Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Wescor Evaporative Cooling White Paper

Caricato da

calvin.bloodaxe4478Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Wescor Evaporative Cooling White Paper

Caricato da

calvin.bloodaxe4478Copyright:

Formati disponibili

Wescor evaporative cooling white paper

We offer solutions, not just products

Evaporative Cooling Basics

printer-friendly version

Coolerado's TECH INFO page contains more

information on evaporative cooling, including

informative videos that show how Coolerado

air conditioners work.

Summary

What is evaporative cooling?

What’s so great about evaporative cooling?

What kind of temperature reduction can I expect with evaporative cooling?

Where can I use evaporative cooling?

How much tonnage can I save using supplementary indirect/indirect evaporative cooling?

Appendix A: Psychrometric chart 101

Summary

Evaporative cooling has made summers more bearable for thousands of years and with 21st century technology provides effective,

economical, environmentally friendly, and healthy cooling. Evaporative cooling comes in five flavors: direct, indirect, indirect/direct,

indirect/indirect, and indirect/DX. Evaporative cooling works well in the Pacific Northwest, alone or as a supplement to a chiller or DX

system.

What is evaporative cooling?

Evaporative cooling is responsible for the chill you feel when a breeze strikes your skin—the air evaporates the water on your skin,

with your body heat providing the energy. The ancient Egyptians hung wet mats in their doors and windows, and wind blowing through

the mats cooled the air—-the first attempt at air conditioning. This basic idea was refined through the centuries: mechanical fans to

provide air movement in the 16th century, cooling towers with fans that blew water-cooled air inside factories in the early 19th century,

swamp coolers in the 20th century.

These simple examples illustrate direct evaporative cooling. Modern technology has dramatically increased the efficiency and

effectiveness of direct evaporative cooling and made possible four other types of evaporative cooling: indirect evaporative cooling,

indirect/direct evaporative cooling, indirect/indirect evaporative cooling, and indirect/DX evaporative cooling.

Direct evaporative cooling

http://www.wescorhvac.com/Evaporative%20cooling%20white%20paper.htm (1 of 10)28/04/2009 3:55:47 PM

Wescor evaporative cooling white paper

With direct evaporative cooling, outside air is blown through a water-saturated medium (usually

cellulose) and cooled by evaporation. The cooled air is circulated by a blower.

Direct evaporative cooling adds moisture to the air stream until the air stream is close to

saturation. The dry bulb temperature* is reduced, while the wet bulb temperature** stays the

same.

*dry bulb: Sensible air temperature (as measured by a thermometer).

**wet bulb: The lowest air temperature achievable by evaporating water into the air to bring the air to saturation.

Indirect evaporative cooling

With indirect evaporative cooling, a secondary (scavenger) air stream is cooled by water.

The cooled secondary air stream goes through a heat exchanger, where it cools the

primary air stream. The cooled primary air stream is circulated by a blower.

Indirect evaporative cooling does not add moisture to the primary air stream. Both the dry

bulb and wet bulb temperatures are reduced.

During the heating season, an indirect system’s heat exchanger can preheat outside air if

exhaust air is used as the secondary air stream.

Indirect/direct evaporative cooling

With indirect/direct evaporative

cooling, the primary air stream

is cooled first with indirect

evaporative cooling and then

cooled further with direct

evaporative cooling.

Indirect/indirect evaporative cooling

In the first stage of indirect/indirect evaporative cooling, the primary air

stream is cooled by indirect evaporative cooling.

In the second stage, the water used in first-stage cooling passes through

the wet side of a coil. Additional sensible heat is removed from the primary

air stream, and no moisture is added to the primary air.

indirect evaporative cooling/DX

With indirect

evaporative cooling

with DX back-up, the

primary air stream is

cooled first with indirect

evaporative cooling.

Most of the time, this

cools the primary air

stream to the desired

temperature. When

more cooling is

required, the

supplemental DX module cools the air further to reach the desired temperature.

http://www.wescorhvac.com/Evaporative%20cooling%20white%20paper.htm (2 of 10)28/04/2009 3:55:47 PM

Wescor evaporative cooling white paper

This unit is in beta release, and achievable energy savings are still being tested.

What’s so great about evaporative cooling?

Evaporative cooling is economical, effective, environmentally friendly, and healthy.

Economical

Evaporative cooling is economical because it:

■ Reduces DX/chilled water cooling requirements for fresh air.

■ Cuts mechanical cooling costs 25% to 65%.

■ Provides 100% make-up air cooling at half the cost of mechanical equipment cooling.

■ Increases existing equipment cooling capacities without adding mechanical cooling.

■ Increases compressor life.

■ Increases heat exchanger life.

Effective

■ Evaporative cooling actually becomes more effective as the temperature increases—just when DX air conditioning becomes

less effective.

■ Evaporative cooling works in all areas of the country, not just in hot, dry climates. Although the Pacific Northwest is certainly

damp in winter, it is dry in summer. In fact, humidity in this region of the country almost always decreases proportionally as the

temperature increases. So the cooling power of evaporative systems increases as the temperature increases.

Environmentally friendly

Because evaporative cooling does not use chlorofluorocarbons (CFCs), it does not contribute to ozone depletion.

Healthy

Evaporative cooling is healthy and comfortable because it:

■ Brings in outside air and exhausts stale air, smoke, odors, and germs.

■ Helps maintain natural humidity levels, which benefits both people and furniture and cuts static electricity.

■ Does not need an air-tight structure for maximum efficiency, so building occupants can open doors and windows.

What kind of temperature reductions can I expect with evaporative cooling?

The greater the difference between the wet bulb and dry bulb temperatures, the greater the achievable temperature reduction. Here’s

how to calculate temperature reductions achievable with direct, indirect, indirect/direct, and indirect/indirect evaporative cooling. These

examples use a starting dry bulb (DB) temperature of 86 degrees F and wet bulb (WB) temperature of 66 degrees F.

Temperature reduction achievable using direct evaporative cooling

NOTE

With direct evaporative cooling, the dry bulb temperature is reduced while the web bulb temperature remains the same.

1. Temp drop achievable = (dry bulb - wet bulb ) x (efficiency* of the media)

Example: (86 degrees - 66 degrees) x .9 = 18 degrees

2. Achievable temp = dry bulb - temp drop achievable

Example: 86 degrees - 18 degrees = 68 degrees DB/66 degrees WB**

3. Starting DB: 86 degrees

Ending DB: 68 degrees

*Efficiency is usually 90%

**Because cooling is achieved by adding moisture to the supply air stream, the new dry bulb/web

bulb temperatures are found on the wet bulb gradient.

http://www.wescorhvac.com/Evaporative%20cooling%20white%20paper.htm (3 of 10)28/04/2009 3:55:47 PM

Wescor evaporative cooling white paper

Refer to Appendix A for more information on using psychrometric charts to calculate temperature reduction using evaporative cooling.

Temperature reduction achievable using indirect evaporative cooling

NOTE

With indirect evaporative cooling, both the dry bulb and web bulb temperatures are reduced.

1. Temp drop achievable = (dry bulb – wet bulb) x (efficiency* of indirect module)

Example: (86 degrees - 66 degrees) x .7 = 14 degrees

2. Achievable temp = dry bulb – temp drop achievable

Example: 86 degrees – 14 degrees = 72 degrees DB/61.4 degrees WB**

3. Starting DB: 86 degrees

Ending DB: 72 degrees

*Efficiency is usually 60%-70%

**Because no moisture is added to the supply air stream, the new dry bulb/wet bulb temperatures are

found on the dry bulb gradient.

Temperature reduction achievable using indirect/direct evaporative cooling

First calculate the dry bulb and wet bulb temperatures achievable with indirect evaporative cooling:

1. Temp drop achievable = (dry bulb - wet bulb ) x (efficiency of indirect module)

Example: (86 degrees - 66 degrees) x .7 = 14 degrees

2. Achievable temp = dry bulb - temp drop achievable

Example: 86 degrees - 14 degrees = 72 degrees DB/61.4 degrees WB

3. Starting DB: 86 degrees

Ending DB: 72 degrees

Then use the dry bulb/wet bulb values from step 3 to calculate the dry bulb/wet bulb temperatures achievable with direct evaporative

cooling:

4. Temp drop achievable: (dry bulb - wet bulb ) x (efficiency of the media)

Example: (72 degrees - 61.4 degrees) x .9 = 9.5 degrees

5. Achievable temp = dry bulb - temp drop achievable

Example: 72 degrees - 9.5 degrees = 62.5 degrees DB/61.4 degrees WB

6. Total temperature reduction using indirect/direct evaporative cooling:

Starting DB: 86 degrees

Ending DB: 62.5 degrees

Temperature reduction achievable using indirect/indirect evaporative

cooling

First calculate the dry bulb and wet bulb temperatures achievable with the first

stage of indirect evaporative cooling:

1. Temp drop achievable = (dry bulb - wet bulb ) x (efficiency of indirect module)

Example: (86 degrees - 66 degrees) x .7 = 14 degrees

2. Achievable temp = dry bulb - temp drop achievable

Example: 86 degrees - 14 degrees = 72 degrees DB/61.4 degrees WB

3. Starting DB: 86 degrees

Ending DB: 72 degrees

Then use the dry bulb/wet bulb values from step 3 to calculate the dry bulb/wet bulb temperatures achievable with the second stage of

http://www.wescorhvac.com/Evaporative%20cooling%20white%20paper.htm (4 of 10)28/04/2009 3:55:47 PM

Wescor evaporative cooling white paper

indirect evaporative cooling, assuming 50% effectiveness:

4. Temp drop achievable: (dry bulb - wet bulb ) x (efficiency of the media )

Example: (72 degrees - 61.4 degrees) x .5 = 5.3 degrees

5. Achievable temp = dry bulb - temp drop achievable

Example: 72 degrees - 5.3 degrees = 66.7 degrees DB/59.5 degrees WB

6. Total temperature reduction using indirect/indirect evaporative cooling:

Starting DB: 86 degrees

Ending DB: 66.7 degrees

Where can I use evaporative cooling?

In many locations and for many applications, evaporative cooling is all the cooling required to maintain a comfortable indoor

environment. In hotter areas or where cooling loads are high, such as in office buildings, one of the most useful applications for

indirect/indirect evaporative cooling is supplementing a chiller or DX system. By cooling the air stream before it reaches the cooling

coil, an indirect/indirect evaporative unit extends chiller life, cuts energy costs, and provides the boost the chiller needs to function

effectively on hot days.

You can add an indirect/indirect evaporative cooling unit to an existing system or design a new cooling system that incorporates the

indirect/indirect unit with the chiller or a standard roof-top DX system.

How much tonnage can I save using supplementary indirect/indirect evaporative

cooling?

Example conditions

■ Required outside air volume: 10,000 CFM

■ Required refrigeration tonnage to meet building cooling load: 25 tons

Formula

Tons saved = [1.08][1% Design Delta T][efficiency][CFM]/12,000

Examples

Oregon

Portland: [1.08][86-66][.90][10,000]/12,000 = 16.2 tons saved

Bend: [1.08][89-61][.90][10,000]/12,000 = 22.7 tons saved

Medford: [1.08][95-66][.90][10,000]/12,000 = 23.49 tons saved

Washington

Seattle: [1.08][81-64][.90][10,000]/12,000 = 13.8 tons saved

Spokane: [1.08][89-61][.90][10,000]/12,000 = 22.7 tons saved

WallaWalla: 1.08[[[95-65][.90][10,000]/12,000 = 24.3 tons saved

Idaho

Boise: [1.08][94-63][.90][10,000]/12,000 = 25.11 tons saved

Idaho Falls: [1.08][89-60][.90][10,000]/12,000 = 23.49 tons saved

Pocatello: [1.08][90-60][.90][10,000]/12,000 = 24.3 tons saved

See calculations for additional Northwest cities.

Approximate costs for indirect, indirect/direct, and indirect/indirect evaporative modules

■ Indirect evaporative module: $1.95 to $2.30 per CFM

■ Indirect/direct evaporative module: $3.25 to $3.50 per CFM

■ Indirect/indirect evaporative module: $4.00 to $5.00 per CFM

http://www.wescorhvac.com/Evaporative%20cooling%20white%20paper.htm (5 of 10)28/04/2009 3:55:47 PM

Wescor evaporative cooling white paper

Appendix A

Psychrometric Chart 101

Psychrometry is the study of moist air and the changes in its conditions. The psychrometric chart graphically represents the

relationship between air temperature and moisture content and is a basic design tool for mechanical engineers and designers.

You can represent psychrometric processes (that is, any changes in the condition of the atmosphere) on the psychrometric chart.

Common processes include:

■ Sensible cooling/sensible heating

■ Cooling and dehumidification/heating and humidification

■ Humidification/dehumidification

■ Evaporative cooling/chemical dehydration

Figure 1 shows a basic psychrometric chart.

Figure 1 Psychrometric chart

The following sections explain using a psychrometric chart to calculate how much you can reduce dry bulb temperature using direct,

indirect, indirect/direct, and indirect/indirect evaporative cooling.

Using a psychrometric chart to calculate the dry bulb temperature possible with direct evaporative cooling

NOTE

With direct evaporative cooling, the dry bulb temperature is reduced while the web bulb temperature remains constant.

1. Start with the dry bulb (DB) and wet bulb (WB) design conditions for the location you are interested in. For example, Portland’s

1% design conditions are 86 degrees DB/66 degrees WB F.

2. Find where 86 degrees on the dry bulb line intersects with 66 degrees on the wet bulb line (see Figure 2). That is the starting

point.

http://www.wescorhvac.com/Evaporative%20cooling%20white%20paper.htm (6 of 10)28/04/2009 3:55:47 PM

Wescor evaporative cooling white paper

Figure 2 Starting point

3. Calculate the temperature drop achievable using the following formulas. Figure 3 graphically represents the process.

Temperature drop achievable = (dry bulb - wet bulb) x (efficiency of the media)

Example: (86 degrees - 66 degrees) x .9 = 18 degrees

Achievable temperature = dry bulb - temp drop achievable

Example: 86 degrees - 18 degrees = 68 degrees DB

Because cooling is achieved by adding moisture to the supply air stream, the new dry bulb/wet bulb temperatures are found on

the wet bulb gradient.

Figure 3 Direct evaporative cooling

4. Starting temperatures: 86 degrees DB/66 degrees WB

Ending temperatures: 68 degrees DB/66 degrees WB

Using a psychrometric chart to calculate the dry bulb temperature possible with indirect evaporative cooling

NOTE

With indirect evaporative cooling, both the dry bulb and web bulb temperatures are reduced.

1. Start with the dry bulb (DB) and wet bulb (WB) design conditions for the location you are interested in. For example, Portland’s

1% design conditions are 86 degrees DB/66 degrees WB F.

2. Find where 86 degrees on the dry bulb line intersects with 66 degrees on the wet bulb line (see Figure 2 in the previous

section). That is the starting point.

3. The efficiency of the indirect module determines the percentage of the possible temperature drop you can achieve with indirect

evaporative cooling. Efficiency of the indirect module is usually 60% to 70%.

Calculate the new dry bulb temperature using the following formulas. Figure 4 graphically represents the process.

http://www.wescorhvac.com/Evaporative%20cooling%20white%20paper.htm (7 of 10)28/04/2009 3:55:47 PM

Wescor evaporative cooling white paper

Temp drop achievable = (dry bulb – wet bulb) x (efficiency of indirect module)

Example: (86 degrees - 66 degrees) x .7 = 14 degrees

Achievable temperature = dry bulb – temp drop

Example: 86 degrees – 14 degrees = 72 degrees DB

Because no moisture is added to the supply air stream, the new dry bulb/web bulb temperatures are found on the dry bulb

gradient.

Figure 4 Indirect evaporative cooling: new dry bulb temperature

4. Indirect evaporative cooling decreases the wet bulb temperature as well as the dry bulb temperature. Figure 5 shows how to

use the psychrometric chart to calculate the new wet bulb temperature.

Because no moisture is added to the supply air strean, the new dry bulb/wet bulb temperatures are found on the dry bulb

gradient.

Figure 5 Indirect evaporative cooling: new wet bulb temperature

5. Starting temperatures: 86 degrees DB/66 degrees WB

Ending temperatures: 72 degrees DB/61.4 degrees WB

Using a psychrometric chart to calculate the dry bulb temperature possible with indirect/direct evaporative cooling

First calculate the dry bulb and wet bulb temperatures achievable with indirect evaporative cooling:

1. With starting temperatures of 86 degrees DB/ 66 degrees WB, the achievable temperature using indirect evaporative cooling is

72 degrees DB/61.4 degrees WB (refer to the previous section).

Then use the dry bulb/wet bulb values from step 1 to calculate the dry bulb/wet bulb temperatures achievable with direct evaporative

cooling:

http://www.wescorhvac.com/Evaporative%20cooling%20white%20paper.htm (8 of 10)28/04/2009 3:55:47 PM

Wescor evaporative cooling white paper

2. After being reduced by indirect evaporative cooling, the new starting point is 72/61.4.

3. From the new starting point, use the following formulas to calculate the temperature drop achievable with direct evaporative

cooling. Figure 6 illustrates the process.

Temp drop achievable: (dry bulb - wet bulb) x (efficiency of the media)

Example: (72 degrees - 61.4 degrees) x .9 = 9.5 degrees

Achievable temp = dry bulb - temp drop achievable

Example: 72 degrees - 9.5 degrees = 62.5 degrees DB/61.4 degrees WB

Figure 6 Indirect/direct evaporative cooling temperature drop achievable

4. Starting termperatures: 86 degrees DB/66 degrees WB

Ending temperatures: 62.5 degrees DB/61.4 degrees WB

Using a psychrometric chart to calculate the dry bulb temperature possible with indirect/indirect evaporative cooling

First calculate the dry bulb and wet bulb temperatures achievable with the first stage of indirect evaporative cooling:

1. With starting temperatures of 86 degrees DB/ 66 degrees WB, the achievable temperature using indirect evaporative cooling is

72 degrees DB/61.4 degrees WB (refer to the section on indirect evaporative cooling). Efficiency of 70% is used for the first

indirect stage.

Then use the new dry bulb/wet bulb values from step 1 to calculate the dry bulb/wet bulb temperatures achievable with the second

stage of indirect evaporative cooling:

2. After being reduced by indirect evaporative cooling, the new starting point is 72 degrees DB/61.4 degrees WB.

3. From the new starting point, use the following formulas to calculate the temperature drop achievable with the second-stage of

indirect evaporative cooling. Efficiency of 50% is used for the second indirect stage. Figure 7 illustrates the process.

Temp drop achievable: (dry bulb - wet bulb) x (efficiency of the media)

Example: (72 degrees - 61.4 degrees) x .5 = 5.3 degrees

Achievable temp = dry bulb - temp drop achievable

Example: 72 degrees - 5.3 degrees = 66.7 degrees DB/59.5 degrees WB

http://www.wescorhvac.com/Evaporative%20cooling%20white%20paper.htm (9 of 10)28/04/2009 3:55:47 PM

Wescor evaporative cooling white paper

Figure 7 Indirect/indirect evaporative cooling temperature drop achievable

Starting temperatures: 86 degrees DB/66 degrees WB

Ending temperatures: 66.7 degrees DB/59.5 degrees WB

http://www.wescorhvac.com/Evaporative%20cooling%20white%20paper.htm (10 of 10)28/04/2009 3:55:47 PM

Potrebbero piacerti anche

- Evaporatice Cooling White PaperDocumento11 pagineEvaporatice Cooling White PaperTugay AlmaliNessuna valutazione finora

- 1.7 Evaporative Air Cooling EquipmentDocumento8 pagine1.7 Evaporative Air Cooling EquipmentRio BananNessuna valutazione finora

- Evaporative CoolingDocumento1 paginaEvaporative CoolingHans AdlerNessuna valutazione finora

- Lecture 4-Evaporative CoolingDocumento18 pagineLecture 4-Evaporative CoolingSalemNessuna valutazione finora

- Chill TrainDocumento8 pagineChill TrainExxuNessuna valutazione finora

- Performance and Analysis of An Evaporative Cooling System A Review PDFDocumento9 paginePerformance and Analysis of An Evaporative Cooling System A Review PDF011 BARANI KUMAR KNessuna valutazione finora

- Evaporative CoolerDocumento8 pagineEvaporative Coolerbruce1312100% (1)

- EDR ENews 071Documento4 pagineEDR ENews 071Psd VisaNessuna valutazione finora

- 0407 What's Up With Cooling TowersDocumento9 pagine0407 What's Up With Cooling Towersenlightened1718Nessuna valutazione finora

- WL 320 Wet Cooling Tower: Direct-Contact Heat ExchangersDocumento1 paginaWL 320 Wet Cooling Tower: Direct-Contact Heat ExchangersatheerNessuna valutazione finora

- Vaibhav Rakde BS Principles of RefrigrationDocumento1 paginaVaibhav Rakde BS Principles of RefrigrationKscsiddhant KscsiddhantNessuna valutazione finora

- Hvac Ppt6 Evaporative CoolingDocumento5 pagineHvac Ppt6 Evaporative CoolingMuskaan RajputNessuna valutazione finora

- Direct and Indirect Evaporative CoolingDocumento10 pagineDirect and Indirect Evaporative CoolingSloba H TD-VR-BG-MOSNessuna valutazione finora

- Cryogenic Separation of Atmospheric Air in A Typical Air Separation Unit (ASU) Using Hampson-Linde CycleDocumento5 pagineCryogenic Separation of Atmospheric Air in A Typical Air Separation Unit (ASU) Using Hampson-Linde CycleerpublicationNessuna valutazione finora

- The Effects of Evaporative Cooling in Tropical Climate: KeywordsDocumento6 pagineThe Effects of Evaporative Cooling in Tropical Climate: Keywordspaween saetaeNessuna valutazione finora

- Cooling Towers: Fig. Temperature Relationship Between Water and Air in Counterflow Cooling TowerDocumento20 pagineCooling Towers: Fig. Temperature Relationship Between Water and Air in Counterflow Cooling Towereddie eddNessuna valutazione finora

- Tb2 PDFDocumento4 pagineTb2 PDFViệt Đặng XuânNessuna valutazione finora

- Tb2 PDFDocumento4 pagineTb2 PDFViệt Đặng XuânNessuna valutazione finora

- Air Conditioning RepairedDocumento30 pagineAir Conditioning RepairedendyNessuna valutazione finora

- What Is Air ConditioningDocumento27 pagineWhat Is Air ConditioningMd Firan MondalNessuna valutazione finora

- MECH BLDG HVAC OPDocumento29 pagineMECH BLDG HVAC OPyanot leiNessuna valutazione finora

- 4 Page New Profile-1Documento4 pagine4 Page New Profile-1salman nazeerdzNessuna valutazione finora

- Training Manual (TSE2D) : SAMSUNG TMF RefrigeratorDocumento31 pagineTraining Manual (TSE2D) : SAMSUNG TMF RefrigeratorCesar Calderon GrNessuna valutazione finora

- Fan and Pad Greenhouse Evaporative Cooling Systems1Documento6 pagineFan and Pad Greenhouse Evaporative Cooling Systems1paween saetaeNessuna valutazione finora

- Refrigeration System ReviewerDocumento5 pagineRefrigeration System ReviewerRia Divine Dela CruzNessuna valutazione finora

- ISHRAE Mumbai Technical Talk1Documento65 pagineISHRAE Mumbai Technical Talk1Veronica GonzalesNessuna valutazione finora

- Evaporative Cooler PDFDocumento2 pagineEvaporative Cooler PDFBen100% (1)

- Chapter 10 Refrigeration SystemDocumento88 pagineChapter 10 Refrigeration SystemPHƯƠNG ĐẶNG YẾN100% (1)

- Practical-5 (System Design - Dryers)Documento9 paginePractical-5 (System Design - Dryers)Hassan Iftekhar AhmedNessuna valutazione finora

- Climate Wizard Technical ExplanationDocumento7 pagineClimate Wizard Technical ExplanationGaurav Panditrao UdanshivNessuna valutazione finora

- Evaporative CoolingDocumento1 paginaEvaporative CoolingAvelino Fernan Dela CruzNessuna valutazione finora

- How Heat Pumps WorkDocumento4 pagineHow Heat Pumps Worksh5bootNessuna valutazione finora

- Two Stage Indirect/Direct Evaporative Cooling: Abhishek Sharma, Hemant DarokarDocumento6 pagineTwo Stage Indirect/Direct Evaporative Cooling: Abhishek Sharma, Hemant Darokarsiva8784Nessuna valutazione finora

- Building Services IiiDocumento69 pagineBuilding Services IiivaishaliNessuna valutazione finora

- 360 Degree CoolerDocumento51 pagine360 Degree CoolerVinay Muley33% (3)

- 1.1 Need For Air CoolingDocumento10 pagine1.1 Need For Air CoolingSONUNessuna valutazione finora

- Water Fired Chiller/Chiller-Heater: We Are Friendly To The EarthDocumento12 pagineWater Fired Chiller/Chiller-Heater: We Are Friendly To The EarthAsad KhanNessuna valutazione finora

- Cooling VS Cooling & Dehumidification: Teshvinder Kaur Mann Muhammad Anwar Ibrahim Yu Jun Jie Shu Shik Yuan Sharon ChengDocumento5 pagineCooling VS Cooling & Dehumidification: Teshvinder Kaur Mann Muhammad Anwar Ibrahim Yu Jun Jie Shu Shik Yuan Sharon ChengWednesday SharonNessuna valutazione finora

- Cooling VS Cooling & Dehumidification: Teshvinder Kaur Mann Muhammad Anwar Ibrahim Yu Jun Jie Shu Shik Yuan Sharon ChengDocumento5 pagineCooling VS Cooling & Dehumidification: Teshvinder Kaur Mann Muhammad Anwar Ibrahim Yu Jun Jie Shu Shik Yuan Sharon ChengWednesday SharonNessuna valutazione finora

- Evaporative Cooling - DRIDocumento17 pagineEvaporative Cooling - DRISaravanan SengazhaniNessuna valutazione finora

- Air DryerDocumento6 pagineAir DryerAchmadi LubisNessuna valutazione finora

- Datos Tecnicos CompresoresDocumento57 pagineDatos Tecnicos CompresoresJHON SEGURA GONZALEZNessuna valutazione finora

- Dehumidifier - WikipediaDocumento15 pagineDehumidifier - Wikipediauchechukwu AmanekweNessuna valutazione finora

- 1 Air To Water Heating - Cooling Pump - Data SheetDocumento10 pagine1 Air To Water Heating - Cooling Pump - Data Sheetmostafa mNessuna valutazione finora

- Evaporative Cooling PDFDocumento2 pagineEvaporative Cooling PDFAutumnNessuna valutazione finora

- Fan and Pad Greenhouse Evaporative Cooling Systems: January 2004Documento8 pagineFan and Pad Greenhouse Evaporative Cooling Systems: January 2004Nguyen DuyNessuna valutazione finora

- Evaporative CoolingDocumento1 paginaEvaporative CoolingAvelino Fernan Dela CruzNessuna valutazione finora

- Split Cooling ProjectDocumento43 pagineSplit Cooling ProjectVivek Kumar SinghNessuna valutazione finora

- Evaporative Air Cooling PDFDocumento2 pagineEvaporative Air Cooling PDFChris0% (1)

- Experimental Analysis of 80 TR Capacity PDFDocumento5 pagineExperimental Analysis of 80 TR Capacity PDFAungThawNyeinChanNessuna valutazione finora

- 2 Air-ConditioningDocumento147 pagine2 Air-ConditioningChengxi FUNessuna valutazione finora

- Experimental Performance of Different Evaporative Cooling Pad Material of Direct Evaporative Cooler in Hot and Dry RegionDocumento4 pagineExperimental Performance of Different Evaporative Cooling Pad Material of Direct Evaporative Cooler in Hot and Dry RegionMelak TsehayeNessuna valutazione finora

- Cooling Tower: Flow of Slides: What Is A Cooling Tower Need For A Cooling TowerDocumento9 pagineCooling Tower: Flow of Slides: What Is A Cooling Tower Need For A Cooling TowerAmeya VirkudNessuna valutazione finora

- Dehumidification and CoolingDocumento6 pagineDehumidification and CoolingTangha Muklom KunchaNessuna valutazione finora

- IJETR021301Documento12 pagineIJETR021301erpublicationNessuna valutazione finora

- Ract Reviewer Bsme 2BDocumento8 pagineRact Reviewer Bsme 2BCelene Delmonte GingoNessuna valutazione finora

- Lecture 19 Fundamentals of Climate Responsive Buildings - IIDocumento16 pagineLecture 19 Fundamentals of Climate Responsive Buildings - IInikita chawlaNessuna valutazione finora

- Cooling Tower AshraeDocumento18 pagineCooling Tower AshraeMAITREE JHANessuna valutazione finora

- QualitairPurchase 3Documento1 paginaQualitairPurchase 3calvin.bloodaxe4478Nessuna valutazione finora

- Polycab Cables PricelistDocumento4 paginePolycab Cables Pricelistcalvin.bloodaxe4478Nessuna valutazione finora

- GO GREEN!!!!: My Role in Improving The Living Conditions of PuneDocumento7 pagineGO GREEN!!!!: My Role in Improving The Living Conditions of Punecalvin.bloodaxe4478Nessuna valutazione finora

- Contact ListDocumento3 pagineContact Listcalvin.bloodaxe4478Nessuna valutazione finora

- Harry Potter DetailsDocumento3 pagineHarry Potter Detailscalvin.bloodaxe4478Nessuna valutazione finora

- SIGuide ConversionsDocumento12 pagineSIGuide Conversionscalvin.bloodaxe4478Nessuna valutazione finora

- Shubharambh Banquets HL - All Halls 26-5-2017Documento5 pagineShubharambh Banquets HL - All Halls 26-5-2017calvin.bloodaxe4478Nessuna valutazione finora

- Jmsoadn Enterprises: SR - No GI Sheets Qty Site Jmsoadn Measurment Bill Amount TDS Cut 1% CHQ No CHQ Date CHQ Amount BankDocumento1 paginaJmsoadn Enterprises: SR - No GI Sheets Qty Site Jmsoadn Measurment Bill Amount TDS Cut 1% CHQ No CHQ Date CHQ Amount Bankcalvin.bloodaxe4478Nessuna valutazione finora

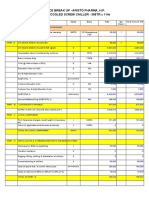

- Vat Break UpDocumento2 pagineVat Break Upcalvin.bloodaxe4478Nessuna valutazione finora

- Atlas Copco - Auditorium BOQ 170919Documento4 pagineAtlas Copco - Auditorium BOQ 170919calvin.bloodaxe4478Nessuna valutazione finora

- Dynapac - Equipment ScheduleDocumento1 paginaDynapac - Equipment Schedulecalvin.bloodaxe4478Nessuna valutazione finora

- Selection of Water Cooled Chiller - 221 TR PDFDocumento2 pagineSelection of Water Cooled Chiller - 221 TR PDFcalvin.bloodaxe4478Nessuna valutazione finora

- STPI - Equipment ListDocumento3 pagineSTPI - Equipment Listcalvin.bloodaxe4478Nessuna valutazione finora

- Ciaq Webinar MullerDocumento56 pagineCiaq Webinar MullerAgozie AnosikeNessuna valutazione finora

- Annexure - 1 Scope of Supply Rev (04.12.08)Documento1 paginaAnnexure - 1 Scope of Supply Rev (04.12.08)calvin.bloodaxe4478Nessuna valutazione finora

- Evergreen Chiller Performance Outputs: Tag Name: 23XRV 350TRDocumento1 paginaEvergreen Chiller Performance Outputs: Tag Name: 23XRV 350TRcalvin.bloodaxe4478Nessuna valutazione finora

- 30xa602 FullloadDocumento1 pagina30xa602 Fullloadcalvin.bloodaxe4478Nessuna valutazione finora

- Detailed Performance Summary For Untitled1 (1) : Packaged Chiller Builder EMEA 3.24 Page 1 of 2Documento2 pagineDetailed Performance Summary For Untitled1 (1) : Packaged Chiller Builder EMEA 3.24 Page 1 of 2calvin.bloodaxe4478Nessuna valutazione finora

- Selection of Water Cooled Screw ChillerDocumento1 paginaSelection of Water Cooled Screw Chillercalvin.bloodaxe4478Nessuna valutazione finora

- Factory Certificate On Chilled Water Pipe ConnectionsDocumento1 paginaFactory Certificate On Chilled Water Pipe Connectionscalvin.bloodaxe4478Nessuna valutazione finora

- Price Break Up in INR With Duties (04.12.08)Documento2 paginePrice Break Up in INR With Duties (04.12.08)calvin.bloodaxe4478Nessuna valutazione finora

- Data Sheet - Carrier ChillerDocumento4 pagineData Sheet - Carrier Chillercalvin.bloodaxe4478Nessuna valutazione finora

- Price Break Up in INR With Duties (04.06.08)Documento2 paginePrice Break Up in INR With Duties (04.06.08)calvin.bloodaxe4478Nessuna valutazione finora

- Price Break Up in INR With Duties (04.06.08)Documento2 paginePrice Break Up in INR With Duties (04.06.08)calvin.bloodaxe4478Nessuna valutazione finora

- 30xa0452 FullloadDocumento1 pagina30xa0452 Fullloadcalvin.bloodaxe4478100% (1)

- Detailed Performance Summary For Untitled1Documento3 pagineDetailed Performance Summary For Untitled1calvin.bloodaxe4478Nessuna valutazione finora

- Selection Sheet - 30XA452 Screw ChillerDocumento1 paginaSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478Nessuna valutazione finora

- Annexure - I Scope of SupplyDocumento1 paginaAnnexure - I Scope of Supplycalvin.bloodaxe4478Nessuna valutazione finora

- Selection of Water Cooled Screw ChillerDocumento1 paginaSelection of Water Cooled Screw Chillercalvin.bloodaxe4478Nessuna valutazione finora

- 30RB0262 Partload Chiller DataDocumento3 pagine30RB0262 Partload Chiller Datacalvin.bloodaxe4478Nessuna valutazione finora

- Chemsheets GCSE 1365 The Electron Structure of IonsDocumento2 pagineChemsheets GCSE 1365 The Electron Structure of IonsMorziqNessuna valutazione finora

- Adge CompiledDocumento18 pagineAdge CompiledNovelyn LumboyNessuna valutazione finora

- CCW - Cooling Water Treatment ProgramsDocumento43 pagineCCW - Cooling Water Treatment Programszerocool86Nessuna valutazione finora

- 1999 Andreozzi - Advanced Oxidation Processes AOP For Water Purification and RecoveryDocumento9 pagine1999 Andreozzi - Advanced Oxidation Processes AOP For Water Purification and RecoveryHerick Bulhões100% (1)

- UnitTest - D11 Feb 2024Documento3 pagineUnitTest - D11 Feb 2024muniharshit16Nessuna valutazione finora

- Lecture 3 Geometric Optics PDFDocumento36 pagineLecture 3 Geometric Optics PDFPuja KasmailenNessuna valutazione finora

- Lec 22 PDFDocumento2 pagineLec 22 PDFabdulzahraNessuna valutazione finora

- Near East University: Department of Petroleum and Natural Gas EngineeringDocumento38 pagineNear East University: Department of Petroleum and Natural Gas Engineeringolga ibanNessuna valutazione finora

- Pipe Sizing - SSDocumento4 paginePipe Sizing - SSFERRY IRAWANNessuna valutazione finora

- Periodic Table - Study NotesDocumento19 paginePeriodic Table - Study NotesTamoghna DeyNessuna valutazione finora

- Science 8 Curriculum GuideDocumento54 pagineScience 8 Curriculum GuideDaisy Soriano PrestozaNessuna valutazione finora

- SG Test3MCQ 64ac8bc86f1720.64ac8bcaa19898.54250131Documento34 pagineSG Test3MCQ 64ac8bc86f1720.64ac8bcaa19898.54250131390108263Nessuna valutazione finora

- Shielding Gases ACM Vs CO2Documento34 pagineShielding Gases ACM Vs CO2ukavathekar100% (2)

- A Review On Durability of Fiber Reinforced Polymer (FRP) Bars ReinforcedDocumento18 pagineA Review On Durability of Fiber Reinforced Polymer (FRP) Bars Reinforcedsherif fodaNessuna valutazione finora

- Aiats Aieee 2012 Test-1 SolutionDocumento10 pagineAiats Aieee 2012 Test-1 Solutionblue_l1Nessuna valutazione finora

- Fiber OpticsDocumento10 pagineFiber OpticsVishal Kumar ShawNessuna valutazione finora

- Optical Communication and NetworkingDocumento15 pagineOptical Communication and NetworkingRaji SharmiNessuna valutazione finora

- Blaine Number - Average Particle SizeDocumento2 pagineBlaine Number - Average Particle Sizedondo1004Nessuna valutazione finora

- Norma MAT2004Documento12 pagineNorma MAT2004Marcelo Carvalho100% (1)

- Edexcel GCE: Chemistry (Nuffield)Documento16 pagineEdexcel GCE: Chemistry (Nuffield)Danny AdonisNessuna valutazione finora

- Loc Corr SS Weldments SummaryDocumento52 pagineLoc Corr SS Weldments SummarySatheesh KumarNessuna valutazione finora

- Padhye Rsi 2016 PDFDocumento24 paginePadhye Rsi 2016 PDFsabaris ksNessuna valutazione finora

- Idemitsu - Mechanic Oil SeriesDocumento2 pagineIdemitsu - Mechanic Oil SeriesarieprachmanNessuna valutazione finora

- Al. (9), Though The Feature Here Is Less Pronounced. The: ReferencesDocumento3 pagineAl. (9), Though The Feature Here Is Less Pronounced. The: ReferencesKrishna KumarNessuna valutazione finora

- CBR Test Results ExplainedDocumento3 pagineCBR Test Results ExplainedLudwig McwillsNessuna valutazione finora

- Spray-Type Deaerating Heaters: TABLE 12.2Documento2 pagineSpray-Type Deaerating Heaters: TABLE 12.2Yanuar KrisnahadiNessuna valutazione finora

- 3 Atoms, Elements, & The Periodic TableDocumento4 pagine3 Atoms, Elements, & The Periodic TableMichael RatliffNessuna valutazione finora

- Pages From Pipenet Transient (Surge)Documento2 paginePages From Pipenet Transient (Surge)absahkahNessuna valutazione finora

- Analisa Box Culvert Otiola 1Documento12 pagineAnalisa Box Culvert Otiola 1agussalim lammaseNessuna valutazione finora