Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TS 112 Process and Instrument Diagrams PDF

Caricato da

prakash b jTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TS 112 Process and Instrument Diagrams PDF

Caricato da

prakash b jCopyright:

Formati disponibili

IS Method

Engineering Services

Technical Standard

TS 112

Process and Instrumentation

Diagrams (P&ID)

IS Method

Revision: 2.0

Date: 16 December 2015

© 2015 SA Water Corporation. All rights reserved.

This document may contain confidential information of SA Water Corporation.

Disclosure or dissemination to unauthorised individuals is strictly prohibited.

Unauthorised printed copies are ‘uncontrolled’.

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

Copyright

This Standard is an intellectual property of the South Australian Water Corporation. It is copyright

and all rights are reserved by SA Water. No part may be reproduced, copied or transmitted in any

form or by any means without the express written permission of SA Water.

The information contained in this Standard is strictly for the private use of the intended recipient in

relation to works or projects of SA Water.

This Standard has been prepared for SA Water’s own internal use and SA Water makes no

representation as to the quality, accuracy or suitability of the information for any other purpose.

Application & Interpretation of this Document

It is the responsibility of the users of this Standard to ensure that the application of information is

appropriate and that any designs based on this Standard are fit for SA Water’s purposes and comply

with all relevant Australian Standards, Acts and regulations.

Users of this Standard accept sole responsibility for interpretation and use of the information

contained in this Standard. Users should independently verify the accuracy, fitness for purpose and

application of information contained in this Standard.

Only the current revision of this Standard should be used which is available for download from the SA

Water website.

Significant/Major Changes Incorporated in This Edition

Appendix B – Treatment Plant Area Numbers, Added

Revision 2.0 - 16 December 2015 Page 2 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

Document Controls

Revision History

Revision Date Author Comments

1.0 14 August 2015 M Stephens

2.0 16 December 2015 M Stephens

Template: Technical Standard Version 4.00, 02/11/2015

Approvers

Role Signature and Date

Responsible Discipline Lead 1 7 /1 2 /2 0 1 5

Mark Stephens

X

S ig n e r 's N a m e

S ig n e d b y : S T 0 0 2 5 1 6

Manager Engineering Technical Services 2 3 /1 2 /2 0 1 5

Murat Aksoy

X

S ig n e r 's N a m e

S ig n e d b y : A K 0 0 3 3 0 5

Senior Manager Engineering Services 2 3 /1 2 /2 0 1 5

Richard Gray

X

S ig n e r 's N a m e

S ig n e d b y : G R 0 0 1 9 6 4

Reviewers

Role Name Revision Review Date

Revision 2.0 - 16 December 2015 Page 3 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

Contents

1 Introduction ............................................................................................................... 6

1.1 Purpose .......................................................................................................................... 6

1.2 Glossary.......................................................................................................................... 6

1.3 References ..................................................................................................................... 6

1.3.1 Australian and International ..................................................................................... 6

1.3.2 SA Water Documents................................................................................................ 6

1.4 Definitions ...................................................................................................................... 7

2 Scope ......................................................................................................................... 8

3 Precedence ................................................................................................................ 8

4 P&ID Requirements .................................................................................................... 8

4.1 Introduction ................................................................................................................... 8

4.2 Process Flow Designation .............................................................................................. 9

4.2.1 General ..................................................................................................................... 9

4.2.2 Process Flow Tag Format .......................................................................................... 9

4.3 Piping Designation ......................................................................................................... 9

4.3.1 Piping Designation Code ........................................................................................... 9

4.3.2 Tie-in or Termination Points (TPs) .......................................................................... 10

4.4 Equipment Designation ............................................................................................... 10

4.4.1 General ................................................................................................................... 10

4.4.2 Equipment Designation Code ................................................................................. 10

4.5 Instrumentation ........................................................................................................... 11

4.6 Pressure Piping Hazard Levels ..................................................................................... 11

4.7 Summary Equipment Technical Information ............................................................... 13

4.8 Existing Numbering and Tagging Conventions ............................................................ 13

5 Drawing & Drafting Requirements ............................................................................ 14

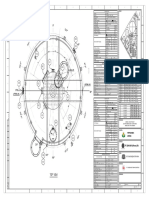

Appendix A P&ID Standard Drawings ............................................................................ 15

A1 4003-00001-01............................................................................................................. 16

A2 4003-00001-02............................................................................................................. 17

Appendix B Treatment Plant Area Numbers .................................................................. 18

B1 Bolivar WWTP .............................................................................................................. 18

B1.1 Treatment Plant ...................................................................................................... 18

B1.2 DAFF Plant............................................................................................................... 19

B1.3 High Salinity Plant ................................................................................................... 20

B1.4 Bolivar Mawson Lakes ............................................................................................ 21

B2 Port Adelaide Re-Lift PS (PARPS) ................................................................................. 22

B3 Glenelg WWTP ............................................................................................................. 23

B3.1 Treatment Plant ...................................................................................................... 23

B3.2 Glenelg to Park Lands Treatment Plant (GAP) ........................................................ 24

B4 Christies Beach WWTP ................................................................................................. 25

B5 Water Treatment Plants .............................................................................................. 27

Revision 2.0 - 16 December 2015 Page 4 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

List of figures

Figure 1 - Typical process flow tag format for incoming process flow (left of page) .................... 9

Figure 2 - Typical termination point indicator............................................................................. 10

Figure 3 - Typical instrument identification symbol.................................................................... 11

Figure 4 - SA Water hazard level classification............................................................................ 12

Figure 5 - Example P&ID hazard classification for a liquid chlorine draw off system ................. 12

Figure 6 - Example summary equipment information (located top of page) ............................. 13

List of tables

Table 1 - List of typical chemical fluids and typical hazard level rating used by SA Water ......... 12

Revision 2.0 - 16 December 2015 Page 5 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

1 Introduction

SA Water is responsible for operation and maintenance of an extensive amount of engineering

infrastructure.

This standard has been developed to assist in the design, maintenance, construction, and

management of this infrastructure.

1.1 Purpose

The purpose of this standard is to detail minimum requirements to ensure that assets covered by the

scope of this standard are constructed and maintained to consistent standards and attain the

required asset life.

1.2 Glossary

The following glossary items are used in this document:

Term Description

SA Water South Australian Water Corporation

TG SA Water Technical Guideline

TS SA Water Technical Standard

1.3 References

1.3.1 Australian and International

The following table identifies Australian and International standards and other similar documents

referenced in this document:

Number Title

AS 1101 Graphical Symbols (numerous Parts are listed as obsolete and are to be used for

historical reference only)

ISO 3511-3 Process Measurement Control Functions and Instrumentation; Symbolic Representation

ISO 3511-4 Industrial Process Measurement Control Functions and Instrumentation; Symbolic

Representation

1.3.2 SA Water Documents

The following table identifies the SA Water standards and other similar documents referenced in this

document:

Number Title

TS 95 Requirements for Technical Drawings

4003-00001-01 P&ID Standard Drafting Symbols Chart

4003-00001-02 P&ID Standard Drafting Symbols Chart

Revision 2.0 - 16 December 2015 Page 6 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

1.4 Definitions

The following definitions are applicable to this document:

Term Description

SA Water’s Representative The SA Water representative with delegated authority under a Contract or

engagement, including (as applicable):

Superintendent’s Representative (e.g. AS 4300 & AS 2124 etc.)

SA Water Project Manager

SA Water nominated contact person

Responsible Discipline Lead The engineering discipline expert responsible for TS 112 defined on page 3

(via SA Water’s Representative)

Revision 2.0 - 16 December 2015 Page 7 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

2 Scope

This Technical Standard (TS) shall apply to all the Process / Piping and Instrumentation Diagrams

(P&IDs) produced for or by SA Water, and for all SA Water projects.

SA Water requires P&IDs to be prepared at the Concept Design stage for all plant and systems that

include operable elements or instrumentation. Operable elements include manual, actuated, and

automatic operation. P&IDs may be prepared prior to the Concept Design stage as appropriate.

P&IDs shall be revised for each subsequent phase of the project or works.

This Technical Standard specifies P&ID content and format, and particular SA Water requirements. It

is generally consistent with Australian and International Standards and with water industry practice.

Reference to this Technical Standard shall also be taken to include reference to SA Water Drawings

4003-00001-01 and 4003-00001-02. Reference to drawings shall also be taken as reference to

drawing sheets. Refer to TS 95 for explanation of the SA Water drawing-and-sheet system.

This Technical Standard and SA Water Drawings 4003-00001-01 and 4003-00001-02 supersede all

previous SA Water documentation on this subject.

3 Precedence

Where symbols or codes differ across the relevant standards the following order of precedence shall

apply, in descending order:

SA Water TS 112 and supporting Standard Drawings 4003-00001-01 and 4003-00001-02

Australian Standard 1101 (as current and applicable)

ISO Standard 3511

Custom symbol or code

4 P&ID Requirements

4.1 Introduction

A P&ID shows information on piping, fittings, equipment, instrumentation, and process plant in a

representative and sequential arrangement on the basis of product flow paths. The P&ID layout does

not necessarily reflect physical arrangements. A P&ID is not drawn to scale.

Where hydraulic elevations and levels of equipment are important to the process, this information

shall be shown on the P&ID by referring to Elevation (EL) with respect to the Australian Height Datum

(AHD).

Where multiple P&IDs are required, the layout shall be logical and sequential across the drawings

and the break up between the drawings or sheets shall be based on plant or process areas.

This Technical Standard and Standard Drawings 4003-00001-01 and 4003-00001-02 specify

numerous coding systems for use in P&IDs. If coding systems are required for other attributes, they

may be developed on an individual project basis. In this case, the systems must be consistent in

format with the specified systems and shall be defined on the drawing where they are used and/or in

a master legend for the set of drawings.

The code formats specified in this Technical Standard and the codes specified on Standard Drawings

4003-00001-01 and 4003-00001-02 are specifically for use on P&IDs but may be used in other

applications as appropriate (often on a general arrangement drawing showing a P&ID tag reference

on a pipe, valve and/or other equipment for process clarity).

Revision 2.0 - 16 December 2015 Page 8 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

4.2 Process Flow Designation

4.2.1 General

The flow direction of main process streams shall, where possible, be from left to right. Flows shall

leave P&IDs at the sides, not at the top or bottom.

Existing process streams, pipes and/or equipment shall be shown in a light weight, broken and/or

dotted line. New or proposed process streams, pipes and/or equipment shall be shown in a solid

heavy-weighted line distinct from the line for the existing process streams, pipes and/or equipment.

The distinction between line styles must be such that it is clearly evident on a drawing printed at A3

size.

Additionally, P&IDs shall show the primary process streams, pipes and/or equipment in a solid heavy

weighted line type – clearly identifying the primary process.

Process streams leaving or entering drawings or sheets shall have a “process flow tag” at the side of

the drawing indicating the direction of flow, as well as text describing the source and/or destination

of the stream.

4.2.2 Process Flow Tag Format

Process flow tags shall contain the following information as appropriate:

FLUID code or description with source or destination

EQUIPMENT Name and Number

DRAWING NUMBER of source or destination drawing.

Example: Incoming process (service) water from a booster pump on a previous sheet might be

designated as shown in Error! Not a valid bookmark self-reference. below:

Process Water from

Booster Pump XXXX

Drawing YYYY-XXXXX-XX

Figure 1 - Typical process flow tag format for incoming process flow (left of page)

4.3 Piping Designation

4.3.1 Piping Designation Code

Piping designation shall be in the form: DIAM-FLU-MATL-XXX

Where:

DIAM is the pipe size, either nominal or actual

FLU is the Fluid Code for the contained fluid as per Standard Drawing 4003-00001-02

MATL is the pipe Material Code as per Standard Drawing 4003-00001-02

XXX is the line number (optional)

Example: An effluent pipe of 200 diameter polyethylene on line 006 might be designated as 200-EFF-

HDPE-006

Revision 2.0 - 16 December 2015 Page 9 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

In all cases where codes are used that are not shown on Standard Drawing 4003-00001-02 they shall

be defined on the drawing where they are used and/or in a master legend for the set of drawings.

4.3.2 Tie-in or Termination Points (TPs)

New work that ties in to existing works at the termination points for contracts shall be designated

with the Termination Point (TP) symbol.

Where more than one TP is used, each point will be designated with a unique identification number

as shown in Figure 2 below:

Figure 2 - Typical termination point indicator

4.4 Equipment Designation

4.4.1 General

Equipment titles shall be functionally descriptive in terms of process and generic in terms of

equipment type (e.g., a treated water pump which could be abbreviated to TWP).

Equipment may be designated and numbered with respect to location as appropriate. Any new

equipment added to a particular location shall be incremented numerically from the existing

equipment in that location.

Equipment details shall be vertically aligned to the respective equipment on the P&ID.

4.4.2 Equipment Designation Code

Equipment designation shall be in the form: EQPT-LOCN-XXX

where:

EQPT is the equipment or valve title abbreviation which often includes the fluid identifier and

may be project specific

LOCN is the location code (letters or numbers) – this refers to the location of the equipment

within a treatment plant for example, not a geographic location/township, and is optional

depending on the size and complexity of the plant

XXX is the equipment number

Examples:

A process water pump 2 in a chemical dosing area might be designated as PRWP-CHEM-002

A manual ball valve might be designated as HV-010

A process globe valve (pressure sustaining) in a chemical dosing area might be designated as

PV-002-009

A compressor at the Happy Valley WTP might be designated as CO-096-300

A chlorinator at the Happy Valley WTP might be designated as CH-096-001

Revision 2.0 - 16 December 2015 Page 10 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

The equipment numbering/naming system shall be as advised by or agreed with SA Water

Engineering.

In all cases where codes are used that are not shown on Standard Drawing 4003-00001-02 they shall

be defined on the drawing where they are used and/or in a master legend for the set of drawings.

The equipment designation shall be shown inside or adjacent to the equipment symbol and/or

representation on the P&ID.

4.5 Instrumentation

Instrumentation names and symbols shall be as per Standard Drawing 4003-00001-01.

Instruments may be designated and numbered with respect to location as appropriate. Any new

instruments added to a particular location shall be incremented numerically from the existing

instruments in that location.

Instrument numbering shall be in the form: INST-LOCN-XXX

where:

INST is the instrument title abbreviation

LOCN is the location code

XXX is the instrument number

Instrument identification shall be as shown in Figure 3 below:

Figure 3 - Typical instrument identification symbol

The instrument number shall be shown inside or near the equipment symbol on the P&ID.

4.6 Pressure Piping Hazard Levels

SA Water requires P&IDs to nominate and show the piping hazard level ratings according to the

product (e.g., wastewater chemicals, chlorine gas, digester gas, sludge, supernatant, etc…). All

chemicals and process fluids are grouped into one of three hazard level categories:

Hazard Level B (medium (average) level hazard): very harmful fluids, powders, etc… (e.g., typically

acids pH<2 or alkalis pH>11)

Hazard level C (low hazard): harmful fluids or powders, low strength acids or alkalis, combustible,

corrosive or high temperature fluids

Hazard Level E (negligible hazard): non-harmful fluids or powders, typically all water and wastewater

streams and normal process air

Revision 2.0 - 16 December 2015 Page 11 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

The piping hazard level rating shall be shown on P&IDs using the symbols as shown in Figure 4 below:

Figure 4 - SA Water hazard level classification

Piping hazard level symbols shall be shown on each process stream/pipe (i.e., positioned at left and

right per drawing sheet and across the full process stream) - see the example as shown in Figure 5

below for a liquid chlorine system. Typical process fluids encountered in SA Water systems, and their

associated piping hazard level ratings, are listed in Table 1 below.

Figure 5 - Example P&ID hazard classification for a liquid chlorine draw off system

Table 1 - List of typical chemical fluids and typical hazard level rating used by SA Water

TYPICAL FLUIDS USED BY SA WATER SA WATER TYPICAL HAZARD LEVEL FOR PIPING

Activated Carbon (PAC) (up to 10% slurry) E

Activated Silicate B

Air, compressed E

Aluminium Sulphate (Alum) (50% solution) B

Ammonia, Anhydrous (100% gas/liquid) B

Ammonia, Aqua (25% solution)Ammonia Solution B

Calcium Hydroxide (Hydrated lime) (up to 20% slurry) B

Calcium Oxide (Quicklime) (up to 20% slurry) B

Chlorine (100% liquid & gas) B

Chlorine Solution C

Citric Acid (50% solution) C

Diesel / Fuels C

Ferrous Chloride (42% solution) B

Fluorosilicic Acid (20% solution) B

Formic Acid (up to 85% solution) B

Hydrochloric Acid (up to 10% solution) B

Hydrogen Sulphide (up to 400 ppm in Sewer Gas) C

Revision 2.0 - 16 December 2015 Page 12 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

TYPICAL FLUIDS USED BY SA WATER SA WATER TYPICAL HAZARD LEVEL FOR PIPING

Magnesium Hydroxide (60% slurry) E

Methane or Natural Gas (Digester gas: 70% Methane) B

Oxygen, compressed (100% liquid & gas) B

Polyelectrolytes (various) (> 60% solutions) E

Potassium Permanganate (5% solution) C

Sodium Carbonate (Soda Ash) (Assume 15% solution) E

Sodium Chloride (Saturated Brine) (up to 25% solution) E

Sodium Hydroxide (Caustic Soda) (up to 50% solution) B

Sodium Hypochlorite (13% solution) B

Sodium Silicate B

Sucrose (Liquid Sugar or Molasses) (up to 67% solution) E

Sulfamic Acid (30% solution) B

Sulphuric Acid (98% liquid) B

Water, fresh & sea water (including wastewater) E

Water, hot or steam (including wastewater) C

4.7 Summary Equipment Technical Information

The top of the P&ID drawing sheet shall be reserved for all equipment technical information, such as

process equipment titles, equipment descriptors, number and size, capacity, duty, duty arrangement,

power and energy ratings. A typical example is shown in Figure 2Figure 6 below.

Figure 6 - Example summary equipment information (located top of page)

4.8 Existing Numbering and Tagging Conventions

There may be occasions where new capital plant needs to be retro-fitted and/or interfaced with

existing operational plant. It is possible that existing numbering and tagging conventions exist for

Revision 2.0 - 16 December 2015 Page 13 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

specific sites. At the commencement of design works, designers shall engage with plant operators

and/or the contract superintendent’s representative to establish if a site has an existing (and

established) numbering and tagging convention. This rule only applies to work associated with a site

and/or plant that has an established convention and where introduction of a new convention would

lead to operator and maintenance staff confusion and error.

Any established convention identified within the design phase of a new project shall be

communicated back to SA Water Engineering for assessment and confirmation.

5 Drawing & Drafting Requirements

P&IDs are considered to be Engineering Drawings. They shall be prepared, managed, formatted (i.e.,

line types and styles), presented and numbered in accordance with TS95 “Requirements for Technical

Drawings”.

Symbols and representations used on P&IDs shall be as per Standard Drawings 4003-00001-01 and

4003-00001-02.

Revision 2.0 - 16 December 2015 Page 14 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

Appendix A P&ID Standard Drawings

Note: P&ID standard drawings included in this appendix were those current at the time of issue of

this standard and are subject to change without notice. The current revision of these drawings at any

point in time is available from the SA Water Website Standard Drawings page.

Revision 2.0 - 16 December 2015 Page 15 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

A1 4003-00001-01

Revision 2.0 - 16 December 2015 Page 16 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

A2 4003-00001-02

Revision 2.0 - 16 December 2015 Page 17 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

Appendix B Treatment Plant Area Numbers

B1 Bolivar WWTP

B1.1 Treatment Plant

Sub Sub

Area Description Area Description

Area Area

B00 GENERAL B60 DISSOLVED AIR FLOTATION THICKENERS

01 Plant Site, Hazardous Goods Store 61 DAFT 1

02 HV & LV Substation 62 DAFT 2

03 Site Electrics 63 DAFT 3

04 Main Switchroom 64 DAFT 4

05 Existing Main Plant Control Room 65 DAFT Effluent Tanks, Recycle & Effluent Pumps

66 DAFT Sludge Tank & Sludge Pumps

67 Compressed Air System

68 DAFT Bottom Sludge Pumps

RAW SEWAGE INLET WORKS

B10 B70 SLUDGE DIGESTION

& ODOUR CONTROL WORKS

11 Salisbury Pump Station 71 Digester 1

12 Adelaide Pump Station 72 Digester 2

13 Screens and Inlet Channel 73 Digester 3

74 Digester 4

75 Digester 5

76 Digester 6

77 Digester 1 & 4 Sludge Recycle Pumps

78 Digester 2 & 3 Sludge Recycle Pumps

79 Digester 5 & 6 Sludge Recycle Pumps

GRIT REMOVAL &

B20 B80 DIGESTED SLUDGE & GAS HANDLING

PRIMARY SEDIMENTATION

21 Primary Sedimentation Tank 1 81 Bolivar Digested Sludge Pumps

22 Primary Sedimentation Tank 2 82 Gas Separation Facility

23 Primary Sedimentation Tank 3 83 Digested Gas Burners

24 Primary Sedimentation Tank 4 84 Digester Gas Mixing Compressor System

25 Primary Sludge Pumps 85 Digestor Gas Turbine Booster Compressor System

26 Grit Hoppers & Pumps 86 Port Adelaide Glenelg Sludge Booster PS

27 Primary Effluent Wet Well & Pumps 87 Sludge Dewatering (Centrifuge) Plant

88 Digester Gas Fired Standby Boiler

ACTIVATED SLUDGE REACTORS

B30 B90 EFFLUENT WATER SYSTEM

& AERATION BLOWERS

31 Activated Sludge Reactor 1 91 Potable Water (General)

32 Activated Sludge Reactor 2 92

33 Activated Sludge Reactor 3 93

34 Activated Sludge Reactor 4 94 Ferrous Chloride Dosing

95 Fluoride Storage

B40 SECONDARY SEDIMENTATION TANKS

41 RAS Pump Station 1

42 RAS Pump Station 2

43 RAS Pump Station 3

44 RAS Pump Station 4

B50 PRIMARY GRAVITY THICKENERS

51 Thickened Primary Sludge Pumps

52 PGT Scum Tank & Scum Pumps

53 PGT Effluent Tank & Effluent Pumps

Revision 2.0 - 16 December 2015 Page 18 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

B1.2 DAFF Plant

Sub Sub

Area Description Area Description

Area Area

00 NOT USED 60 RECYCLE DISPERSION SYSTEM

61 Saturation Vessel #1 (Modules 1-3)

62 Saturation Vessel #2 (Modules 4-6)

63 Saturation Vessel #3 (Modules 7-9)

64 Saturation Vessel #4 (Modules 10-12)

10 GENERAL 70 CHEMICAL DOSING

11 Siteworks 71 Alum. Dosing

12 Electrical 72 Polymer Dosing

13 Control/Machinery/Switch Build. 73 Chlorine Dosing

14 Chem. Dosing Building

15 Alum. Tank Area

16 Chlorine Building

17 Instrument and Control

20 RAW WATER INLET WORKS 80 BACKWASH AND SLUDGE HANDLING

21 Control Weir Lagoons 1,2 & 3 81 Wash Water Recovery System

22 Control Weir Lagoons 4,5 & 6 82 Sludge Transfer System

23 Raw Water Pump Station

30 DAFF PLANT STAGE 1 90 TREATED WATER OUTLET WORKS

31 DAFF Module 1 91 Plant Sampling & Analysis

32 DAFF Module 2 92 Laboratory Sampling & Analysis

33 DAFF Module 3 93 Flow Split, Bypass & Contact Channel

34 DAFF Module 4

35 DAFF Module 5

36 DAFF Module 6

40 DAFF PLANT STAGE 2

41 DAFF Module 7

42 DAFF Module 8

43 DAFF Module 9

44 DAFF Module 10

45 DAFF Module 11

46 DAFF Module 12

50 MACHINERY ROOM

51 Backwash System

52 Air Scour System

53 Compressed Air System

54 Plant Water System (Potable)

55 Plant Water System (Non - Potable)

Revision 2.0 - 16 December 2015 Page 19 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

B1.3 High Salinity Plant

Sub Sub

Area Description Area Description

Area Area

S00 GENERAL S60 DAFT GENERAL

01 Plant site 61 DAF Thickener

02 HV & LV Substation 62

03 Site Electrics 63 DAFT Recycle

04 Main Switchroom 64 Compressed Air & Instrumentation Air Systems

65 DAFT Transfer System

66 DAFT Effluent System

67 DAFT Sludge Tank & Transfer System

S10 NOT USED S70 NOT USED

S20 PLANT INLET S80 NOT USED

21 Plant Inlet Distribution Box

22

23 Foul Air Collection

24 Odour Scrubber Unit

25 Odour Control Plant Chemical Dosing &

Storage

S30 SBRs & AERATION BLOWERS S90 SITE UTILITIES

31 Sequencing Batch Reactor No. 1 91 Potable water

32 Sequencing Batch Reactor No. 2 92 Fire Services

33 Sequencing Batch Reactor No. 3 93

34 Sequencing Batch Reactor No. 4 94 Effluent Water

35 Sequencing Batch Reactor No. 5 95

36 Sequencing Batch Reactor No. 6 96

97 SBR Underfloor Drain Sump Station No. 1 (South)

98 SBR Underfloor Drain Sump Station No. 2 (North)

S40 MIXED LIQUOR RETURN & WAS PUMPS

41 Mixed Liquor Return & WAS PS No.1

42 Mixed Liquor Return & WAS PS No.2

43 Mixed Liquor Return & WAS PS No.3

44 Mixed Liquor Return & WAS PS No.4

45 Mixed Liquor Return & WAS PS No.5

46 Mixed Liquor Return & WAS PS No.6

S50 OUTFLOW & DISINFECTION SYSTEMS

51 Effluent Pump Station

52 UV Disinfection Facility

53 Effluent Outfall

54 Gravity Overflow

Revision 2.0 - 16 December 2015 Page 20 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

B1.4 Bolivar Mawson Lakes

Sub Sub

Area Description Area Description

Area Area

M00 GENERAL

M01 Plant Site

M10 NOT USED

M20 NOT USED

M30 NOT USED

M40 NOT USED

M50 NOT USED

M60 NOT USED

M70 CHEMICAL DOSING

M71 Chlorine Dosing

M80 NOT USED

M90 PUMPING STATION

M91 Potable Water

Revision 2.0 - 16 December 2015 Page 21 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

B2 Port Adelaide Re-Lift PS (PARPS)

Sub Sub

Area Description Area Description

Area Area

P00 GENERAL P70 NOT USED

01 Plant Site

02 HV & LV Substation

03 Site Electrics

04 Main Switchroom

05 Dry Well

P10 FEEDER PUMP STATIONS P80 NOT USED

11 Fulham Gardens Pump Station

12 West Lakes Pump Station

13 Woodlake Pump Station (SPS No. 202)

14 Queensbury Pump Station

15 Royal Park Pump Station (SPS No.198)

16 Port Adelaide Pump Station

17 Ethelton Pump Station

18 Port River Outfall Return Pump Station

P20 INLET WORKS P90 SITE UTILITIES

21 Inlet Screens, Washer Units & Conveyors 91

22 Grit Removal System 92

23 Foul Air Collection 93

24 Odour Scrubber Unit 94

25 Odour Control Plant Chemical Dosing & Storage 95

96

P30 RELIFT PUMP STATION DRY WELL

31 Emergency Gas Driven Pumpset

32 Dry Well Sumps

33 Pump Station Ventilation Systems

P40 TRANSFER PIPELINE

41 Transfer Pipeline-PARPS to South Rd Expressway

42 Transfer Pipeline-South Rd Expressway to Dry Creek Transfer

43 Transfer Pipeline-Dry Creek Transfer to Bolivar High Salinity WWTP

P50 GLENELG / PORT ADELAIDE PS

P60 NOT USED

Revision 2.0 - 16 December 2015 Page 22 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

B3 Glenelg WWTP

B3.1 Treatment Plant

Sub Sub

Area Description Area Description

Area Area

G00 GENERAL/SITE UTILITIES G60 CHEMICAL DOSING

00 HV Supply 61

01 Mains Natural Gas Supply 62 Chlorination

02 Site Electrical (inc. General Light & Power) 63

03 On-Site Power Generation (Power Generation) 64

04 65

05 Fire Detection and Evacuation System 66 Carbon / Molasses Dosing

06 Stormwater Drainage

G10 PRELIMINARY TREATMENT G70 SLUDGE TREATMENT

11 Inlet WWPS 70

12 71 WAS Pumping

13 Inlet Screens 72 WAS Thickening Filtrate

14 Vortex Grit Removal & Grit Handling 73 WAS Thickening Sludge

15 74 Dissolved Air Flotation Thickener (DAFT)

16 75 DAFT Thickened Sludge Tank

17 Inlet Works Foul Air Collection

18 Inlet Works Odour Control Plant

G20 PRIMARY TREATMENT G80 DIGESTION

20 Grit Removal (Old) 80 Digester Gas Detection System

21 Primary Sed. Tank 1 80 Digester Gas Ventilation System

22 Primary Sed. Tank 2 81 Sludge Digester 1

23 Primary Sed. Tank 3 82 Sludge Digester 2

24 Primary Sed. Tank 4 83 Sludge Digester 3

25 Raw Sludge Pumps 84 Sludge Digester 4

26 Foul Air Removal Duct 85 Sludge Digester 5

86 Sludge Digester 6

87 Digester Hot Water System

88

89 Digester Gas System

G30 SECONDARY TREATMENT G90 TERTIARY TREATMENT

30 Air Blowers 90 Effluent Pumping

31 Aeration Tank B1

32 Aeration Tank B2

33 Aeration Tank B3

34 Aeration Tank B4

35 Aeration Tank C1

36 Aeration Tank C2

37 Aeration Tank C3

38 Aeration Tank C4

39 Aeration Tanks D

G40 CLARIFIERS & RAS

G50 NOT USED

Revision 2.0 - 16 December 2015 Page 23 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

B3.2 Glenelg to Park Lands Treatment Plant (GAP)

Sub Sub

Area Description Area Description

Area Area

G00 GENERAL

00 G50 ULTRA VIOLET

01 50

02 51 UV Reactors

52

53

54 Comp Room Ventilation

G10 PRELIMINARY TREATMENT G60 CHEMICAL DOSING

10 60

11 61 Chlorine Storage

12 Effluent PS 62 Chlorination

13 Screens 63 Chlorination

14 Screens Waste 64

65

66 Sampling/Quality Monitoring Post CL2

67 Sampling/Quality Monitoring Post UV

G20 FEED WATER G70 TREATED WATER STORAGE

20 70

21 71 Transfer PS Basin 1

22 72 Transfer PS Basin 2

73 Sample Pump Post Cl2

G30 FEED PUMPS G80 TRANSFER PS

30 80 Transfer Pumps

31 UF Feed Pumps 80 Transfer Large Pumps

32 81 Surge Vessel

33 82 Surge vessels Air

34 83 Transfer PS ventilation

35

36

37

38

39

G40 ULTRA FILTRATION G90 EFFLUENT

40 Sample Pumps 90

41 CIP General 91 Chlorine Booster Pumps

42 Scour Air Blowers 92

43 Inst Air

44 UF CIP Recirc

45 UF CIP Hypo

46 UF CIP Citric Acid

47 UF CIP Sulphuric Acid

48 UF CIP Waste

49 UF BW Pumps

Revision 2.0 - 16 December 2015 Page 24 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

B4 Christies Beach WWTP

Sub Sub

Area Description Area Description

Area Area

00 GENERAL 60 CHEMICAL DOSING

01 Plant Site 61 Ethanol Dosing

02 Electrical – HV Sup., Transformers, LV Bld./Dist. 62 Chlorine Dosing

03 On–Site Power Generation 63

04 64 Polymer Dosing - DAFT/Dewatering

05 Workshop/Administration Areas 65 Polymer Dosing - RSTs

06 66

07 67 Membrane Chemical Cleaning System

10 INLET WORKS 70 ROTARY SCREW THICKENERS

11 71 RST Thickening

12 Inlet Screens 72 RST Thickening Filtrate Return

13

14 Vortex Grit Removal/Flow Splitting

15 C Plant Fine Screens

16

17 Inlet Works Foul Air Collection

18 Inlet Works Odour Control Plant

20 GRIT REMOVAL AND PSTs 80 SLUDGE DIGESTION

21 Primary Sedimentation Tank A1 81 Digester 1

22 Primary Sedimentation Tank A2 82 Digester 2

23 Primary Sedimentation Tank B1 83 Digested Sludge Recirculation

24 Primary Sedimentation Tank B2 84 Digested Sludge Transfer

25 Primary Sludge and Scum Pumping 85 Digested Sludge Disposal

86 Digested Sludge Supernatant

87 Digester Hot Water System

88 Digesters 3 and 4 (Future)

89 Digester Gas Handling and Conditioning

30 ASRs & AERATION FACILITY 90 TERTIARY TREATMENT & OUTFALLS

31 ASR A1 91

32 ASR A2 92 UV Disinfection

33 ASR B1 93 Effluent Outfalls and Reuse

34 ASR B2 94 Recycled Water Transfer Pump Station (SURP)

35 ASR C1 95

36 ASR C2 96

97

98

99

40 SECONDARY SEDIMENTATION 100 SLUDGE CONDITIONING

41 A Plant Sludge Wasting 101 Sludge Hydrolysis

42 B Plant Sludge Wasting 102

43 C Plant Sludge Wasting 103

104

105

50 DAF THICKENERS 110 DIGESTED SLUDGE DEWATERING

51 DAFT Cell 1 111 Digested Sludge Dewatering (Centrifuges)

52 DAFT Cell 2 112 Digested Sludge Loading

53 113 Sludge Dewatering Odour Control

54

55 DAFT Effluent System

56 DAFT Sludge System

57 DAFT Compressed Air System

58 DAFT Bottom Sludge Pumps

Revision 2.0 - 16 December 2015 Page 25 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

Sub Sub

Area Description Area Description

Area Area

120 C PLANT MEMBRANE SEPARATION 230 SITE UTILITIES

121 C Plant Membrane UF Train 1 231 Potable Water

122 C Plant Membrane UF Train 2 232 Fire Fighting

123 C Plant Membrane UF Train 3 233 Natural Gas

124 C Plant Membrane UF Train 4 234 Process Water

125 C Plant Membrane UF Train 5 235 Site Waste Pump Station

126 C Plant Membrane UF Train 6 236 Liquid Waste Disposal Station

127 C Plant Membrane Process Pumps 237

128 C Plant Mixed Liquor Recycle 238

129 239

Revision 2.0 - 16 December 2015 Page 26 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

TS 112 - Process and Instrumentation Diagrams (P&ID) SA Water - Technical Standard

B5 Water Treatment Plants

Sub Sub

Area Description Area Description

Area Area

00 GENERAL 50 CHEMICAL DOSING

00 50

01 51 Alum Dosing

02 52 Poly Dosing

03 53

04 54 Fluoride Dosing

05 55

56

57 Lime Dosing

58

10 RAW WATER 60 CHEMICAL STORAGE

10 60

11 61 Alum Storage

12 62 Poly Storage

13 63

14 64 Fluoride Storage

15 65

66

67 Lime Storage

20 SLUDGE PROCESSING 70 TREATED WATER STORAGE

20 70

21 71

22 72

23 73

24 74

25 75

30 SEDIMENTATION / FLOCCULATION 80 TREATED WATER PUMPING

30 80

31 81

32 82

33 83

34 84

35

36

40 FILTRATION 90 CHLORINATION

40 90

41 91

42 92

43 93

44 94

45 95

96

97

98

99

Revision 2.0 - 16 December 2015 Page 27 of 27

For Official Use Only Uncontrolled When Printed Or Downloaded

Potrebbero piacerti anche

- Manual MN-026 Champion 700 Series Motor Grader Series III Operators Manual L-4014-01!5!1991Documento306 pagineManual MN-026 Champion 700 Series Motor Grader Series III Operators Manual L-4014-01!5!1991estefaniacs100% (22)

- Saep 311Documento29 pagineSaep 311Sunny Thundil100% (1)

- OIS SOP 2.4.1 Internal PenetrationDocumento11 pagineOIS SOP 2.4.1 Internal PenetrationRobase0650% (2)

- Vendor Document Master ListDocumento3 pagineVendor Document Master ListGeetha_jagadish30Nessuna valutazione finora

- Standardsof Wastewater DesignDocumento97 pagineStandardsof Wastewater DesignMagin Idelfonso Torreblanca100% (1)

- EPC Level 4 Schedule PDFDocumento7 pagineEPC Level 4 Schedule PDFGeetha_jagadish30Nessuna valutazione finora

- Wastewater DesignDocumento37 pagineWastewater Designscarmathor90Nessuna valutazione finora

- ADCO SIL ProcedureDocumento42 pagineADCO SIL ProcedureGianfrancoMangiapaneNessuna valutazione finora

- Thickeners: It Pays To Talk To A SpecialistDocumento8 pagineThickeners: It Pays To Talk To A SpecialistKumardasNsNessuna valutazione finora

- Presentation of Apex Consultants - NewDocumento20 paginePresentation of Apex Consultants - NewSudhirNessuna valutazione finora

- Mod04 Lec06 Electro Deionization (EDI)Documento43 pagineMod04 Lec06 Electro Deionization (EDI)Mario Antonio Araya MorosoNessuna valutazione finora

- Odour Control in WWTPDocumento10 pagineOdour Control in WWTPMadhavan DurairajNessuna valutazione finora

- Goods Lifts: 300 - 2000kg CapacityDocumento14 pagineGoods Lifts: 300 - 2000kg CapacityAnton LyakhovNessuna valutazione finora

- Piping and Instrumentation DiagramDocumento17 paginePiping and Instrumentation Diagramengr_rim50% (2)

- Application of Electro-Membrane Technologies in Zero Liquid Discharge TechnologyDocumento27 pagineApplication of Electro-Membrane Technologies in Zero Liquid Discharge TechnologyYesid Tapiero MartínezNessuna valutazione finora

- Biowin InstructionsDocumento4 pagineBiowin Instructionsomaraldeeb4Nessuna valutazione finora

- Air Insulated Indoor SwitchgearDocumento6 pagineAir Insulated Indoor SwitchgearvurumuuNessuna valutazione finora

- Typical Project SequenceDocumento10 pagineTypical Project SequenceGeetha_jagadish30Nessuna valutazione finora

- Ats BrochureDocumento28 pagineAts BrochureQuốc Anh KhổngNessuna valutazione finora

- EPC Level 3 ScheduleDocumento72 pagineEPC Level 3 ScheduleGeetha_jagadish300% (1)

- SUEZ Hand Book For Industrial Water TreatmentDocumento1 paginaSUEZ Hand Book For Industrial Water TreatmentJahidul IslamNessuna valutazione finora

- Operation and Maintenance Manual For The Lo/Pro Odor Control SystemDocumento48 pagineOperation and Maintenance Manual For The Lo/Pro Odor Control SystemVinish HARIDAS NAIRNessuna valutazione finora

- Inclined Plate ClarifierDocumento2 pagineInclined Plate ClarifierKelvin SiewNessuna valutazione finora

- Desalination Plant: Let's Explore!Documento33 pagineDesalination Plant: Let's Explore!saqlainNessuna valutazione finora

- GE EDI O&M Manual - 10jul06Documento14 pagineGE EDI O&M Manual - 10jul06Geancarlo GutierrezNessuna valutazione finora

- Vendor Document Register List VDRL PDFDocumento1 paginaVendor Document Register List VDRL PDFGeetha_jagadish3050% (2)

- Standards For Technical DrawingDocumento14 pagineStandards For Technical Drawing4gen_7Nessuna valutazione finora

- Engineering ManagerDocumento1 paginaEngineering ManagerGeetha_jagadish30Nessuna valutazione finora

- Demineralized Water System Calculation LTCA P-6010 DMS - RaDocumento5 pagineDemineralized Water System Calculation LTCA P-6010 DMS - RaOmar Escudero0% (1)

- Controlling Risk PDFDocumento44 pagineControlling Risk PDFGeetha_jagadish30Nessuna valutazione finora

- Application Manual: Allison 8000 Series ModelsDocumento11 pagineApplication Manual: Allison 8000 Series Modelsamin chaaben100% (1)

- RFP Evaluation WorksheetDocumento1 paginaRFP Evaluation WorksheetGeetha_jagadish30Nessuna valutazione finora

- Treatment of Slaughterhouse Wastewater - CE 479 - Lawrence - Fall 2006Documento27 pagineTreatment of Slaughterhouse Wastewater - CE 479 - Lawrence - Fall 2006sauroNessuna valutazione finora

- Ultra Pure WaterDocumento6 pagineUltra Pure Watergauravgarg115Nessuna valutazione finora

- Motor Operating Instruction - 102008Documento106 pagineMotor Operating Instruction - 102008Luis LopezNessuna valutazione finora

- JJ104 Workshop Technology Chapter6 Milling MachineDocumento27 pagineJJ104 Workshop Technology Chapter6 Milling MachineAh Tiang100% (3)

- Industrial RO Plant in AhmedabadDocumento5 pagineIndustrial RO Plant in AhmedabadShubham India - Sewage Treatment PlantNessuna valutazione finora

- Calculation of Pressure RegulatorsDocumento5 pagineCalculation of Pressure RegulatorsKlubowoloya11Nessuna valutazione finora

- Wastewater Treatment TechnologyDocumento125 pagineWastewater Treatment TechnologySheryl MH-PradaNessuna valutazione finora

- Plant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)Documento12 paginePlant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)Dev Kumar DwivediNessuna valutazione finora

- Specific Energy Consumption of Membrane Bioreactor (MBR) For SewageDocumento14 pagineSpecific Energy Consumption of Membrane Bioreactor (MBR) For Sewagesulihah12Nessuna valutazione finora

- Process and Instrumentation Diagram DevelopmentDocumento14 pagineProcess and Instrumentation Diagram DevelopmentATUL SONAWANENessuna valutazione finora

- Project Management PlanDocumento2 pagineProject Management PlanGeetha_jagadish30100% (1)

- GPSX - Techref 01Documento372 pagineGPSX - Techref 01felixNessuna valutazione finora

- Bi Water Membrane BrochureDocumento8 pagineBi Water Membrane BrochurebazediNessuna valutazione finora

- Technical Aspects of Desalination PlantDocumento12 pagineTechnical Aspects of Desalination PlantMonica UrbietaNessuna valutazione finora

- SEKO Biogas PlantsDocumento28 pagineSEKO Biogas PlantsddzoningcomNessuna valutazione finora

- TS 95 Requirements For Technical Drawings 20160124Documento29 pagineTS 95 Requirements For Technical Drawings 20160124Anonymous TG3lMENessuna valutazione finora

- 100 PF01Documento87 pagine100 PF01Việt Hoàng Bùi100% (2)

- AL MARAI HADCO ETP - Process Description and SeqDocumento43 pagineAL MARAI HADCO ETP - Process Description and SeqHumaid ShaikhNessuna valutazione finora

- Water Treatment ProceduresDocumento38 pagineWater Treatment ProceduresMauro Domingo'sNessuna valutazione finora

- Control Philosophy - DM PlantDocumento11 pagineControl Philosophy - DM Plantnileshwarke100% (1)

- Pptonfab MBBR 130616081952 Phpapp01Documento18 paginePptonfab MBBR 130616081952 Phpapp01TAREK ALMAHDY100% (3)

- Brushbond TGPDocumento2 pagineBrushbond TGPBalasubramanian AnanthNessuna valutazione finora

- Degasifier 18-02-2017 Sheet 1Documento1 paginaDegasifier 18-02-2017 Sheet 1Abu SuraisyNessuna valutazione finora

- RWL Water Nirobox SWDocumento3 pagineRWL Water Nirobox SWAlexander HerreraNessuna valutazione finora

- Diaphragm Pump:Design & Working: Prepared By:-Sidra HafeezDocumento21 pagineDiaphragm Pump:Design & Working: Prepared By:-Sidra Hafeezmahmoud EissaNessuna valutazione finora

- Small Scale Wastewater Treatment For Single HousesDocumento16 pagineSmall Scale Wastewater Treatment For Single HousesvalerieNessuna valutazione finora

- Water Treatment SystemDocumento12 pagineWater Treatment SystemArunNessuna valutazione finora

- Co2 Degasifier To Adjust The PHDocumento2 pagineCo2 Degasifier To Adjust The PHGhuna UcihaNessuna valutazione finora

- Pilot Units From LiqTech - v2 PDFDocumento2 paginePilot Units From LiqTech - v2 PDFGabriel Montoya CorreaNessuna valutazione finora

- BZ Est PD 002 Control Philosophy TestDocumento55 pagineBZ Est PD 002 Control Philosophy TestMertoiu GabrielNessuna valutazione finora

- Technical Paper SiC Ceramic MembranesDocumento5 pagineTechnical Paper SiC Ceramic MembranesEman El DsoukyNessuna valutazione finora

- ProMinent Operating Instructions Meta HM-HKDocumento20 pagineProMinent Operating Instructions Meta HM-HKivan_shterevNessuna valutazione finora

- Waste Water Treatment Plant Selection, Sizing and TROUBLESHOOTING, Kolmetz Handbook of Process Equipment DesignDocumento39 pagineWaste Water Treatment Plant Selection, Sizing and TROUBLESHOOTING, Kolmetz Handbook of Process Equipment DesignruyNessuna valutazione finora

- Vacuum Swing AdsorptionDocumento3 pagineVacuum Swing AdsorptionnagsraviNessuna valutazione finora

- Up STP Build and Design Project PLC Detailed Wiring Diagram: PlantelligentDocumento22 pagineUp STP Build and Design Project PLC Detailed Wiring Diagram: PlantelligentTimothy CorpusNessuna valutazione finora

- Introduction To Electrodeionization: Jeff Tate Agape Water Solutions, IncDocumento26 pagineIntroduction To Electrodeionization: Jeff Tate Agape Water Solutions, Incsagor sagorNessuna valutazione finora

- PB Filter Press Sidebar Me1500 Me2500 en Web DataDocumento4 paginePB Filter Press Sidebar Me1500 Me2500 en Web DataTiago J C MachadoNessuna valutazione finora

- Anaerobic Processes: Rate Systems. Thus One Can Have A Low-Rate, Suspended-Growth Anaerobic System WhichDocumento6 pagineAnaerobic Processes: Rate Systems. Thus One Can Have A Low-Rate, Suspended-Growth Anaerobic System Whichnickao123Nessuna valutazione finora

- SkemaDocumento47 pagineSkemaAnonymous VJFlyRY0Nessuna valutazione finora

- Coagulation-Flocculation: (Water and Wastewater Treatment)Documento28 pagineCoagulation-Flocculation: (Water and Wastewater Treatment)Shamsa KanwalNessuna valutazione finora

- SMART Digital - DDA With Profibus DP / Modbus Rtu / Profinet Io / Modbus TCPDocumento2 pagineSMART Digital - DDA With Profibus DP / Modbus Rtu / Profinet Io / Modbus TCPRyan GohNessuna valutazione finora

- Instruction Manual MODEL 7200 Cement Hydration Analyzer: Part Number: 7200-1050 Revision M - Apr 2021Documento77 pagineInstruction Manual MODEL 7200 Cement Hydration Analyzer: Part Number: 7200-1050 Revision M - Apr 2021javimeza4Nessuna valutazione finora

- TS 147 Surge Mitigating Infrastructure 20160407Documento30 pagineTS 147 Surge Mitigating Infrastructure 20160407Vinish HARIDAS NAIRNessuna valutazione finora

- Project Plan Odessa Mobile Technology ProjectDocumento22 pagineProject Plan Odessa Mobile Technology Projectsan1432Nessuna valutazione finora

- Sustainability 10 02469Documento31 pagineSustainability 10 02469Geetha_jagadish30Nessuna valutazione finora

- Initiate Review: Proposal Risk ChecklistDocumento3 pagineInitiate Review: Proposal Risk ChecklistGeetha_jagadish30Nessuna valutazione finora

- Engineering ProductivityDocumento15 pagineEngineering ProductivityGeetha_jagadish30Nessuna valutazione finora

- Manual: Procedure Titel: HSE-ManualDocumento11 pagineManual: Procedure Titel: HSE-ManualGeetha_jagadish30Nessuna valutazione finora

- Valdel LLC Gap Analysis Checklist: Ref Gap Analysis Question Finding Yes Implementation Plan (If No)Documento6 pagineValdel LLC Gap Analysis Checklist: Ref Gap Analysis Question Finding Yes Implementation Plan (If No)Geetha_jagadish30Nessuna valutazione finora

- Quality: Commitment - ApproachDocumento1 paginaQuality: Commitment - ApproachGeetha_jagadish30Nessuna valutazione finora

- Comment Resolution Sheet (CRS) : Project NameDocumento1 paginaComment Resolution Sheet (CRS) : Project NameGeetha_jagadish30Nessuna valutazione finora

- Ch1 Z10 AttG R0Documento11 pagineCh1 Z10 AttG R0Geetha_jagadish30Nessuna valutazione finora

- PG Town PlanningDocumento3 paginePG Town PlanningCharan Reddy100% (1)

- Electrocompaniet NemoDocumento3 pagineElectrocompaniet NemoKC PangNessuna valutazione finora

- Welding Product Programme: Duplex and Super Duplex Stainless SteelDocumento6 pagineWelding Product Programme: Duplex and Super Duplex Stainless SteelFERNANDO MIRANDANessuna valutazione finora

- Inspection & Testing Plan (Itp) : Before ManufacturingDocumento2 pagineInspection & Testing Plan (Itp) : Before ManufacturingsonalikeniNessuna valutazione finora

- Care Your HornDocumento8 pagineCare Your HornAlvaro Suarez VazquezNessuna valutazione finora

- Digest Specifications:DepEd SB StandardDocumento4 pagineDigest Specifications:DepEd SB StandardEfren Fernandez ElegadoNessuna valutazione finora

- 15 Years of EIA in BangladeshDocumento30 pagine15 Years of EIA in BangladeshShahriar ShuvaNessuna valutazione finora

- ETSI EG 201 013 - Human Factors (HF) Definitions, Abbreviations and SymbolsDocumento15 pagineETSI EG 201 013 - Human Factors (HF) Definitions, Abbreviations and SymbolsTamer El-TonsyNessuna valutazione finora

- SK Drum Band 2022Documento65 pagineSK Drum Band 2022Rizla GrinderoticaNessuna valutazione finora

- Juno Lighting Vector Track Lights Brochure 1988Documento12 pagineJuno Lighting Vector Track Lights Brochure 1988Alan MastersNessuna valutazione finora

- CCcam - CFG SimpleDocumento3 pagineCCcam - CFG SimpleSadia KanwalNessuna valutazione finora

- 3b Domestic Water Meter Installation in Meter Room GuidelinesDocumento10 pagine3b Domestic Water Meter Installation in Meter Room GuidelinesVinish HARIDAS NAIRNessuna valutazione finora

- ISO 11957 1996 en PreviewDocumento5 pagineISO 11957 1996 en PreviewHoang TraNessuna valutazione finora

- C-508 Rev 2 - Draft PDFDocumento37 pagineC-508 Rev 2 - Draft PDFPravinNessuna valutazione finora

- Rail WheelDocumento8 pagineRail WheelAbdulhmeed MutalatNessuna valutazione finora

- Etsi TS 141 101Documento24 pagineEtsi TS 141 101mozbalNessuna valutazione finora

- Powerflex® 7000 Ac Drive With Direct-To-Drive Technology Re-Installing A Common Mode ChokeDocumento20 paginePowerflex® 7000 Ac Drive With Direct-To-Drive Technology Re-Installing A Common Mode ChokeSGQNessuna valutazione finora

- Inclinimetro Boom RDSR3 BA 09 - BrochDocumento3 pagineInclinimetro Boom RDSR3 BA 09 - BrochedgarlimasNessuna valutazione finora

- Hewlett-Packard Vp6311 ManualDocumento75 pagineHewlett-Packard Vp6311 ManualIngArnaldoParraNessuna valutazione finora

- Pneumatic FeedersDocumento5 paginePneumatic FeedersKaramveer RatheeNessuna valutazione finora

- DD Cen TS 14425-1-2003Documento16 pagineDD Cen TS 14425-1-2003mossamorrisNessuna valutazione finora

- Kraken AKDocumento12 pagineKraken AKRomica Sibisan100% (1)