Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ci IV8 Discharge Valve

Caricato da

Iskandar HasibuanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ci IV8 Discharge Valve

Caricato da

Iskandar HasibuanCopyright:

Formati disponibili

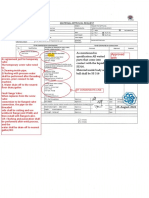

Chapter: Control Inert Page: 1 of 8

Engineering data sheet

Item: Ci IV8 discharge valve

Ci IV8 discharge valve

Item numbers covered by this datasheet

305410 Ci IV8-300 Manosw

305411 Ci IV8-300 Basic

305420 Ci IV8-200 Manosw

305421 Ci IV8-200 Basic

General

Valve for use in INERGEN fire extinguishing systems.

The valve has built-in pneumatic activation for inter-system

activation, back pressure activation and mechanical activation

interface.

The discharge outlet is connected internally to the Pneumatic

Actuator (PA) via a check valve (the check valve allows

pressure from the discharge side to enter the actuator side), this allows for the discharge port to be used as

activation port also (back pressure), hence eliminating the needs for PA circuitry between valves connected

to the same manifold. When more manifolds are used the PA system must be connected at least on one IV8

valve on each manifold.

The port for the PA function works as both inlet and outlet, hence the same connection is used on both pilot

and slave cylinders, and the pilot cylinders can be placed anywhere in the line of IV8 valves. All equipment

connected to the PA connection must be rated at 300/400 bar.

The standard valve is supplied without a burst disc and hence classified as a Type 2 valve when used with Ci

Hand wheel valve, if used with other hand wheel valves it will be classified as a Type 1 valve.

A special version is available where a built-in burst disc releases into the discharge pipe system to prevent

dangerously low oxygen concentrations in the cylinder storage room, this valve is classified as a Type 3 valve

as per EN 12094-4.

Manosw. model Manosw. model Basic model

Document: Ci IV8 discharge valve.doc Text

1

2

Product: Id: KP 3

Inergen® Rev: 18.06.08 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: Control Inert Page: 2 of 8

Engineering data sheet

Item: Ci IV8 discharge valve

Specifications

Pressure

Work: See table 1

Proof (burst): > 1200 bar

Burst disc: Available on request

Temperature: -20 to +70°C

Flow way: 50mm2 (ø8mm)

Smallest container: 2l (200 or 300 bar @ 15°C)

Activation (pneumatic and back pressure)

Triggering pres.: 10 – 400 bar

Min.: 8 bar 2 sec (0.01 l/sec)

Max. no triggering: 2 bar 10 sec

Activation (Mechanical)

Connection tread: M20×1.5 (Female)

Stroke × diameter: 6×ø6mm

Force: 350 N

Tread connections

Cylinder valve: See table 1

Discharge outlet: ISO228 3/8 (+ISO7 1/8”)

Pneu. Active. (in/out): ISO7 1/8”

Pres. gauge/switch: ISO228 1/4" + EN837)

Function

Operation time: < 1 sec

Remains fully open, also after activation.

Materials: Brass, stainless steel, Viton.

Dimension

L×H×W: 90×125/46×90

Weight: 1.3 – 1.5 kg

Table 1

Part Marking Designation Pressure Connection

number tread

Work Fill @

15°C

Bar Bar

305410 Ci-IV8-300 Ci IV8-300 Manosw 400 300 M25×1.5

305411 Ci-IV8-300 Ci IV8-300 Basic 400 300 M25×1.5

305420 Ci-IV8-200 Ci IV8-200 Manosw 300 200 W24.32×1/14

305421 Ci-IV8-200 Ci IV8-200 Basic 300 200 W24.32×1/14

Markings

Fire Eater Logo, Ci-IV8-###, Serial number, CE 1116

Document: Ci IV8 discharge valve.doc Text

1

2

Product: Id: KP 3

Inergen® Rev: 18.06.08 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: Control Inert Page: 3 of 8

Engineering data sheet

Item: Ci IV8 discharge valve

Installation

The IV8 valve is fitted to the hand wheel valve (on the cylinder) and the union nut is tightened to 80Nm.

Before fitting the valve, the o-ring must be inspected as per Fire Eater instruction INMON100.

The discharge hose is fitted to the IV8 valve and to the manifold.

Only valves connected to the same manifold will be actuated through the discharge hose. The PA (Pneumatic

Activation) system must be used for activation between manifolds.

If the pneumatic system is used, the PA adapter is fitted and the hoses connected.

The actuator is fitted to the valve.

The hand wheel valve is opened for 1 minute and then closed. After 6 hours the hand wheel valve is opened

again and it is checked that there has been no pressure drop.

The hand wheel valve is opened to the full position and sealed with coarse sealing wire and seal.

Operating

The valves on the pilot cylinders are activated by the actuator (see datasheet for these components).

The additional cylinders are activated by either the

a) Pneumatic (PA) system connected between the cylinders.

This system features both inlet and outlet through the same connection and hence the hoses are only

connected one place on each IV8 valve.

b) Backpressure (BP) from the pressure generated in the manifold during discharge.

Only valves connected to the same manifold can be activated this way. When multiple manifolds are

used the PA system (see A) must be used between the manifolds to activate at least one valve for

each manifold.

Document: Ci IV8 discharge valve.doc Text

1

2

Product: Id: KP 3

Inergen® Rev: 18.06.08 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: Control Inert Page: 4 of 8

Engineering data sheet

Item: Ci IV8 discharge valve

Maintenance

After discharge the piston assembly has to be replaced in order to ensure leak free operation.

Use service kit item number 305401. (Notice that one of the o-rings is PTFE and must be fitted to the piston

at Fire Eater).

The procedure for replacing the piston item 305401 is:

1. Make sure that the IV8 valve is depressurised.

2. Unscrew the end plug 305020 with FE tool 305491.

3. Extract drive piston 305018 (with rod and other parts) and place it in the end plug.

4. Unscrew separator disc 305011 with FE tool 305490.

5. Insert a 4mm in hex wrench in the IV8 valve from the opposite side (though the ø5 hole)

and push out the piston.

6. Assembly is the reverse procedure of dismantling.

O-rings must be lubricated (use lubricant FE part number 203012).

Damaged or dirty o-rings must be replaced.

7. Piston with o-rings (3) is inserted in the valve, piston rod 305019 (with drive piston) may be used to

guide in the piston, but must be removed afterwards.

8. Separator disc is inserted and tightened to 10Nm.

9. Piston 305018 with rod is inserted

10. End plug 305020 is fastened to the valve and tightened to 20Nm.

11. The piston is pushed back with a 4mm hex wrench though the 5 mm hole.

Routine testing

No requirements.

Document: Ci IV8 discharge valve.doc Text

1

2

Product: Id: KP 3

Inergen® Rev: 18.06.08 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: Control Inert Page: 5 of 8

Engineering data sheet

Item: Ci IV8 discharge valve

Symbols of valve function Discharge

Internal valve functions showing restrictions and check valves. Backpressure

Out/In

PA

In/out

Mech.

Act.

Supply

Section drawings pressure

Valve in normal closed and fully opened position

When the valve is closed, pressure is contained in the inlet and between the two O-rings on the piston (blue

areas are the pressurised chambers).

When the valve is opened, pressure is allowed to exit through the outlet port as well as the PA inlet/outlet.

Notice that there is a check valve with a limited leakage between the discharge outlet and the PA

inlet/outlet allowing pressure to go from the discharge outlet to the PA inlet/outlet, hence restricting flow

from PA inlet/outlet to the discharge outlet.

Document: Ci IV8 discharge valve.doc Text

1

2

Product: Id: KP 3

Inergen® Rev: 18.06.08 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: Control Inert Page: 6 of 8

Engineering data sheet

Item: Ci IV8 discharge valve

Valve operated mechanically (initial and half opened)

Valve operated pneumatically (initial and half opened)

Valve operated by pneumatic backpressure (initial and half opened)

Document: Ci IV8 discharge valve.doc Text

1

2

Product: Id: KP 3

Inergen® Rev: 18.06.08 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: Control Inert Page: 7 of 8

Engineering data sheet

Item: Ci IV8 discharge valve

Pos. Item Description

Exploded view 1 212096 O-ring 10 x 1.0

2 212181 Cu Seal 1/4"

3 302070 O-ring 10.1 x 1.6

4 302083 Plug 1/8" BSPT

5 302104 O-ring 7.1 x 1.6

6 302107 O-ring 14.1 x 1.6

7 302108 O-ring 17.1 x 1.6

8 302109 O-ring 6.1 x 1.6

9 302413 O-ring 25.1 x 1.6

10 302413 O-ring 25.1 x 1.6

11 303204 Nippel 3/8 BSPT-BSPP

12 303246 Spring

13 303248 Ball SS Ø3.0 mm

14 304062 Union Nut M25×1.5

303062 Union Nut W24.32×1/14

15 305010 IV8 Body

16 305011 IV8 Separator Disc

17 305014 IV8 Inlet Bolt

18 305017 IV8 Burst Disc BLIND Bolt

19 305018 IV8 Drive Piston

20 305019 IV8 Piston Rod

21 305020 IV8 Act Plug

22 305098 Ø12 Copper Washer

23 305401 Ci IV8 Piston Assembly

24 303014 Manosw 0-250 sp 166

303018 Manosw 0-400 sp 249

303101 Blind plug

Document: Ci IV8 discharge valve.doc Text

1

2

Product: Id: KP 3

Inergen® Rev: 18.06.08 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: Control Inert Page: 8 of 8

Engineering data sheet

Item: Ci IV8 discharge valve

Declaration of conformity & EC certificate (CPD)

1116

Manufacturer:

Fire Eater A/S

Vølundsvej 14

DK-3400 Hillerød

Denmark

EN12094-4

Container valve assembly and their actuators

Control Inert IV8 discharge valve

Type 2 (when used with Ci HWV, otherwise Type 1)

For inert gas (INERGEN)

Without diptube

Work pressure 300, 364, 400 bar

Free flow diameter 8mm

Pneumatic actuator nom pressure 300 bar

Pressure supply 8 – 400 bar min 2 sec

Smallest container 2l

Based upon attached Certificate of conformity, we declare

that the Container valve assembly designated above meets

the provision of Annex ZA of the EN12094-4 standard.

The discharge valve is to be used in combination of Fire Eater

Hand wheel valve and actuator with the Ci designation

Certification body for this product is

CNPP, B.P. 2265, F-27950 Saint_Marcel, www.cnpp.com

CNPP certificate: 1116-CPD-017

Signature: _____________

Michael Kroneder, Technical manager

Date: 2006-12-14

Document: Ci IV8 discharge valve.doc Text

1

2

Product: Id: KP 3

Inergen® Rev: 18.06.08 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Potrebbero piacerti anche

- Ci MT Manifold 1-10Documento3 pagineCi MT Manifold 1-10Iskandar Hasibuan100% (1)

- Ci IS8B Solenoid ActuatorDocumento7 pagineCi IS8B Solenoid ActuatorIskandar Hasibuan100% (2)

- 2102xx In-15 NPT NozzleDocumento2 pagine2102xx In-15 NPT Nozzleafie pio pioNessuna valutazione finora

- Ci IS8B Solenoid ActuatorDocumento1 paginaCi IS8B Solenoid ActuatorIskandar Hasibuan100% (1)

- Engineering Data Sheet: Cylinders W. INERGENDocumento2 pagineEngineering Data Sheet: Cylinders W. INERGENafie pio pioNessuna valutazione finora

- HT Cabezal NeumaticoDocumento2 pagineHT Cabezal NeumaticorafaNessuna valutazione finora

- HPCO2 Spec SheetDocumento6 pagineHPCO2 Spec SheetNORMANessuna valutazione finora

- Eaton Fire Pump ControllerDocumento12 pagineEaton Fire Pump Controllerrajpre1213100% (1)

- Fire Suppression System Using 3M Novec 1230 Fire Protection FluidDocumento28 pagineFire Suppression System Using 3M Novec 1230 Fire Protection FluidDiego Martinez ConteiroNessuna valutazione finora

- Extcat FM200Documento15 pagineExtcat FM200Mohamed FawzyNessuna valutazione finora

- GreenEX - Cataloge - DSPA CompetitorDocumento4 pagineGreenEX - Cataloge - DSPA CompetitorJai GosarNessuna valutazione finora

- Ansul - CV98-CV90-AP-8 Valve Flexible Discharge Bend PDFDocumento1 paginaAnsul - CV98-CV90-AP-8 Valve Flexible Discharge Bend PDFElieser Júnio100% (1)

- Multiple Foam Deluge SystemDocumento10 pagineMultiple Foam Deluge SystemTrần VânNessuna valutazione finora

- KFS FM-200 ECS Modular Balanced Design ManualDocumento110 pagineKFS FM-200 ECS Modular Balanced Design Manualitovarsilva100% (1)

- HygoodDocumento1 paginaHygoodSachin Darne100% (1)

- Product Manual DCP Trolley Mounted 25-50-75 KGDocumento6 pagineProduct Manual DCP Trolley Mounted 25-50-75 KGm4l4ysiaNessuna valutazione finora

- FM 200 Datasheet and DesignDocumento174 pagineFM 200 Datasheet and DesignRichard Rajkumar0% (1)

- HYGOOD iFLOW DatasheetDocumento2 pagineHYGOOD iFLOW DatasheetAry TubagusNessuna valutazione finora

- 5.DEMADEM AV10859650 enDocumento6 pagine5.DEMADEM AV10859650 enEngineering TFINessuna valutazione finora

- Clarke Fire Water PumpDocumento13 pagineClarke Fire Water PumpAnonymous XrHcllNessuna valutazione finora

- ANSUL High Pressure Carbon Dioxide Systems ManualDocumento248 pagineANSUL High Pressure Carbon Dioxide Systems ManualPablo SotoNessuna valutazione finora

- MX Detection Panel FMZ5000 PDFDocumento19 pagineMX Detection Panel FMZ5000 PDFNarendra Reddy BhumaNessuna valutazione finora

- 80L CylinderDocumento2 pagine80L CylinderHaty ATie67% (3)

- Pipe NetDocumento4 paginePipe NetasbuasbuNessuna valutazione finora

- 2 FM200 ComponentsDocumento40 pagine2 FM200 ComponentsJose Antonio Lara0% (1)

- Data Sheet PPR 1002899Documento2 pagineData Sheet PPR 1002899Bhoopendra SinghNessuna valutazione finora

- GW SprinklersDocumento18 pagineGW SprinklersmajdirossrossNessuna valutazione finora

- Extinguishing CatalogDocumento42 pagineExtinguishing Catalogmohsen zeyad1100% (1)

- Water Fire ExtinguishersDocumento4 pagineWater Fire ExtinguishersErica LindseyNessuna valutazione finora

- Minimax BrochureDocumento20 pagineMinimax BrochureDevieAgungNessuna valutazione finora

- Cylinder 80-300 W INERGEN PDFDocumento1 paginaCylinder 80-300 W INERGEN PDFIskandar HasibuanNessuna valutazione finora

- Extcat FM200!Documento15 pagineExtcat FM200!asifaliabid100% (1)

- PN 441880Documento4 paginePN 441880JhojanCeleitaNessuna valutazione finora

- NFPA20 Vs EN12845Documento2 pagineNFPA20 Vs EN12845ing_julio_siviraNessuna valutazione finora

- Kid de Wet ChemicalDocumento110 pagineKid de Wet Chemicalbhima irabatti100% (1)

- Operation and Maintenance Manual - SFFECO Fire Pumps - 2012Documento44 pagineOperation and Maintenance Manual - SFFECO Fire Pumps - 2012mukhtarahmadaNessuna valutazione finora

- Deluge Valve - SD-DVA PDFDocumento15 pagineDeluge Valve - SD-DVA PDFboxyfunNessuna valutazione finora

- BRISTOL Fire PumpsDocumento11 pagineBRISTOL Fire PumpsMohamed Adel100% (1)

- Fire ProDocumento104 pagineFire ProMaiger100% (2)

- DAB 22 Fuel Hydrant PitDocumento2 pagineDAB 22 Fuel Hydrant Pitzelda1022Nessuna valutazione finora

- Microsoft PowerPoint - 2. Design Inert Gas System - HDocumento54 pagineMicrosoft PowerPoint - 2. Design Inert Gas System - HBidang KK3L Unit PLTP Gunung Salak100% (1)

- Foam NaffcoDocumento1 paginaFoam NaffcoMatt TremoglieNessuna valutazione finora

- 1 ProInert2 EquipmentDocumento89 pagine1 ProInert2 EquipmentfereszaNessuna valutazione finora

- Smoke Extraction Fans - 20100830174123Documento10 pagineSmoke Extraction Fans - 20100830174123Kristaps PuļķisNessuna valutazione finora

- Ansul Foam Generator PDFDocumento6 pagineAnsul Foam Generator PDFSuhail EhtishamNessuna valutazione finora

- Documentation AnsulDocumento40 pagineDocumentation AnsulkdsessionsNessuna valutazione finora

- FTS004 Deep Fat FryersDocumento3 pagineFTS004 Deep Fat FryersWissam JarmakNessuna valutazione finora

- Fire Hydrant Equipment NAFFCODocumento6 pagineFire Hydrant Equipment NAFFCOStanisclaus Kostka Rheyno ANessuna valutazione finora

- Co2 System Cylinder Valve AssemblyDocumento2 pagineCo2 System Cylinder Valve AssemblyFahmiNessuna valutazione finora

- Hi-Fog For Buildings: Technical IntroductionDocumento16 pagineHi-Fog For Buildings: Technical IntroductionEsther TapiaNessuna valutazione finora

- CO2 System ManualDocumento11 pagineCO2 System Manualthugsdei100% (1)

- Piping Sensing Line Layout of Fire Pump and Jockey PumpDocumento1 paginaPiping Sensing Line Layout of Fire Pump and Jockey Pumpاحمد الجزار200750% (2)

- Foam System - V.0 - WS PDFDocumento82 pagineFoam System - V.0 - WS PDFSajjadNessuna valutazione finora

- 2 - Instruction ManualDocumento98 pagine2 - Instruction ManualFILIN VLADIMIR100% (2)

- Engineering Data Sheet: Ci-Hoses PA 1Documento3 pagineEngineering Data Sheet: Ci-Hoses PA 1afie pio pio100% (1)

- Hojas Datos Planta FESTODocumento184 pagineHojas Datos Planta FESTOPaul GálvezNessuna valutazione finora

- Engineering Data Sheet: Manifold For Connecting 3/8" Hoses With Pressure SwitchDocumento2 pagineEngineering Data Sheet: Manifold For Connecting 3/8" Hoses With Pressure Switchafie pio pioNessuna valutazione finora

- SV Test Port KitDocumento3 pagineSV Test Port KitIskandar HasibuanNessuna valutazione finora

- IO Data Cable Data SheetDocumento194 pagineIO Data Cable Data SheetadiamiruNessuna valutazione finora

- Cargill Bromo ClashDocumento10 pagineCargill Bromo ClashIskandar HasibuanNessuna valutazione finora

- Clash FF BromoDocumento27 pagineClash FF BromoIskandar HasibuanNessuna valutazione finora

- Cella Warehouse - Manhour Estimation-PlumbingDocumento19 pagineCella Warehouse - Manhour Estimation-PlumbingIskandar HasibuanNessuna valutazione finora

- RFI-MECH-01 Hydrant & Sprikler Layout-RHDocumento3 pagineRFI-MECH-01 Hydrant & Sprikler Layout-RHIskandar HasibuanNessuna valutazione finora

- Penawaran ProdukDocumento1 paginaPenawaran ProdukIskandar HasibuanNessuna valutazione finora

- Ta2862-Ql-Mar-Spgn-M-0029r1 (Approval Steam & Condensate Valve) - Approved With Comment.Documento5 pagineTa2862-Ql-Mar-Spgn-M-0029r1 (Approval Steam & Condensate Valve) - Approved With Comment.Iskandar HasibuanNessuna valutazione finora

- Ta2862-Ql-Mar-Spgn-M-0027r1 (Approval Compressed Air Valve) - Approved With Comment.Documento4 pagineTa2862-Ql-Mar-Spgn-M-0027r1 (Approval Compressed Air Valve) - Approved With Comment.Iskandar HasibuanNessuna valutazione finora

- Grey Water CalculationDocumento2 pagineGrey Water CalculationIskandar HasibuanNessuna valutazione finora

- (Indicative Only - Package Provided by Others) : NotesDocumento1 pagina(Indicative Only - Package Provided by Others) : NotesIskandar HasibuanNessuna valutazione finora

- K181008 UT PID PW 002 - RevA - 02aug19Documento1 paginaK181008 UT PID PW 002 - RevA - 02aug19Iskandar HasibuanNessuna valutazione finora

- SV Test Port KitDocumento3 pagineSV Test Port KitIskandar HasibuanNessuna valutazione finora

- Ta2862-Ql-Mar-Spgn-M-0026r1 (Approval Town Water Valve) - Approved With Comment.Documento4 pagineTa2862-Ql-Mar-Spgn-M-0026r1 (Approval Town Water Valve) - Approved With Comment.Iskandar HasibuanNessuna valutazione finora

- Project Name: 3M Indonesia Factory 25.2 Area Reference: Most Remote AreaDocumento5 pagineProject Name: 3M Indonesia Factory 25.2 Area Reference: Most Remote AreaIskandar HasibuanNessuna valutazione finora

- Foam Concentrates and Solutions: Technical BulletinDocumento3 pagineFoam Concentrates and Solutions: Technical BulletinIskandar HasibuanNessuna valutazione finora

- SMO-DWG-DD-ME-00-FF-6301.01 P&ID Fire Sprinklers & Fire Hydrant SystemDocumento1 paginaSMO-DWG-DD-ME-00-FF-6301.01 P&ID Fire Sprinklers & Fire Hydrant SystemIskandar HasibuanNessuna valutazione finora

- Engineering Data Sheet: Ci Discharge HosesDocumento1 paginaEngineering Data Sheet: Ci Discharge HosesIskandar HasibuanNessuna valutazione finora

- In-Line Balanced Pressure (ILBP) Proportioning UnitsDocumento4 pagineIn-Line Balanced Pressure (ILBP) Proportioning UnitsIskandar HasibuanNessuna valutazione finora

- Cylinder 80-300 W INERGEN PDFDocumento1 paginaCylinder 80-300 W INERGEN PDFIskandar HasibuanNessuna valutazione finora

- Spe 36761 MSDocumento13 pagineSpe 36761 MSKarla CotesNessuna valutazione finora

- Dokumen - Tips Onshore Pipeline EngineeringpptDocumento52 pagineDokumen - Tips Onshore Pipeline Engineeringpptfxoption4057Nessuna valutazione finora

- CG 2015132 02 - 2019 HccavDocumento4 pagineCG 2015132 02 - 2019 HccavRangga AsengNessuna valutazione finora

- IVOK Sensors - For Caterpillar Navistar Detroit DEEREDocumento8 pagineIVOK Sensors - For Caterpillar Navistar Detroit DEEREPeter SanjayaNessuna valutazione finora

- INSPECT AND SERVICE COOLING SYSTEMS - QuizDocumento8 pagineINSPECT AND SERVICE COOLING SYSTEMS - QuizbalalaNessuna valutazione finora

- Mechanical Puller Catalog - EUDocumento20 pagineMechanical Puller Catalog - EUSergiSerranoNessuna valutazione finora

- dc16 PDFDocumento111 paginedc16 PDFecihatNessuna valutazione finora

- Types of Pattern and Its ApplicationDocumento24 pagineTypes of Pattern and Its ApplicationMitul PatelNessuna valutazione finora

- Everest Full Synthetic Motor OilDocumento1 paginaEverest Full Synthetic Motor OilLa YaungNessuna valutazione finora

- Restoration of The Contact Surface in The HLL-Riemann SolverDocumento10 pagineRestoration of The Contact Surface in The HLL-Riemann SolverRafael HenriqueNessuna valutazione finora

- 2.13.5 Phet Lab Sim Forces & Motion BasicsDocumento5 pagine2.13.5 Phet Lab Sim Forces & Motion BasicsT. Danielle Dockery100% (1)

- Section 4 Electrical System: Group 1 Component LocationDocumento2 pagineSection 4 Electrical System: Group 1 Component LocationSONNessuna valutazione finora

- 132 30422 182 PDFDocumento10 pagine132 30422 182 PDFJJNessuna valutazione finora

- Bag In-Bag Out CamfilDocumento12 pagineBag In-Bag Out CamfilbinhjukiNessuna valutazione finora

- Parameters For Pump Selection - Part 1 PDFDocumento5 pagineParameters For Pump Selection - Part 1 PDFpalluraviNessuna valutazione finora

- 3-69 ShigleyDocumento3 pagine3-69 ShigleyinivlaviNessuna valutazione finora

- Aph PRESENTATIONDocumento42 pagineAph PRESENTATIONRajneesh VachaspatiNessuna valutazione finora

- Is 1893 1984Documento83 pagineIs 1893 1984rcdk2Nessuna valutazione finora

- Experimental Works For The Beter Understanding Failure Activity Aspects and ResultsDocumento16 pagineExperimental Works For The Beter Understanding Failure Activity Aspects and Resultsbagas prakosoNessuna valutazione finora

- Spare Parts Catalogue: Vibratory Roller CC1200Documento248 pagineSpare Parts Catalogue: Vibratory Roller CC1200Juan Carlos100% (1)

- Practice Problems in Timber Design PDFDocumento9 paginePractice Problems in Timber Design PDFRuby AsensiNessuna valutazione finora

- PCI 7 - Tinh Toan Dau Dam KhacDocumento4 paginePCI 7 - Tinh Toan Dau Dam KhachNessuna valutazione finora

- DC09-311A 240kW ATSDocumento4 pagineDC09-311A 240kW ATSJulio SullaymeNessuna valutazione finora

- Engine ThesisDocumento8 pagineEngine Thesisjessicafinsonmanchester100% (1)

- Derivation of Gravitational Potential Energy Using Calculus2Documento7 pagineDerivation of Gravitational Potential Energy Using Calculus2W-d DomNessuna valutazione finora

- Ir CR-24-30 22 16-0002-0402 PDFDocumento2 pagineIr CR-24-30 22 16-0002-0402 PDFRicardo Rincon VegaNessuna valutazione finora

- Sub-Spec 023 - Tenaris DSTJ, WT™Documento4 pagineSub-Spec 023 - Tenaris DSTJ, WT™Josue FishNessuna valutazione finora

- Technical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHDocumento77 pagineTechnical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHAnonymous uEOZ7raPkzNessuna valutazione finora

- Uniformly Accelerated Particle Model: Review Sheet: Name Date PDDocumento4 pagineUniformly Accelerated Particle Model: Review Sheet: Name Date PDvahikef986Nessuna valutazione finora

- ES SeriesDocumento32 pagineES Seriesduongbk24 luu quang duongNessuna valutazione finora