Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Monitoring and Lab Analysis - Assays: David Bolzonella

Caricato da

Anonymous i9ytPrBlenDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Monitoring and Lab Analysis - Assays: David Bolzonella

Caricato da

Anonymous i9ytPrBlenCopyright:

Formati disponibili

University of Verona, Department of Biotechnology

Lecture 3

Monitoring and

lab analysis - assays

David Bolzonella

Jyvaskyla Summer School 2013 1

University of Verona, Department of Biotechnology

Contents

1. Why monitoring

2. Different monitoring approaches

3. Basic and sophisticated parameters for process

monitoring

4. Evaluation of the biogas potential (BMP) of a

substrate

Jyvaskyla Summer School 2013 2

University of Verona, Department of Biotechnology

First of all, answer the question ….

Why monitoring ?!

(credits: prof Juan Lema)

Jyvaskyla Summer School 2013 3

University of Verona, Department of Biotechnology

…. to really control the process !!!

If…

…then…

(credits: prof Juan Lema)

Jyvaskyla Summer School 2013 4

Anaerobic digestion:

a complex combination of biochemical and physical-chemical processes

University of Verona, Department of Biotechnology

Jyvaskyla Summer School 2013 5

University of Verona, Department of Biotechnology

“Primitive” monitoring

We can have a VERY basic monitoring, based on the

determination of the typical engineering parameters like

the organic loading rate (OLR, kgVS per m3 of reactor per

day) or the hydraulic retention time (HRT, days)…..

In this case, all we need to know is the volume of the

reactor, the flowrate fed and the total and volatile solids

concentration of the feed ….. The biogas flowrate ….

Uncreadibly, sometimes these are unknown …

Jyvaskyla Summer School 2013 6

University of Verona, Department of Biotechnology

However, to really “drive” the process, beside engineering

(operational) parameters, like temperature, hydraulic

retention time, organic loading rate … physical-chemical

parameters need to be regularly monitored to check the

state of the process (stability).

Among the most important we can remember here:

pH

alkalinity

volatile fatty acids concentration and speciation

biogas flowrate and composition

ammonia concentration

Jyvaskyla Summer School 2013 7

University of Verona, Department of Biotechnology

These are also called “stability parameters” as they are

helpful to define the “stable” operation of the

anaerobic biological process ….

Jyvaskyla Summer School 2013 8

University of Verona, Department of Biotechnology

These are also called “stability parameters” as they are

helpful to define the “stable” operation of the

anaerobic biological process ….

Jyvaskyla Summer School 2013 9

University of Verona, Department of Biotechnology

Which level of monitoring ?!

Keep it simple …

but do not exsagerate ….

Jyvaskyla Summer School 2013 10

University of Verona, Department of Biotechnology Simple monitoring (… but with some evident drawbakcs …)

(credits: prof Juan Lema)

Jyvaskyla Summer School 2013 11

University of Verona, Department of Biotechnology Sophisticated monitoring ( … but not that much … )

(credits: prof Juan Lema)

Jyvaskyla Summer School 2013 12

University of Verona, Department of Biotechnology Off – line monitoring

(credits: prof Juan Lema)

Jyvaskyla Summer School 2013 13

University of Verona, Department of Biotechnology On – line monitoring

Jyvaskyla Summer School 2013 14

University of Verona, Department of Biotechnology temperature

“BASIC” MONITORING

pH

temperature,

“MILD” MONITORING pH

total and partial alkalinity

temperature

pH

total and partial alkalinity

“HARD” MONITORING

VFA conc and composition

Biogas flowrate and composition

Any other parameter……………

Jyvaskyla Summer School 2013 15

Monitoring of pH

University of Verona, Department of Biotechnology

pH is a measure of H+ activity in an aqueous solution.

Because of its simplicity to be determined it is the

most used parameter for AD monitoring:

unfortunately, it is a “generic” parameter and almost

useless in most of the case (see below) !

“Normal” pH values for AD processes follow in the

range 6.5 – 8.5 but very different values can be found

in stable AD processes perfectly working: this is

because pH is the result of the presence several

compounds in the bulk

(ammonia, VFA, phosphates ….)

Jyvaskyla Summer School 2013 16

University of Verona, Department of Biotechnology Lab pH-meters (off-line) or industrial on-line systems can be

used for the purpose of pH measure

Jyvaskyla Summer School 2013 17

University of Verona, Department of Biotechnology

Please note that

In terms of routine monitoring, pH measurement

cannot form the sole indication of imminent failure,

because in medium or well-buffered solutions high VFA

concentration would have to form in order to cause a

detectable drop in pH, by which time failure would

already occur.

Consequently, direct measurement of either (or both)

VFA, partial and total alkalinity concentration is

necessary.

Jyvaskyla Summer School 2013 18

Monitoring of alkalinity

University of Verona, Department of Biotechnology

Alkalinity measures the capability of a solution to neutralize

acids and can be expressed using several different units

(typically calcium carbonate concentration).

In AD processes it is strongly influenced by the presence of

carbonate and bicarbonate (CO2 dissolved in water),

ammonia, phosphate, silicate, volatile fatty acids …. And is

generally very high (some g/L as CaCO3).

It is generally determined by tritation using 0.1 N HCl (or

another strong acid like H2SO4) at two equivalent points:

pH 5.75 partial alkalinity (PA)

pH 4.3 or total alkalinity (TA)

(or similar, see specific literature)

Jyvaskyla Summer School 2013 19

University of Verona, Department of Biotechnology

The difference between TA and PA is the so called IA

(intermediate alkalinity) and is related to VFA presence

pH 8

Partial

Alkalinity (pH 5.7),

Total due to OH-, NH3 ,

Alkalinity HCO3- , CO3=

(from pH

around 7-8

down to pH

4.3)

pH 5.7

“Volatile acid”

Alkalinity due to

pH 4.3 organic acids

(from pH 5.7 to 4.3)

Jyvaskyla Summer School 2013 20

Partial to total alkalinity ratio (Ripley et al., 1986)

University of Verona, Department of Biotechnology

They suggested the tritation of the digestate to two final

points: 5.75 and 4.3.

Then, the ratio (α) between the “VFA alkalinity”

(determined as the difference between alkalinity at pH

4.5 and 5.75, intermediate alkalinity) and the partial

alkalinity, determined at pH 5.75, is suggested to define

the “state” of the anaerobic process.

In particular, they suggested that values < 0.3 indicate a

good state of the anaerobic process:

𝐼𝐴

𝛼= < 0.3

𝑇𝐴

P

(this is also known as FOS/TAC in German, but obtained at different pH values)

Jyvaskyla Summer School 2013 21

University of Verona, Department of Biotechnology Alkalinity determines the buffer capacity of the system and,

differently from pH, is sensitive to process changes !

5000 8

Total Alkalinity, mgCaCO3/L

4000

6

3000

pH (-)

4

2000

Partialalkalinity

Total alkalinity

2

1000

pH

0 0

0 1000 2000 3000 4000 5000 6000

VFA, mgCOD/L

pH versus partial alkalinity for increasing VFA concentrations

in the AD reactor

Jyvaskyla Summer School 2013 22

University of Verona, Department of Biotechnology Clearly, different species in the bulk will contribute with a

different “intensity” to the buffering capability of the system

Lahav & Morgan, JCTB, 79(2004), 1331-1341

Jyvaskyla Summer School 2013 23

University of Verona, Department of Biotechnology Monitoring of volatile fatty acids (VFA)

The fatty acids used for monitoring purposes are the so

called short-chain volatile fatty acids (SC-VFA) with less than

6 atoms of carbon, from acetate (C2) to valerate (C5).

In a stable reactor, where the hydrolytic and methanogenic

rates are balanced, with kmethane ̴ khydrolysis their presence will

be constant, and normally at a very low level of

concentration (however, AD reactors treating very

biodegradable substrates can be an exception).

hydrolysis methanogenic

VFA CH4

kh kmethane

Substrate

(particulate organic matter)

Jyvaskyla Summer School 2013 24

University of Verona, Department of Biotechnology

VFA presence in an AD reactor (standard)

Jyvaskyla Summer School 2013 25

University of Verona, Department of Biotechnology

Concentration levels in the system can be very

different, from 100 to X,000 mg/L ….

Without upsetting the process stability …..

…… but …………

The higher the VFA presence in the digestate, the

lower the biogas production ….

(1 g COD as acetate produce 0.35 L CH4)

Jyvaskyla Summer School 2013 26

University of Verona, Department of Biotechnology

Current methods for VFA measurement include

distillation, colorimetry, gas or liquid chromatography

and various titration techniques.

Despite titration techniques are simple and low in

time and money consuming, only GC and LC analysis

allow for the definition of the different VFA species

present in the reactor, and this info is particularly

valuable ….

Jyvaskyla Summer School 2013 27

University of Verona, Department of Biotechnology After a perturbation of a stable system (change in hydraulic

retention time or organic loading or temperature) VFAs, all

of them, tend to increase. Then, acetate, which is rapidly

converted to CH4 and CO2 decrease, while propionate,

butyrate and valerate acids remain at considerably high

levels for a longer time.

Changes in acetate (Δ) and propionate (₳) concentrations and P/A ratio (●)

after a change in the HRT (left) and organic loading (right)

(from Ahring et al., Appl Microbiol Biotechnol 43(1995), 559)

Jyvaskyla Summer School 2013 28

University of Verona, Department of Biotechnology

Propionic acid is typically the major compound found in unbalanced situations …

(+ formic acid).

Jyvaskyla Summer School 2013 29

University of Verona, Department of Biotechnology

Propionic acid is typically the major compound found in unbalanced situations ….

(+ formic acid).

TVFA

H Pr

Jyvaskyla Summer School 2013 30

University of Verona, Department of Biotechnology

Changes in isobutyrate (Δ) and butyrate (▪) and isovalerate (◊) and valerate (▪)

concentrations after a change in the HRT (left) and organic loading (right)

(from Ahring et al., Appl Microbiol Biotechnol 43(1995), 559)

Jyvaskyla Summer School 2013 31

However, more properly, the three parameters pH,

University of Verona, Department of Biotechnology

alkalinity and VFA should be considered as a whole

(then H2/CO2/CH4 presence in biogas complete the set of

info).

In fact, under stable operating conditions, H2 (with CO2)

and acetic acid formed by acidogenic and acetogenic

bacterial activity are utilized immediately by the

methanogens and converted to methane.

Consequently, the VFA concentration in properly running

anaerobic digesters is typically fairly stable and (generally)

low as carbonate alkalinity is not consumed in excess and

the pH is stable.

Jyvaskyla Summer School 2013 32

University of Verona, Department of Biotechnology

Monitoring of biogas flowrate and composition

Biogas flowrate and its composition in terms of

methane, dioxide carbon and hydrogen is strongly

dependent on the substrate characteristics of course but

also feeding conditions and the state of the reactor.

These are therefore fundamental parameters to be

known.

It is clear that an increase in terms of H2 and CO2

presence in biogas is related to an over-loading situation

and, probably, SC-VFA accumulation.

Jyvaskyla Summer School 2013 33

University of Verona, Department of Biotechnology

Determination of the

Biochemical Methane Potential

(BMP)

Jyvaskyla Summer School 2013 34

University of Verona, Department of Biotechnology

Biomethane potential of substrates is

important as energy is one of the 3 pillars of

AD engineering (tariff+heat)

Credits:

Michae l Chesshire

Jyvaskyla Summer School 2013 35

University of Verona, Department of Biotechnology

AD is a proven technology which is gaining more and more

appeal in recent years. Now, several “new” substrates are fed

to reactors

Because of the necessity of defining yields and economic

balances, the assessment of the biomethane potential of a

given substrate is very important

Several standard methods have been proposed by different

agencies during the last years. They generally focus on the

biodegradability concept of single molecules rather than the

biogas potential and some of them are really questionable

From the scientific stand point, hundreds of papers have

been publishing reporting different methods and using

different units for the definition of the BMP…..

Jyvaskyla Summer School 2013 36

University of Verona, Department of Biotechnology

In 2007 the ABAI task group of the International Water

Association proposed a protocol for the BMP

determination

(see Angelidaky et al. (2009), WST 59(5), 927)

The objective of the protocol is to provide important

experimental guidelines to carry out an accurate

assessment of the anaerobic biodegradability of any

compound or material to methane and carbon dioxide

and define the ultimate methane production of a given

substrate in terms of m3CH4/kgVS

Jyvaskyla Summer School 2013 37

University of Verona, Department of Biotechnology

Jyvaskyla Summer School 2013

38

University of Verona, Department of Biotechnology What you need for a BMP trial at a given temperature is :

I. The substrate

II. An active and sufficient inoculum

III. A device for biogas measurement

Jyvaskyla Summer School 2013 39

University of Verona, Department of Biotechnology

Inoculum

The inoculum should be “fresh”, i.e. inoculum that is

not stored for periods longer than a few days, originating

from any type of active anaerobic reactor (e.g., sludge

reactors, manure reactors or sludge bed reactors, such as

UASB).

The inoculum should have a “broad trophic” microbial

composition in order to ensure that the anaerobic

conversion of different substrates is not limited.

Characteristics in terms of TS, TVS, COD and activity

(on acetate) should be always stated

Jyvaskyla Summer School 2013 40

University of Verona, Department of Biotechnology

Inoculum pre-treatment (some suggestion …)

The inoculum should be “degassed” (i.e., pre-incubated)

in order to deplete the residual biodegradable organic

material (endogenous)

The inoculum should be a close representation of the one

sampled from the reactor, and SHOULD NOT (as

described on previous ISO 11734, ASTM E 2170 (2001))

be washed to remove residual substrate material and

inorganic carbon compounds.

Jyvaskyla Summer School 2013 41

University of Verona, Department of Biotechnology Activity of the inoculum

The quality of inoculum could be examined by

performing activity tests on acetate and cellulose (or

gelatine or both)

Specific Methanogenic Activity on acetate

Jyvaskyla Summer School 2013 42

University of Verona, Department of Biotechnology

Typical SMA determined on acetate are in the range 30

– 40 mlCH4/gVSSd but can be as low as 10

mlCH4/gVSSd; in last case the inoculum concentration

in the test vessel should be very high (typically being

70% to 80% of the total liquid used in the test).

High inoculum concentrations should always be

preferred. This offers an excess of active biomass and

buffer capacity, conditions similar to those of real

anaerobic reactors (generally CSTR)

Jyvaskyla Summer School 2013 43

University of Verona, Department of Biotechnology

Inoculum to

substrate ratio

Jyvaskyla Summer School 2013 44

University of Verona, Department of Biotechnology 2100

1800 15 g bw; I/S = 5/1

30 g bw; I/S = 2/1

1500 3 g bw; I/S = 20/1

1200

ml CH4

900

600

300

0

0 400 hours 800 1200

100

CH4

Too much substrate … 80

CO2

Initial flat curve and CO2 60

%

evolution … 40

Acidogenic conditions ! 20

0

0 20 40 60 80 100

days

Jyvaskyla Summer School 2013 45

2100

University of Verona, Department of Biotechnology

1800 15 g bw; I/S = 5/1

30 g bw; I/S = 2/1

1500 3 g bw; I/S = 20/1

1200

ml CH4

900

600

300

0

0 400 hours 800 1200

100

90 CO2

Right proportion … 80

70

CH4

60

Good curve, useful also

%

50

40

for kinetic tests and CH4 30

evolution … 20

10

0

0 1 2 3 4 5 6 7 8 9 10

days

Jyvaskyla Summer School 2013 46

University of Verona, Department of Biotechnology

If the specific activity and hydrolysis constant are known (or

at least estimated) the correct ratio can eventually be

determined according the mass balance for VS, which gives:

X SSV ww k h

Vinoculum

VSS inoculumSMAinoculum

XSS concentration of hydrolysable substrate (g/L), Vww volume

of waste(water) in the assay vessel (L), kh first order hydrolysis

constant (day-1), VSSinoculum content of the inoculum (gVSS/L)

and SMAinoculum specific methanogenic activity of the

inoculum (g COD-CH4/(gVSSday)).

Angelidaki and Sanders, 2004, Rev in Env Sci & BioTechnol , 3(2), 117

Jyvaskyla Summer School 2013 47

Medium

Necessary nutrients/micronutrient/vitamins/buffers are generally

required for optimal performance of anaerobic microorganisms

Jyvaskyla Summer School 2013 48

University of Verona, Department of Biotechnology Data collection of produced biogas

Jyvaskyla Summer School 2013 49

University of Verona, Department of Biotechnology

The methane accumulated in the headspace of the closed

vessel should be measured by gas chromatography (GC). For

that, a sample volume of e.g. 100 μL should be collected with

a gas-tight syringe and injected into the GC. Either a Thermal

Conductivity Detector (TCD) or a Flame Ionization Detector

(FID) can be used. The obtained peak area should be

compared to that obtained by injecting the same volume of a

standard gas mixture of the known composition.

The volume of methane produced is obtained by

multiplying the headspace volume by the % of CH4 in the

headspace as determined by GC analysis. For publication

and comparison with other studies, the values are often

calculated to STP conditions, i.e. converted to 0˚C and 1

atm.

Jyvaskyla Summer School 2013 50

University of Verona, Department of Biotechnology

90

80

70

mL Biogas Produced

60

50

thermophilic

40 experimental

30 mesophilic

experimental

20 theoretical

10

0

0 10 20 30 40

hours

Jyvaskyla Summer School 2013 51

University of Verona, Department of Biotechnology

Biogas potential for different substrates

Jyvaskyla Summer School 2013 52

University of Verona, Department of Biotechnology Determination of the hydrolysis constant (d-1)

(first order kinetic)

Fit on Methane

0

0 5 10 15

-0.5

y = -0.1362x + 0.0087

R2 = 0.9567

-1

LN (S/S0)

-1.5

-2

y = -0.3645x - 0.0233 y = -0.1776x + 0.0491

-2.5

R2 = 0.993 R2 = 0.9906

-3

Time (day)

Jyvaskyla Summer School 2013 53

University of Verona, Department of Biotechnology

As a first indication, the following range of values can be

considered:

kh > 0.5 d-1, very biodegradable substrates (e.g., food

waste, material rich in carbohydrates ….)

kh = 0.2-0.3 d-1, intermediate biodegradable substrates

(e.g., food waste, material rich in carbohydrates ….)

kh = 0.1 d-1, slowly biodegradable substrates (e.g., waste

activated sludge, or biological sludge)

Jyvaskyla Summer School 2013 54

University of Verona, Department of Biotechnology Round-test in 16 Italian labs

Milk whey Maize silage Food waste

Box plot: median + 25° and 75° percentile

Jyvaskyla Summer School 2013 55

Potrebbero piacerti anche

- DBghtjkdllllllllll547899221455 1 PDFDocumento49 pagineDBghtjkdllllllllll547899221455 1 PDFgabNessuna valutazione finora

- Lecture 11 - Mechanical Pre-Treatment Processes For Residual Wastes and Anaerobic DigestionDocumento53 pagineLecture 11 - Mechanical Pre-Treatment Processes For Residual Wastes and Anaerobic DigestionAnonymous i9ytPrBlenNessuna valutazione finora

- Week 1 Course Introduction - Aquatic BiotechnologyDocumento48 pagineWeek 1 Course Introduction - Aquatic Biotechnologywave alexanderNessuna valutazione finora

- Experimental Endocrinology: A Sourcebook of Basic TechniquesDa EverandExperimental Endocrinology: A Sourcebook of Basic TechniquesNessuna valutazione finora

- Chemical BiologyDocumento14 pagineChemical BiologyVaibhav MardeNessuna valutazione finora

- Aubf Outline EditedDocumento16 pagineAubf Outline EditedNoraine Princess TabangcoraNessuna valutazione finora

- Chen 2013Documento16 pagineChen 2013Alexandru ArcireNessuna valutazione finora

- How Should Apples Be Prepared For A Fruit Salad? A Guided Inquiry Physical Chemistry ExperimentDocumento7 pagineHow Should Apples Be Prepared For A Fruit Salad? A Guided Inquiry Physical Chemistry ExperimentDany PandaNessuna valutazione finora

- Bio F110 1001Documento2 pagineBio F110 1001AmanNessuna valutazione finora

- 11 Biological MonitoringDocumento17 pagine11 Biological MonitoringShelly NataniaNessuna valutazione finora

- BBCCL 102Documento70 pagineBBCCL 102Sat ezNessuna valutazione finora

- Yuan Et Al 2023 Microfluidics For Biofilm StudiesDocumento23 pagineYuan Et Al 2023 Microfluidics For Biofilm StudiesRobert StryjakNessuna valutazione finora

- Navarrete Splitt 2013Documento2 pagineNavarrete Splitt 2013Celular DanielaNessuna valutazione finora

- Chem Soc Rev: Review ArticleDocumento40 pagineChem Soc Rev: Review ArticleKimmy ArabellaNessuna valutazione finora

- Biocompatibility of Dental MaterialsDocumento55 pagineBiocompatibility of Dental Materialsshivanshi jainNessuna valutazione finora

- Bty222 - Ip - Medical and Veterinary MicrobiologyDocumento9 pagineBty222 - Ip - Medical and Veterinary MicrobiologyVishnu KirthiNessuna valutazione finora

- Chemical Experi 1Documento3 pagineChemical Experi 1varinay1611Nessuna valutazione finora

- 1 - Ditta - BIO173 - Introduction - 20204Documento23 pagine1 - Ditta - BIO173 - Introduction - 20204John ChoiNessuna valutazione finora

- BIOF110 BioLabDocumento2 pagineBIOF110 BioLabYash BhardwajNessuna valutazione finora

- Engr Neri Forensic 3 Alternative Laboratory Activities 1st Sem 2021-22Documento6 pagineEngr Neri Forensic 3 Alternative Laboratory Activities 1st Sem 2021-22Luisito S. Mama Jr.Nessuna valutazione finora

- 2003 Review Biosensors Food ND EnvironDocumento12 pagine2003 Review Biosensors Food ND EnvironAndreea GabrielaNessuna valutazione finora

- Annual Plan For Grade 11 Academic Year 2010 EDocumento3 pagineAnnual Plan For Grade 11 Academic Year 2010 EZemetu Gimjaw Alemu100% (3)

- G Kim 2007 J. Phys. Conf. Ser. 61 555Documento6 pagineG Kim 2007 J. Phys. Conf. Ser. 61 555ungureanucameliaNessuna valutazione finora

- Bio F110 1001Documento3 pagineBio F110 1001qweNessuna valutazione finora

- Fchem 08 00837Documento11 pagineFchem 08 00837bilou hertNessuna valutazione finora

- Molecular Biology - Some Techniques and ApplicatioDocumento9 pagineMolecular Biology - Some Techniques and ApplicatioCarlos CastroNessuna valutazione finora

- Dinis Oliveira 2010Documento52 pagineDinis Oliveira 2010Consuelo VegaNessuna valutazione finora

- College of Nursing Academic Year 2021-2022Documento10 pagineCollege of Nursing Academic Year 2021-2022cristina gloriosoNessuna valutazione finora

- GENBIO2 Lab Topic Guide P1 2021-2022Documento2 pagineGENBIO2 Lab Topic Guide P1 2021-2022Nathaniel FelicianoNessuna valutazione finora

- Chowdhury 2016Documento14 pagineChowdhury 2016bhatttanmayhNessuna valutazione finora

- Kinetics Lab AssayDocumento17 pagineKinetics Lab AssaySaravanan JothiNessuna valutazione finora

- (1969) Halberg CHRONOBIOLOGY PDFDocumento51 pagine(1969) Halberg CHRONOBIOLOGY PDFGisell Hurtado VillanuevaNessuna valutazione finora

- Quorum Sensing: Molecular Mechanism and Biotechnological ApplicationDa EverandQuorum Sensing: Molecular Mechanism and Biotechnological ApplicationGiuseppina TommonaroNessuna valutazione finora

- Monitoring Neonatal Fungal Infection With MetabolomicsDocumento5 pagineMonitoring Neonatal Fungal Infection With MetabolomicsQuetzi Victoria Gutiérrez RayasNessuna valutazione finora

- Birla Institute of Technology and Science, Pilani Pilani Campus Instruction DivisionDocumento2 pagineBirla Institute of Technology and Science, Pilani Pilani Campus Instruction Divisionsaurjyesh nayakNessuna valutazione finora

- Electrochemical Biosensors: Chemical Society Reviews May 2010Documento18 pagineElectrochemical Biosensors: Chemical Society Reviews May 2010ANVESH DONTULANessuna valutazione finora

- Course OutlineDocumento3 pagineCourse OutlinebkrmnbxbjtNessuna valutazione finora

- RSC Li/chemical-ScienceDocumento24 pagineRSC Li/chemical-SciencePunita BathlaNessuna valutazione finora

- Lesson Plan of Microteaching Direct Instruction Learning ModelDocumento22 pagineLesson Plan of Microteaching Direct Instruction Learning ModelFaradillah AsriNessuna valutazione finora

- Detailed 6 Week Study Schedule UsmleDocumento43 pagineDetailed 6 Week Study Schedule Usmlecansemerci86% (7)

- A1 Bioluminescent Biosensors Based Food AnalysisDocumento14 pagineA1 Bioluminescent Biosensors Based Food AnalysisElkyn BohórquezNessuna valutazione finora

- BIOL200L General Biology I LABDocumento4 pagineBIOL200L General Biology I LABadeeb ahmedNessuna valutazione finora

- School of Natural Sciences Status Report Details School of Natural Sciences Intern's ReportDocumento4 pagineSchool of Natural Sciences Status Report Details School of Natural Sciences Intern's ReportAgyao Yam FaithNessuna valutazione finora

- Biomolecules Come Alive: A Computer-Based Laboratory Experiment For Chemistry StudentsDocumento7 pagineBiomolecules Come Alive: A Computer-Based Laboratory Experiment For Chemistry StudentsNeelam BuxaniNessuna valutazione finora

- The Missing Response To Selection in The Wild: OpinionDocumento10 pagineThe Missing Response To Selection in The Wild: OpinionOanaNessuna valutazione finora

- Aquatic Toxicology: Research PaperDocumento11 pagineAquatic Toxicology: Research PaperTiago TorresNessuna valutazione finora

- Jurat FuentesetalARE2021Documento50 pagineJurat FuentesetalARE2021Fernanda RodriguezNessuna valutazione finora

- Electrochemical Biosensors in Pharmaceutical AnalyDocumento17 pagineElectrochemical Biosensors in Pharmaceutical AnalyRimaNessuna valutazione finora

- Yu Et Al 2014 Smartphone Fluorescence SpectrosDocumento9 pagineYu Et Al 2014 Smartphone Fluorescence SpectrosSubhadip BanerjeeNessuna valutazione finora

- Optical Fiber-Based Synchronous Fluorescence Spectroscopy For Bacterial Discrimination Directly From Colonies On Agar PlatesDocumento11 pagineOptical Fiber-Based Synchronous Fluorescence Spectroscopy For Bacterial Discrimination Directly From Colonies On Agar PlatesFrancisca MartinichNessuna valutazione finora

- Levering Mechanically Activated Piezo Channels For Potential Pharmacological InterventionDocumento24 pagineLevering Mechanically Activated Piezo Channels For Potential Pharmacological InterventionHans MenaresNessuna valutazione finora

- Physiology of Reproduction and AIDocumento69 paginePhysiology of Reproduction and AItsv anilNessuna valutazione finora

- Ecological Physiology of Diet and Digestive SystemsDocumento28 pagineEcological Physiology of Diet and Digestive SystemsemeredinNessuna valutazione finora

- Materials Chemistry B: Journal ofDocumento29 pagineMaterials Chemistry B: Journal ofBharathi RajaNessuna valutazione finora

- Curriculum Vitae: AI CV Partially Updated 10/2007 1Documento12 pagineCurriculum Vitae: AI CV Partially Updated 10/2007 1ifahNessuna valutazione finora

- Cells 11 02455Documento17 pagineCells 11 02455Maliki IdrisNessuna valutazione finora

- Materials Chemistry B: Journal ofDocumento10 pagineMaterials Chemistry B: Journal ofShashikant PathakNessuna valutazione finora

- 2006 Biochemistry of Mammalian Peroxisomes RevisitedDocumento41 pagine2006 Biochemistry of Mammalian Peroxisomes RevisiteddragoncytoNessuna valutazione finora

- Enzyme PromiscuityDocumento38 pagineEnzyme PromiscuityCésar Guevara PérezNessuna valutazione finora

- Salonenetal DNAextractionJMM2010 PDFDocumento8 pagineSalonenetal DNAextractionJMM2010 PDFumiNessuna valutazione finora

- Design and Techno Economic Evaluation of Biomass Gasifier For Industrial Thermal ApplicationsDocumento7 pagineDesign and Techno Economic Evaluation of Biomass Gasifier For Industrial Thermal ApplicationsAnonymous i9ytPrBlenNessuna valutazione finora

- Introduction To Anaerobic Digestion Economics: Michael ChesshireDocumento7 pagineIntroduction To Anaerobic Digestion Economics: Michael ChesshireAnonymous i9ytPrBlenNessuna valutazione finora

- RE2 Gasification Basics Konttinen PDFDocumento55 pagineRE2 Gasification Basics Konttinen PDFAnonymous i9ytPrBlenNessuna valutazione finora

- Optimization of Bioenergy UseDocumento36 pagineOptimization of Bioenergy UseAnonymous i9ytPrBlenNessuna valutazione finora

- Digestate Quality, Standard and Nutrient Recovery Potential: Dr. Cristina CavinatoDocumento78 pagineDigestate Quality, Standard and Nutrient Recovery Potential: Dr. Cristina CavinatoAnonymous i9ytPrBlenNessuna valutazione finora

- Lecture 8Documento52 pagineLecture 8Anonymous i9ytPrBlenNessuna valutazione finora

- Introduction To MATLAB 7 For Engineers: Electrical Engineering DeptDocumento37 pagineIntroduction To MATLAB 7 For Engineers: Electrical Engineering DeptAnonymous i9ytPrBlenNessuna valutazione finora

- Anaerobic Digestion Fundamentals I: Dr. Cristina CavinatoDocumento47 pagineAnaerobic Digestion Fundamentals I: Dr. Cristina CavinatoAnonymous i9ytPrBlenNessuna valutazione finora

- Introduction To Anaerobic Digestion Engineering: Michael ChesshireDocumento32 pagineIntroduction To Anaerobic Digestion Engineering: Michael ChesshireAnonymous i9ytPrBlenNessuna valutazione finora

- Dr. John Taulo: Malawi University of Science & Technology Department of EngineeringDocumento20 pagineDr. John Taulo: Malawi University of Science & Technology Department of EngineeringAnonymous i9ytPrBlenNessuna valutazione finora

- Appendix 1Documento5 pagineAppendix 1Anonymous i9ytPrBlenNessuna valutazione finora

- Appendix 1 - Calculation of The Power Output of A Producer Gas EngineDocumento2 pagineAppendix 1 - Calculation of The Power Output of A Producer Gas EngineAnonymous i9ytPrBlenNessuna valutazione finora

- Oilseeds Gap Analysis - Steering Committee Meeting - 2018.09.20Documento34 pagineOilseeds Gap Analysis - Steering Committee Meeting - 2018.09.20Anonymous i9ytPrBlenNessuna valutazione finora

- Lecture 12 Human 1factors EngineeringDocumento36 pagineLecture 12 Human 1factors EngineeringAnonymous i9ytPrBlenNessuna valutazione finora

- ChE 132 - Oct 17Documento49 pagineChE 132 - Oct 17datUPstudentdoe0% (2)

- DC Motors and Generatos QuestionsDocumento2 pagineDC Motors and Generatos QuestionsvpzfarisNessuna valutazione finora

- 820-3740 Technical OverviewDocumento238 pagine820-3740 Technical Overviewppjim100% (1)

- Cruise Control (3RZ-FE)Documento6 pagineCruise Control (3RZ-FE)Esteban LefontNessuna valutazione finora

- MSupply BuilderDocumento21 pagineMSupply BuilderRohan BagadiyaNessuna valutazione finora

- A Research Instrument Is A SurveyDocumento1 paginaA Research Instrument Is A SurveyHasan YusuvNessuna valutazione finora

- ABS Buckling Requirements For OffshoreDocumento94 pagineABS Buckling Requirements For Offshorecurvedbrain100% (1)

- CV Europass 20160805 Kolla EN PDFDocumento2 pagineCV Europass 20160805 Kolla EN PDFKeshav KollaNessuna valutazione finora

- 14 Design of Bolted JointsDocumento13 pagine14 Design of Bolted JointsPRASAD32675% (4)

- Agricultural Machinery Is Machinery Used in The Operation of An Agricultural Area or FarmDocumento4 pagineAgricultural Machinery Is Machinery Used in The Operation of An Agricultural Area or FarmvinzyyNessuna valutazione finora

- ISRA University FormDocumento4 pagineISRA University Formpure14Nessuna valutazione finora

- Platinum Collection v-22 Osprey ManualDocumento24 paginePlatinum Collection v-22 Osprey ManualP0wer3D100% (2)

- Testing A SCRDocumento2 pagineTesting A SCRtenisonNessuna valutazione finora

- Datapipe Fact SheetDocumento1 paginaDatapipe Fact SheetDeneme Deneme AsNessuna valutazione finora

- EHB02 Technical Specifications: 1. External DimensionsDocumento5 pagineEHB02 Technical Specifications: 1. External DimensionsArmandoCalderonNessuna valutazione finora

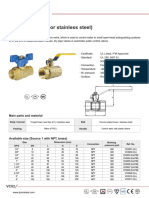

- VC02 Brass Ball Valve Full Port Full BoreDocumento2 pagineVC02 Brass Ball Valve Full Port Full Boremahadeva1Nessuna valutazione finora

- B-Trees and B+-Trees: Jay Yim CS 157B Dr. LeeDocumento34 pagineB-Trees and B+-Trees: Jay Yim CS 157B Dr. LeemaskplyNessuna valutazione finora

- Lesson 4: Advanced Spreadsheet SkillsDocumento15 pagineLesson 4: Advanced Spreadsheet Skillserika gail sorianoNessuna valutazione finora

- Priska (Full)Documento4 paginePriska (Full)Eka MurdaniNessuna valutazione finora

- Warehouse OK 19 JuniDocumento85 pagineWarehouse OK 19 JunihalyNessuna valutazione finora

- Syntel Mock 2Documento18 pagineSyntel Mock 2Ashutosh MauryaNessuna valutazione finora

- Tutorial 5 UpdatedDocumento2 pagineTutorial 5 UpdatedChiraag ChiruNessuna valutazione finora

- Airtag Wallet Keyword Search-2Documento15 pagineAirtag Wallet Keyword Search-2Azhar ShakeelNessuna valutazione finora

- Pakistan Machine Tool Factory Internship ReportDocumento14 paginePakistan Machine Tool Factory Internship ReportAtif MunirNessuna valutazione finora

- Applications of Genetic Algorithm in Water Resources Management and OptimizationDocumento11 pagineApplications of Genetic Algorithm in Water Resources Management and OptimizationGarima TyagiNessuna valutazione finora

- Notice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsDocumento2 pagineNotice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsJustia.comNessuna valutazione finora

- African Music Re-Examined in The Light of New Materials From The Belgian Congo and Ruanda Urundi Akab P Merriam African Music Re-ExaminedDocumento9 pagineAfrican Music Re-Examined in The Light of New Materials From The Belgian Congo and Ruanda Urundi Akab P Merriam African Music Re-Examinedberimbau8Nessuna valutazione finora

- GS-1930 GS-1530 Service Manual: Technical PublicationsDocumento137 pagineGS-1930 GS-1530 Service Manual: Technical PublicationshabibullaNessuna valutazione finora

- ACI Concrete International Vol 45 No 8 2023Documento76 pagineACI Concrete International Vol 45 No 8 2023Cristopher TenorioNessuna valutazione finora

- Authorization For Entering Manual ConditionsDocumento15 pagineAuthorization For Entering Manual ConditionsSushil Sarkar100% (2)