Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Galoa Proceedings Cobeq 2016 40185 New Method of Pu

Caricato da

Wilson LiangCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Galoa Proceedings Cobeq 2016 40185 New Method of Pu

Caricato da

Wilson LiangCopyright:

Formati disponibili

NEW METHOD OF PURIFICATION OF GLYCERIN FROM

BIODIESEL USING SILICA GEL AS ADSORBENT

J. Q. GALVÃO NETO1, F. B. ROSSATO2, T. T. VINHAL3, S. ELYASI4

1

Universidade Federal da Paraíba

2

Instituto Mauá de Tecnologia, Escola de Engenharia Mauá

3

Universidade de São Paulo, Escola de Engenharia de Lorena

4

Lakehead University, Canada

E-mail: joaodequeiroz@msn.com

ABSTRACT – Biodiesel is a well-known fuel from renewable resource. During the

production of biodiesel, glycerin is the main by-product. Considering the amount and

type of impurities in glycerin such as, water, methanol, and salt; it cannot be directly

used as a raw material. It should be refined. Traditionally, the raw glycerin undergoes a

purification method that uses vacuum distillation, which is an energy extensive and

complicated method. Purifying glycerine, we developed a new purification process that

runs at ambient temperature and pressure using silica gel as adsorbent being able to

achieve a concentration of +99% glycerin. The adsorption material can also be reused

over more than 50 cycles without losing its performance. For regeneration of sorbent,

low grade heat stream at low temperature (below 120 ⁰C) may be used. As a result, the

proposed purification technology is not complicated and can be easily designed and

integrated into existing biodiesel facilities with minimum modifications.

1. INTRODUCTION

Biodiesel as a biofuel is produced by a transesterification process using vegetable oils or animal

fats with methanol, frequently catalyzed using alkali reagents (e.g., sodium hydroxide and potassium

hydroxide (Saleh, 2010). Glycerin is the main by-product, 10% by weight of oil yields (Kongjao et

al., 2010), with low energy value considering the impurities. Crude glycerin is separated from

biodiesel layer after completion of transesterification reaction. The main impurities are salt, water,

soap, traces amount of methanol and esters.

Most researchers used conventional methods to purify glycerine (+99%) at high temperatures

and low pressure (vacuum) which will end up to high operating cost, for instance, using vacuum

distillation to obtain a high grade glycerine up to 99.5 weight percent (Carmona et al., 2009). Other

non-distillation methods were developed. Hajek et al. (2010) used saponification, neutralization and

filtration processes obtaining 86% glycerine. Kongjao et al. (2010) applied acidification,

neutralization, separation of the phases, and extraction of alcohol achieving glycerine purification up

to 93.3%. Moreover, some biodiesel producers use the glycerine by-product as fuel but when it is

combusted at high temperatures (200 – 300 ºC), releases harmful substances such as acrolein

(Steinmetz et al., 2013).

Glycerine is widely employed as raw material in many industries such as, pharmaceutical, food

and cosmetic industries (Thompson; He, 2006). However, the methods known lately to treat glycerine

show that the purification process is economically unfeasible. As a result, it is essential to find

economical feasible alternative for purification of this valuable by-product (Quispe et al., 2013).

In order to increase the utilization of glycerin, it is necessary to obtain glycerine with less

impure chemical substances and in a concentrated form. Further improvement in the use of the by-

product would affect positively the biodiesel production. Aiming to overcome the costs of

purification, it was developed a new method that purifies glycerin at ambient pressure and

temperature. This method uses compressed dry air sparging through raw glycerine to remove water

and alcohol. Air is dried using silica gel and returns back to the glycerine column through a close

loop system. Using this technique, glycerine with +99% could be obtained without using high

temperature and low pressure process.

Considering this method, some sorbents were tested, such as calcium chloride, silica gel, and

water-absorbing polymer known as water-gel crystal. Calcium chloride is a known desiccant with

high hygroscopic properties. Solid dry calcium chloride is converted to liquid after absorbing

moisture. This behavior it causes to be extremely difficult to handle and dry the desiccant. After

drying, it forms a solid layer which needs to be crushed to a proper size. As a result, calcium chloride

is not a proper sorbent for the purpose of this study. Water-gel crystal absorbs high quantities of

water, around two to four hundred times when compared to its original weight, but the mass transfer

is a barrier when compared to silica gel. It needs a long period of time to absorb water. In addition,

glycerin is absorbed to the water-gel crystal which reduces the total recovery of glycerin. Silica gel,

as non-corrosive chemical, has been selected due to its relatively high adsorption capacity, low level

energy consumption during the regeneration process (below 120 °C), easy to handle, and moderately

its low cost (Fang et al., 2014).

2. MATERIAL AND METHODS

2.1 Material

Pure glycerin (USP grade) with 99.5% purity was used. The main impurity in glycerin was

water. Orange indicating silica gel desiccant was purchased from local Canadian supplier. The silica

gel was in the form of small sphere with uniform size of 3 mm. Producing raw glycerin, edible canola

oil was reacted with anhydrous ethanol (99.5%) supplied by Fisher Scientific. The reaction was

catalyzed by sodium hydroxide pellets supplied by Fisher Scientific. The aqueous phase obtained

from biodiesel reaction was neutralized using 5% sulfuric acid supplied by Fisher Scientific.

2.2 Method for measuring concentration of glycerin

In order to measure the glycerin concentration during the tests, an Abbe 3L Refractometer

AKA Bausch refractometer was used. Using a lab balance (0.1 milligram), several known

concentrations of distilled water and glycerin were prepared. The known solution was used to

generate a calibration curve. This curve correlated the refractive index vs the weight percent of

glycerin in the mixture (w/w%).

To construct the calibration curve, a solution of Glycerin USP (pure) and distillated water in

different concentrations was made. The refractive index was measured for each solution and a graph

was generated which is shown as Figure 1.

1.48

Refractive Index

1.46

1.44

1.42

1.4

y = 0.1375x + 1.3281

1.38 R² = 0.99809

1.36

1.34

1.32

0% 20% 40% 60% 80% 100%

Concentration of glycerin (wt%)

Figure 1 – Calibration curve utilized for measuring glycerin concentration using a refractometer.

2.3 Apparatus

New equipment was developed to perform the experiment. The apparatus was first designed

using Solid Works (2014) Software and built using a 3D printer with ABS plastic. The apparatus

consisted of two parts. One chamber holds silica gel. Crude glycerin was kept in the other

compartment. The parts were connected with plastic tubes through an air compressor. The entire setup

was in a closed loop of air flow. Air after passing through crude glycerin was send to the silica gel

compartment to be dried. The dry air was recirculated to the glycerin compartment by a miniature size

compressor (HARGRAVES). Considering the fact that vapor pressure of water is much higher than

glycerin, air could remove water from crude glycerin. Additionally, unreacted alcohol was carried by

the air and absorbed by the silica gel. Overall, crude glycerin lost water and alcohol. Soluble salts

(after neutralization of crude glycerin with sulfuric acid) were precipitated as fine solids. Removing

water caused over saturation for solution of salt that produced solid salt. Inside of each compartment,

there was a vertical plastic tube that directed air to the bottom of solution and silica gel compartment.

This mechanism provided maximum residence time between solution or silica gel with air.

Consequently, it increased the mass transfer considerably by distributing air at the bottom of each

compartment. Each compartment has a cap to isolate it from atmosphere. The cap is removable for

charging the chemical to the compartment or removing it. The cap has a groove with an O-ring to seal

and make sure the air does not escape. The developed apparatus is shown in Figure 2.

Compressor

Part II Part I

Figure 2 – Apparatus assembly, where part I and II are the solution and silica gel compartments

2.4 Purification of glycerin

The procedure for purification of crude glycerine was primarily tested using USP glycerine to

prove the concept of using silica gel, thereafter, the biodiesel was produced to obtain the crude

glycerine which was used as crude glycerin.

USP Glycerin: The apparatus was prepared to start the purification process. First, a 2-g

sample of silica gel was placed inside part II of the apparatus and 3mL of glycerine-water solution

previously prepared (>45% wt. glycerine) was placed in the other compartment. The process was

executed by several experiments. Each run took 0.5 hours. After 0.5 hour, the glycerine solution was

tested to measure the refractive index and to find concentration of glycerin.

Crude Glycerin: The same procedure was applied to the crude glycerine that was separated

from produced biodiesel as the by-product (glycerine). Thereafter, the glycerin was neutralized with

sulfuric acid (H2SO4 5%) until pH 5-6; the fatty acids were removed by separation funnel. The

remaining solution containing glycerine (>68% wt.), salt, water and very trace amount of soap was

utilized to be purified. During the process it was observed that when glycerin concentration reached a

certain level (about 70 % wt.), salt was precipitated as fine crystals. Fine solids were collected at the

bottom of the apparatus.

3. RESULTS AND DISCUSSION

3.1 Purification of glycerin using silica gel

Figure 3 show that the glycerine-water solution with concentration of about 48% was purified

to concentration of +99%. The overall duration of this experiment was 13 hours (27 steps, each half

an hour). The result is promising considering that other researchers used costly methods to obtain

glycerin +93% (Carmona et al., 2009 and Kongjao et al., 2010).

110

Concentration (wt %)

100

90

80

70

60

50

40

30

20

10

0

1 3 5 7 9 11 13 15 17 19 21 23 25 27

Experiment runs

Figure 3 – Number of steps that required to purify USP glycerin from water solution

The results using the crude glycerin originated from the produced biodiesel are shown in

Figure 4. Regardless the fact that the crude glycerin had more impurities as explained previously, it

took almost the same steps to achieve the desired concentration. It can be concluded that those

impurities do not have observable impact on mass transfer and overal performance of this process.

Nevertheless, it was also possible to achieve a high pure grade of +99% glycerin.

110

Concentration (wt %) 100

90

80

70

60

50

40

30

20

10

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Experiment runs

Figure 4 – Crude glycerin concentration during the purification process using designed apparatus

3.2 Regeneration of sorbents

As mentioned before, the sorbent used was silica gel. This material has the capacity to adsorb

water, however, in the developed apparatus the sorbent needs to be regenerated. Regeneration process

could revive the sorption capacity of silica gel. Regeneration was carried out at 100⁰C for half an

hour.

In order to prove that silica gel does not loss its sorption capacity, sorbent was tested

through many cycles of sorption and desorption. The process basically was to introduce a small

mass of the silica gel into a saturated water vapour atmosphere in a closed container until the

sorbent adsorbs maximum possible amount of moisture. The color of silica gel was the best

indicator to determine the end of sorption process. The color of gel went from orange to green.

The weight gains and losses of silica gel were recorded and shown in Figure 5. It is obvious that

even after 50 cycles silica gel does not lose its sorption capacity.

Figure 5 – Initial and final mass of silica gel during sorption/desorption cycles.

4. CONCLUSIONS

The results from this study proved the concept that crude glycerin can be purified at ambient

pressure and temperature. The main goal of this research was not to develop an equipment that

converts the crude glycerin to concentrated form continuously. This method needs more rigorous

study in order to develop optimum equipment that enhances mass transfer between different phases.

However, it was proved that glycerin with different chemical impurities such as salts, water, alcohol

can be purified with no technical issue. The impurity does not have any measurable impact on the

performance of this method. Additionally, glycerin with +99% purity could be obtained easily and

silica gel can be reused many times without losing its sorption capacity. These results are aligned with

the project’s main idea to produce pure glycerin using a simple and low cost method. Further

investigation is required to optimize the design and develop a new equipment and process for

continuous production of glycerin.

5. REFERENCES

CARMONA, M.; LECH, A.; DE LUCAS, A.; PEREZ, A.; RODRIGUEZ, J. F. Purification of

Glycerol/Water Solutions from Biodiesel Synthesis by Ion Exchange: Sodium and Chloride

Removal. Part II. J. Chem. Technol. Biotechnol, v. 84, p. 1130−1135, 2009.

FANG, Y.T.; LIU, T.; ZHANG, Z.C.; GAO, X.N. Silica gel adsorbents doped with Al, Ti, andCo ions

improved adsortion capacity, thermal stability and aging resistance. Renewable Energy, v. 63, p.

755-761, 2014.

HÁJEK, M.; SKOPAL, F. Treatment of glycerol phase formed by biodiesel production. Bioresource

Technology, v. 101(9), p. 3242-3245, 2010.

KONGJAO, S.; DAMRONGLERD, S.; HUNSOM, M. Purification of crude glycerol derived from

waste used-oil methyl ester plant. Korean J. Chem. Eng, v. 27(3), p. 944-949, 2010.

QUISPE, C.A.G.; CORONADO, C.J.R.; CARVALHO Jr., J.A. Glycerol: Production, consumption,

prices, characterization and new trends in combustion. Renewable and Sustainable Energy

Reviews, v. 27, p. 475-493, 2013.

SALEH, J. Glycerol removal from biodiesel using membrane separation technology. Fuel, v. 89(9), p.

2260-2266, 2010.

STEINMETZ, S.A.; HERRINGTON, J.S.; WINTERROWD, C.K.; ROBERTS, W.L.; WENDT,

J.O.L.; Linak, W.P. Crude glycerol combustion: Particulate, acrolein, and other volatile organic

emissions. Proceedings of the Combustion Institute, v. 34(2), p. 2749-2757, 2013.

THOMPSON, J. C.; HE, B. B. Characterization of crude glycerol from biodiesel production from

multiple feedstocks. Applied Engineering in Agriculture, v. 22.2, p. 261-265, 2006.

Potrebbero piacerti anche

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Revision For The First 1 English 8Documento6 pagineRevision For The First 1 English 8hiidaxneee urrrmNessuna valutazione finora

- 02 Unit I Environmental Studies-A Multidisciplinary Subject 14-01-2022Documento69 pagine02 Unit I Environmental Studies-A Multidisciplinary Subject 14-01-2022doramonbhaiyaNessuna valutazione finora

- Air Show - Blue Angels in Flying K - The News of NAS KingsvilleDocumento16 pagineAir Show - Blue Angels in Flying K - The News of NAS KingsvilleAlan GuggenheimNessuna valutazione finora

- Roles and Responsibilities of ASHADocumento3 pagineRoles and Responsibilities of ASHAmohanpskohli8310Nessuna valutazione finora

- Thermal Imaging Tech ResourceDocumento20 pagineThermal Imaging Tech Resourceskimav86100% (1)

- Project Final PDFDocumento98 pagineProject Final PDFNgonidzashe MhukaNessuna valutazione finora

- Growth Rate and Fattening Potetial of Meat AnimalsDocumento54 pagineGrowth Rate and Fattening Potetial of Meat AnimalsMuhammad Shahzad ChandiaNessuna valutazione finora

- 03 Soil Classification Numerical PDFDocumento5 pagine03 Soil Classification Numerical PDFabishrantNessuna valutazione finora

- What Is Geyi - V MairDocumento31 pagineWhat Is Geyi - V MairbodhitanNessuna valutazione finora

- Experiment - 5Documento26 pagineExperiment - 5Dilip GangopadhyayNessuna valutazione finora

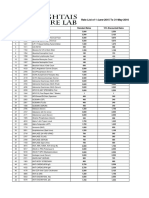

- Rate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesDocumento25 pagineRate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesMirza BabarNessuna valutazione finora

- Air Quality Index Analysis & PredictionDocumento34 pagineAir Quality Index Analysis & PredictionGottumukkala Sravan KumarNessuna valutazione finora

- TNB Ar2011Documento334 pagineTNB Ar2011Duncan LeeNessuna valutazione finora

- Shri Fa 4Documento44 pagineShri Fa 4Veena H NayakNessuna valutazione finora

- Electromagnetic and Thermal AnalysisDocumento5 pagineElectromagnetic and Thermal AnalysishamidrezaNessuna valutazione finora

- Nelson Tables All in One PDFDocumento618 pagineNelson Tables All in One PDFAmulya Ramakrishna100% (7)

- Eric Dollard MWO Update 2012Documento21 pagineEric Dollard MWO Update 2012pic2007100% (7)

- Trucks Fin Eu PCDocumento117 pagineTrucks Fin Eu PCjeanpienaarNessuna valutazione finora

- FEED Deliverable List (Sample) : Project InformationDocumento3 pagineFEED Deliverable List (Sample) : Project Informationamilasri100% (1)

- Be Project Presentation SuspensionDocumento17 pagineBe Project Presentation SuspensionGabrielNessuna valutazione finora

- Medical BiotechnologyDocumento4 pagineMedical Biotechnologyعمر بن عليNessuna valutazione finora

- ABB Photovoltaic DisconnectorsDocumento6 pagineABB Photovoltaic DisconnectorsBog PenNessuna valutazione finora

- r315 Quick Start PDFDocumento80 paginer315 Quick Start PDFfdsfasdsfadsNessuna valutazione finora

- E2870-13 Standard Test Method For Evaluating RelativDocumento6 pagineE2870-13 Standard Test Method For Evaluating RelativA MusaverNessuna valutazione finora

- Grade 7 Information Writing: The Bulldog: A Dog Like No OtherDocumento5 pagineGrade 7 Information Writing: The Bulldog: A Dog Like No Otherapi-202727113Nessuna valutazione finora

- Mechanical Components SectionDocumento428 pagineMechanical Components Sectionxristo xristovNessuna valutazione finora

- NL0520 NEPAL SagarmathaDocumento12 pagineNL0520 NEPAL SagarmathaPrashantpal RaiNessuna valutazione finora

- Zeolites and Ordered Porous Solids - Fundamentals and ApplicationsDocumento376 pagineZeolites and Ordered Porous Solids - Fundamentals and ApplicationsHenrique Souza100% (1)

- Ace of Spades + Outlaw 125 2019Documento85 pagineAce of Spades + Outlaw 125 2019Nelson RodrigoNessuna valutazione finora

- Examination Speaking Assignments Term III - 2021Documento2 pagineExamination Speaking Assignments Term III - 2021Khrystyna ShkilniukNessuna valutazione finora