products For Welding and CladdingDocumento25 pagineHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- Domex 100 XF hot rolled steel data sheetDocumento2 pagineDomex 100 XF hot rolled steel data sheetzubblwump5063Nessuna valutazione finora

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocumento2 pagineStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNessuna valutazione finora

- Experiences With Zeron 100® Superduplex Stainless Steel in The Process IndustriesDocumento12 pagineExperiences With Zeron 100® Superduplex Stainless Steel in The Process IndustriesMukeshNessuna valutazione finora

- Datasheet-Sandvik-254-Smo-En-V2021-04-22 18 - 35 Version 1Documento10 pagineDatasheet-Sandvik-254-Smo-En-V2021-04-22 18 - 35 Version 1darioNessuna valutazione finora

- Alloy904L SpecSheet PDFDocumento2 pagineAlloy904L SpecSheet PDFPieter BrodeouxNessuna valutazione finora

- Aalco Metals LTD Stainless Steel 14021 Bar 311Documento2 pagineAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNessuna valutazione finora

- 25CR20NIDocumento2 pagine25CR20NIShariq KhanNessuna valutazione finora

- Recom. de Soldadura XARDocumento4 pagineRecom. de Soldadura XARelias667Nessuna valutazione finora

- Duplex WeldingDocumento4 pagineDuplex WeldingVishal Sparkle QE3100% (1)

- Self-shielded electrode for heavy component repairDocumento1 paginaSelf-shielded electrode for heavy component repairAravind rajNessuna valutazione finora

- Metrode E2209 (B-60) ElectrodeDocumento6 pagineMetrode E2209 (B-60) ElectrodeClaudia MmsNessuna valutazione finora

- SAW Electrode DescriptionDocumento1 paginaSAW Electrode DescriptionNAVANEETHNessuna valutazione finora

- Heb 100 MTCDocumento1 paginaHeb 100 MTCNAVANEETHNessuna valutazione finora

- Stainless Steel Solid Wire for 304L and 321 ApplicationsDocumento1 paginaStainless Steel Solid Wire for 304L and 321 ApplicationsJoshua WalkerNessuna valutazione finora

- Hea 100-40 STRDocumento2 pagineHea 100-40 STRNAVANEETHNessuna valutazione finora

- Hea 160x12mtrDocumento1 paginaHea 160x12mtrNAVANEETHNessuna valutazione finora

- Elcometer 319Documento8 pagineElcometer 319pajalcaNessuna valutazione finora

- Stainless Steel Solid Wire for 304L and 321 ApplicationsDocumento1 paginaStainless Steel Solid Wire for 304L and 321 ApplicationsJoshua WalkerNessuna valutazione finora

- Zeron 100Documento2 pagineZeron 100NAVANEETHNessuna valutazione finora

- Zeron 100Documento2 pagineZeron 100NAVANEETHNessuna valutazione finora

- Coulomb's LawDocumento6 pagineCoulomb's LawAarush MishraNessuna valutazione finora

- 85000-071 - TECH - F300 - IPS PipeDocumento248 pagine85000-071 - TECH - F300 - IPS PipeVân TrầnNessuna valutazione finora

- DAB 2018 Componenets CatalogueDocumento20 pagineDAB 2018 Componenets CataloguegobilgobilNessuna valutazione finora

- Membrane Transport: Sherwood, Human PhysiologyDocumento12 pagineMembrane Transport: Sherwood, Human PhysiologyĐồng Ngọc HàNessuna valutazione finora

- En 10213-2007Documento30 pagineEn 10213-2007Sidnei CarraschiNessuna valutazione finora

- Physics Advanced Level Problem Solving (ALPS-8) - PaperDocumento14 paginePhysics Advanced Level Problem Solving (ALPS-8) - PaperSwapnil MandalNessuna valutazione finora

- Engineering Chemistry (BCHY101L) : Energy DevicesDocumento84 pagineEngineering Chemistry (BCHY101L) : Energy DevicesDeepali Mishra 21BCE3440Nessuna valutazione finora

- 15.1 PPTDocumento28 pagine15.1 PPTKingProNessuna valutazione finora

- Chapter 2: Earth in SpaceDocumento75 pagineChapter 2: Earth in SpaceKen AguilaNessuna valutazione finora

- SEMM Prelim AnalysisDocumento23 pagineSEMM Prelim AnalysisMao Cristhian Pinto CruzNessuna valutazione finora

- A203 - 17 Standard Specification For Pressure Vessel Plates, Alloy Steel, NickelDocumento3 pagineA203 - 17 Standard Specification For Pressure Vessel Plates, Alloy Steel, Nickelalucard375Nessuna valutazione finora

- Amendment No 1 - IS 875 - Part 3Documento7 pagineAmendment No 1 - IS 875 - Part 3Parthiban KandhasamyNessuna valutazione finora

- Introduction To Design of Seismically-Isolated Structure in JapanDocumento45 pagineIntroduction To Design of Seismically-Isolated Structure in JapanSyafrudin MegnumzNessuna valutazione finora

- Laws of MotionDocumento5 pagineLaws of Motionkatie4834Nessuna valutazione finora

- Definition and Purposes of ExplanationDocumento4 pagineDefinition and Purposes of ExplanationArka WiguaNessuna valutazione finora

- Lecture 11 - Multiple Reactions 2Documento14 pagineLecture 11 - Multiple Reactions 2Sabrina AzharNessuna valutazione finora

- Solar Load Through Transparent SurfacesDocumento6 pagineSolar Load Through Transparent SurfacesJayson OrosaNessuna valutazione finora

- Maxifloor MFT 323 SL Epoxy CoatingDocumento2 pagineMaxifloor MFT 323 SL Epoxy CoatinganggaNessuna valutazione finora

- Optical Fiber Structure & Light TransmissionDocumento83 pagineOptical Fiber Structure & Light Transmissionece Ms.G.Bhargavi100% (1)

- Bend Testing of Material For Ductility: Standard Test Methods ForDocumento10 pagineBend Testing of Material For Ductility: Standard Test Methods ForSyafiq Irsyadillah JafarNessuna valutazione finora

- Pipeline JournalDocumento68 paginePipeline Journal구용찬Nessuna valutazione finora

- Designand Performanceof Soft Ground Improvement Using PVDwithandwithout Vacuum ConsolidationDocumento17 pagineDesignand Performanceof Soft Ground Improvement Using PVDwithandwithout Vacuum ConsolidationShadabNessuna valutazione finora

- Determination of Molecular Weight of MacromoleculesDocumento8 pagineDetermination of Molecular Weight of MacromoleculesKaaya Godfrey100% (1)

- Hf-Erw Hf-Erw: Pipes & Tubes Pipes & TubesDocumento8 pagineHf-Erw Hf-Erw: Pipes & Tubes Pipes & Tubesmoechamad_aditiaNessuna valutazione finora