Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Erection Method Statement

Caricato da

sathiyan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

46 visualizzazioni1 paginaFlexcell is a bitumen impregnated expansion joint filler made of hard and soft wood fibers. It is ideal for use in highways, bridges, and other civil engineering projects. Flexcell is resilient, durable, and weather resistant. It is available in standard sizes and thicknesses to suit a variety of applications.

Descrizione originale:

S SATHIYARUBAN

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoFlexcell is a bitumen impregnated expansion joint filler made of hard and soft wood fibers. It is ideal for use in highways, bridges, and other civil engineering projects. Flexcell is resilient, durable, and weather resistant. It is available in standard sizes and thicknesses to suit a variety of applications.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

46 visualizzazioni1 paginaErection Method Statement

Caricato da

sathiyanFlexcell is a bitumen impregnated expansion joint filler made of hard and soft wood fibers. It is ideal for use in highways, bridges, and other civil engineering projects. Flexcell is resilient, durable, and weather resistant. It is available in standard sizes and thicknesses to suit a variety of applications.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Owens Supply Co. Plainfield (chicago), Il. 1-866-566-7151 www.owensupply.

com

Flexcell

bitumen impregnated expansion joint filler

An introduction to Flexcell Identification Standard sizes

Bitumen impregnated insulating board (as Flexcell is available in a range of standard sizes and thicknesses as shown below:

described in BS 1142) for use as an expansion

Cut size Thicknesses Pieces No. of pieces per ⋅ 2440

No. of 1220

Concrete expands and contracts according to temperature joint filler.

(mm) per pack 1220⋅ 2440 sheet sheets per pallet

changes, and therefore some of type of filler is needed between 75 ⋅ 2440 10 10 15 110

Composition and manufacture

slabwork to keep the concrete from buckling when it expands, 12 10 15 90

Made from hard and soft wood fibres with 20 10 15 55

and to fill the resultant gaps when the concrete contracts. approximately 12.5% bitumen content. 25 10 15 44

Expansion (movement) joints may be used between the slabs, 100 ⋅ 2440 10 10 11 110

12 10 11 90

and also to separate the slabs from structures, thereby preventing Standards and authority

20 10 11 55

Tested to BS 1142: 1989. 25 10 11 44

damage which may occur during these expansion and

125 ⋅ 2440 10 10 9 110

Department of Transport specification for

contraction cycles. highway works, Part 3, Series 1000, Clause

12 10 9 90

20 10 9 55

1015.

Flexcell is a bitumen impregnated wood fibre board, which 25 10 9 44

150 ⋅ 2440 10 10 7 110

is ideal for use as an expansion joint filler. It offers excellent Dry density 12 10 7 90

compressive and recovery properties, is simple to handle and Typical dry density for all thicknesses is

20 10 7 55

25 10 7 44

approximately 275 kg/m3.

install and is available in a range of sizes to suit most highway 175 ⋅ 2440 10 10 6 110

12 10 6 90

and civil engineering requirements, including roads, bridges, Bending strength? 20 10 6 55

car parks, airports and brick walls. Copy here

25 10 6 44

200 ⋅ 2440 10 10 5 110

12 10 5 90

Typical applications 20 10 5 55

Copy here 25 10 5 44

Compression to 50% thickness in the initial state

Features and benefits

Thicknesses Specific weight Load Recovery Mass loss

• Resilient – the unique composition of Flexcell (kg/m 3) (N/mm 2) (%) (%)

permits it to compress 50% of its thickness

19 275 >2 82 <1

without extruding, and to recover to a

20 295 >2 80 <1

minimum of 70% of its original thickness.

20 290 >2 80 <1

• Durability – proven long lasting product

• Weather resistant – the bitumen impregnated

Weathering and compression to 50% thickness

wood fibre provide low water absorption and

will not become brittle in cold weather. Tests Thicknesses Specific weight Load Recovery Extrusion

show no damage due to freezing or thawing. (kg/m 3) (N/mm 2) (%) (%)

• Excellent bond – the textures surface provides 19 275 >2 70 0.50

an excellent interface with poured concrete, 20 295 >2 72 0.50

so it resists working loose during concrete 20 290 >2 71 0.50

expansion and contraction.

Potrebbero piacerti anche

- TS For BrideDocumento24 pagineTS For BrideSammy ChanNessuna valutazione finora

- Upgrading Internal Solid Walls Pl4000 Application Datasheet Dec17Documento3 pagineUpgrading Internal Solid Walls Pl4000 Application Datasheet Dec17ajh1994Nessuna valutazione finora

- Tuned Mass Dampers Under Excessive Structural ExcitationDocumento7 pagineTuned Mass Dampers Under Excessive Structural ExcitationVictor SainiucNessuna valutazione finora

- Limited and Float InstallationDocumento2 pagineLimited and Float InstallationGoran PetrovicNessuna valutazione finora

- Rankirimada TempleDocumento13 pagineRankirimada TempleChinthakaNessuna valutazione finora

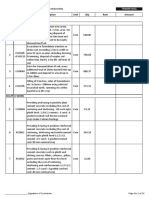

- Bill of Quantities: No. Job No. DRG No. Sheet No. 1 of 1 Rev. Designed Checked DateDocumento2 pagineBill of Quantities: No. Job No. DRG No. Sheet No. 1 of 1 Rev. Designed Checked DateSitche ZisoNessuna valutazione finora

- Absolute Roughness (MM) Coefficient of Maning Hazen Williams (C)Documento6 pagineAbsolute Roughness (MM) Coefficient of Maning Hazen Williams (C)Cesar PachacamaNessuna valutazione finora

- QQQDocumento7 pagineQQQtejas nandaniNessuna valutazione finora

- 07 - TDS - Concresive 1418Documento4 pagine07 - TDS - Concresive 1418aahtagoNessuna valutazione finora

- Chapter 11Documento1 paginaChapter 11sde psd9Nessuna valutazione finora

- En Iso Mattex Geomatt TB - I-25!08!2013Documento1 paginaEn Iso Mattex Geomatt TB - I-25!08!2013FarhatNessuna valutazione finora

- EstimationDocumento4 pagineEstimationArif AbbihalNessuna valutazione finora

- SpecificationDocumento100 pagineSpecificationSUSOVAN BISWASNessuna valutazione finora

- C. Milewskietal.2020Shearingresistanceofroughpolymer-sandinterfacesDocumento11 pagineC. Milewskietal.2020Shearingresistanceofroughpolymer-sandinterfacesJaime SeguraNessuna valutazione finora

- Sudha Nallah CompartiveDocumento16 pagineSudha Nallah CompartivetosworldNessuna valutazione finora

- NAME OF WORK: (1) VERAVAL: Repairs To Damaged Roof of Health Unit atDocumento9 pagineNAME OF WORK: (1) VERAVAL: Repairs To Damaged Roof of Health Unit atamitdostNessuna valutazione finora

- MCHW Vol 1 1000 - Web PDFDocumento51 pagineMCHW Vol 1 1000 - Web PDFalejandraoy9Nessuna valutazione finora

- Revised Vvip Road 29-03-2020Documento3 pagineRevised Vvip Road 29-03-2020rohith eticalaNessuna valutazione finora

- Reinforced Concrete - I: (CENG 3502)Documento28 pagineReinforced Concrete - I: (CENG 3502)ashenafiNessuna valutazione finora

- DrainDocumento3 pagineDrainPachuau MesiahNessuna valutazione finora

- Chapter - 22: Bridge Works - Miscellaneous: Item No. Description of Item Unit Rate (RS.) Cement Qty. (QTL.)Documento10 pagineChapter - 22: Bridge Works - Miscellaneous: Item No. Description of Item Unit Rate (RS.) Cement Qty. (QTL.)basuNessuna valutazione finora

- Cementing Integrity EvaluationDocumento67 pagineCementing Integrity EvaluationKalou BoniNessuna valutazione finora

- Cementing Integrity EvaluationDocumento67 pagineCementing Integrity EvaluationBagahadum Abdul AzizNessuna valutazione finora

- B. Bill of QuantitiesDocumento21 pagineB. Bill of QuantitiesPaul OtimNessuna valutazione finora

- Summary of Rates: S.N. Norms No Description Unit Rate (NRS.) Specification Clause NoDocumento28 pagineSummary of Rates: S.N. Norms No Description Unit Rate (NRS.) Specification Clause Nonitish JhaNessuna valutazione finora

- ArcelorMittal DOMSpecsDocumento12 pagineArcelorMittal DOMSpecsAnurag DixitNessuna valutazione finora

- Cost Rob LC 112Documento7 pagineCost Rob LC 112Abhijeet SahuNessuna valutazione finora

- Pub139 26Documento1 paginaPub139 26satnamNessuna valutazione finora

- CIVIL & StructureDocumento94 pagineCIVIL & StructuresamarbtechNessuna valutazione finora

- Bill of Quantities: Royal Audit Authority Training Centre, TsirangDocumento4 pagineBill of Quantities: Royal Audit Authority Training Centre, TsirangNasir UllahNessuna valutazione finora

- Monolithic Membrane 6125: PremiumDocumento8 pagineMonolithic Membrane 6125: PremiumSam YoonNessuna valutazione finora

- MeasurIT Tideflex Valves 0912Documento4 pagineMeasurIT Tideflex Valves 0912cwiejkowskaNessuna valutazione finora

- Feh 2Documento1 paginaFeh 2rentfarNessuna valutazione finora

- SOR Item No. Description Unit No. L (M) B (M) D (M) Qty. Rate AmountDocumento2 pagineSOR Item No. Description Unit No. L (M) B (M) D (M) Qty. Rate AmountShubham KhareNessuna valutazione finora

- BAUER Ground Improvement by Depth Vibrator - 2011Documento16 pagineBAUER Ground Improvement by Depth Vibrator - 2011eduardomanar1224100% (1)

- BOQTibbiCollegeDocumento38 pagineBOQTibbiCollegeVinay KumarNessuna valutazione finora

- Ubp SpecsDocumento1 paginaUbp SpecsAKASH FERAGNessuna valutazione finora

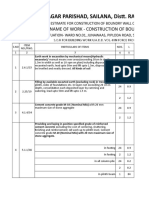

- Boundry WallDocumento6 pagineBoundry Wallvivek deogamNessuna valutazione finora

- Data Sheet - Mirafi® HPa (200 613-td-05-15)Documento1 paginaData Sheet - Mirafi® HPa (200 613-td-05-15)khairul umamNessuna valutazione finora

- Sub Estimate HPC1200Documento1 paginaSub Estimate HPC1200Daljeet SidhuNessuna valutazione finora

- CV1013 - Concrete - 8 Properties of Hardened Concrete - S2 19-20Documento46 pagineCV1013 - Concrete - 8 Properties of Hardened Concrete - S2 19-20Ash KongNessuna valutazione finora

- Andal Gsu 1st RaDocumento6 pagineAndal Gsu 1st RaEr Anup BiswasNessuna valutazione finora

- Trial Rate Conc M25 Rate Analysis 2021Documento8 pagineTrial Rate Conc M25 Rate Analysis 2021Gautam DuttaNessuna valutazione finora

- Wit-Vm 250 MDocumento24 pagineWit-Vm 250 MQCNessuna valutazione finora

- Substructure: Take Off ListDocumento141 pagineSubstructure: Take Off ListTinashe KurauoneNessuna valutazione finora

- Global Cellulose Ether GradeDocumento23 pagineGlobal Cellulose Ether GradeWANGYUSHENG Kima Chemical Co LtdNessuna valutazione finora

- Soil Consolidation (Vertical Drains)Documento20 pagineSoil Consolidation (Vertical Drains)E Hammam El MissiryNessuna valutazione finora

- Global RoadDocumento2 pagineGlobal RoadLucky KumarNessuna valutazione finora

- GST of 12 % Shall Be Claimed Seperately in Bills. (Refer KSR Page E Point 5-7Documento29 pagineGST of 12 % Shall Be Claimed Seperately in Bills. (Refer KSR Page E Point 5-7Anweesha Nileshwar MejariNessuna valutazione finora

- DPR - PKG-3 - Ra-28 Date 13.12.2018Documento7 pagineDPR - PKG-3 - Ra-28 Date 13.12.2018Prasanta ParidaNessuna valutazione finora

- Second Semester: 20CE202L Building Drafting and Modeling LaboratoryDocumento3 pagineSecond Semester: 20CE202L Building Drafting and Modeling LaboratoryUma MaheshwaranNessuna valutazione finora

- Nagar Parishad, Sailana, Distt. Ratlam (M.P.) : Name of Work - Construction of Boundry WallDocumento6 pagineNagar Parishad, Sailana, Distt. Ratlam (M.P.) : Name of Work - Construction of Boundry WallDALJEET SINGHNessuna valutazione finora

- Doka Design Calculations-13Documento1 paginaDoka Design Calculations-13Akif0% (1)

- Uac Berhadbf3e11ce98Documento12 pagineUac Berhadbf3e11ce98ruzain rahmatNessuna valutazione finora

- T 860 and T 1250: Parts ListDocumento70 pagineT 860 and T 1250: Parts Listmanish agrawal100% (1)

- ESTIMATIONDocumento8 pagineESTIMATIONpujar constructionsNessuna valutazione finora

- Repair/Rehabilitation of University Grandstand: Week 1 Week 2 Week 3 Week 4Documento1 paginaRepair/Rehabilitation of University Grandstand: Week 1 Week 2 Week 3 Week 4MILACEL GAMIDONessuna valutazione finora

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsDa EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNessuna valutazione finora

- Flow Crete OverviewDocumento1 paginaFlow Crete OverviewsathiyanNessuna valutazione finora

- Detail of Rubble Paving at Wing Wall: 60Mm Thk. Wearing CourseDocumento1 paginaDetail of Rubble Paving at Wing Wall: 60Mm Thk. Wearing CoursesathiyanNessuna valutazione finora

- Section of Road Center Line: Project: Engineer ContractorDocumento1 paginaSection of Road Center Line: Project: Engineer ContractorsathiyanNessuna valutazione finora

- Shanmuganathan Sathiyaruban - Cv-2019 OctoberDocumento3 pagineShanmuganathan Sathiyaruban - Cv-2019 OctobersathiyanNessuna valutazione finora

- 001 PDFDocumento1 pagina001 PDFsathiyanNessuna valutazione finora

- Detail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)Documento1 paginaDetail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)sathiyanNessuna valutazione finora

- Reinforcement Details of Single Box Type: SectionDocumento1 paginaReinforcement Details of Single Box Type: SectionsathiyanNessuna valutazione finora

- Section A-A Detail of Rubble Paving at Wing Wall: 60Mm Thk. Wearing CourseDocumento1 paginaSection A-A Detail of Rubble Paving at Wing Wall: 60Mm Thk. Wearing CoursesathiyanNessuna valutazione finora

- Section of Road Center Line: CL BridgeDocumento1 paginaSection of Road Center Line: CL BridgesathiyanNessuna valutazione finora

- 002Documento1 pagina002sathiyan100% (1)

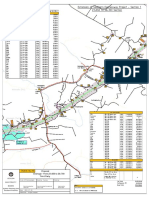

- Extension of Southern Expressway Project - Section 1 - 0+250 To 4+000 SectionDocumento1 paginaExtension of Southern Expressway Project - Section 1 - 0+250 To 4+000 SectionsathiyanNessuna valutazione finora

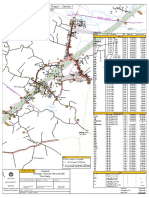

- Drawing Title:: Project: Engineer ContractorDocumento1 paginaDrawing Title:: Project: Engineer ContractorsathiyanNessuna valutazione finora

- Reinforcement Details of Single Box Type: SectionDocumento1 paginaReinforcement Details of Single Box Type: Sectionsathiyan100% (2)

- Extension of Southern Expressway From Matara To HambantotaDocumento1 paginaExtension of Southern Expressway From Matara To HambantotasathiyanNessuna valutazione finora

- Section A-A Detail of Rubble Paving at Wing Wall: 60Mm Thk. Wearing CourseDocumento1 paginaSection A-A Detail of Rubble Paving at Wing Wall: 60Mm Thk. Wearing CoursesathiyanNessuna valutazione finora

- Extension of Southern Expressway Project - Section 1 15+900 To 20+800 SectionDocumento1 paginaExtension of Southern Expressway Project - Section 1 15+900 To 20+800 SectionsathiyanNessuna valutazione finora

- Extension of Southern Expressway Project - Section 1 23+650 To 26+700 SectionDocumento1 paginaExtension of Southern Expressway Project - Section 1 23+650 To 26+700 SectionsathiyanNessuna valutazione finora

- Extension of Southern Expressway Project - Section 1 26+700 To 30+000 SectionDocumento1 paginaExtension of Southern Expressway Project - Section 1 26+700 To 30+000 SectionsathiyanNessuna valutazione finora

- Extension of Southern Expressway Project - Section 1 11+500 To 15+900 SectionDocumento1 paginaExtension of Southern Expressway Project - Section 1 11+500 To 15+900 SectionsathiyanNessuna valutazione finora

- Extension of Southern Expressway Project - Section 1 6+250 To 8+500 SectionDocumento1 paginaExtension of Southern Expressway Project - Section 1 6+250 To 8+500 SectionsathiyanNessuna valutazione finora

- Fisher Imprints: Inter-Disciplinary PressDocumento8 pagineFisher Imprints: Inter-Disciplinary PressUndi GunawanNessuna valutazione finora

- Converging To The CloudDocumento39 pagineConverging To The CloudmkivNessuna valutazione finora

- WS 4 Minutes - 2.9.2019Documento3 pagineWS 4 Minutes - 2.9.2019Andrea KakuruNessuna valutazione finora

- BTS 84Documento4 pagineBTS 84Kiara Ticangan ArgelNessuna valutazione finora

- EPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Documento20 pagineEPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Ion IonutNessuna valutazione finora

- Ac To DC Converter Project Report PDFDocumento75 pagineAc To DC Converter Project Report PDFVishal Bhadalda100% (1)

- 5 Easy Tips On How To Get Canadian Experience: Job SearchDocumento15 pagine5 Easy Tips On How To Get Canadian Experience: Job Searchranvirsingh76Nessuna valutazione finora

- E MAX - E Max Brushless Motor Specs EE July 08Documento11 pagineE MAX - E Max Brushless Motor Specs EE July 08ewaigel0% (1)

- Information: Reading Images - The Grammar of Visual DesignDocumento5 pagineInformation: Reading Images - The Grammar of Visual DesignAndang Prasetya Adiwibawa BernardusNessuna valutazione finora

- PanasonicBatteries NI-MH HandbookDocumento25 paginePanasonicBatteries NI-MH HandbooktlusinNessuna valutazione finora

- Plant and Maintenance Managers Desk BookDocumento477 paginePlant and Maintenance Managers Desk BookHugoCabanillasNessuna valutazione finora

- Binary and Decimal Number Systems: Addressing The Network - Ipv4Documento3 pagineBinary and Decimal Number Systems: Addressing The Network - Ipv4Mase Astrid C. BarayugaNessuna valutazione finora

- K C Chakrabarty: Financial Inclusion and Banks - Issues and PerspectivesDocumento9 pagineK C Chakrabarty: Financial Inclusion and Banks - Issues and PerspectivesAnamika Rai PandeyNessuna valutazione finora

- Gea 01 RyDocumento2 pagineGea 01 RyHasan CelebesNessuna valutazione finora

- Internet and Java ProgrammingDocumento4 pagineInternet and Java ProgrammingsharmaarakeyshNessuna valutazione finora

- Understand Digital Marketing and Role of Twitter and Content Marketing in Digital MarketingDocumento64 pagineUnderstand Digital Marketing and Role of Twitter and Content Marketing in Digital MarketingJoy SahaNessuna valutazione finora

- Self Priming Centrifugal Pump: Models 03H1-GL, 03H1-GR, 03H3-GL and 03H3-GRDocumento4 pagineSelf Priming Centrifugal Pump: Models 03H1-GL, 03H1-GR, 03H3-GL and 03H3-GRdougNessuna valutazione finora

- CH 01Documento28 pagineCH 01Deepu MaroliNessuna valutazione finora

- Complete Tank FabricationDocumento8 pagineComplete Tank Fabricationnike_y2kNessuna valutazione finora

- Travel Fellowship Application FormDocumento4 pagineTravel Fellowship Application FormAsma100% (1)

- Agricultural Machinery Is Machinery Used in The Operation of An Agricultural Area or FarmDocumento4 pagineAgricultural Machinery Is Machinery Used in The Operation of An Agricultural Area or FarmvinzyyNessuna valutazione finora

- Resetting of Computers - A320: Systems That Can Be Reset in The Air or On The GroundDocumento8 pagineResetting of Computers - A320: Systems That Can Be Reset in The Air or On The Groundanarko arsipelNessuna valutazione finora

- Learn PowerShell Core 6.0Documento800 pagineLearn PowerShell Core 6.0Felippe Coelho100% (2)

- BRF90Documento10 pagineBRF90Lukas Van VuurenNessuna valutazione finora

- Sts Lesson 6Documento13 pagineSts Lesson 6Ivy Joy BelzaNessuna valutazione finora

- Specialty Lubricants Molykote®: 44MA GreaseDocumento2 pagineSpecialty Lubricants Molykote®: 44MA GreasefadhlidzilNessuna valutazione finora

- Pinhole Camera InformationDocumento4 paginePinhole Camera InformationD'ferti AnggraeniNessuna valutazione finora

- Shot PeeningDocumento5 pagineShot Peeningcaddcentre velacheryNessuna valutazione finora

- ISRA University FormDocumento4 pagineISRA University Formpure14Nessuna valutazione finora