Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ci IS8B Solenoid Actuator

Caricato da

Iskandar HasibuanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ci IS8B Solenoid Actuator

Caricato da

Iskandar HasibuanCopyright:

Formati disponibili

Chapter: 21 Actuators Page: 1 of 7

Engineering data sheet

Sheet No.: Ci IS8B Solenoid Actuator

Ci IS8B Solenoid actuator

Item numbers covered by his datasheet

305450 Ci IS8B Solenoid only

305451 Ci IS8B Solenoid & Manual

General

The Solenoid actuator is part of the Control Inert (Ci) series.

The Ci IS8B has superior performance with regards to shock,

vibration and reliability, as it utilizes neodymium magnets,

hence reducing the number of moving parts to a minimum.

There are two versions; a standard solenoid and a solenoid

with built-in manual activator.

The Ci IS8B has a built-in EOL resistor allowing monitoring of the complete activation circuit, this resistor can

be changed to make it compatible with most control panels.

Two actuators can be used in a parallel with control panels rated at 1 Amp, if the panel is capable of

supplying minimum 2 Amp for minimum 10 msec.

When replacing an old IS8 the connection cable has to be replaced.

Specifications

Voltage (Activation): 24 VDC

Max.: 36 VDC, 100% duty cycle

Min.: 21 VDC

Current (Activation): 0.9A (minimum 0.6 amp for 10 msec)

1.34 A @ 36 VDC

Max. monitoring: 20 mA

No triggering max.: 100mA 120 sec.

Power limited circuit: The device contain a limited energy circuit

Manual activation: Rotation < 225° clockwise, < 1 Nm

Temperature:

Operation: -25 to +70°C (mounted on valve)

Storage: -60 to + 100°C (not mounted on valve)

Resistance:

Monitoring: 6800 Ω (EOL resistor dependent), (only with “Reverse Polarity Activation”)

Activation: 27 Ω (coil only)

Valve interface: M20×1.5 (male)

Electrical connection: M12 male connector (optional: cable gland M12x1.5)

Integrity: IP67 (with cable installed)

Pin configuration:

Activation: pin 1+ 2 +ve, pin 3+4 –ve

Monitoring pin 1+ 2 -ve, pin 3+4 +ve (reversed polarity)

Dimension (øD×L): ø64× 76 mm (installed ø64×68 mm) (solenoid only)

ø64× 108 mm (installed ø64×100 mm) (with manual)

Weight: 1.1 kg

Document: Ci IS8B Solenoid Actuator Text

1

2

Category: Id: MK 3

Control inert Rev: 16.11.10 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: 21 Actuators Page: 2 of 7

Engineering data sheet

Sheet No.: Ci IS8B Solenoid Actuator

Markings

Fire Eater Logo, Ci IS8B, 24VDC 0.9A, Serial number, CE1116, YY

Manual knob actuation direction arrows

White ø10 label “Ul2127”

Installation

The Ci IS8B is screwed into the IV8 valve actuator connection and tightened by hand (10Nm)

The device may be mounted in any position from vertical to horizontal.

Before installing the Ci IS8B it must be checked that it is reset (plunger app. 1mm submerged), failure to do

so may cause unintended discharge of system.

The M12 connector is a male, screw type, with 4 pins. A corresponding cable (supplied with the actuator)

must be used.

1: +Ve Brown

2: +Ve White

3: -Ve Black

4: -Ve Blue

Operating

Electrical

1. Follow control panel instruction for activation of fire extinguishing.

(Current is applied to pin 1/2 and 3/4 from the control panel)

2. Current is applied to pin 1/2 and 3/4 from the control panel.

Manual

1. Break the seal.

2. Remove the pin.

3. Rotate the knob min. ¾ of a turn clockwise.

Document: Ci IS8B Solenoid Actuator Text

1

2

Category: Id: MK 3

Control inert Rev: 16.11.10 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: 21 Actuators Page: 3 of 7

Engineering data sheet

Sheet No.: Ci IS8B Solenoid Actuator

Maintenance

After activation the Ci IS8B must be reset manually, by below procedures.

Solenoid only actuator:

1. Unplug the electrical connection.

Unscrew the Ci IS8B from the Ci-IV8 valve.

2. Connect the Ci IS8B to FE tool 305495.

(Make sure that the reset tool is screwed all the way back before connecting)

3. Operate the reset tool until a low “click” is heard from the Ci IS8B and then turn the knob approx.

one more turn.

The actuator is reset when the knob becomes significantly harder to turn (do not exceed 10Nm)

4. Turn back the reset tool.

Remove the Ci IS8B from the tool.

5. Check that the plunger is submerged into the body approximately 1 mm.

6. Refit the Ci IS8B to the discharge valve as described under installation.

Solenoid & Manual actuator:

As the Solenoid only with these deviations (also applies when it has been activated electrically)

1. Turn back the manual activation knob (counter clockwise) (pin and seal must be removed)

2. Use reset tool as described in the Solenoid only.

3. Gently turn the manual knob clockwise until increased torque is noticed.

4. Turn the manual knob back between 45° and 180°, until the locking pin can be inserted fully.

5. Secure the locking pin with fine sealing wire and seal through the Ø2 holes in the knob and pin.

Routine testing

To verify correct function of the electrical actuation system the solenoid may be activated annually.

To verify sufficient force of the Ci IS8B a scale may be used to measure the force.

A force of 350N is required to start pushing back the piston.

Document: Ci IS8B Solenoid Actuator Text

1

2

Category: Id: MK 3

Control inert Rev: 16.11.10 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: 21 Actuators Page: 4 of 7

Engineering data sheet

Sheet No.: Ci IS8B Solenoid Actuator

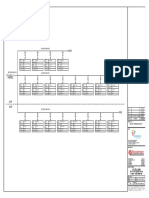

Section drawings

Ci IS8B in normal (non activated) position

The armature is held in the closed position by a magnetic

field created by the permanent magnet in the actuator body.

Ci IS8B in fully activated position (electrical actuation)

When an electrical current passes through the coil windings

in the correct direction, the magnetic field is weakened,

releasing the armature. The armature, rod and piston are

driven forward by the Belleville springs, pushing the front

of the rod out of the actuator. This actuates the Ci IV8

valve.

Ci IS8B in fully activated position (manual actuation)

When the manual knob is turned clockwise, the knob screw

pushes on the piston. This lifts the armature away from its

seat, weakening the magnetic field. Once the magnetic field

has been weakened, the armature, rod and piston are driven

forward by the Belleville springs, pushing the front of the rod

out of the actuator. This actuates the Ci IV8 valve.

Symbols of electrical system of Ci IS8B

Current

Limiter

End Of Line

2

Solenoid

1

Resistor

Coil

3 4

Document: Ci IS8B Solenoid Actuator Text

1

2

Category: Id: MK 3

Control inert Rev: 16.11.10 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: 21 Actuators Page: 5 of 7

Engineering data sheet

Sheet No.: Ci IS8B Solenoid Actuator

Exploded view Ci IS8B

Pos. Item Description Material Pos. Item Description Material

1 2061160 O-ring 6.1 x 1.6 EPDM 19 305811 CM IS8B Knob Al (anodized)

2 2071160 O-ring 7.1 x 1.6 EPDM 20 305812 CM IS8B Knob screw SS

3 2081160 O-ring 8.1 x 1.6 EPDM 21 305813 CM IS8B Locking pin Brass

4 2091160 O-ring 9.1 x 1.6 EPDM 22 305817 CM IS8B PCB seal EPDM cell

5 2351160 O-ring 35.1x1.6 EPDM 23 305819 CM IS8B wire insulator PUR

6 2568180 O-ring 56.78x1.78 EPDM 24 305821 CM IS8B Spr Body Sol Brass (plated)

7 305064 CM IS8 Center part Steel 25 305831 M12x1.5 Body Brass (plated)

8 305067 CM IS8 Piston Brass 26 305835 M12-4 Press fit plug PA12 GF30

9 305069 CM IS8 Magnet Neodymium 27 305889 PCBwC IS8B

10 305332 Disc spring Steel 29 509054 Screw M3xL5 SS

11 305352 Ring Ø38xØ2 SS 30 509058 Screw M3xL20 SS

12 305801 CM IS8B Rod SS 31 777211 Seal ø3 SS+NBR

13 305802 CM IS8B Coil Cu 500200 Coil putting Epoxy

14 305803 CM IS8B Armature Steel (plated) 500201 Coil putting Epoxy

15 305805 CM IS8B Hld mag body Steel (plated) 506250 Wire 0.25 Black (0.03m)

506251 Wire 0.25Red (0.03m)

16 305806 CM IS8B M20 Conn Brass (plated)

305465 Cable: M12-4 p 2m Fem 1end

17 305808 CM IS8B Spring Body Brass

18 305810 CM IS8B Cover Brass

Document: Ci IS8B Solenoid Actuator Text

1

2

Category: Id: MK 3

Control inert Rev: 16.11.10 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: 21 Actuators Page: 6 of 7

Engineering data sheet

Sheet No.: Ci IS8B Solenoid Actuator

Electrical interfaces

Sigma XT control panel connection:

If only one Ci IS8B is connected to a Sigma XT, the end-of-line resistance must be changed to approximately

3400 Ω. Otherwise the Sigma XT will indicate an open circuit fault.

The recommended solution is to replace the end-of-line (EOL) resistor with a 3300 Ω resistor. Alternatively an

external 6800 Ω resistor can be fitted in parallel with the Ci IS8B.

Changing the end-of-line resistor

This operation can only be performed by Fire Eater (during production).

An EOL resistance of less than 1k2 should never be used (due to heat issues).

If monitoring voltage exceeds 34V, the minimum EOL resistance is 2k4.

Remove the black cover plate secured by two in-hex screws.

Locate the EOL resistor, remove it and install the desired resistor.

When replacing the cover, be careful to align the screws properly and see that all seals are in place.

Screws are tightened 0.15 – 0.80 Nm.

Test the electrical actuation circuit by activating the Ci IS8B electrically.

Special cables

This operation can only be performed by Fire Eater (during production)

The M12 connector may be replaced with a standard cable gland (M12x1.5) if required, as there is a screw

terminal behind the cover plate.

Remove the black cover plate secured by two in-hex screws.

Locate the terminals that connect to the M12 connector and unscrew the wires.

Unscrew the M12 connector and install the cable gland.

Route the cable trough the cable gland and connect the bare wires in the appropriate terminals.

Tighten the cable gland nut to seal and secure the cable

When replacing the cover, be careful to align the screws properly and see that all seals are in place.

Screws are tightened 0.15 – 0.80 Nm.

Test for short circuit (resistance must exceed 1MΩ) between housing and wires.

Test the electrical actuation circuit by activating the Ci IS8B electrically.

Grounding

This operation can only be performed by Fire Eater (during production)

It is not recommend to ground the actuator to the control panel as it may create a ground loop trough the

cylinders/pipe system.

If it is absolutely necessary to ground the actuator body through the cable, this is possible by using the M3

grounding screw under the black cover (opposite the PCB).

The M12 connector must be replaced with a standard cable gland to allow use of this.

As a lot of circumstances are to be considered when grounding the actuator it is recommended that the

installer is aware of his responsibility with regards to system integrity before doing so.

Document: Ci IS8B Solenoid Actuator Text

1

2

Category: Id: MK 3

Control inert Rev: 16.11.10 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Chapter: 21 Actuators Page: 7 of 7

Engineering data sheet

Sheet No.: Ci IS8B Solenoid Actuator

Declaration of conformity

1116

Manufacturer:

Fire Eater A/S

Vølundsvej 14

DK-3400 Hillerød

Denmark

EN12094-4

Electrical Actuator

Control Inert Ci-IS8B Solenoid Actuator

For use with the Control Inert valve series

Activation (norm):

Voltage: 24 VDC

Current: 0.9 Amp

Monitoring Current: 20 mA

Based upon attached Certificate of conformity, we declare

that the Actuator designated above meets the provision of

Annex ZA of the EN12094-4 standard.

The Actuator is to be used in combination of Fire Eater

Discharge valves with the Ci designation.

Attached Certificate:

CNPP certificate: 1116-CPD-xxx

Signature: _____________

Michael Kroneder, Technical manager

Date: xxxxxxx

Document: Ci IS8B Solenoid Actuator Text

1

2

Category: Id: MK 3

Control inert Rev: 16.11.10 4

5

6

Vølundsvej 17 7

DK- 3400 Hillerød

Tel +45 7022 2769 8

Fax +45 7023 2769 9

Potrebbero piacerti anche

- Ci IV8 Discharge ValveDocumento8 pagineCi IV8 Discharge ValveIskandar Hasibuan80% (5)

- Ci IS8B Solenoid ActuatorDocumento1 paginaCi IS8B Solenoid ActuatorIskandar Hasibuan100% (1)

- CEREXEN NITROGEN Gas System QuoteDocumento41 pagineCEREXEN NITROGEN Gas System QuoteDien HuynhNessuna valutazione finora

- ULLD For Nohmi - Brand - (TN51483e - Rev.0)Documento33 pagineULLD For Nohmi - Brand - (TN51483e - Rev.0)vu thien100% (1)

- 5.DEMADEM AV10859650 enDocumento6 pagine5.DEMADEM AV10859650 enEngineering TFINessuna valutazione finora

- EG2490 Equipment ManualDocumento96 pagineEG2490 Equipment ManualphatNessuna valutazione finora

- Mini Max SlidesDocumento25 pagineMini Max Slidesphatdaz100% (1)

- CO2 System ManualDocumento11 pagineCO2 System Manualthugsdei100% (1)

- LPG CO2 System Data Sheets PDFDocumento156 pagineLPG CO2 System Data Sheets PDFRazaulKareem83% (12)

- Fire Alarm Control Panel Specifications and FeaturesDocumento1 paginaFire Alarm Control Panel Specifications and FeaturesBlack Shadow50% (2)

- 80L CylinderDocumento2 pagine80L CylinderHaty ATie67% (3)

- Engineering Data Sheet: Cylinders W. INERGENDocumento2 pagineEngineering Data Sheet: Cylinders W. INERGENafie pio pioNessuna valutazione finora

- Monitor and protect industrial equipment with control relaysDocumento49 pagineMonitor and protect industrial equipment with control relaysTayeb KaderNessuna valutazione finora

- FM200 Fire Extinguishing Systems ManualDocumento175 pagineFM200 Fire Extinguishing Systems Manualozer100% (1)

- Avery Tronix Load Cell T302Documento4 pagineAvery Tronix Load Cell T302Cardoso MalacaoNessuna valutazione finora

- ASENWARE AW-D301 Addressable Smoke Detector User ManualDocumento5 pagineASENWARE AW-D301 Addressable Smoke Detector User ManualMasudParvezSajibNessuna valutazione finora

- Ci MT Manifold 1-10Documento3 pagineCi MT Manifold 1-10Iskandar Hasibuan100% (1)

- MX Detection Panel FMZ5000 PDFDocumento19 pagineMX Detection Panel FMZ5000 PDFNarendra Reddy BhumaNessuna valutazione finora

- TOTAL WALTHER CI-Technology: Technical ManualDocumento140 pagineTOTAL WALTHER CI-Technology: Technical ManualJORDAN LOPEZNessuna valutazione finora

- Eaton Fire Pump ControllerDocumento12 pagineEaton Fire Pump Controllerrajpre1213100% (1)

- AC30 Electronic Pulses Transmitter Technical DescriptionDocumento13 pagineAC30 Electronic Pulses Transmitter Technical DescriptionLizardo Ramos100% (1)

- Extcat FM200Documento15 pagineExtcat FM200Mohamed FawzyNessuna valutazione finora

- Pitot Pressure Flow ChartDocumento2 paginePitot Pressure Flow ChartRyan GeisslerNessuna valutazione finora

- 2102xx In-15 NPT NozzleDocumento2 pagine2102xx In-15 NPT Nozzleafie pio pioNessuna valutazione finora

- Operating Manual MX - Sep04 PDFDocumento35 pagineOperating Manual MX - Sep04 PDFTomNessuna valutazione finora

- BOOKLET - Om80 Operator ManualV8-4Documento12 pagineBOOKLET - Om80 Operator ManualV8-4Zuky ProzitNessuna valutazione finora

- 700XA Rev CDocumento248 pagine700XA Rev CMiguel I. Roman BarreraNessuna valutazione finora

- LPG Carbon Dioxide Fire Suppression System Installation Manual .Documento50 pagineLPG Carbon Dioxide Fire Suppression System Installation Manual .hrhgk100% (1)

- Notifier FZM 1 Interface ModuleDocumento2 pagineNotifier FZM 1 Interface Modulenastyn-1Nessuna valutazione finora

- FM 200 Maintenance ProcedureDocumento2 pagineFM 200 Maintenance Procedureultrasonic81Nessuna valutazione finora

- Surse MINIMAXDocumento2 pagineSurse MINIMAXRadu67% (3)

- E - FM-200 Flow CalcDocumento33 pagineE - FM-200 Flow CalcfereszaNessuna valutazione finora

- Datasheet - Mini Monitor Module 55000-765Documento2 pagineDatasheet - Mini Monitor Module 55000-765João Augusto De Carvalho NaganoNessuna valutazione finora

- Hi-Flo 6 Hi-Flo 9 Twin Hi-Flo 6 Twin Hi-Flo 9 and Triple Media Filters 2000 LineDocumento37 pagineHi-Flo 6 Hi-Flo 9 Twin Hi-Flo 6 Twin Hi-Flo 9 and Triple Media Filters 2000 LineДмитрий Черных100% (4)

- 1 UL 864 Compliance: Network Communications Module NCM-W/F Product Installation DocumentDocumento7 pagine1 UL 864 Compliance: Network Communications Module NCM-W/F Product Installation DocumentRicardo StimpelNessuna valutazione finora

- Final Inspection Report for Venturi Pin LinersDocumento1 paginaFinal Inspection Report for Venturi Pin LinersSenthil KumarNessuna valutazione finora

- Fmz-5000 Konvansiyonel ModulDocumento2 pagineFmz-5000 Konvansiyonel ModulEyüp YurdusevenNessuna valutazione finora

- Minerva Marine: MX / T2000 Panel RangeDocumento20 pagineMinerva Marine: MX / T2000 Panel RangeNguyen Phuoc HoNessuna valutazione finora

- Ceodeux-480 SeriesDocumento32 pagineCeodeux-480 Serieskranthichokkakula100% (1)

- Trafo B & DDocumento4 pagineTrafo B & Dlithasinergi.01Nessuna valutazione finora

- JB-QB-5Ei Programming Software Operation ManualDocumento15 pagineJB-QB-5Ei Programming Software Operation ManualPVelozoNessuna valutazione finora

- Co2 Marine 220610 - PrintDocumento170 pagineCo2 Marine 220610 - PrintCoquin Ant100% (1)

- Addressable Fire Alarm Control Panel AW-FP100 User ManualDocumento29 pagineAddressable Fire Alarm Control Panel AW-FP100 User Manualsergio0696100% (1)

- Manual Actuator: Code: FR2:LB700050008 Reference: CM16Documento2 pagineManual Actuator: Code: FR2:LB700050008 Reference: CM16rafa100% (1)

- BS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFDocumento28 pagineBS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFambition1340cn100% (2)

- 06-433 Fm200 Design ServiceDocumento116 pagine06-433 Fm200 Design ServiceOctavio Cortes100% (1)

- Pressure Switch DMT02ATEX E019 - Op Manual - Decl of Conf - enDocumento6 paginePressure Switch DMT02ATEX E019 - Op Manual - Decl of Conf - ennemi90Nessuna valutazione finora

- INTEGLEX NOHMI BOSAI - PDF Version 1Documento109 pagineINTEGLEX NOHMI BOSAI - PDF Version 1Reymart Manablug93% (15)

- MANUAL IOMFES-iflow REV01 PDFDocumento139 pagineMANUAL IOMFES-iflow REV01 PDFambition1340cnNessuna valutazione finora

- KFS FM-200 ECS Modular Balanced Design ManualDocumento110 pagineKFS FM-200 ECS Modular Balanced Design Manualitovarsilva100% (1)

- Operator Unit 130-626.NG001 Standard 22 GYRO COMPASS: Operator and Service ManualDocumento101 pagineOperator Unit 130-626.NG001 Standard 22 GYRO COMPASS: Operator and Service ManualEstetNessuna valutazione finora

- Fire Alarm System DBRDocumento19 pagineFire Alarm System DBRKirty VardhanNessuna valutazione finora

- MCFA 4100ES (250 Devices)Documento10 pagineMCFA 4100ES (250 Devices)Dani AhmadNessuna valutazione finora

- Spare parts list by numberDocumento26 pagineSpare parts list by numberfrduranNessuna valutazione finora

- 1 ProInert2 EquipmentDocumento89 pagine1 ProInert2 EquipmentfereszaNessuna valutazione finora

- Datasheet KTM-MB31194P 1078048 enDocumento7 pagineDatasheet KTM-MB31194P 1078048 enBhupendra SinghNessuna valutazione finora

- Encoder_DBS36E-BBEP01000_1064687_enDocumento8 pagineEncoder_DBS36E-BBEP01000_1064687_enTomasz KownackiNessuna valutazione finora

- Cylindrical Photoelectric Sensors Product Data SheetDocumento7 pagineCylindrical Photoelectric Sensors Product Data Sheetzaky yamaniNessuna valutazione finora

- KT5G-2P1111 product sheetDocumento8 pagineKT5G-2P1111 product sheetМилутин БошковићNessuna valutazione finora

- Clash FF BromoDocumento27 pagineClash FF BromoIskandar HasibuanNessuna valutazione finora

- Cargill Bromo ClashDocumento10 pagineCargill Bromo ClashIskandar HasibuanNessuna valutazione finora

- Cella Warehouse - Manhour Estimation-PlumbingDocumento19 pagineCella Warehouse - Manhour Estimation-PlumbingIskandar HasibuanNessuna valutazione finora

- RFI-MECH-01 Hydrant & Sprikler Layout-RHDocumento3 pagineRFI-MECH-01 Hydrant & Sprikler Layout-RHIskandar HasibuanNessuna valutazione finora

- Ta2862-Ql-Mar-Spgn-M-0029r1 (Approval Steam & Condensate Valve) - Approved With Comment.Documento5 pagineTa2862-Ql-Mar-Spgn-M-0029r1 (Approval Steam & Condensate Valve) - Approved With Comment.Iskandar HasibuanNessuna valutazione finora

- PTMC-RHI-ZZ-XX-DR-M-5550-1107 - P&ID Fuel Distribution at Power Station AreaDocumento1 paginaPTMC-RHI-ZZ-XX-DR-M-5550-1107 - P&ID Fuel Distribution at Power Station AreaIskandar HasibuanNessuna valutazione finora

- Ta2862-Ql-Mar-Spgn-M-0026r1 (Approval Town Water Valve) - Approved With Comment.Documento4 pagineTa2862-Ql-Mar-Spgn-M-0026r1 (Approval Town Water Valve) - Approved With Comment.Iskandar HasibuanNessuna valutazione finora

- Ta2862-Ql-Mar-Spgn-M-0027r1 (Approval Compressed Air Valve) - Approved With Comment.Documento4 pagineTa2862-Ql-Mar-Spgn-M-0027r1 (Approval Compressed Air Valve) - Approved With Comment.Iskandar HasibuanNessuna valutazione finora

- PTMC-RHI-ZZ-XX-DR-M-5550-1105 - P&ID Fuel Transfer Pump SystemDocumento1 paginaPTMC-RHI-ZZ-XX-DR-M-5550-1105 - P&ID Fuel Transfer Pump SystemIskandar HasibuanNessuna valutazione finora

- Penawaran ProdukDocumento1 paginaPenawaran ProdukIskandar HasibuanNessuna valutazione finora

- PTMC-RHI-ZZ-XX-DR-M-5030-1101 - PFD Sewage Water at Ablution AreaDocumento1 paginaPTMC-RHI-ZZ-XX-DR-M-5030-1101 - PFD Sewage Water at Ablution AreaIskandar HasibuanNessuna valutazione finora

- Ta2862-Ql-Mar-Spgn-M-0028r1 (Approval Industrial Waste Water Valve) - Approved With CommentDocumento3 pagineTa2862-Ql-Mar-Spgn-M-0028r1 (Approval Industrial Waste Water Valve) - Approved With CommentIskandar HasibuanNessuna valutazione finora

- PTMC-RHI-ZZ-XX-DR-M-5550-1106 - P&ID Fuel Distribution at Fuel Storage Transtank AreaDocumento1 paginaPTMC-RHI-ZZ-XX-DR-M-5550-1106 - P&ID Fuel Distribution at Fuel Storage Transtank AreaIskandar HasibuanNessuna valutazione finora

- Cim-Sep-Bd00-Dd-M-055-R0 - Waste Water Site Layout Mezanine Floor-R1Documento1 paginaCim-Sep-Bd00-Dd-M-055-R0 - Waste Water Site Layout Mezanine Floor-R1Iskandar HasibuanNessuna valutazione finora

- Cim-Sep-Bd00-Dd-M-072-R0 - Detail Installation Energy Column M-056-R1Documento1 paginaCim-Sep-Bd00-Dd-M-072-R0 - Detail Installation Energy Column M-056-R1Iskandar HasibuanNessuna valutazione finora

- Cim-Sep-Bd00-Dd-M-073-R0 - Schedule Installation Energy Column-R1Documento1 paginaCim-Sep-Bd00-Dd-M-073-R0 - Schedule Installation Energy Column-R1Iskandar HasibuanNessuna valutazione finora

- Full Hydraulic Calculations for 3M Indonesia FactoryDocumento5 pagineFull Hydraulic Calculations for 3M Indonesia FactoryIskandar HasibuanNessuna valutazione finora

- PTMC-RHI-ZZ-XX-DR-M-5550-1104 - PFD Fuel Distribution at TIA Refuelling Storage Tank AreaDocumento1 paginaPTMC-RHI-ZZ-XX-DR-M-5550-1104 - PFD Fuel Distribution at TIA Refuelling Storage Tank AreaIskandar HasibuanNessuna valutazione finora

- K181008 UT PID DW 002 - RevA - 02aug19Documento1 paginaK181008 UT PID DW 002 - RevA - 02aug19Iskandar HasibuanNessuna valutazione finora

- Vendors responsible for connecting utilitiesDocumento1 paginaVendors responsible for connecting utilitiesIskandar HasibuanNessuna valutazione finora

- Cim-Sep-Bd00-Dd-M-057-R0 - Compressed Air Site Layout Mezanine Floor-R1Documento1 paginaCim-Sep-Bd00-Dd-M-057-R0 - Compressed Air Site Layout Mezanine Floor-R1Iskandar HasibuanNessuna valutazione finora

- Grey Water CalculationDocumento2 pagineGrey Water CalculationIskandar HasibuanNessuna valutazione finora

- Lay Out Fuel StationDocumento6 pagineLay Out Fuel StationIskandar HasibuanNessuna valutazione finora

- (Indicative Only - Package Provided by Others) : NotesDocumento1 pagina(Indicative Only - Package Provided by Others) : NotesIskandar HasibuanNessuna valutazione finora

- K181008 UT PID DW 003 - RevA - 02aug19Documento1 paginaK181008 UT PID DW 003 - RevA - 02aug19Iskandar HasibuanNessuna valutazione finora

- Comparison Rain Water CollectionDocumento2 pagineComparison Rain Water CollectionIskandar HasibuanNessuna valutazione finora

- ENS-PR-ARC-B00-DRW-10300-1.2 - Site Layout-Grey WaterDocumento1 paginaENS-PR-ARC-B00-DRW-10300-1.2 - Site Layout-Grey WaterIskandar HasibuanNessuna valutazione finora

- TA2395 RHI BA ZZ DR M 5301 Collecting Pit DetailDocumento1 paginaTA2395 RHI BA ZZ DR M 5301 Collecting Pit DetailIskandar HasibuanNessuna valutazione finora

- TA2899 RHI ZZ ZZ DR M 3001 Utilities Pipe Supply Composite Site LayoutDocumento1 paginaTA2899 RHI ZZ ZZ DR M 3001 Utilities Pipe Supply Composite Site LayoutIskandar HasibuanNessuna valutazione finora

- TA2395 RHI BA ZZ DR M 5301 Collecting Pit DetailDocumento1 paginaTA2395 RHI BA ZZ DR M 5301 Collecting Pit DetailIskandar HasibuanNessuna valutazione finora

- Sunnen Honing Techniques: Above and Beyond HoningDocumento8 pagineSunnen Honing Techniques: Above and Beyond HoningHenry OlguinNessuna valutazione finora

- 854G Wheel Dozer Electrical System 992G Wheel LoaderDocumento6 pagine854G Wheel Dozer Electrical System 992G Wheel LoaderNorman CoetzeeNessuna valutazione finora

- Programator NodeDocumento17 pagineProgramator NodeIulian BobocNessuna valutazione finora

- EMI - 1819 - Final - Ans - Corrected PDFDocumento10 pagineEMI - 1819 - Final - Ans - Corrected PDFvishwanath c kNessuna valutazione finora

- V3.0 Fundamentals - of - Automation - TechnologyDocumento109 pagineV3.0 Fundamentals - of - Automation - TechnologyBernardo LuzNessuna valutazione finora

- Blaw-Knox PF3200 Paver Finisher Omni 3A (IIIA) 43957513Documento106 pagineBlaw-Knox PF3200 Paver Finisher Omni 3A (IIIA) 43957513viemey19520% (1)

- OLY Engine Interface ModuleDocumento4 pagineOLY Engine Interface ModuleAlejandro Bonilla100% (2)

- FR Error MercyDocumento5 pagineFR Error MercyNoeRtjahya Ahmad100% (1)

- Magnetism Exam Questions StudentDocumento11 pagineMagnetism Exam Questions StudentPAM NOBNessuna valutazione finora

- Injection Molding ControlDocumento15 pagineInjection Molding ControlNalin T BandaraNessuna valutazione finora

- Diagrama Hidraulico 330DLDocumento9 pagineDiagrama Hidraulico 330DLCRIXUS3Nessuna valutazione finora

- E02137K Datasheet PDFDocumento8 pagineE02137K Datasheet PDFMarran AlmarraniNessuna valutazione finora

- Introduction To Electro Magnetism PDFDocumento97 pagineIntroduction To Electro Magnetism PDFDebi Prasad SenNessuna valutazione finora

- Mitsubishi Grandis Wiring Diagram - Configuration DiagramsDocumento22 pagineMitsubishi Grandis Wiring Diagram - Configuration Diagramsrodonganjaya22100% (1)

- 17-594 Shift Lock Control Shift Lock Control Schematic and Routing DiagramsDocumento7 pagine17-594 Shift Lock Control Shift Lock Control Schematic and Routing Diagramsbhanuka2009Nessuna valutazione finora

- Taema NEFTIS Service - ManualDocumento86 pagineTaema NEFTIS Service - ManualAhmerShehzad100% (1)

- Common Trouble-Shooting Method of Road RollerDocumento27 pagineCommon Trouble-Shooting Method of Road RollerLinzaw Win100% (2)

- RC2 Series Screw Compressor Maintenance ManualDocumento122 pagineRC2 Series Screw Compressor Maintenance ManualDennis Arhin100% (1)

- Electrical Systems: Wiring DiagramsDocumento27 pagineElectrical Systems: Wiring DiagramsBilly RoperNessuna valutazione finora

- Solenoid Valve: 3-Way, 2-Position Spool Type Solenoid Valve 11 L/Min (3 Usgpm) - 210 Bar (3000 Psi)Documento2 pagineSolenoid Valve: 3-Way, 2-Position Spool Type Solenoid Valve 11 L/Min (3 Usgpm) - 210 Bar (3000 Psi)allexanders fiazNessuna valutazione finora

- BICS Control Valve 863 Parts ListDocumento3 pagineBICS Control Valve 863 Parts ListHenry HuayhuaNessuna valutazione finora

- 24vdiesel Diagram PDFDocumento2 pagine24vdiesel Diagram PDFMohamed Abdel MageedNessuna valutazione finora

- Engine Electrical SystemDocumento58 pagineEngine Electrical SystemCesar GiraccaNessuna valutazione finora

- D9R Tractor With 3408E Engine Electrical System: Electrical Schematic Symbols and DefinitionsDocumento2 pagineD9R Tractor With 3408E Engine Electrical System: Electrical Schematic Symbols and Definitionsssinokrot100% (2)

- Final Control ElementDocumento8 pagineFinal Control ElementZulkernain Omer TariqNessuna valutazione finora

- Airtec KN05 Solenoid ValveDocumento4 pagineAirtec KN05 Solenoid ValveJessicalba LouNessuna valutazione finora

- Magnetic Field of Current Carrying WireDocumento44 pagineMagnetic Field of Current Carrying WireRanjit SinghNessuna valutazione finora

- 966H Electrical Schematic RENR6332Documento6 pagine966H Electrical Schematic RENR6332cristian dela nuezNessuna valutazione finora

- RS-60-R200S 3-22-2016 MpartesDocumento46 pagineRS-60-R200S 3-22-2016 MpartesEvert Vargas Torrez100% (1)

- Starter+and+Dynastarter+Components 2011 2012Documento849 pagineStarter+and+Dynastarter+Components 2011 2012jaduzyNessuna valutazione finora