Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

KBR Inspection Test Plan For Shop Fabricated Piping

Caricato da

Syafril AkbarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

KBR Inspection Test Plan For Shop Fabricated Piping

Caricato da

Syafril AkbarCopyright:

Formati disponibili

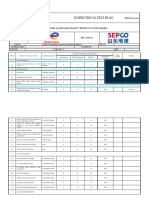

KBR

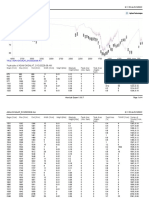

INSPECTION TEST PLAN FOR SHOP FABRICATED PIPING

NO. INSPECTION ACTIVITY Level 1 Level 2 Level 3

Selected Level of Inspection >

1 PRE-INSPECTION MEETING H H H

2 DOCUMENTATION REVIEW

Vendor Quality Plan (To be submitted prior to Pre-Inspection Meeting) R R R

Manufacturing Schedule R R R

List of Major Sub-Orders R R R

Material Substitution Requests R R R

Material Test Reports R R R

NDE Procedures R R R

NDE Personnel Qualifications R R R

Welding Procedures (WPS's & PQR's) R R R

Welder Performance Qualifications R R R

PWHT Procedures R R R

Hydrostatic Test Procedure R R R

Manufacturer's Data Report R R R

3 FABRICATION INSPECTION (In Process)

Material Examination SW SW SW

Material Traceability - Transfer of Marking SW SW SW

Bending & Forming SW/R SW/R SW/R

Monitor Production Welding SW SW SW

Flanged Ends & Connections SW SW SW

Butt Welded Ends & Connections SW SW SW

Gasket Surfaces SW SW SW

Gaskets SW SW SW

Bolting SW SW SW

Post Weld Heat Treatment W/R SW/R R

4 NON-DESTRUCTIVE EXAMINATION & SPECIAL TESTING

Radiography (Review all Radiographs) R R R

Ultrasonic Examination W/R SW/R SW/R

Magnetic Particle Examination W/R SW/R SW/R

Liquid Penetrant Examination W/R SW/R SW/R

Positive Material Identification (Alloy Verification) W/R SW/R R

Hardness Testing W/R SW/R SW/R

Chemical Analysis W/R SW/R R

Ferrite Testing W/R SW/R R

Corrosion Tests W/R SW/R R

Impact Tests W/R SW/R SW/R

Other Tests

Note: H = Hold Point

W = Witness Point

SW = Spot Witness

R = Review

N/A = Not Applicable

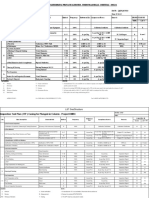

KBR

INSPECTION TEST PLAN FOR SHOP FABRICATED PIPING

NO. INSPECTION ACTIVITY Level 1 Level 2 Level 3

Selected Level of Inspection >

5 FINAL VISUAL & DIMENSIONAL INSPECTION (Random 10-20%) H H H

6 PRESSURE & LEAK TESTING (Random 10-20%)

Pneumatic Testing of Reinforcing Pads W/R SW/R SW/R

Hydrostatic Test (If Required) H W SW/R

Pneumatic Test (If Required) H W SW/R

Other Tests

7 LINING INSPECTION (Random 10-20%)

Corrosion Resistant Overlay or Cladding W W SW

Refractory Lining H H W

Rubber, Phenolic, Glass H H W

8 PAINTING, MARKING & SHIPPING INSPECTION (Random 10-20%)

Cleaning, Dry Out & Surface Preparation H H H

Painting, Preservation & Marking W SW SW

Flange and Butt Weld End Shipping Protection W SW SW

9 MANUFACTURER'S DATA REPORTS H H H

10 COMMENTS

If a discrepancy exists between this document and the applicable Engineering

drawings, the information listed on the Engineering documents shall take

precedent.

If discrepancies are detected during random sampling, additional inspection

shall be conducted to verify compliance.

Note: H = Hold Point

W = Witness Point

SW = Spot Witness

R = Review

N/A = Not Applicable

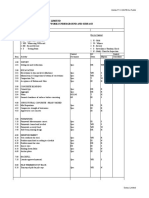

KBR

INSPECTION TEST PLAN FOR SHOP FABRICATED PIPING

Level 4

N/A

R

R

R

R

R

N/A

N/A

R

R

N/A

R

R

N/A

R

N/A

N/A

SW

SW

SW

SW

N/A

R

R

R

R

R

R

R

R

R

R

R

Note: H = Hold Point

W = Witness Point

SW = Spot Witness

R = Review

N/A = Not Applicable

KBR

INSPECTION TEST PLAN FOR SHOP FABRICATED PIPING

Level 4

R

R

R

SW

SW

SW

SW

SW

SW

Note: H = Hold Point

W = Witness Point

SW = Spot Witness

R = Review

N/A = Not Applicable

Potrebbero piacerti anche

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachDa EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNessuna valutazione finora

- Itp Line PipeDocumento8 pagineItp Line Pipekaml100% (1)

- Jeritp P 170300Documento1 paginaJeritp P 170300NicolaMasteNessuna valutazione finora

- Itp-Shop Fabricated PipingDocumento4 pagineItp-Shop Fabricated PipingkamlNessuna valutazione finora

- Mar HM 18.06.22Documento302 pagineMar HM 18.06.22özgen bölükNessuna valutazione finora

- Itp-Fbe Pipe CoatingDocumento4 pagineItp-Fbe Pipe CoatingpertmasterNessuna valutazione finora

- Itp Pipe SupportsDocumento4 pagineItp Pipe SupportskamlNessuna valutazione finora

- Inspeksi Trafo - Sabtu SiangDocumento24 pagineInspeksi Trafo - Sabtu SiangJAN OJANNessuna valutazione finora

- Inspection Test Plan PV Nozzle Modification/AlterationDocumento4 pagineInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNessuna valutazione finora

- Itp Concrete CoatingDocumento4 pagineItp Concrete Coatingkaml100% (1)

- # Inspection Test Plan #: Dokumen EngineeringDocumento2 pagine# Inspection Test Plan #: Dokumen EngineeringDIANTORONessuna valutazione finora

- Itp For Tank Fabrication Installation Work1 Rev02 PDFDocumento22 pagineItp For Tank Fabrication Installation Work1 Rev02 PDFMichelNessuna valutazione finora

- Mvtp11-Ct Supervision RelayDocumento2 pagineMvtp11-Ct Supervision RelayTHILAKKUMARNessuna valutazione finora

- Section 7 Test and InspectionDocumento12 pagineSection 7 Test and InspectionThaigroup CementNessuna valutazione finora

- Inspection PlanDocumento1 paginaInspection PlanMohit SharmaNessuna valutazione finora

- Itp For Tank Fabrication Installation Work1 Rev02Documento22 pagineItp For Tank Fabrication Installation Work1 Rev02au9t5teyrNessuna valutazione finora

- SR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignDocumento1 paginaSR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignAlpine ProjectsNessuna valutazione finora

- Process Piping Inspection and Test PlanDocumento6 pagineProcess Piping Inspection and Test Planmanoj thakkarNessuna valutazione finora

- Inspection Test Plan LPSDocumento3 pagineInspection Test Plan LPSsafetyofficer752Nessuna valutazione finora

- Itp Internal CoatingDocumento4 pagineItp Internal CoatingkamlNessuna valutazione finora

- KBR Inspection Test Plan For Instruments: Level 1 Level 2 Level 3Documento2 pagineKBR Inspection Test Plan For Instruments: Level 1 Level 2 Level 3kamlNessuna valutazione finora

- ITP Electrical New MCCDocumento3 pagineITP Electrical New MCCMpuwh 'Riczky Syaputra'Nessuna valutazione finora

- ITP PaintingDocumento3 pagineITP PaintingAnoop ChandranNessuna valutazione finora

- Itp SwitchgearDocumento3 pagineItp Switchgearmuhammad afrizalNessuna valutazione finora

- SFDSF PDFDocumento3 pagineSFDSF PDFbishnu sahNessuna valutazione finora

- ITP Heat ExchangerDocumento3 pagineITP Heat ExchangerĐỗ Thị Huyền100% (3)

- Inspection and Test Plan For Switchgear: Before ManufacturingDocumento5 pagineInspection and Test Plan For Switchgear: Before ManufacturingELE FutureWillNessuna valutazione finora

- ITP Piping Stainless Steel (REV2.0)Documento3 pagineITP Piping Stainless Steel (REV2.0)mohd as shahiddin jafriNessuna valutazione finora

- Itp GeneratorDocumento4 pagineItp Generatormuhammad afrizalNessuna valutazione finora

- ITP For PV Mounting Structure and Module Installation-2023!05!19Documento3 pagineITP For PV Mounting Structure and Module Installation-2023!05!19Mohammad BayisNessuna valutazione finora

- ITP For Pipeline (Sampel)Documento5 pagineITP For Pipeline (Sampel)Reza RkndNessuna valutazione finora

- Mbch12-Differential RelayDocumento4 pagineMbch12-Differential RelayTHILAKKUMARNessuna valutazione finora

- Inspection and Test Plan For Grouting of Equipments / StructuresDocumento2 pagineInspection and Test Plan For Grouting of Equipments / StructuresHariom GuptaNessuna valutazione finora

- QAP - Filter Press FinalDocumento1 paginaQAP - Filter Press FinalStepworthNessuna valutazione finora

- ITP-PRESSURE VESSEL ExistingDocumento2 pagineITP-PRESSURE VESSEL ExistingArisNessuna valutazione finora

- Itp WeldingDocumento2 pagineItp WeldingAnoop ChandranNessuna valutazione finora

- UNQ-00-K-143b - 001-EQ-017 - Inspection and Test Plan For U.G. FuelGas Pipe InstallationDocumento3 pagineUNQ-00-K-143b - 001-EQ-017 - Inspection and Test Plan For U.G. FuelGas Pipe InstallationrakibnjtechNessuna valutazione finora

- Weir Projects QCPDocumento1 paginaWeir Projects QCPJessicaNessuna valutazione finora

- Inspection and Test Plan Rotating Equipment:: LPG PumpDocumento4 pagineInspection and Test Plan Rotating Equipment:: LPG PumpErico Haryanto LumbanrajaNessuna valutazione finora

- Inspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyDocumento6 pagineInspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyAhmad DagamsehNessuna valutazione finora

- Itp Electric MotorsDocumento4 pagineItp Electric Motorskaml100% (1)

- Inspection Testing Plan (ITP)Documento1 paginaInspection Testing Plan (ITP)Kdown 99100% (1)

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocumento4 pagineRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksVijaya Barani100% (1)

- ITP For Sprinkler and Spary SystemDocumento6 pagineITP For Sprinkler and Spary System梁奇龙100% (2)

- IRT - CWC Coating Anode InstallationDocumento3 pagineIRT - CWC Coating Anode InstallationPrafulla PatilNessuna valutazione finora

- Inspection and Test Plan For Steel StructureDocumento1 paginaInspection and Test Plan For Steel Structureeva maniceNessuna valutazione finora

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Documento2 pagineVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- ITP (Can Gas)Documento1 paginaITP (Can Gas)Kemas Muhandis MancapaniNessuna valutazione finora

- Quality Control in Fabricaton 1 Quality Assurance Plan 2 Inspection Report 3 NDT Report 4Documento13 pagineQuality Control in Fabricaton 1 Quality Assurance Plan 2 Inspection Report 3 NDT Report 4Varun MalhotraNessuna valutazione finora

- Vibrating Screen QAP-17Documento8 pagineVibrating Screen QAP-17Mohammad AdilNessuna valutazione finora

- Attach-2 ITP For Building WaterDocumento29 pagineAttach-2 ITP For Building WaterSukalyan BasuNessuna valutazione finora

- Itp Structural SteelDocumento4 pagineItp Structural SteelkamlNessuna valutazione finora

- Dayang Enterprise Sdn. BHD.: Inspection and Test Plan (Helideck Netting Frame Modification)Documento2 pagineDayang Enterprise Sdn. BHD.: Inspection and Test Plan (Helideck Netting Frame Modification)AmyNessuna valutazione finora

- Inspection-and-Test-Plan-for-Fabrication and Erection of Structural SteelDocumento4 pagineInspection-and-Test-Plan-for-Fabrication and Erection of Structural SteelVinayaga MoorthiNessuna valutazione finora

- Quality Assurance Protocol: Raw MaterialDocumento2 pagineQuality Assurance Protocol: Raw MaterialShah Newaz KabirNessuna valutazione finora

- Contractor: Sotau Limited Client: Lubambe Copper Mine Limited Project: Civil Construction Works Underground and SurfaceDocumento2 pagineContractor: Sotau Limited Client: Lubambe Copper Mine Limited Project: Civil Construction Works Underground and SurfaceBornfacetumba SotauNessuna valutazione finora

- KBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3Documento4 pagineKBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3kamlNessuna valutazione finora

- Inspection and Test Plan For Switchgear: Before ManufacturingDocumento5 pagineInspection and Test Plan For Switchgear: Before ManufacturingzsmithNessuna valutazione finora

- In Uence of Pre-Gelatinised Maize Starch On The Rheology, Microstructure and Processing of Imitation CheeseDocumento8 pagineIn Uence of Pre-Gelatinised Maize Starch On The Rheology, Microstructure and Processing of Imitation CheeseLina1929Nessuna valutazione finora

- Converting Saltwater Into Drinkwater As A Solution For Global Crisis in A Fresh Water Needs Using Green TechnologyDocumento4 pagineConverting Saltwater Into Drinkwater As A Solution For Global Crisis in A Fresh Water Needs Using Green TechnologyNurrahmah AzizahNessuna valutazione finora

- Soil Analysis Bitupan LastDocumento25 pagineSoil Analysis Bitupan Lastbitupon boraNessuna valutazione finora

- Dna Extraction and SpoolingDocumento4 pagineDna Extraction and SpoolingHas AlqisNessuna valutazione finora

- Siemens Power Cables Amp Their Applications PDFDocumento240 pagineSiemens Power Cables Amp Their Applications PDFEsteban De la CruzNessuna valutazione finora

- White LED DatasheetDocumento22 pagineWhite LED DatasheettuzarahulNessuna valutazione finora

- Asam Oksalat PDFDocumento4 pagineAsam Oksalat PDFfadhilNessuna valutazione finora

- Life Cycle of A StarDocumento22 pagineLife Cycle of A Starေအာင္ ေက်ာ္ စြာNessuna valutazione finora

- Basics of Pipe Stress AnalysisDocumento6 pagineBasics of Pipe Stress AnalysisKhuldoonNessuna valutazione finora

- Specific Weight PDFDocumento7 pagineSpecific Weight PDFengrjeffNessuna valutazione finora

- Overview : Process of ElectrolysisDocumento5 pagineOverview : Process of Electrolysisn73686861Nessuna valutazione finora

- Barrel Casing Type Boiler Feed Pump - SUZLONDocumento41 pagineBarrel Casing Type Boiler Feed Pump - SUZLONsen_subhasis_58100% (2)

- Tutorial FEPDocumento39 pagineTutorial FEPDr-Rehan Zafar ParachaNessuna valutazione finora

- Packaging in GlassDocumento18 paginePackaging in GlassEmmanuel AlemakaNessuna valutazione finora

- Section 1: Identification: Safety Data Sheet: Simple Green® All-Purpose CleanerDocumento5 pagineSection 1: Identification: Safety Data Sheet: Simple Green® All-Purpose CleanerHARIS SHAHIDNessuna valutazione finora

- 22.mohar Pal Meena GallDocumento11 pagine22.mohar Pal Meena GallVaidya NurNessuna valutazione finora

- Manual OsterDocumento22 pagineManual Osternaja_sjNessuna valutazione finora

- Salient Features of MycesmmDocumento59 pagineSalient Features of Mycesmmracing.phreak100% (2)

- Alpha-Lipoic Acid and Diabetic NeuropathyDocumento7 pagineAlpha-Lipoic Acid and Diabetic NeuropathyPedro Rodriguez PicazoNessuna valutazione finora

- 3 - Durability of Reinforced Concrete StructureDocumento24 pagine3 - Durability of Reinforced Concrete StructureyakaNessuna valutazione finora

- Helisea AcantoDocumento2 pagineHelisea AcantobirlograresNessuna valutazione finora

- Final Plant DesignDocumento31 pagineFinal Plant DesignRishya Prava ChatterjeeNessuna valutazione finora

- Avalanche Photodiodes PDFDocumento3 pagineAvalanche Photodiodes PDFcmenikarachchiNessuna valutazione finora

- Soal InstrumenDocumento7 pagineSoal InstrumenErvin CrespoNessuna valutazione finora

- Poly Ols For Polyurethane SDocumento6 paginePoly Ols For Polyurethane SA MahmoodNessuna valutazione finora

- Example CoagulFloccu1Documento3 pagineExample CoagulFloccu1Adarsh Agrawal100% (3)

- MSDS Colamine CdaDocumento3 pagineMSDS Colamine Cdamndmatt100% (2)

- Properties of Water WorksheetDocumento3 pagineProperties of Water WorksheetTaylor Delancey100% (1)

- Jee Main 2022 26 July Morning Shift Question Paper With Solutions PDFDocumento26 pagineJee Main 2022 26 July Morning Shift Question Paper With Solutions PDFALEKHYA KANCHIBHATLANessuna valutazione finora