Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Traffic Coatings

Caricato da

Ghayas JawedCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Traffic Coatings

Caricato da

Ghayas JawedCopyright:

Formati disponibili

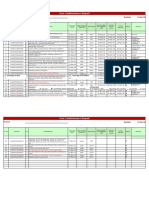

Project: DMS No.

145117 Deira Islands – Construction of Deira Mall,

DEIRA MALL

Works: LG+G+2 COMMERCIAL BUILDING – PALM DEIRA, DUBAI, UAE

Title: DOCUMENT VOLUME 02.01

GENERAL SPECIFICATIONS ARCHITECTURE & INTERIOR DESIGN

SECTION 071800 – TRAFFIC COATINGS FOR EXPOSED & ROOF DECKS

Part of Waterproofing System: WPE-03 & WPE-04

AREAS OF APPLICATION

• Parking Roof Slab (WPE-03)

• Parking Intermediate Slab (WPE-04)

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings, waterproofing schedule and general provisions of the Contract, including General

and Supplementary Conditions and Division 01 Specification Sections, apply to this Section.

B. Related Section includes, but not limited to the following:

1. Civil Specification Section 321723 – Pavement Markings

1.2 SUMMARY

A. This Section includes traffic coatings for the following applications:

1. Vehicular traffic.

2. Pavement markings.

B. Related Sections include the following:

1. Division 03 Section "Cast-in-Place Concrete" for concrete substrates.

2. Division 03 Section "Concrete Topping" for traffic-bearing toppings applied over base

slabs or precast concrete units.

3. Division 05 Section "Steel Decking" for permanent metal forms for concrete substrates.

4. Division 07 Section "Expansion Control" for expansion and seismic joints in surfaces to

receive traffic coatings.

5. Division 09 Section "Resinous Flooring" for general-use commercial, high-performance

resinous floorings.

1.3 SUBMITTALS

A. Product Data: For each product indicated.

B. LEED Submittals:

Division 07 Section 071800 Page 1 of 9 Traffic Coatings for Exposed Decks

Project: DMS No. 145117 Deira Islands – Construction of Deira Mall,

DEIRA MALL

Works: LG+G+2 COMMERCIAL BUILDING – PALM DEIRA, DUBAI, UAE

Title: DOCUMENT VOLUME 02.01

GENERAL SPECIFICATIONS ARCHITECTURE & INTERIOR DESIGN

1. Product Test Reports for Credit SS 7.2: For traffic coatings that are roof coverings,

documentation indicating compliance with Solar Reflectance Index requirement.

2. Product Data for Credit IEQ 4.2: For interior field-applied traffic coatings and pavement-

marking paints, documentation including printed statement of VOC content.

3. Laboratory Test Reports for Credit IEQ 4: For interior traffic coatings and pavement-

marking paints, documentation indicating that products comply with the testing and

product requirements of the California Department of Health Services' "Standard Practice

for the Testing of Volatile Organic Emissions from Various Sources Using Small-Scale

Environmental Chambers."

C. Shop Drawings: Show extent of each traffic coating. Include details for treating substrate joints

and cracks, flashings, deck penetrations, and other termination conditions.

1. Indicate layout of pavement markings.

D. Samples for Initial Selection: For each type of finish indicated.

E. Samples for Verification: For each type of traffic coating required, prepared on rigid backing

and of same thickness and material indicated for the Work.

1. Provide stepped Samples on backing large enough to illustrate buildup of traffic coatings.

F. Qualification Data: For Installer.

G. Material Test Reports: For each traffic coating.

H. Material Certificates: For each traffic coating, signed by manufacturers.

I. Maintenance Data: For traffic coatings to include in maintenance manuals. Identify substrates

and types of traffic coatings applied. Include recommendations for periodic inspections,

cleaning, care, maintenance, and repair of traffic coatings.

J. Warranty: Special warranty specified in this Section.

1.4 QUALITY ASSURANCE

A. Installer Qualifications: Manufacturer's authorized representative who is trained and approved

for installation of traffic coatings required for this Project.

B. Source Limitations:

1. Obtain traffic coatings from a single manufacturer.

2. Obtain primary traffic coating materials, including primers, from traffic coating

manufacturer. Obtain secondary materials including aggregates, sheet flashings, joint

sealants, and substrate repair materials of type and from source recommended in writing

by primary material manufacturer.

C. Mockups: Apply mockups to set quality standards for materials and execution.

Division 07 Section 071800 Page 2 of 9 Traffic Coatings for Exposed Decks

Project: DMS No. 145117 Deira Islands – Construction of Deira Mall,

DEIRA MALL

Works: LG+G+2 COMMERCIAL BUILDING – PALM DEIRA, DUBAI, UAE

Title: DOCUMENT VOLUME 02.01

GENERAL SPECIFICATIONS ARCHITECTURE & INTERIOR DESIGN

1. Architect will select one representative surface for each traffic coating and each substrate

to receive traffic coatings. Apply each coating to at least 20 sq. m of each substrate to

demonstrate surface preparation, joint and crack treatment, thickness, texture, color, and

standard of workmanship.

2. Remove and reapply mockups until they are approved by Architect.

3. Approved mockups may become part of the completed Work if undisturbed at time of

Substantial Completion.

D. Pre-installation Conference: Conduct conference at Project site to comply with requirements in

Division 01 Section "Project Management and Coordination."

1. Before installing traffic coatings, meet with representatives of authorities having

jurisdiction, manufacturer's technical representative, Owner, Architect, consultants,

independent testing agency, and other concerned entities. Review requirements for traffic

coatings. Notify participants at least seven days before conference.

1.5 DELIVERY, STORAGE, AND HANDLING

A. Deliver materials in original packages and containers with seals unbroken and bearing

manufacturer's labels showing the following information:

1. Manufacturer's brand name.

2. Type of material.

3. Directions for storage.

4. Date of manufacture and shelf life.

5. Lot or batch number.

6. Mixing and application instructions.

7. Color.

B. Store materials in a clean, dry location protected from exposure to direct sunlight. In storage

areas, maintain environmental conditions within range recommended in writing by

manufacturer.

1.6 PROJECT CONDITIONS

A. Environmental Limitations: Apply traffic coatings within the range of ambient and substrate

temperatures recommended in writing by manufacturer. Do not apply traffic coatings to damp

or wet substrates. Recommended substrate temperatures are in the range of +12 deg C to +35

deg C.

1. Do not apply traffic coatings in high humidity conditions (exceeding 85%), or when such

weather conditions are imminent during the application and curing period.

B. Do not install traffic coating until items that will penetrate membrane have been installed.

Division 07 Section 071800 Page 3 of 9 Traffic Coatings for Exposed Decks

Project: DMS No. 145117 Deira Islands – Construction of Deira Mall,

DEIRA MALL

Works: LG+G+2 COMMERCIAL BUILDING – PALM DEIRA, DUBAI, UAE

Title: DOCUMENT VOLUME 02.01

GENERAL SPECIFICATIONS ARCHITECTURE & INTERIOR DESIGN

1.7 WARRANTY

A. Special Warranty: Manufacturer's standard form in which traffic coating manufacturer agrees to

repair or replace traffic coatings that deteriorate during the specified warranty period.

Warranty does not include deterioration or failure of traffic coating due to unusual weather

phenomena, failure of prepared and treated substrate, formation of new substrate cracks

exceeding 1.6 mm in width, fire, vandalism, or abuse by maintenance equipment, and truck

traffic.

1. Deterioration of traffic coatings includes the following:

a. Adhesive or cohesive failures.

b. Abrasion or tearing failures.

c. Surface crazing or spalling.

d. Intrusion of water, oils, gasoline, grease, salt, deicer chemicals, or acids into deck

substrate.

2. Warranty Period 10 years from date of Substantial Completion.

PART 2 - PRODUCTS

2.1 MATERIALS

A. Traffic Coatings: Complying with ASTM C 957.

B. Material Compatibility: Provide primers; base, intermediate, and topcoats; and miscellaneous

materials that are compatible with one another and with substrate under conditions of service

and application, as demonstrated by manufacturer based on testing and field experience.

2.2 TRAFFIC COATING TO PARKING ROOF SLAB

A. Available Products: Subject to compliance with requirements, products that may be incorporated

into the Work include, but are not limited to, the following:

1. UV stable, polyurethane based multi-layered car park decking system

for exposed roof traffic decks where Dynamic Crack Bridging and

Waterproofing properties are required.

2. Product must be tested and comply with following Standards:

A. Complies to ASTM C957: 1993 when tested in accordance with:

ASTM C501: 1990

Division 07 Section 071800 Page 4 of 9 Traffic Coatings for Exposed Decks

Project: DMS No. 145117 Deira Islands – Construction of Deira Mall,

DEIRA MALL

Works: LG+G+2 COMMERCIAL BUILDING – PALM DEIRA, DUBAI, UAE

Title: DOCUMENT VOLUME 02.01

GENERAL SPECIFICATIONS ARCHITECTURE & INTERIOR DESIGN

3. Tested for crack bridging in accordance with: ASTM C957: Dynamic crack bridging (to

1.6mm).

4. Tested for Slip Resistance in accordance with: BS 7976-2:2002

5. Tested for Abrasion Resistance in accordance with: ASTM C501.

6. Tested for Fire Resistance in accordance with: BS EN ISO 11925-2: 2010.

B. Primer: Primer is a two component epoxy.

C. Base Coat (Waterproof membrane): is a two component, liquid polyurethane, elastomeric

membrane.

D. Intermediate Coat: Two component, elastomeric pigmented polyurethane coating designed for

application in trafficked areas.

E. Topcoat: Two component, Aliphatic (UV stable), elastomeric, polyurethane coating designed for

application as a top coat on traffic deck systems.

1. Color: As selected by Architect from manufacturer's full range

F. Component Coat Consumption: As recommended by manufacturer for substrate and service

conditions indicated, but not less than the following (measured excluding aggregate):

1. Primer: 0.15-0.3kg/m2 depending on surface texture and porosity.

2. Wearing aggregate: Aggregate total of 1.6kg/m2 broadcast in Primer (0.6kg/m2) and

Intermediate Coat (1.0kg/m2).

3. Base: Elastomeric, polyurethane, waterproofing membrane not less than 1.0kg/m2 and

suffice to provide the required crack bridging properties.

4. Intermediate Coat: 0.35kg/m2 minimum.

5. Topcoat: 0.6kg/m2 minimum.

G. Aggregate: Graded high quality quartz aggregate with a particle size in the range of 0.3-0.9

mm. It is used as a multi-function mechanical key, wear enhancer and to provide skid resistance.

1. Spreading Rate: As recommended by manufacturer for substrate and service conditions

indicated, but not less than the following:

a. Primer Coat: 0.6kg/m2

b. Intermediate Coat: 1.0kg/m2

2.3 TRAFFIC COATING TO PARKING INTERMEDIATE SLAB

A. Available Products: Subject to compliance with requirements, products that may be incorporated

into the Work include, but are not limited to, the following:

Division 07 Section 071800 Page 5 of 9 Traffic Coatings for Exposed Decks

Project: DMS No. 145117 Deira Islands – Construction of Deira Mall,

DEIRA MALL

Works: LG+G+2 COMMERCIAL BUILDING – PALM DEIRA, DUBAI, UAE

Title: DOCUMENT VOLUME 02.01

GENERAL SPECIFICATIONS ARCHITECTURE & INTERIOR DESIGN

1. Polyurethane based multi-layered car park decking system for

intermediate traffic decks where Dynamic Crack Bridging and

Waterproofing properties are required.

2. Product is tested in accordance with following Standards:

A. Complies to ASTM C957: 1993 when tested in accordance with:

ASTM C501: 1990

ASTM C794: 1993

2. Tensile test to ASTM D412 after exposure in accordance with: ASTM G53, ASTM B117.

3. Tested for Slip Resistance in accordance with: BS 7976-2:2002.

4. Tested for Abrasion Resistance in accordance with: ASTM C501.

B. Primer: Primer is multi component epoxy.

C. Intermediate Coat: Option of One or Two-component, liquid polyurethane elastomer

(MasterSeal TC 240, MasterSeal TC 258 or MasterSeal TC 242).

D. Topcoat: One component, UV Resistant, liquid polyurethane elastomer (MasterSeal TC 258).

1. Color: As selected by Architect from manufacturer's full range

E. Component Coat Consumption: As recommended by manufacturer for substrate and service

conditions indicated, but not less than the following (measured excluding aggregate):

1. Primer: 0.15-0.3kg/m2 depending on surface texture and porosity.

2. Wearing aggregate: SRA Aggregate total of 0.6 -2.0kg/m2.

3. Intermediate: 0.45kg/m2 minimum (1 component) or 0.6kg/m2 minimum (for 2

component option).

4. Topcoat: 0.25kg/m² per coat (one or two coats depending on Area of Usage: Refer to

Manufacturer)

F. Aggregate: Mastertop SRA No.3 graded high quality quartz aggregate with a particle size in

the range of 0.3- 0.9 mm. It is used as a multi-function mechanical key, wear enhancer and to

provide skid resistance.

1. Spreading Rate: As recommended by manufacturer for substrate and service conditions

indicated, recommended range for: Primer Coat: 0.6- 2.0 kg/m2.

2.4 MISCELLANEOUS MATERIALS

A. Joint Sealants: As specified in Division 07 Section "Joint Sealants."

Division 07 Section 071800 Page 6 of 9 Traffic Coatings for Exposed Decks

Project: DMS No. 145117 Deira Islands – Construction of Deira Mall,

DEIRA MALL

Works: LG+G+2 COMMERCIAL BUILDING – PALM DEIRA, DUBAI, UAE

Title: DOCUMENT VOLUME 02.01

GENERAL SPECIFICATIONS ARCHITECTURE & INTERIOR DESIGN

B. Adhesive: Contact adhesive recommended in writing by traffic coating manufacturer.

C. Reinforcing Strip: Fiberglass mesh recommended in writing by traffic coating

manufacturer.

2.5 PAVEMENT MARKINGS

A. Pavement-Marking Paint: Based on a mixture of modified Alkyd resin and chlorinated rubber.

B. Select colors from options in first subparagraph below; show locations of each on Drawings if

more than one color is required.

a. Color: Standard colour as per manufacturers colour chart.

PART 3 - EXECUTION

3.1 EXAMINATION

A. Examine substrates, with Installer present, for compliance with requirements and for other

conditions affecting performance of traffic coatings.

1. For the record, prepare written report, endorsed by Installer, listing conditions detrimental

to performance.

2. Verify compatibility with and suitability of substrates.

3. Begin coating application only after minimum concrete curing and drying period

recommended by traffic coating manufacturer has passed, after unsatisfactory conditions

have been corrected, and after surfaces are dry.

4. Verify that substrates are visibly dry and free of moisture using either of the following

options:

a. Test for moisture vapor transmission by plastic sheet method according to

ASTM D 4263.

b. Test for moisture content by measuring with an electronic moisture meter.

5. Application of coating indicates acceptance of surfaces and conditions.

3.2 PREPARATION

A. Clean and prepare substrates according to ASTM C 1127 and manufacturer's written

recommendations to produce clean, dust-free, dry substrate for traffic coating application.

B. Mask adjoining surfaces not receiving traffic coatings, deck drains, and other deck substrate

penetrations to prevent spillage, leaking, and migration of coatings.

Division 07 Section 071800 Page 7 of 9 Traffic Coatings for Exposed Decks

Project: DMS No. 145117 Deira Islands – Construction of Deira Mall,

DEIRA MALL

Works: LG+G+2 COMMERCIAL BUILDING – PALM DEIRA, DUBAI, UAE

Title: DOCUMENT VOLUME 02.01

GENERAL SPECIFICATIONS ARCHITECTURE & INTERIOR DESIGN

C. Concrete Substrates: Using a Captive Blasting Machine, mechanically prepare concrete surfaces

to a uniform profile according to ASTM D 4259. Do not acid etch.

1. Remove grease, oil, paints, and other penetrating contaminants from concrete.

2. Remove concrete fins, ridges, and other projections.

3. Remove laitance, glaze, efflorescence, curing compounds, concrete hardeners, form-

release agents, and other incompatible materials that might affect coating adhesion.

4. Remove remaining loose material to provide a sound surface, and clean surfaces

according to ASTM D 4258.

3.3 TERMINATIONS AND PENETRATIONS

A. Prepare vertical and horizontal surfaces at terminations and penetrations through traffic coatings

and at expansion joints, drains, and sleeves according to ASTM C 1127 and manufacturer's

written recommendations.

B. Provide sealant cants at penetrations and at reinforced and non-reinforced, deck-to-wall butt

joints.

C. Terminate edges of deck-to-deck expansion joints with preparatory base-coat strip.

3.4 JOINT AND CRACK TREATMENT

A. Prepare, treat, rout, and fill joints and cracks in substrates according to ASTM C 1127 and

manufacturer's written recommendations. Before coating surfaces, remove dust and dirt from

joints and cracks according to ASTM D 4258.

1. Comply with recommendations in ASTM C 1193 for joint-sealant installation.

3.5 TRAFFIC COATING APPLICATION

A. Apply traffic coating material according to ASTM C 1127 and manufacturer's written

recommendations.

1. Start traffic coating application in presence of manufacturer's technical representative.

2. Verify that wet film thickness of each component coat complies with requirements of the

Manufacturers recommendations (random sampling).

B. Apply traffic coatings to prepared wall terminations and vertical surfaces to height indicated,

and omit aggregate on vertical surfaces.

C. Cure traffic coatings according to manufacturer's written recommendations. Prevent

contamination and damage during application and curing stages.

3.6 PAVEMENT MARKINGS

Division 07 Section 071800 Page 8 of 9 Traffic Coatings for Exposed Decks

Project: DMS No. 145117 Deira Islands – Construction of Deira Mall,

DEIRA MALL

Works: LG+G+2 COMMERCIAL BUILDING – PALM DEIRA, DUBAI, UAE

Title: DOCUMENT VOLUME 02.01

GENERAL SPECIFICATIONS ARCHITECTURE & INTERIOR DESIGN

A. Do not apply traffic paint for striping and other markings until traffic coating has cured

according to manufacturer's written recommendations.

B. Apply traffic paint for striping and other markings with mechanical equipment to produce

uniform straight edges. Apply at manufacturer's recommended rates for a minimum dry film

thickness of 100 microns (0.1mm).

3.7 FIELD QUALITY CONTROL

A. Final Traffic Coating Inspection: Arrange for traffic coating manufacturer's technical personnel

to inspect membrane installation on completion.

1. Notify Architect or Owner 48 hours in advance of date and time of inspection.

B. Additional testing and inspecting, at Contractor's expense, will be performed to determine

compliance of replaced or additional work with specified requirements.

3.8 PROTECTING AND CLEANING

A. Protect traffic coatings from damage and wear during remainder of construction period.

B. Clean spillage from adjacent construction using cleaning agents and procedures recommended

by manufacturer of affected construction.

END OF SECTION 071800

Division 07 Section 071800 Page 9 of 9 Traffic Coatings for Exposed Decks

Potrebbero piacerti anche

- An RambTel Monopole Presentation 280111Documento29 pagineAn RambTel Monopole Presentation 280111Timmy SurarsoNessuna valutazione finora

- Plaster Work, Renders and Screeds PDFDocumento23 paginePlaster Work, Renders and Screeds PDFDiana Alexandra Comaromi0% (1)

- Intermediate Accounting (15th Edition) by Donald E. Kieso & Others - 2Documento11 pagineIntermediate Accounting (15th Edition) by Donald E. Kieso & Others - 2Jericho PedragosaNessuna valutazione finora

- Ceramic TilingDocumento11 pagineCeramic TilingGhayas JawedNessuna valutazione finora

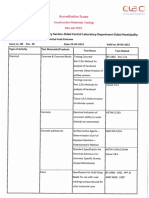

- SCOPE+OF+ACCREDITATION (Construction+Materials+Testing) DCL TestingDocumento34 pagineSCOPE+OF+ACCREDITATION (Construction+Materials+Testing) DCL TestingGhayas JawedNessuna valutazione finora

- Deira Mall Main Works BILLS OF QUANTITIES - Tender Addendum Revision T08Documento1 paginaDeira Mall Main Works BILLS OF QUANTITIES - Tender Addendum Revision T08Ghayas JawedNessuna valutazione finora

- Waterproofing (Cementitious+HDPE)Documento12 pagineWaterproofing (Cementitious+HDPE)masahinNessuna valutazione finora

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDa EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNessuna valutazione finora

- Tiling WorksDocumento21 pagineTiling WorksGhayas JawedNessuna valutazione finora

- Fluid Applied WaterproofingDocumento8 pagineFluid Applied WaterproofingHamza MamiNessuna valutazione finora

- Cladding Specifications - Ifc Material SpecsDocumento4 pagineCladding Specifications - Ifc Material SpecsGhayas JawedNessuna valutazione finora

- Termination LetterDocumento2 pagineTermination Letterultakam100% (1)

- SPH4U Assignment - The Wave Nature of LightDocumento2 pagineSPH4U Assignment - The Wave Nature of LightMatthew GreesonNessuna valutazione finora

- 5 Star Hotels in Portugal Leads 1Documento9 pagine5 Star Hotels in Portugal Leads 1Zahed IqbalNessuna valutazione finora

- Sheet Membrance Water ProofingDocumento6 pagineSheet Membrance Water ProofingphilipyapNessuna valutazione finora

- ID Specs - CarpetDocumento5 pagineID Specs - CarpetGhayas JawedNessuna valutazione finora

- SECTION 09 96 00 High Performance Coatings GeneralDocumento8 pagineSECTION 09 96 00 High Performance Coatings Generalraja qammarNessuna valutazione finora

- TLE - IA - Carpentry Grades 7-10 CG 04.06.2014Documento14 pagineTLE - IA - Carpentry Grades 7-10 CG 04.06.2014RickyJeciel100% (2)

- BS 8541-1-2012Documento70 pagineBS 8541-1-2012Johnny MongesNessuna valutazione finora

- Section 071800 - Traffic Coatings: As Revised by Addendum No. 1 & Addendum No. 2 MAY 25, 2012Documento8 pagineSection 071800 - Traffic Coatings: As Revised by Addendum No. 1 & Addendum No. 2 MAY 25, 2012rheriNessuna valutazione finora

- 096723-Resinous Floor SpecsDocumento7 pagine096723-Resinous Floor SpecsGhayas JawedNessuna valutazione finora

- January - 2021 - FinalDocumento13 pagineJanuary - 2021 - FinalMohammed FasilNessuna valutazione finora

- SECTION 07180 Traffic Coatings Part 1 General: 1 Inch 4 by 8 InchesDocumento6 pagineSECTION 07180 Traffic Coatings Part 1 General: 1 Inch 4 by 8 InchesMoath AlhajiriNessuna valutazione finora

- Related SpecsDocumento13 pagineRelated SpecsAhmed GhariebNessuna valutazione finora

- BMW Technical Guideline Corrosion ProtectionDocumento5 pagineBMW Technical Guideline Corrosion ProtectionJiahui WuNessuna valutazione finora

- Jotun Gbs 099123 Interior Painting-Revised Nov 2020 1Documento12 pagineJotun Gbs 099123 Interior Painting-Revised Nov 2020 1JISHNU TKNessuna valutazione finora

- 09 70 00mmmDocumento8 pagine09 70 00mmmAngela MaeNessuna valutazione finora

- Section 02870 Site FurnishingsDocumento19 pagineSection 02870 Site FurnishingsMØhãmmed ØwięsNessuna valutazione finora

- Volume Ii: Specifications (Exterior Painting) : Issue: FINAL, 14th FEB 2013Documento4 pagineVolume Ii: Specifications (Exterior Painting) : Issue: FINAL, 14th FEB 2013Ahmad SaadeldinNessuna valutazione finora

- SYS3PDocumento6 pagineSYS3PBaugh Graphic DesignNessuna valutazione finora

- Architecture Specifications For W - FDocumento12 pagineArchitecture Specifications For W - FDileepa DissanayakeNessuna valutazione finora

- HydroStop System Spec PDFDocumento21 pagineHydroStop System Spec PDFRafaelNessuna valutazione finora

- Volume Ii: Specifications (Water Proofing) : Issue: FINAL, 14th FEB 2013Documento11 pagineVolume Ii: Specifications (Water Proofing) : Issue: FINAL, 14th FEB 2013Ahmad SaadeldinNessuna valutazione finora

- CCCC Et Ha Spec ST 650 00 Reply BDocumento5 pagineCCCC Et Ha Spec ST 650 00 Reply B黄赛赛Nessuna valutazione finora

- Joint SealantsDocumento17 pagineJoint Sealantsy2kareinNessuna valutazione finora

- SECTION 07 24 00 Exterior Insulation and Finish SystemsDocumento12 pagineSECTION 07 24 00 Exterior Insulation and Finish SystemsJuanPaoloYbañezNessuna valutazione finora

- Section 07572 Athletic Surface 3Documento4 pagineSection 07572 Athletic Surface 3bravo deltafoxNessuna valutazione finora

- 03 06 00 - Schedules For ConcreteDocumento5 pagine03 06 00 - Schedules For ConcreteHardeo Dennis ChattergoonNessuna valutazione finora

- University of Houston Master Construction SpecificationsDocumento5 pagineUniversity of Houston Master Construction SpecificationsTaher AmmarNessuna valutazione finora

- SECTION 07 13 52 Modified Bituminous Sheet WaterproofingDocumento7 pagineSECTION 07 13 52 Modified Bituminous Sheet WaterproofingJuanPaoloYbañezNessuna valutazione finora

- SYS3BSWDocumento6 pagineSYS3BSWBaugh Graphic DesignNessuna valutazione finora

- ASP U91S42 30 10 GacoFlex U91 S4200 Over AsphaltDocumento6 pagineASP U91S42 30 10 GacoFlex U91 S4200 Over Asphaltwebhareggebru06Nessuna valutazione finora

- Spec 092400 (Plastering Works)Documento11 pagineSpec 092400 (Plastering Works)Ayman BadrNessuna valutazione finora

- Section 07141 Cold Fluid Applied WaterproofingDocumento6 pagineSection 07141 Cold Fluid Applied WaterproofingMØhãmmed ØwięsNessuna valutazione finora

- 07 91 26 SealantDocumento10 pagine07 91 26 SealantshajbabyNessuna valutazione finora

- Section 033000 - Cast-In-Place ConcreteDocumento39 pagineSection 033000 - Cast-In-Place ConcreteMIL RABNessuna valutazione finora

- Joint Sealants - MSTDocumento9 pagineJoint Sealants - MSTwafikmh4Nessuna valutazione finora

- Specification Concrete Deck/Between SlabDocumento6 pagineSpecification Concrete Deck/Between SlabBaugh Graphic DesignNessuna valutazione finora

- 09 25 13 - Acrylic Plastering PDFDocumento8 pagine09 25 13 - Acrylic Plastering PDFmasoodaeNessuna valutazione finora

- Eme745 Csi 3 Part Guide Specification RTF 2577Documento8 pagineEme745 Csi 3 Part Guide Specification RTF 2577Eldhose VargheseNessuna valutazione finora

- Painting For Structural Steel: SECTION 09972Documento8 paginePainting For Structural Steel: SECTION 09972kuganNessuna valutazione finora

- 03 05 00iseDocumento5 pagine03 05 00isemp4 ghad mp4Nessuna valutazione finora

- Section 035440 - Cement-Based ScreedDocumento11 pagineSection 035440 - Cement-Based ScreedWENDING HUNessuna valutazione finora

- SECTION 07 54 19 Polyvinyl-Chloride (PVC) RoofingDocumento23 pagineSECTION 07 54 19 Polyvinyl-Chloride (PVC) RoofingJuanPaoloYbañezNessuna valutazione finora

- Specification Concrete Deck/Between Slab (Reinforced)Documento6 pagineSpecification Concrete Deck/Between Slab (Reinforced)Baugh Graphic DesignNessuna valutazione finora

- Guide Specification Walls, Interior, Wood or Metal Studs, Cementitious Backer Unit, Latex-Portland Cement Mortar, TCNA W244C-07Documento5 pagineGuide Specification Walls, Interior, Wood or Metal Studs, Cementitious Backer Unit, Latex-Portland Cement Mortar, TCNA W244C-07alex_geus5080Nessuna valutazione finora

- EBVMBDocumento5 pagineEBVMBBaugh Graphic DesignNessuna valutazione finora

- SSH/14040/Main Contract Works 099600 / 1 Document III High-Performance CoatingsDocumento14 pagineSSH/14040/Main Contract Works 099600 / 1 Document III High-Performance CoatingsHussain GodhrawalaNessuna valutazione finora

- Jotun Gbs 099113 Exterior Painting - Revised Nov 2020 2Documento14 pagineJotun Gbs 099113 Exterior Painting - Revised Nov 2020 2Muhammad NoumanNessuna valutazione finora

- Section 321373 - Concrete Paving Joint Sealants: Part 1 - GeneralDocumento5 pagineSection 321373 - Concrete Paving Joint Sealants: Part 1 - Generalery achjariNessuna valutazione finora

- Acrylic Liquid Applied Over Mod BitDocumento10 pagineAcrylic Liquid Applied Over Mod BitTaher AmmarNessuna valutazione finora

- 63 6205 01 Architectural Specifications Section 07 92 00Documento14 pagine63 6205 01 Architectural Specifications Section 07 92 00Jovenal TuplanoNessuna valutazione finora

- Floor MatsDocumento3 pagineFloor MatsGhayas JawedNessuna valutazione finora

- Part 1 - General: Coatings Manual HRSD Section 7 Standard Coatings SpecificationsDocumento49 paginePart 1 - General: Coatings Manual HRSD Section 7 Standard Coatings SpecificationswilliamjdtNessuna valutazione finora

- King Abdullah Bin Abdulaziz Project Third Saudi Expansion of The Holy Haram Makkah and Surrounding AreasDocumento5 pagineKing Abdullah Bin Abdulaziz Project Third Saudi Expansion of The Holy Haram Makkah and Surrounding AreaswooderNessuna valutazione finora

- Volume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Documento8 pagineVolume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Ahmad Saadeldin100% (1)

- SECTION 07 92 00 Joint SealantsDocumento13 pagineSECTION 07 92 00 Joint SealantsJuanPaoloYbañezNessuna valutazione finora

- Guide Specification: NeoflexDocumento4 pagineGuide Specification: NeoflexruloNessuna valutazione finora

- Project Specification: Exterior PaintingDocumento6 pagineProject Specification: Exterior PaintingSoumojit SamantaNessuna valutazione finora

- SpecsDocumento6 pagineSpecsTAHANINessuna valutazione finora

- 03930-Concrete Repair-Rev.0 PDFDocumento16 pagine03930-Concrete Repair-Rev.0 PDFMithun UdayanarayanaNessuna valutazione finora

- 07 10 00 Dampproofing and WaterproofingDocumento7 pagine07 10 00 Dampproofing and WaterproofingshajbabyNessuna valutazione finora

- PRDT MasterSpec 074213 23 3A Composites ALUCOBOND U1 4 24 20Documento12 paginePRDT MasterSpec 074213 23 3A Composites ALUCOBOND U1 4 24 20Mikel Lasa MuñagorriNessuna valutazione finora

- Spare Parts Requirement On Construction ProjectDocumento67 pagineSpare Parts Requirement On Construction ProjectGhayas JawedNessuna valutazione finora

- Vendor Performance Service Report SupplierDocumento14 pagineVendor Performance Service Report SupplierGhayas JawedNessuna valutazione finora

- Metal FabricationsDocumento10 pagineMetal FabricationsGhayas JawedNessuna valutazione finora

- Internal Wooden Door SnaggingDocumento18 pagineInternal Wooden Door SnaggingGhayas JawedNessuna valutazione finora

- External Finishes DetailsDocumento1 paginaExternal Finishes DetailsGhayas JawedNessuna valutazione finora

- Retractable Roofing Comparison Sheet: Specs Vol 02.04/3.4.4 Specs Vol 02.01/133457/4.1.L.2 (ASHRAE 90.1)Documento2 pagineRetractable Roofing Comparison Sheet: Specs Vol 02.04/3.4.4 Specs Vol 02.01/133457/4.1.L.2 (ASHRAE 90.1)Ghayas JawedNessuna valutazione finora

- Tiles For Stone and Slates ComparisonDocumento2 pagineTiles For Stone and Slates ComparisonGhayas JawedNessuna valutazione finora

- Tiles For RAK ComparisonDocumento2 pagineTiles For RAK ComparisonGhayas JawedNessuna valutazione finora

- Floor MatsDocumento3 pagineFloor MatsGhayas JawedNessuna valutazione finora

- Sample Quality MetricsDocumento16 pagineSample Quality MetricsGhayas JawedNessuna valutazione finora

- External NCR MonitoringDocumento7 pagineExternal NCR MonitoringGhayas JawedNessuna valutazione finora

- Steel Staircase and Cladding DetailsDocumento12 pagineSteel Staircase and Cladding DetailsGhayas JawedNessuna valutazione finora

- Bison Kit Adhesive GlueDocumento1 paginaBison Kit Adhesive GlueGhayas JawedNessuna valutazione finora

- MAS-251 OAI-TS-025-Silicon MSDDocumento19 pagineMAS-251 OAI-TS-025-Silicon MSDGhayas JawedNessuna valutazione finora

- DCD Material Test Standards - September - 2018Documento128 pagineDCD Material Test Standards - September - 2018Ghayas JawedNessuna valutazione finora

- DCL Construction Material Testing StandardsDocumento43 pagineDCL Construction Material Testing StandardsGhayas JawedNessuna valutazione finora

- Ucm6510 Usermanual PDFDocumento393 pagineUcm6510 Usermanual PDFCristhian ArecoNessuna valutazione finora

- Lactobacillus Acidophilus - Wikipedia, The Free EncyclopediaDocumento5 pagineLactobacillus Acidophilus - Wikipedia, The Free Encyclopediahlkjhlkjhlhkj100% (1)

- Shubham Tonk - ResumeDocumento2 pagineShubham Tonk - ResumerajivNessuna valutazione finora

- Maths PDFDocumento3 pagineMaths PDFChristina HemsworthNessuna valutazione finora

- COOKERY10 Q2W4 10p LATOJA SPTVEDocumento10 pagineCOOKERY10 Q2W4 10p LATOJA SPTVECritt GogolinNessuna valutazione finora

- Republic of The Philippines National Capital Judicial Region Regional Trial Court Manila, Branch 1Documento4 pagineRepublic of The Philippines National Capital Judicial Region Regional Trial Court Manila, Branch 1brendamanganaanNessuna valutazione finora

- Cancellation of Deed of Conditional SalDocumento5 pagineCancellation of Deed of Conditional SalJohn RositoNessuna valutazione finora

- Jerome4 Sample Chap08Documento58 pagineJerome4 Sample Chap08Basil Babym100% (7)

- Microsoft Word - Claimants Referral (Correct Dates)Documento15 pagineMicrosoft Word - Claimants Referral (Correct Dates)Michael FourieNessuna valutazione finora

- Introduction To Motor DrivesDocumento24 pagineIntroduction To Motor Drivessukhbat sodnomdorjNessuna valutazione finora

- Unit-5 Shell ProgrammingDocumento11 pagineUnit-5 Shell ProgrammingLinda BrownNessuna valutazione finora

- Chapter 5Documento3 pagineChapter 5Showki WaniNessuna valutazione finora

- Capital Expenditure DecisionDocumento10 pagineCapital Expenditure DecisionRakesh GuptaNessuna valutazione finora

- Case Assignment 2Documento5 pagineCase Assignment 2Ashish BhanotNessuna valutazione finora

- Presentation Report On Customer Relationship Management On SubwayDocumento16 paginePresentation Report On Customer Relationship Management On SubwayVikrant KumarNessuna valutazione finora

- Personal Best B1+ Unit 1 Reading TestDocumento2 paginePersonal Best B1+ Unit 1 Reading TestFy FyNessuna valutazione finora

- Hexoskin - Information For Researchers - 01 February 2023Documento48 pagineHexoskin - Information For Researchers - 01 February 2023emrecan cincanNessuna valutazione finora

- ATPDraw 5 User Manual UpdatesDocumento51 pagineATPDraw 5 User Manual UpdatesdoniluzNessuna valutazione finora

- Cabling and Connection System PDFDocumento16 pagineCabling and Connection System PDFLyndryl ProvidoNessuna valutazione finora

- Peoria County Jail Booking Sheet For Oct. 7, 2016Documento6 paginePeoria County Jail Booking Sheet For Oct. 7, 2016Journal Star police documents50% (2)

- Privacy: Based On Slides Prepared by Cyndi Chie, Sarah Frye and Sharon Gray. Fifth Edition Updated by Timothy HenryDocumento50 paginePrivacy: Based On Slides Prepared by Cyndi Chie, Sarah Frye and Sharon Gray. Fifth Edition Updated by Timothy HenryAbid KhanNessuna valutazione finora

- Accomplishment ReportDocumento1 paginaAccomplishment ReportMaria MiguelNessuna valutazione finora

- Rofi Operation and Maintenance ManualDocumento3 pagineRofi Operation and Maintenance ManualSteve NewmanNessuna valutazione finora