Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Thrust Restraint For Expansion Joint

Caricato da

DGW0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

22 visualizzazioni2 pagineExpansion Joint Thrust Restraint

Titolo originale

Thrust Restraint for Expansion Joint

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoExpansion Joint Thrust Restraint

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

22 visualizzazioni2 pagineThrust Restraint For Expansion Joint

Caricato da

DGWExpansion Joint Thrust Restraint

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Description

Kinetics HSR Thrust Restraints are used to counteract KINETICS®

the discharge force created by fans during operation.

HSR Thrust Restraints are used in pairs and best uti- Thrust Restraint

lized when located on the centerline of the discharge

outlet of the fan, bridging the flexible duct connector.

Model HSR

HSR Thrust Restraints consist of high deflec-

tion, large diameter, laterally stable steel coil

springs assembled into a threaded rod and brack-

et assembly. The coil springs have a lateral spring

stiffness greater than 1.0 times the rated vertical

stiffness to assure coil stability. The coil springs are

designed to provide a minimum of 50% overload

deflection capability to solid. The coil springs are

polyester powder coated for corrosion protection,

having passed a 1,000 hour salt spray test per ASTM

Standard B-117. HSR thrust restraints feature molded

neoprene end load plate assemblies for light

capacities. For heavier capacities, Model HSR utilizes

stamped steel end cups. HSR Thrust Restraints

include threaded adjustment rod with hardware,

fan and ductwork mounting bracket angles, bracket Application

back-up plates, and all attachment hardware. ASHRAE recommends that thrust restraints such

as Kinetics HSR incorporate the same coil spring

deflection as the support isolators. HSR Thrust

Flexible Connector Restraints are to be used for all fan heads,

Ductwork suspended fans, and all base-mounted and

Fan Discharge

Air Flow

suspended air-handling equipment operating at 2

inches or greater total static pressure (TSP). HSR

Thrust Restraints are always installed in pairs and

often work in conjunction with inertia bases for floor-

mounted fans to counteract fan thrust.

Total fan thrust can be calculated using the following

formula:

Specifications

Thrust Restraints shall consist of high deflection, 0.036 x {TSP (in.)} x

large diameter, laterally stable steel coil springs Thrust (lbs.) =

{Fan Discharge Outlet Area (sq. in.)}

assembled into a threaded rod and angle bracket

assembly. Coil springs shall have a lateral spring

To select the correct HSR Thrust Restraint to be used,

stiffness greater than 1.0 times the rated vertical stiff-

this total calculated thrust is to be divided by two (2)

ness to assure coil stability. Coil springs shall provide

and then rounded up to the next highest standard coil

a minimum of 50% overload deflection capability to

spring capacity.

solid and shall be safe when temporarily loaded to

solid capacity. Coil springs shall be polyester powder Kinetics HSR Thrust Restraints are best utilized when

coated for corrosion protection and shall demonstrate located on the centerline of the discharge outlet of

successful completion of a 1000 hour salt spray test the fan. Fan instability can occur when attempts are

per ASTM Standard B-117. Thrust Restraints shall made to control fan thrust only at the (floor-mounted)

feature molded neoprene end load plate assemblies isolator locations. The attachment of the HSR

for light capacities or stamped steel end cups for brackets must be made at structurally sound

heavier capacities. Thrust Restraints shall include locations and cannot be attached to bare

threaded adjustment rod with zinc-plated hardware, unreinforced sheet metal ductwork.

and shall include primer painted fan and ductwork

The HSR coil spring is to be preloaded to allow for

mounting bracket angles, bracket back-up plates,

approximately 0.25” (6 mm) of additional deflection

and complete fan / ductwork attachment hardware.

due to fan motion upon start-up. HSR Thrust

Thrust Restraints shall be Model HSR as Restraint movement adjustment must be made under

manufactured by Kinetics Noise Control, Inc. normal fan operational static pressures.

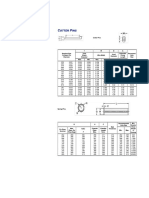

Spring Coil Rated Dimensions

Isolator Free HT O.D. Load Deflection A C E H

Type Color in mm in mm lbs kg in mm in mm in mm in mm in mm

HSR-1-35 Blue 3.19 81 1.75 44 35 16 1.52 39 3.50 89 1.25 32 1.75 44 3.00 76

HSR-1-70 Green 3.19 81 1.75 44 70 32 1.36 35 3.50 89 1.25 32 1.75 44 3.00 76

HSR-1-120 Gray 3.19 81 1.75 44 120 54 1.18 30 3.50 89 1.25 32 1.75 44 3.00 76

HSR-1-220 Brown 3.19 81 1.75 44 220 100 1.07 27 3.50 89 1.25 32 1.75 44 3.00 76

HSR-1-370 Orange 3.19 81 1.75 44 370 168 0.96 24 3.50 89 1.25 32 1.75 44 3.00 76

HSR-1-500 Beige 3.19 81 1.75 44 500 227 1.00 25 3.50 89 1.25 32 1.75 44 3.00 76

HSR-1-600 Chrome 3.19 81 1.75 44 600 272 1.00 25 3.50 89 1.25 32 1.75 44 3.00 76

HSR-1-50 Beige 4.20 107 3.00 76 50 23 1.00 25 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-100 Chrome 4.20 107 3.00 76 100 45 1.00 25 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-250 Blue 4.20 107 3.00 76 250 113 1.79 45 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-450 Green 4.20 107 3.00 76 450 204 1.54 39 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-625 Black 4.20 107 3.00 76 625 284 1.44 37 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-800 Gray 4.20 107 3.00 76 800 363 1.31 33 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-1000 Red 4.20 107 3.00 76 1000 454 1.15 29 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-1250 Brown 4.20 107 3.00 76 1250 568 1.09 28 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-1700 Orange 4.20 107 3.00 76 1700 772 0.95 24 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-2200 Org/Gry 4.20 107 3.00 76 2200 999 1.00 26 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-2465 Blue 4.20 107 3.00 76 2465 1119 1.00 25 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-2865 Blu/Gry 4.20 107 3.00 76 2865 1301 1.00 25 5.00 127 1.00 25 2.50 64 4.00 102

HSR-1-3500 Blu/Brn 4.20 107 3.00 76 3500 1589 1.00 25 5.00 127 1.00 25 2.50 64 4.00 102

HSR-2-35 Blue 4.13 105 1.75 44 35 16 2.00 51 3.50 89 1.25 32 1.75 44 3.25 83

HSR-2-70 Green 4.13 105 1.75 44 70 32 2.00 51 3.50 89 1.25 32 1.75 44 3.25 83

HSR-2-120 Gray 4.13 105 1.75 44 120 54 2.00 51 3.50 89 1.25 32 1.75 44 3.25 83

HSR-2-220 Brown 4.13 105 1.75 44 220 100 2.00 51 3.50 89 1.25 32 1.75 44 3.25 83

HSR-2-100 Gray 6.09 155 3.50 89 100 45 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-135 Beige 6.09 155 3.50 89 135 61 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-185 Brown 6.09 155 3.50 89 185 84 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-225 Gry/Brn 6.09 155 3.50 89 225 102 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-250 Blue 6.09 155 3.50 89 250 113 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-375 Blu/Brn 6.09 155 3.50 89 375 180 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-500 Green 6.09 155 3.50 89 500 227 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-625 Grn/Brn 6.09 155 3.50 89 625 283 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-750 Black 6.09 155 3.50 89 750 340 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-875 Blk/Brn 6.09 155 3.50 89 875 397 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-995 Orange 6.09 155 3.50 89 995 451 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-1120 Org/Brn 6.09 155 3.50 89 1120 508 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-1400 Org/Grn 6.09 155 3.50 89 1400 635 2.01 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-1600 Red 6.09 155 3.50 89 1600 726 2.00 51 5.00 127 1.00 25 2.50 64 5.25 133

HSR-2-1975 Red/Grn 6.09 155 3.50 89 1975 896 1.98 50 5.00 127 1.00 25 2.50 64 5.25 133

kineticsnoise.com

sales@kineticsnoise.com

1-800-959-1229

MADE IN USA Kinetics Noise Control, Inc. is continually upgrading the quality of our products. HSR │ 02/17

We reserve the right to make changes to this and all products without notice.

Potrebbero piacerti anche

- He130 - Driveway Asphalt Coating: Physical PropertiesDocumento2 pagineHe130 - Driveway Asphalt Coating: Physical PropertiesDGWNessuna valutazione finora

- Overkote Asphalt Pavement Coating: DescriptionDocumento1 paginaOverkote Asphalt Pavement Coating: DescriptionDGWNessuna valutazione finora

- What Is Sealcoating - Asphalt Sealcoating - Seal CoatDocumento2 pagineWhat Is Sealcoating - Asphalt Sealcoating - Seal CoatDGWNessuna valutazione finora

- Flat Washer and FastenersDocumento49 pagineFlat Washer and FastenersDGWNessuna valutazione finora

- Schedule 80 Pipe Dimensions & Pressure RatingsDocumento1 paginaSchedule 80 Pipe Dimensions & Pressure RatingsDGWNessuna valutazione finora

- Masonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)Documento2 pagineMasonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)DGWNessuna valutazione finora

- Lee Spring CatalogDocumento391 pagineLee Spring CatalogDGWNessuna valutazione finora

- Nord-Lock Washers: The Original Wedge-Locking SolutionDocumento16 pagineNord-Lock Washers: The Original Wedge-Locking SolutionDGWNessuna valutazione finora

- Wood Finishing Basics: Application Techniques & Product SelectionDocumento13 pagineWood Finishing Basics: Application Techniques & Product SelectionDGWNessuna valutazione finora

- 01 04tocDocumento428 pagine01 04tocFaltooNessuna valutazione finora

- Standard Pipe Sizes ME303-4.1.1Documento5 pagineStandard Pipe Sizes ME303-4.1.1manashbdNessuna valutazione finora

- Standard Pipe Sizes ME303-4.1.1Documento5 pagineStandard Pipe Sizes ME303-4.1.1manashbdNessuna valutazione finora

- The First Hillside Washer That Eliminated Back-Up Plates!Documento1 paginaThe First Hillside Washer That Eliminated Back-Up Plates!DGWNessuna valutazione finora

- Pipe Chart PDFDocumento2 paginePipe Chart PDFCarlos Rivera0% (1)

- D-01 7041 Flange-ANSI 125,150-RevlDocumento4 pagineD-01 7041 Flange-ANSI 125,150-RevlJohanna RojasNessuna valutazione finora

- Steel Rebar SizesDocumento1 paginaSteel Rebar SizesDGWNessuna valutazione finora

- Technical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDocumento2 pagineTechnical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDGWNessuna valutazione finora

- PVC Gravity Sewer PipeDocumento1 paginaPVC Gravity Sewer PipeDGWNessuna valutazione finora

- Tap Drill ChartDocumento2 pagineTap Drill ChartDGWNessuna valutazione finora

- Rubber Expansion JointsDocumento9 pagineRubber Expansion JointsDGWNessuna valutazione finora

- Threaded Rod AccessoriesDocumento1 paginaThreaded Rod AccessoriesDGWNessuna valutazione finora

- CAD-012854 - ROMAC 612 PIPE RESTRAINT FOR C905 PVCDocumento1 paginaCAD-012854 - ROMAC 612 PIPE RESTRAINT FOR C905 PVCDGWNessuna valutazione finora

- Countersinking Drill Bit ReamerDocumento1 paginaCountersinking Drill Bit ReamerDGWNessuna valutazione finora

- Bolt - Astm A449Documento2 pagineBolt - Astm A449DGWNessuna valutazione finora

- JLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDocumento2 pagineJLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDGWNessuna valutazione finora

- Cotter Pins and Spring PinsDocumento1 paginaCotter Pins and Spring PinsDGWNessuna valutazione finora

- Tap Drill DataDocumento1 paginaTap Drill DataDGWNessuna valutazione finora

- Standard Pipe Schedules and Sizes ChartDocumento1 paginaStandard Pipe Schedules and Sizes ChartDGWNessuna valutazione finora

- Screw Threads DesignDocumento1 paginaScrew Threads DesignDGWNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- PD MeterDocumento3 paginePD Meterreach_arindomNessuna valutazione finora

- Chillers, AHU, RTU How They Work - The Engineering MindsetDocumento8 pagineChillers, AHU, RTU How They Work - The Engineering Mindsetadk100% (1)

- Practical Techniques For Laptop RepairDocumento3 paginePractical Techniques For Laptop RepairGary FilbeeNessuna valutazione finora

- PRESSURE DROP CALCULATION FOR DRILL WATER PIPEDocumento9 paginePRESSURE DROP CALCULATION FOR DRILL WATER PIPEdasubhaiNessuna valutazione finora

- S. Senthilkumar CV FormatDocumento6 pagineS. Senthilkumar CV FormatdashNessuna valutazione finora

- Advanced FRP Panel Tank DesignDocumento4 pagineAdvanced FRP Panel Tank DesignEstimasi ATI SurabayaNessuna valutazione finora

- Process for Producing Ammonium Nitrate from Ammonia OxidationDocumento20 pagineProcess for Producing Ammonium Nitrate from Ammonia OxidationGracia ManurungNessuna valutazione finora

- Guided Wave and WeldingDocumento44 pagineGuided Wave and Weldingharoub_nas100% (1)

- UMP Faculty of Mechanical Engineering assignment on mechanics of composite materialsDocumento2 pagineUMP Faculty of Mechanical Engineering assignment on mechanics of composite materialsRima ChinnasamyNessuna valutazione finora

- Triplex Pump ManualDocumento11 pagineTriplex Pump ManualDustin WhiteNessuna valutazione finora

- Human Skull 3D Papercraft: Paper ArtDocumento8 pagineHuman Skull 3D Papercraft: Paper ArtReyes YessNessuna valutazione finora

- Alkasite Restorative Material: Exural and Compressive Strength EvaluationDocumento5 pagineAlkasite Restorative Material: Exural and Compressive Strength EvaluationMiguel Sánchez Marco AntonioNessuna valutazione finora

- !QFPIRA00T7VKInstruction ManualDocumento35 pagine!QFPIRA00T7VKInstruction ManualcarlosNessuna valutazione finora

- Detail of Mesh-1 Reinforcement Details of Pier Cap Section D-DDocumento1 paginaDetail of Mesh-1 Reinforcement Details of Pier Cap Section D-DSaurabh PandeyNessuna valutazione finora

- ProTech CatalogDocumento132 pagineProTech CatalogAlvaro AlejandroNessuna valutazione finora

- Class XI Redox Reactions NotesDocumento5 pagineClass XI Redox Reactions NoteseasaNessuna valutazione finora

- Rotary Seal V-Ring GuideDocumento25 pagineRotary Seal V-Ring GuideAnonymous D5QForitcNessuna valutazione finora

- Paper, 49th Annual Syp, ADDocumento12 paginePaper, 49th Annual Syp, ADPhilNessuna valutazione finora

- Separation TechniquesDocumento4 pagineSeparation TechniquesNicola Faye BronNessuna valutazione finora

- PO format-ACCDocumento17 paginePO format-ACCSpace designNessuna valutazione finora

- Barangay Ordinance On Open Burning 2022Documento4 pagineBarangay Ordinance On Open Burning 2022Catherine Parinas100% (4)

- Modern Hydraulic Systems for Mini ExcavatorsDocumento22 pagineModern Hydraulic Systems for Mini ExcavatorsRaul RiveraNessuna valutazione finora

- JacketIngDocumento28 pagineJacketIngVelmurugan Balasubramanian0% (1)

- 13M244 Instructions PDFDocumento430 pagine13M244 Instructions PDFDark ShadowNessuna valutazione finora

- Catalogo de Filtros Separador de Aire (Parker)Documento112 pagineCatalogo de Filtros Separador de Aire (Parker)Mikel1020Nessuna valutazione finora

- Hitachi Shirokuma floor-mounted air conditioner features and benefitsDocumento2 pagineHitachi Shirokuma floor-mounted air conditioner features and benefitsCristian TopalaNessuna valutazione finora

- DLP 6 LO2 Safe Disposal of Tools and MaterialsDocumento13 pagineDLP 6 LO2 Safe Disposal of Tools and MaterialsReybeth Tahud Hamili - Matus100% (2)

- Preventive Maintanance Interval 10 Whell Loader SDLGDocumento40 paginePreventive Maintanance Interval 10 Whell Loader SDLGAdy Prasetyo100% (2)

- Production of Formaldehyde From MethanolDocumento7 pagineProduction of Formaldehyde From MethanolThrese AreolaNessuna valutazione finora

- PRODUCTION OF INTERLOCKING ThisisDocumento43 paginePRODUCTION OF INTERLOCKING Thisisjohn mark pampo100% (1)