Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Engine Coolant Reference Guide: Als Tribology

Caricato da

lukasjoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Engine Coolant Reference Guide: Als Tribology

Caricato da

lukasjoCopyright:

Formati disponibili

ALS TRIBOLOGY

Engine Coolant Reference Guide

Engine coolants are a mixture of glycol, inhibitors, and water. Each formula is designed for specific protection and engine

requirements. Mixing different coolants is not recommended and can compromise the coolant’s general overall protective

capability, resulting in decreased coolant life and damage to the cooling system and/or engine. The following is a reference

guide to assist in understanding engine coolant data.

Appearance Assessment

The visual appearance of a coolant sample can say a lot about the condition of the coolant. In-service coolants should appear

clear and bright, with no solid residues or sediment. Four visual assessments are conducted and reported.

Appearance

Target Observation Possible Result Corrective Action

Assessment

Degraded or

contaminated engine

Check shelf life of the coolant;

Clarity Clear Appears hazy or opaque coolants or a mixture

check coolant handling practices

of incompatible coolant

types

Clear, bright, and Verify original coolant color of

representative of Brown could indicate improper Decreased coolant product in use; if brown was

Color

the original engine mixing of different coolants protection reported, check coolant handling

coolant color practices

Water pump and seal

deterioration, liner

Presence of sediment is

pitting, copper and Add a non-SCA filter for ELC

typically indicative of additive

Visible Sediment None aluminum corrosion, coolants; add an SCA filter to

fallout, corrosion, rust, scale

plugged oil cooler and conventional coolant systems

buildup, or other contaminants

radiator; poor sampling

technique.

Indication of fuel or oil Combustion gas blow-

Visible Petroleum contamination will be by into the coolant, Check for any seal failures and

None

Layer observed usually in the form leaking oil cooler; poor system integrity

of a separated layer sampling technique

March 2015 Page 1

pH

Indicates the level of acidity (low pH) or alkalinity (high pH). Typical baseline pH values of a coolant can vary but remain

relatively consistent unless the coolant and/or cooling system has been compromised. Allowing the coolant to become acidic

will lead to metal corrosion in the cooling system, so it is critical to monitor. One key item that can affect coolant is age; review

storage practices and make sure coolant stock is properly rotated.

Observation Observation

pH Target Corrective Action

Low pH High pH

ELC Low pH (< 7.5 ) ELC High pH ( > 9.5);

Conventional Low pH Conventional High pH

(< 8.5 ) (>11.0)

Check coolant volume

Check for air leaks

Extended Life Low pH can lead to metal Mixed coolant types

7.5 – 9.5pH corrosion Pressure check radiator cap

Over additized SCA

Conventional Air leaks will lower pH concentration Check SCA filter and replace if needed

ELC Engine

8.5 – 11.0pH (conventional coolant only)

Coolant

Improper coolant volume

and

Electrical grounding issues (if coolant

Conventional

Shelf life of coolant, age has a burnt smell)

Engine Coolant

will lower the pH

Combustion gas leak if pH is below 7.0

Under additized

SCA concentration Remove SCA filter when ELC coolants

(conventional coolant) are in use, this will add pH buffer and

raise the pH

Drain, flush, refill then resample

Freeze Point / Percent Glycol Concentration

Freeze point is a critical element in coolant analysis. If improper glycol concentration is maintained, it can lead to decreased

protection or over concentration of the inhibitor, both of which can lead to cooling system problems and engine damage.

Coolants are typically available as a concentrate or as pre-diluted with several different ratios of concentrations. However,

freeze points in North America should be maintained between -15˚F and -60˚F (equivalent to 40% – 60% glycol concentration).

Glycol concentration (ethylene or propylene) is used to suppress the freeze point and elevate the boiling point of the coolant.

The ratio required depends on the environment in which the equipment is operating. Always ensure that equipment and

environmental requirements are met.

March 2015 ALS TRIBOLOGY ENGINE COOLANT REFERENCE GUIDE Page 2

Observation

Glycol Observation

Target High Glycol Corrective Action

Concentration Low Glycol Concentration

Concentration

Check proper coolant volumes

Pressure check radiator cap

Low Glycol ( < 40 % ) High Glycol ( > 60 %)

Freeze Point ( > -15 F ) Freeze Point (< - 60 F)

Confirm bulk source of coolant for

inadequate concentration

Confirm adequate Too high indicates over

protection requirements use of concentrate or

If the coolant has been over diluted

Percent Glycol 40% to 60% for application water is boiling off

or under diluted, by manufacturer’s

guidelines, take corrective action

Improper adjustment with This can reduce heat

by adjusting the glycol or water

water transfer properties

level following the manufacturer’s

resulting in cavitations

recommendations. The use of

and liner pitting

deionized or distilled water is

recommended when needing to

utilize water to adjust concentration.

Conductivity / Total Dissolved Solids (TDS)

This is a concern in heavy duty, conventional coolants because of the practice of adding Supplemental Coolant Additives

(SCAs), which can lead to overloading of these, resulting in water pump failures and cooling system corrosion. It measures the

coolant’s ability to resist carrying an electrical charge.

Observation Observation

Target Corrective Action

Low TDS High TDS

Confirm water source; distilled or

Improper source water, deionized is recommended

TDS 20000 max Normal over concentration of

SCAs Check for improper SCA filter

drain, flush and refill

Nitrites

For many years, heavy duty coolants contained nitrites to protect against cavitation and corrosion. However, with the

advancements in technology, there are now many coolants that are nitrite-free because the organic acid based technology

provides protection without the need for nitrites. Conversely, engine manufacturers require either nitrites or nitrite-free

coolants, so it is important to ensure the proper coolant formula is in use to meet the equipment manufacturer’s requirements.

For proper diagnostic review, always provide the coolant in use in order to properly diagnose the nitrite level of the coolant.

March 2015 ALS TRIBOLOGY ENGINE COOLANT REFERENCE GUIDE Page 3

Observation Observation

Nitrites Target Corrective Action

Low Nitrites High Nitrites

Check the coolant mixture, if under

or over concentrated, this will impact

the nitrite level when present

If low, look at nitrate level; if pH has

dropped, check for head gasket leaks,

low coolant volumes, and pressure

check radiator cap

Initial coolant

Rapid depletion could indicate

concentration Verify coolant type in use Verify coolant type in use

overheating of the cooling system

typically:

and localized hot spots, check; this

> 1200 PPM Under concentrated with Over concentration of

will occur along with an increase in

glycol glycol

glycolates

Nitrite only

Nitrite formulas Improper coolant mixing Improper coolant mixing

Rapid depletion could also indicate

> 300 PPM

electrical shorts; check grounding,

for nitrite/ Under concentration of Over concentration of

coolant will have a burnt smell

molybdate SCAs for conventional SCAs for conventional

formulas coolants coolants

If using ELC, check for a pre-charged

< 25 for nitrite

SCA filter and replace with a non-pre-

free

charged filter

If nitrites are low, but carboxylate

acid inhibitor passed, resample at

next service interval

Drain 50% of system and add 50/50

coolant, resample

Carboxylate Acid Technology

In extended life coolants, the previous mineral based additives have been replaced with carboxylic and fatty acids, allowing

the coolant life to be greatly extended and enhancing coolant system protection. However, not all formulas are the same!

There are a variety of signature formula’s available on the market today, each formulated for equipment requirements and/

or longevity differences. Because there are a variety of formulas available on the market, it is wise to confirm that the right

coolant for your equipment was chosen. Most, if not all, coolants allow for some acceptable dilution without compromising

the inhibitor’s capability to protect. If the coolant inhibitor has been compromised by diluting, mixing, etc., beyond the

manufacturer’s recommended allowable dilution, follow the manufacturer’s corrective action and adjust the inhibitor

concentration. Maintaining proper inhibitor levels is key to maintaining proper cooling system protection.

March 2015 ALS TRIBOLOGY ENGINE COOLANT REFERENCE GUIDE Page 4

Observation Observation

Carboxylate Acid Target Corrective Action

Low OAI High OAI

Adjust coolant concentration; if over

concentrated, add proper source

water; if under concentrated, add

glycol concentrate; check freeze point

Verify coolant type in use

and resample at next service interval

Passing level Under concentrated with Verify coolant type in use

If the inhibitor level has been under-

depends on the glycol

diluted, by manufacturer’s guidelines,

initial extended Over concentrated with

take corrective action by adjusting

OAI life coolant’s Improper coolant mixing glycol

the inhibitor level following the

inhibitor level

manufacturer’s recommendations.

formula Coolant is brown – possible Improper coolant mixing

improper conversion from

If the coolant was improperly mixed

conventional to extended

with conventional and extended life

life

coolant, significantly affecting the

inhibitor level’s protection capability,

either drain and flush or contact your

OEM for corrective action.

Other Ion Chromatography Data

If the coolant has been over-diluted, by manufacturer’s guidelines, take corrective action by adjusting the inhibitor level

following the manufacturer’s recommendations.

Ion

Chromatography Source

Results

Outside contaminants and can come from improper source water or air leaks. It has the potential to form acids and

Chlorides

cause corrosion. It can also come from coolant degradation due to aging.

Is among a group of acids that form as coolant degrades. This will also increase when overheating or hot spots are

Glycolates

occurring. As this acid increases, iron corrosion is at risk.

Molybdate Provides protection of cast iron corrosion and cavitations.

Provides protection of light alloys also provides aluminum and solder protection. If nitrites are being exposed to air,

Nitrates

they will chemically transform to nitrate – when this occurs look for air leaks.

pH buffer utilized in some coolant brands and provides iron corrosion protection. Over treating the cooling system

Phosphates can lead to sediment detection resulting in possible plugged oil cooler or radiator. Some engines that are aluminum

must be phosphate free, check OEM requirements before using a phosphate coolant.

This contaminant can combine with calcium to create scale. This can also indicate coolant degradation due to aging

Sulfates

or improper source water is being used.

March 2015 ALS TRIBOLOGY ENGINE COOLANT REFERENCE GUIDE Page 5

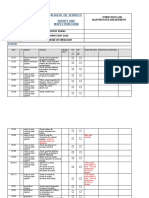

Coolant Spectrochemical Data

A series of specific elements are measure for additive, wear, and improper source water contamination.

Molybdenum (Mo)

Magnesium (Mg)

Phosphorus (P)

Aluminum (Al)

Potassium (K)

Sodium (Na)

Calcium (Ca)

Copper (Cu)

Silver (Ag)

Silicon (Si)

Boron (B)

Lead (Pb)

Zinc (Zn)

Iron (Fe)

Tin (Sn)

Coolant Spectrochemical

Data

Additive Elements ● ● ● ● ● ●

Wear Elements ● ● ● ● ● ● ●

Water Elements ● ●

March 2015 ALS TRIBOLOGY ENGINE COOLANT REFERENCE GUIDE Page 6

Potrebbero piacerti anche

- Interpretation of Used Coolant Analysis: Reco-Cool Technical Bulletin 0006/12Documento5 pagineInterpretation of Used Coolant Analysis: Reco-Cool Technical Bulletin 0006/12Christina GrayNessuna valutazione finora

- Application Engineering Bulletin: Automotive Industrial Marine G-Drive Genset Powergen Antifreeze in Warm ClimatesDocumento3 pagineApplication Engineering Bulletin: Automotive Industrial Marine G-Drive Genset Powergen Antifreeze in Warm ClimatesCesar G.Nessuna valutazione finora

- Tech Doc Coolant AnalysisDocumento2 pagineTech Doc Coolant AnalysisJakub BohdálekNessuna valutazione finora

- ASTM D 1121-07 REZERVA ALCALINITATE ANTIGEL PDFDocumento3 pagineASTM D 1121-07 REZERVA ALCALINITATE ANTIGEL PDFCorina Stanculescu100% (3)

- DOALL-tech F KleenKoolDocumento1 paginaDOALL-tech F KleenKoolJAY CORTEZ MAMABICHONessuna valutazione finora

- 1.1 Best Practice - Desalter OperationDocumento11 pagine1.1 Best Practice - Desalter OperationramuNessuna valutazione finora

- Metalworking Fluids Foam Control Based On Novel Surfactants TechnologyDocumento29 pagineMetalworking Fluids Foam Control Based On Novel Surfactants Technologywadi ajanaNessuna valutazione finora

- (BS 2000-129 - 2003) - Methods of Test For Petroleum and Its Products. Determination of Bromine Number. Colour Indicator Titration MethodDocumento8 pagine(BS 2000-129 - 2003) - Methods of Test For Petroleum and Its Products. Determination of Bromine Number. Colour Indicator Titration MethodAdelNessuna valutazione finora

- 4-Wheeler General Service Checklist: Test Run-Vehicle DiagnosisDocumento8 pagine4-Wheeler General Service Checklist: Test Run-Vehicle DiagnosisaravNessuna valutazione finora

- Fluidscan Q1100 PresentationDocumento16 pagineFluidscan Q1100 PresentationFraz AhmadNessuna valutazione finora

- Darkening Hydraulic FluidDocumento6 pagineDarkening Hydraulic FluidKelly RobertsNessuna valutazione finora

- This Document Has Been Printed From SPI2. NOT FOR RESALE: AdditivesDocumento1 paginaThis Document Has Been Printed From SPI2. NOT FOR RESALE: AdditivesAHMADNessuna valutazione finora

- Ab-141 4 en PDFDocumento17 pagineAb-141 4 en PDFAfthirah AmiraNessuna valutazione finora

- Why It Pays To Maintain Your BoilerDocumento2 pagineWhy It Pays To Maintain Your BoilerOmar KhaledNessuna valutazione finora

- Oilfield Emulsion Control: A Major Issue During Heavy Crude Oil ProductionDocumento10 pagineOilfield Emulsion Control: A Major Issue During Heavy Crude Oil ProductionDaniel DamboNessuna valutazione finora

- 119 01903 01 Triton Qs 15 Surfactant Technical Data SheetDocumento1 pagina119 01903 01 Triton Qs 15 Surfactant Technical Data Sheetqdu05483Nessuna valutazione finora

- Polymer Flooding in Heavy OilDocumento11 paginePolymer Flooding in Heavy OilCamiloAndresGuerreroNessuna valutazione finora

- Troubleshooting engine issuesDocumento10 pagineTroubleshooting engine issuesLeonNessuna valutazione finora

- Datasheet - FluidScan LibraryDocumento2 pagineDatasheet - FluidScan Libraryhouston machacaNessuna valutazione finora

- MWF Training - Level 1 CourseDocumento37 pagineMWF Training - Level 1 Coursevivek nuthiNessuna valutazione finora

- CSI Analysis LubricDocumento12 pagineCSI Analysis LubricOscar CampoNessuna valutazione finora

- FOWA SystemDocumento77 pagineFOWA SystemAnangtri WahyudiNessuna valutazione finora

- Webinar Power PointDocumento12 pagineWebinar Power Pointmara2proleta100% (1)

- Apresentação - Oil and Water SeparationDocumento55 pagineApresentação - Oil and Water SeparationAlisson AlmeidaNessuna valutazione finora

- Water Requirements, Volvo CoolantsDocumento1 paginaWater Requirements, Volvo CoolantsCesar BlancoNessuna valutazione finora

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Documento201 pagineMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNessuna valutazione finora

- 2015corrosion Inhibitor Selection Guideeversion PDFDocumento4 pagine2015corrosion Inhibitor Selection Guideeversion PDFPhelia Kosasih0% (1)

- Official Methods List of RefractometerDocumento3 pagineOfficial Methods List of RefractometerkominooNessuna valutazione finora

- Landfill-Gas-Engine-Oil AnalysisDocumento2 pagineLandfill-Gas-Engine-Oil AnalysisKeith ChengNessuna valutazione finora

- System Analysis (Service Profile)Documento2 pagineSystem Analysis (Service Profile)dhavit wijayantoNessuna valutazione finora

- Crude Distiller RBI Intro (Updated)Documento31 pagineCrude Distiller RBI Intro (Updated)harrinsonf100% (2)

- CoolantsDocumento89 pagineCoolantshaleemrayyanNessuna valutazione finora

- Al-Ajeal Oil Services Survey and Inspection Form: EngineDocumento5 pagineAl-Ajeal Oil Services Survey and Inspection Form: EnginemagveyNessuna valutazione finora

- Water quality control of boilers to prevent corrosionDocumento3 pagineWater quality control of boilers to prevent corrosionengdpaliNessuna valutazione finora

- New - Coladet LD-150Documento2 pagineNew - Coladet LD-150mndmattNessuna valutazione finora

- Equipment O&M ChecklistsDocumento11 pagineEquipment O&M ChecklistsAsebaho BadrNessuna valutazione finora

- ISL Cummins EspecificacionesDocumento2 pagineISL Cummins EspecificacionesItalo Giuliano Tronci Iriarte0% (2)

- Engine Analysis: This Service Monitors Engine and Lubricant Conditions To Detect Premature Wear and ContaminationDocumento2 pagineEngine Analysis: This Service Monitors Engine and Lubricant Conditions To Detect Premature Wear and ContaminationTùng AnhNessuna valutazione finora

- Marathon's Guide to Troubleshooting Jet Fuel Thermal Stability IssuesDocumento2 pagineMarathon's Guide to Troubleshooting Jet Fuel Thermal Stability IssuesM.AS100% (2)

- Water quality control of boiler 【Subject model: Auxiliary Boiler, Composite Boiler, Steam Separating Drum】Documento4 pagineWater quality control of boiler 【Subject model: Auxiliary Boiler, Composite Boiler, Steam Separating Drum】Zhengwei YinNessuna valutazione finora

- Lube Oil Analysis TestsDocumento11 pagineLube Oil Analysis TestsPrudhvi RajNessuna valutazione finora

- Analysis of Edible Oils and Fats Water Content: Application Bulletin 141/4 eDocumento18 pagineAnalysis of Edible Oils and Fats Water Content: Application Bulletin 141/4 eاحمد سالم الشبيبيNessuna valutazione finora

- Calibrate Ignition and Brake Fluid TestersDocumento39 pagineCalibrate Ignition and Brake Fluid Testerskallatis100% (1)

- Jet Fuel Anti-Icing Inhibitor StandardDocumento7 pagineJet Fuel Anti-Icing Inhibitor StandardRezaNessuna valutazione finora

- METTLER TOLEDO 2012 Best Practice Guide To Process Analytics in The Chemical Industry 2Documento36 pagineMETTLER TOLEDO 2012 Best Practice Guide To Process Analytics in The Chemical Industry 2s_hassan_167419Nessuna valutazione finora

- 184-CI Catalogue - EmailDocumento20 pagine184-CI Catalogue - EmailChun HuangNessuna valutazione finora

- Determination of Metals in Lubricating Oil by ICP-OES: Application NoteDocumento6 pagineDetermination of Metals in Lubricating Oil by ICP-OES: Application NoteIan RidzuanNessuna valutazione finora

- 1014-2092-1-SMDocumento6 pagine1014-2092-1-SMopthseNessuna valutazione finora

- Clariant Brochure Corrosion Inhibitor Selection Guide 2020 ENDocumento4 pagineClariant Brochure Corrosion Inhibitor Selection Guide 2020 ENmarucsNessuna valutazione finora

- WP - MeasuringGlycolContamination - Final With JCM EditsDocumento4 pagineWP - MeasuringGlycolContamination - Final With JCM EditsFajar EkoNessuna valutazione finora

- CoolantsDocumento8 pagineCoolantsCristian GuerraNessuna valutazione finora

- Drilling FluidsDocumento18 pagineDrilling FluidsMohammed Alnasry0% (1)

- Explanation of CoolantDocumento1 paginaExplanation of CoolantjeganNessuna valutazione finora

- Water Treatment - EngineerTraining2021fffDocumento49 pagineWater Treatment - EngineerTraining2021fffRakeshKrishnanNessuna valutazione finora

- Phenol - High Purity Grade: DescriptionDocumento2 paginePhenol - High Purity Grade: DescriptionBrayonoFloNessuna valutazione finora

- Oil Base Mud Systems for Well Site SupervisionDocumento97 pagineOil Base Mud Systems for Well Site SupervisionKhanh Pham Minh100% (1)

- SERVO Kool NFSCDocumento1 paginaSERVO Kool NFSCJoker DanNessuna valutazione finora

- Jenbacher: Aid To Interpreting Used Oil Analyses of Engine LubricantsDocumento8 pagineJenbacher: Aid To Interpreting Used Oil Analyses of Engine LubricantsArîfNessuna valutazione finora

- SOP No. 10 Recommended Standard Operating Procedure For Calibration of Rigid RulesDocumento9 pagineSOP No. 10 Recommended Standard Operating Procedure For Calibration of Rigid RuleslukasjoNessuna valutazione finora

- C Manuals Access AccessDocumento188 pagineC Manuals Access AccesstaufiqsaidinNessuna valutazione finora

- Se-500 G082060372ea A4 PDFDocumento60 pagineSe-500 G082060372ea A4 PDFlukasjoNessuna valutazione finora

- Aerospace Stds SpecifDocumento100 pagineAerospace Stds SpecifJesse Krebs100% (1)

- C - Manuals - Access - Access 2010 Part 1 PDFDocumento190 pagineC - Manuals - Access - Access 2010 Part 1 PDFObid RasulovNessuna valutazione finora

- Dewey Decimal SystemDocumento38 pagineDewey Decimal SystemUota FaqNessuna valutazione finora

- Instruction Manual: HD/SD 6-Channel Digital Video SwitcherDocumento38 pagineInstruction Manual: HD/SD 6-Channel Digital Video SwitcherLukas LukasNessuna valutazione finora

- BS en 62353-2014 - (2020-05-18 - 09-25-35 Am)Documento66 pagineBS en 62353-2014 - (2020-05-18 - 09-25-35 Am)Haran Pragalath100% (4)

- Precision thermometry bridge for calibration labsDocumento4 paginePrecision thermometry bridge for calibration labslukasjoNessuna valutazione finora

- GB2 User Guide PDFDocumento38 pagineGB2 User Guide PDFlukasjoNessuna valutazione finora

- Updating Distortion Control Lens Data: - WindowsDocumento6 pagineUpdating Distortion Control Lens Data: - WindowsRendy FahleviNessuna valutazione finora

- Dewey Decimal SystemDocumento38 pagineDewey Decimal SystemUota FaqNessuna valutazione finora

- C10 Silicone MSDSDocumento8 pagineC10 Silicone MSDSlukasjoNessuna valutazione finora

- AMS 2750 E Heat Treatment Standards ComplianceDocumento3 pagineAMS 2750 E Heat Treatment Standards ComplianceQualidadeTFNessuna valutazione finora

- Engine Coolant Reference Guide: Als TribologyDocumento6 pagineEngine Coolant Reference Guide: Als TribologylukasjoNessuna valutazione finora

- Brake FL Is.8654.2001Documento24 pagineBrake FL Is.8654.2001lukasjoNessuna valutazione finora

- Steril DiskDocumento3 pagineSteril DisklukasjoNessuna valutazione finora

- Calibrating Differential Pressure SensorsDocumento5 pagineCalibrating Differential Pressure SensorscejavierNessuna valutazione finora

- CoolantDocumento3 pagineCoolantlukasjoNessuna valutazione finora

- AM9050 User's GuideDocumento3 pagineAM9050 User's GuidelukasjoNessuna valutazione finora

- EdgeTech DewMasterDocumento2 pagineEdgeTech DewMasterlukasjoNessuna valutazione finora

- Accubridge 6010DDocumento6 pagineAccubridge 6010DlukasjoNessuna valutazione finora

- 2015 CatalogueDocumento593 pagine2015 CataloguelukasjoNessuna valutazione finora

- Owners Handbook BUKH U125Documento79 pagineOwners Handbook BUKH U125Alexandros KontosNessuna valutazione finora

- Workshop Manual D16 Tai Lieu May Thuy Volvo PDFDocumento228 pagineWorkshop Manual D16 Tai Lieu May Thuy Volvo PDFLonghuynh Lê100% (1)

- Manual Instalare OMEGAS ENGDocumento48 pagineManual Instalare OMEGAS ENGAlexandra Geanina50% (2)

- 5.5 KW Diesel DC GeneratorDocumento5 pagine5.5 KW Diesel DC GeneratorCoordinador RanMauNessuna valutazione finora

- 2.5-Ton 6x6 Truck Technical ManualDocumento545 pagine2.5-Ton 6x6 Truck Technical ManualArielNessuna valutazione finora

- Lada Niva 1600: Maintenance ManualDocumento30 pagineLada Niva 1600: Maintenance ManualAcH1LeNessuna valutazione finora

- Skoda Kodaiq Auxiliary Heating EngDocumento40 pagineSkoda Kodaiq Auxiliary Heating EngСергей ДаниловNessuna valutazione finora

- Operation and Maintenance Manual - R926 (EN)Documento362 pagineOperation and Maintenance Manual - R926 (EN)min thet100% (5)

- AHRI - Standard - 550-590 - I-P - 2018 - ErrataDocumento118 pagineAHRI - Standard - 550-590 - I-P - 2018 - ErrataPhangSSNessuna valutazione finora

- Evox Antifreeze Coolants: All-Round Protection, Extra Long LifeDocumento8 pagineEvox Antifreeze Coolants: All-Round Protection, Extra Long LifeJerko AndreićNessuna valutazione finora

- 3054E and 3056E Industrial Engines-Maintenance IntervalsDocumento36 pagine3054E and 3056E Industrial Engines-Maintenance IntervalsprabumnNessuna valutazione finora

- Generac - Motor MTU 18V2000G85Documento26 pagineGenerac - Motor MTU 18V2000G85July E. Maldonado M.100% (1)

- Cat 330D FMDocumento24 pagineCat 330D FMIvan100% (1)

- 2206 Service ManualDocumento56 pagine2206 Service Manualjengandxb100% (4)

- Bar's Head Gasket SealerDocumento2 pagineBar's Head Gasket SealerMatt CrummittNessuna valutazione finora

- Motor Mercedes Benz - Om501 Om502 em InglêsDocumento122 pagineMotor Mercedes Benz - Om501 Om502 em InglêsVitor Alves100% (4)

- Cooling SystemDocumento5 pagineCooling SystemIzz BaharNessuna valutazione finora

- WPS600SDocumento5 pagineWPS600SMuhammad Zaky ElhamyNessuna valutazione finora

- 3508 CAT - Parts BookDocumento2.145 pagine3508 CAT - Parts BookJoshua Angermeyer100% (2)

- AMK Racing Kit 4 Wheel Drive "Formula Student Electric"Documento103 pagineAMK Racing Kit 4 Wheel Drive "Formula Student Electric"abdelmoumene djafer beyNessuna valutazione finora

- Cylinder Head InstallDocumento2 pagineCylinder Head InstallMiguel Moreno FernándezNessuna valutazione finora

- Uaz-3741-3303-3909 Operation Maintenance Manual enDocumento112 pagineUaz-3741-3303-3909 Operation Maintenance Manual enАсен АнгеловNessuna valutazione finora

- Thermosyphon Oil CoolingDocumento22 pagineThermosyphon Oil CoolingRenato MendesNessuna valutazione finora

- Media Search - SEBF8009 - Visual Inspection of Main Bearings and Connecting Rod Bearings (1202, 1203, 1225, 1230)Documento62 pagineMedia Search - SEBF8009 - Visual Inspection of Main Bearings and Connecting Rod Bearings (1202, 1203, 1225, 1230)Derrick AramNessuna valutazione finora

- 303-03A+Engine+CoolingDocumento33 pagine303-03A+Engine+CoolingP HandokoNessuna valutazione finora

- Coolling System CalculusDocumento33 pagineCoolling System CalculusȘtefan PravățNessuna valutazione finora

- CAT Engine 3516 C. PARTS MANUAL PDFDocumento1.003 pagineCAT Engine 3516 C. PARTS MANUAL PDFreza92% (13)

- Waukesha Asset Performance Management (APM)Documento68 pagineWaukesha Asset Performance Management (APM)DIego100% (3)

- Service Manual: 6720772 (7-92) Printed in U.S.A. Melroe Company 1992Documento294 pagineService Manual: 6720772 (7-92) Printed in U.S.A. Melroe Company 1992Joe Caballero100% (1)