Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PSP330

Caricato da

Ali HadiDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PSP330

Caricato da

Ali HadiCopyright:

Formati disponibili

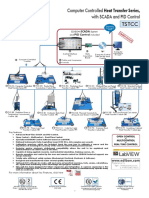

Universal Process Control Trainer…Code 330

Objective

To demonstrate wide range of experiments, applications and

advanced control techniques using industry standard

instrumentation and controls

Features

DCS control

MODBUS communication

SCADA control

Manual tuning and Auto tuning

Patch board configurable experiments

Facility to introduce external controller

SS wetted parts

Inbuilt compressor and Diaphram pump with VFD

Study of I/P, DPT, control valve, valve positioner

Study of rotameter, orifice meter, venturimeter

Temperature, flow, level, pressure control

On-off, P, PI, PID control, PLC control

Open loop tuning by process reaction curve

Closed loop tuning by Zigler Nicholas method

Stability analysis by Bode plot

Cascade, Feed-forward and Ratio control

Three element control and interactive control

Setup

Universal Process Control Trainer Code 330

resembles a typical small industrial process plant

with different processes and parameters. The plant

is controlled using DCS control (Hybrid controller)

with specially developed software for supervisory

control systems. A jack plug and socket patch board

provided at the interface of the process facilitates

configuration of different experiments and allows

user to develop and test own control strategies.

The patch board also allows direct access to

transmitters and control elements enabling user to

connect external controllers, PLCs & DCSs. The

product layout is designed to educate, train and

develop the user to cover various aspects of process

control. User can configure the product from study

of basic components to advanced study of complex

process control loops using advanced DCS control.

More than 25 different experimental

configurations are incorporated to support the

study. The product allows user to experience the

feel of physical use of industrial components and

processes, routing the flow for intended

configuration and observing the process

controllability.

05-04-2017 Page 1/4 PSP330

Universal Process Control Trainer…Code 330

Setup subassemblies

Heating tank module Control panel & I/P converter

1) Heating tank module consisting

of Heating tank, Heater, RTD

sensors, heating control unit and

Piping.

2) Control panel module with DCS

controller, power supply units,

push buttons and patch board.

3) I/P converter module with I/P

converters, pressure regulators

and pressure gauges.

Water supply module Control valve module

4) Water supply module consisting

of Diaphram pump, centrifugal

pump, water supply tank,

rotameter, VFD for Diaphram

pump, float switches, solenoid

valve and piping.

5)Control valve module consisting

of two pneumatic control valves,

valve positioned and position

transmitter

Process tanks module VFD for plunger pump

6) Process tanks module

consisting of process tank (SS)

with pressure transmitter, level

tank with level transmitter and

interconnected piping.

7) Flow sensing elements

consisting of orifice meter,

venturimeter and DP transmitter.

8) Air supply module consisting air

compressor

These modules and components

are mounted on stand-alone type

structure and interconnected with

valves and piping.

Along with MNC grade controllers

and transmitters, an industrial

grade SS used for wetted parts

increases reliability of the

product.

05-04-2017 Page 2/4 PSP330

Universal Process Control Trainer…Code 330

Range of Experiments

Study of component basics 14. Level control by outlet flow manipulation using

1. Study of I/P : Input-output, Calibration pneumatic valve

2. Study of DP transmitter: Input /output 15. Level control by inlet flow manipulation using

3. Study of control valve characteristics: Valve Plunger pump

coefficient and control valve characteristics 16. Pressure control of closed tank (Air)

4. Study of valve positioner: Input/output 17. Pressure control of closed tank (Water)

Study of flow measuring devices Multi-loop control

5. Study of Rotameter: Calibration 18. Cascade control (Level + Flow)

6. Study of Orifice meter: Coefficient of discharge 19. Cascade control (Temperature + Flow)

7. Study of Venturi meter: Coefficient of discharge 20. Cascade control (Level + Pressure)

Interacting and non interacting study 21. Feed forward control (temperature)

8. Study of interacting system: Step response 22. Feed forward + Feedback control (Level)

9. Study of non interacting system: step response 23. Ratio control (Flow)

Single loop feedback control 24. Three element control (Level)

PID control, tuning, Stability of following processes Multi input multi output control

10. Temperature control of direct heating process 25. Pressure and Level control (Interactive loops)

11. Flow control of pump outlet 26. Level and Flow control (Interactive loops)

12. Flow control of process outlet Study of PLC

13. Level control by inlet flow manipulation using 27. PLC Study and control

pneumatic valve

Software

Set up is supplied with Hybrid control designer

software and specially developed supervisory

control software. The hybrid control designer

software can be used for development of new FBD

as per user’s requirements and can be downloaded

for execution.

The supervisory control software is easy to use,

flexible & scalable with features like Data access,

trend plots, Data logging, Printing, Data export.

05-04-2017 Page 3/4 PSP330

Universal Process Control Trainer…Code 330

Specifications

Product Universal Process Control Trainer (Code 330)

Type of control DCS and SCADA

Control unit Hybrid controller, Make Honey well, Model HC900, AI 8, AO 4, DI 16, DO 16,

Control loops 8 with

Communication RS232, RS485, Ethernet

Software package DCS: Hybrid Control Designer

Temperature sensor Make Radix, RTD, PT100, Range 0-100 deg.C, 2Nos

Temperature transmitter Make ABUSTEK, PT100, Type 2 wire, Range 0-100 deg.C, Output 4-20mA,

2Nos

Flow transmitter Make Yokogawa, DPT, Type 2 wire, Range 0–200 mm H2O, Output 4–20 mA,

Sq. root

Level transmitter Make Yokogawa, DPT, Type 2 wire, Range 0–500 mm H2O, Output 4–20 mA,

Linear

Level transmitter Make Wika, GPT, Type 2 wire, Range 0–600 mm H2O, Output 4–20 mA

Pressure transmitter Make Wika, GPT, Type 2 wire, Range 0–2.5 bar, Output 4–20 mA

Position transmitter Type Electronic, 2 wire, O/P 4–20mA

I/P converter Make Control Air Inc., Input 4-20mA, Output 3-15 psig (2Nos)

Heating control Proportional power controller (SSR), Input 4-20 mA

Heater Type Electrical 2 coil, Capacity 3 KW

Rotameter Make Euraka, 40-400LPH

Solenoid valves Make Avcon Controls, Type 2/2way normally closed, 1/4"BSP, water(2Nos)

Control valve Make Pneucon Valve, Type: Pneumatic, Size:1/2", Input: 3–15psig, Linear &

Equal % (2Nos)

VFD Input single phase 200VAC, 1.1A, output AC3 phase

Pump Make Kirloskar, Fractional horse power, type centrifugal

Diaphram pump Make SITC Spanish, Positive displacement Diaphram pump, Cap 200Lph

Compressor Make ELGI, 1 Hp,3.8CFM, 10 kg/cm^2 with 45 lit inbuilt tank receiver

Overall dimensions 1150mmL x 800mmW x 1900mmh

Our other products

1. Temperature control trainer (SCADA) 9. First and second order system

2. Flow control trainer (SCADA) 10. Temperature measurement

3. Level control trainer (SCADA) 11. Flapper nozzle system

4. Pressure control trainer (SCADA) 12. Multi variable control trainer

5. Cascade control trainer: Level + Flow (SCADA) 13. Interacting and non interacting system

6. Multi process trainer: Level, Flow, Cascade, Ratio 14. DCS trainer (Hybrid controller)

& FF 15. Level measurement

7. Flow measurement 16. Universal process control trainer

8. Control valve characteristics

Specifications subject to change without notice

APEX INNOVATIONS PVT. LTD.

E9/1, MIDC, Kupwad, Sangli - 416436 (MS) India Telefax: +91 233 2644098/2644398

Email: support@apexinnovations.co.in Web: www.apexinnovations.co.in

Potrebbero piacerti anche

- Flow Control Trainer: DescriptionDocumento2 pagineFlow Control Trainer: DescriptionshubhamNessuna valutazione finora

- Pressure Control TrainerDocumento1 paginaPressure Control TrainerVirender RanaNessuna valutazione finora

- PLCDocumento5 paginePLCAika CatalanNessuna valutazione finora

- Instrumentatio N & Control: Submitted To: DR - Khalid MehmoodDocumento10 pagineInstrumentatio N & Control: Submitted To: DR - Khalid Mehmoodali ayanNessuna valutazione finora

- Level Control TrainerDocumento1 paginaLevel Control TrainerVirender RanaNessuna valutazione finora

- TRCVCDocumento4 pagineTRCVCedwin dableoNessuna valutazione finora

- Kfetrkt: Plant T) Process KeDocumento4 pagineKfetrkt: Plant T) Process KeAmogh RNessuna valutazione finora

- Feedback 38-004Documento15 pagineFeedback 38-004aditya narayan shuklaNessuna valutazione finora

- PCT23MkII - Process Plant Trainer (Process Control Trainer)Documento10 paginePCT23MkII - Process Plant Trainer (Process Control Trainer)veronicaNessuna valutazione finora

- Process & Instrumentation Diagram (P&ID) : Dr. RameshDocumento66 pagineProcess & Instrumentation Diagram (P&ID) : Dr. Rameshalejandro inostrozaNessuna valutazione finora

- Process & Instrumentation Diagram (P&ID)Documento66 pagineProcess & Instrumentation Diagram (P&ID)Syed HameedNessuna valutazione finora

- P&id PDFDocumento66 pagineP&id PDFFarook MohideenNessuna valutazione finora

- Tech - 09bb259606301e9cpct 200 081Documento4 pagineTech - 09bb259606301e9cpct 200 081AhmedAmer1Nessuna valutazione finora

- LevelDocumento4 pagineLevelsankathali srikanthNessuna valutazione finora

- Beta Star 2038 AutoclaveDocumento47 pagineBeta Star 2038 AutoclaveJaved KarimNessuna valutazione finora

- M MegaTronDocumento32 pagineM MegaTronabherreraNessuna valutazione finora

- 2-Instrumentation and Control SystemDocumento236 pagine2-Instrumentation and Control Systemferdhian RahmansyahNessuna valutazione finora

- PCT100 PL0214Documento2 paginePCT100 PL0214Wael AhmedNessuna valutazione finora

- Proses Trainer DatasheetDocumento2 pagineProses Trainer DatasheetDenny ChrisnandaNessuna valutazione finora

- Instruction Manual: Pid Based Pressure Loop TrainerDocumento28 pagineInstruction Manual: Pid Based Pressure Loop TrainerKiran BennyNessuna valutazione finora

- Unit 5 Closed Loop ControllersDocumento64 pagineUnit 5 Closed Loop ControllersHriday AryaNessuna valutazione finora

- Guidelines For Online ApplicationDocumento26 pagineGuidelines For Online ApplicationAnonymous Xf4w0D2cNessuna valutazione finora

- CPB 30004 - CHAPTER 1 - INTRO Sept 2014Documento52 pagineCPB 30004 - CHAPTER 1 - INTRO Sept 2014Ashwin MNessuna valutazione finora

- Transformer Monitoring Systems - MRDocumento4 pagineTransformer Monitoring Systems - MRKelly chatingNessuna valutazione finora

- PID - Scanner 2000Documento12 paginePID - Scanner 2000hectorivantovarjaimesNessuna valutazione finora

- YL-363 Process Control Training BenchDocumento8 pagineYL-363 Process Control Training BenchMichealNessuna valutazione finora

- Automation and Process Control CRT - Temperature Control and Regulation Study UnitDocumento4 pagineAutomation and Process Control CRT - Temperature Control and Regulation Study Unitjoao0honoratoNessuna valutazione finora

- Automation With PLCDocumento26 pagineAutomation With PLCKannan S100% (2)

- ObjectivesDocumento7 pagineObjectivesPeeka booNessuna valutazione finora

- Es Hydroranger 200Documento6 pagineEs Hydroranger 200tediNessuna valutazione finora

- BUILDING MANAGEMENT SYSTEM BMS - Pamela DavidDocumento66 pagineBUILDING MANAGEMENT SYSTEM BMS - Pamela DavidSimon Wong100% (1)

- In-Situ Fermentors CatalogueDocumento4 pagineIn-Situ Fermentors CatalogueVineet GuptaNessuna valutazione finora

- Lab Report: University of Enginering and Techonology, LahoreDocumento20 pagineLab Report: University of Enginering and Techonology, LahoremjunaidNessuna valutazione finora

- Pci Lab Manual (2) StudentDocumento67 paginePci Lab Manual (2) StudentTewodros AsfawNessuna valutazione finora

- Design and Application of Marine Boiler Control System Based On PLC and Touch ScreenDocumento4 pagineDesign and Application of Marine Boiler Control System Based On PLC and Touch ScreenWai Min ThuNessuna valutazione finora

- Catalogo Notifier 8Documento2 pagineCatalogo Notifier 8Ali HadiNessuna valutazione finora

- PCT100Documento2 paginePCT100lockas222Nessuna valutazione finora

- The PROCON PH Process Control System Is Based Around The PH Rig and Is A SelfDocumento10 pagineThe PROCON PH Process Control System Is Based Around The PH Rig and Is A Selfmiantahir89Nessuna valutazione finora

- Bms System-Basic PDFDocumento59 pagineBms System-Basic PDFWaelBou95% (21)

- Controller Design For Temperature Control of Heat Exchanger System: Simulation StudiesDocumento7 pagineController Design For Temperature Control of Heat Exchanger System: Simulation StudiesAnonymous G04WC68JXfNessuna valutazione finora

- A125703 288 PDFDocumento7 pagineA125703 288 PDFAnonymous G04WC68JXfNessuna valutazione finora

- 00 Industrial Automation - OverviewDocumento38 pagine00 Industrial Automation - OverviewRAJESH PANIGRAHINessuna valutazione finora

- Vacon NXL ManualDocumento62 pagineVacon NXL ManualKarthik SriramakavachamNessuna valutazione finora

- Pid Feature ProfileDocumento12 paginePid Feature ProfilePrasanna RamanathanNessuna valutazione finora

- Basic Concept of Process ControlsDocumento28 pagineBasic Concept of Process ControlsLe Manh Hai100% (1)

- EN 231215 160835 ME mgb7tDDocumento4 pagineEN 231215 160835 ME mgb7tDplennyNessuna valutazione finora

- System For Water Level & Flow Regulation by PID: Products 2 Years GuaranteeDocumento33 pagineSystem For Water Level & Flow Regulation by PID: Products 2 Years GuaranteeAugusto CamposNessuna valutazione finora

- Lab Manual: Instrumentation and ControlDocumento42 pagineLab Manual: Instrumentation and ControlJu Naid MalikNessuna valutazione finora

- Edibon SCADADocumento37 pagineEdibon SCADAMusa MohammadNessuna valutazione finora

- Lecture 2Documento16 pagineLecture 2Ahmed K JirnazNessuna valutazione finora

- Instrumentation & Control and Control Valves CoursesDocumento11 pagineInstrumentation & Control and Control Valves CoursesNej SaNessuna valutazione finora

- Computer Controlled Heat Conduction Unit, With SCADA and PID ControlDocumento15 pagineComputer Controlled Heat Conduction Unit, With SCADA and PID Controlmohamadreza1368Nessuna valutazione finora

- What Is PID ControllerDocumento3 pagineWhat Is PID ControllerVraja DasiNessuna valutazione finora

- RT Svp02a en PDFDocumento80 pagineRT Svp02a en PDFFabian Lopez100% (1)

- Moscosa Santillan1999Documento10 pagineMoscosa Santillan1999Huyền Trần ThuNessuna valutazione finora

- 2 - CIEP Charts and Equations-2Documento22 pagine2 - CIEP Charts and Equations-2Muhammad NaeemNessuna valutazione finora

- PROCON Student ManualDocumento48 paginePROCON Student ManualPaul100% (1)

- The PIC Microcontroller: Your Personal Introductory CourseDa EverandThe PIC Microcontroller: Your Personal Introductory CourseValutazione: 1 su 5 stelle1/5 (2)

- Networked Control System: Fundamentals and ApplicationsDa EverandNetworked Control System: Fundamentals and ApplicationsNessuna valutazione finora

- 3500-25 Enhanced Keyphasor Module Datasheet - 141532Documento10 pagine3500-25 Enhanced Keyphasor Module Datasheet - 141532Ali HadiNessuna valutazione finora

- Ael 3 PDFDocumento63 pagineAel 3 PDFAli HadiNessuna valutazione finora

- 6.1 Industrial Pump Panels: Freedom-Fusible Disconnect and Circuit BreakerDocumento29 pagine6.1 Industrial Pump Panels: Freedom-Fusible Disconnect and Circuit BreakerAli HadiNessuna valutazione finora

- Catalogo Notifier 8Documento2 pagineCatalogo Notifier 8Ali HadiNessuna valutazione finora

- RT 512 Level Control Trainer Gunt 1178 PDF 1 en GBDocumento3 pagineRT 512 Level Control Trainer Gunt 1178 PDF 1 en GBAli HadiNessuna valutazione finora

- 7me3723 1LK22 1ua3 ZDocumento2 pagine7me3723 1LK22 1ua3 ZAli HadiNessuna valutazione finora

- 7MT2351 0BB01 1GB2 (Thermowell)Documento30 pagine7MT2351 0BB01 1GB2 (Thermowell)Ali HadiNessuna valutazione finora

- Mafp GB PDFDocumento23 pagineMafp GB PDFAli HadiNessuna valutazione finora

- The Study of Regulation and Control,: Computer Controlled Teaching Unit For With SCADA and PID Control RYCDocumento26 pagineThe Study of Regulation and Control,: Computer Controlled Teaching Unit For With SCADA and PID Control RYCAli HadiNessuna valutazione finora

- Multi Power Supply FlyerDocumento4 pagineMulti Power Supply FlyerAli HadiNessuna valutazione finora

- TC 25C e Un 1Documento2 pagineTC 25C e Un 1Ali HadiNessuna valutazione finora

- Unipro 25C e PL 0Documento1 paginaUnipro 25C e PL 0Ali HadiNessuna valutazione finora

- HOWTO Setup and Connect Panel To S5Documento1 paginaHOWTO Setup and Connect Panel To S5Ali HadiNessuna valutazione finora

- Modbus Communication Card Cm1241 Rs232Documento4 pagineModbus Communication Card Cm1241 Rs232Ali HadiNessuna valutazione finora

- Pressure Temperature Flow TrainerDocumento3 paginePressure Temperature Flow TrainerAli HadiNessuna valutazione finora

- Ultrasonic Level Transmitter NUS ManualDocumento39 pagineUltrasonic Level Transmitter NUS ManualAli Hadi100% (1)

- PSP330Documento4 paginePSP330Ali HadiNessuna valutazione finora

- Mod. CPMS/EV: Modular Process Control PlantDocumento7 pagineMod. CPMS/EV: Modular Process Control PlantAli HadiNessuna valutazione finora

- Temperature Measurement: DescriptionDocumento2 pagineTemperature Measurement: DescriptionAli HadiNessuna valutazione finora

- Flow Measurement: DescriptionDocumento2 pagineFlow Measurement: DescriptionAli HadiNessuna valutazione finora

- Chubb ExtinguisherDocumento14 pagineChubb Extinguisherprsiva2420034066Nessuna valutazione finora

- 23janmtech2012 PDFDocumento24 pagine23janmtech2012 PDFPradeep ReddyNessuna valutazione finora

- Fin FannerDocumento10 pagineFin FannerkylegazeNessuna valutazione finora

- NASA MetrologyDocumento330 pagineNASA MetrologyFianti Femmilia DarmawanNessuna valutazione finora

- Procedure For Design and Development Control-01Documento29 pagineProcedure For Design and Development Control-01Ahmad MukhtarNessuna valutazione finora

- OMBD - QB WTH Answer - June 2012-1Documento38 pagineOMBD - QB WTH Answer - June 2012-1Karthick SalemNessuna valutazione finora

- 220 QsDocumento46 pagine220 QsPrathamesh Parker100% (1)

- S-990-5131-312 - 1 Progress Measurement ProcedureDocumento17 pagineS-990-5131-312 - 1 Progress Measurement ProcedureMahadevan Mahalingam100% (4)

- Complet Majid CV DDDDDDDDDDDDDDocumento13 pagineComplet Majid CV DDDDDDDDDDDDDSathish DavulaNessuna valutazione finora

- Explo - Lirika OTC PDFDocumento6 pagineExplo - Lirika OTC PDFMariusz PawlasNessuna valutazione finora

- 6 FM 175Documento2 pagine6 FM 175wajidiftikharNessuna valutazione finora

- Western Forms MaintenanceDocumento16 pagineWestern Forms MaintenanceSamir ParabNessuna valutazione finora

- 19 Shaheen ProfileDocumento14 pagine19 Shaheen Profilexeemac100% (1)

- C++ Term Paper On Railway Reservation SystemDocumento17 pagineC++ Term Paper On Railway Reservation SystemChitransh Rajat0% (1)

- Catalogue Vacuum Circuit Breakers 3ah3 enDocumento48 pagineCatalogue Vacuum Circuit Breakers 3ah3 enmrfawadNessuna valutazione finora

- PERP Program - Optimizing Aromatics Production New Report AlertDocumento4 paginePERP Program - Optimizing Aromatics Production New Report AlertTissa Novida Aulia ZahraNessuna valutazione finora

- Primeserv Academy Image BrochureDocumento28 paginePrimeserv Academy Image BrochureM SarfarazNessuna valutazione finora

- Japan Inspection ReportDocumento39 pagineJapan Inspection ReportSuhailshah1234Nessuna valutazione finora

- Instructor Guide40 - HR307 - Config of System ControlsDocumento33 pagineInstructor Guide40 - HR307 - Config of System ControlsRogério Andrade Dos SantosNessuna valutazione finora

- AALCO Stainless Steel TubeDocumento4 pagineAALCO Stainless Steel TubeRoberto CamaraNessuna valutazione finora

- Cemil KocDocumento12 pagineCemil KocCemil KoçNessuna valutazione finora

- Audit Risk and Internal ControlDocumento17 pagineAudit Risk and Internal ControlAlexandru VasileNessuna valutazione finora

- API Steel Check Valve API Steel Check ValveDocumento3 pagineAPI Steel Check Valve API Steel Check ValveElias SusantoNessuna valutazione finora

- Role of Building SurveyorDocumento3 pagineRole of Building Surveyormozartjr22Nessuna valutazione finora

- Business Blueprint PhaseDocumento4 pagineBusiness Blueprint PhaseNimmy JoseNessuna valutazione finora

- 5S Audit Audit Grinding-Feb 21Documento14 pagine5S Audit Audit Grinding-Feb 21shobha shelarNessuna valutazione finora

- SOF Support Ship ConeptDocumento229 pagineSOF Support Ship Coneptfoxbat05Nessuna valutazione finora

- C374342 Moto 160MDocumento28 pagineC374342 Moto 160MJairo Acosta100% (1)

- Professional Profile: Sunil Rocky D'SouzaDocumento5 pagineProfessional Profile: Sunil Rocky D'SouzaSourabh SharmaNessuna valutazione finora

- Budget of Work in Computer Systems Servicing 9Documento2 pagineBudget of Work in Computer Systems Servicing 9dexie jaime100% (1)