Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

VOLVO2 RTH2610F - Eng - 02 - 1875362

Caricato da

Miguel RamirezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

VOLVO2 RTH2610F - Eng - 02 - 1875362

Caricato da

Miguel RamirezCopyright:

Formati disponibili

Volvo Trucks.

Driving Progress

FACT SHEET

Rear axle RTH2610F

RTH2610F is a tandem axle with hub reduction, dimensioned FEATURES AND BENEFITS

for an engine torque of 3550 Nm. The maximum axle loading

is 26 tons and the combination weight is 100 tons. • Spiral bevel single gear units with high efficiency and low

servicing requirements.

RTH2610F consists of two spiral bevel single gear units, with a • Sturdily dimensioned and hardened shafts and gears.

distribution gearbox in the forward rear axle. The axle casings are • Hub reduction gears reduce loads on the drive line.

cast in nodular iron, giving a compact design with high ground • Wheel bearings in the form of maintenance-free unit bearings

clearance. give longer life and easier servicing.

Most of the torque conversion takes place in the reduction gears • Three reliable diff locks give high vehicle availability.

in the wheel hubs. This is a reliable design which takes the form • High ground clearance.

of a cylindrical planetary gear with straight-cut gears on needle

bearings, giving low drive losses.

RTH2610F is designed for heavy, demanding haulage and

train weights of up to 100 tons. The two-axle drive means that the

tractive effort can be transferred to the ground without wheel slip,

giving excellent grip and very low tyre wear.

RTH2610F has three differential locks, one for the forward and

one for the rear gear units and one of the distribution gearbox. This

guarantees very good grip when the surface is slippery, which

results in higher truck productivity.

The diff locks are controlled by a two-stage switch on the instru-

ment panel. When the first stage of the switch is selected the diff

lock on the distribution gearbox is engaged, coupling the two rear

axles together. When the second stage of the switch is selected,

the driveshafts of the two rear axles are coupled together.

A combination of new production methods and special oil has

resulted in longer oil change intervals. This means lower operating

costs and reduced environmental impact.

With an approved synthetic oil, the oil must be changed after at most

450 000 km or every three years.

2014-03-10 ENG Version 02 1 (2)

FACT SHEET

Rear axle RTH2610F

Tandem gear that produces a great deal of force and Three differential locks give high availability

allows for good access on all terrain RTH2610F is fitted with three diff locks, one for each rear axle and

RTH2610F consists of two single gears of spiral bevel type and one of the distribution gearbox. The diff lock for the distribution

one distribution gear that is built onto the front final drive. gearbox couples together the drives of the two rear axles, whilst

The distribution gear is designed to distribute the driving force the diff locks on the rear axles couple the driveshafts to the diff

evenly between both final drives. casing. When all three diff locks are engaged, all drive wheels are

The driving force from the gearbox goes via the distribution gear’s forced to rotate at the same speed.

input shaft to the differential. From the differential, the driving force The diff locks are in the form of hardened steel dog clutches

is transferred via a cylindrical gear wheel to the front rear axle’s operated by compressed air. There are two lamps on the instru-

final drive and to the distribution gear’s output shaft, which drives ment panel to indicate when the diff locks are engaged. One lamp

the rear axle’s final drive via a driveshaft. is for the distribution gearbox diff lock and the other is for the diff

This type of rear axle combination with tandem driving means that locks of the two rear axles.

a large propelling force can be transferred to the ground without The diff lock function guarantees very good grip when the sur-

slipping because the total axle pressure is high. This means it is face is slippery, which results in higher truck vehicle availability.

easy to get around and there is less wearing of the tyres.

The distribution gear in the front Single gear in the front final drive.

final drive.

Hub reduction with high reliability Differential lock engaged. Differential lock engaged.

RTH2610F is fitted with reduction gears in each hub. The hub

reduction gearing consists of a cylindrical planetary gear with

straight-cut gears on needle bearings, giving low drive losses. SPECIFICATION

The sun wheel is mounted on the driveshaft. From the sun wheel, Type designation.................................................................................RTH2610F

the power is transferred to three planetary gears connected to Gear............................................ Single gear, spiral bevel with hub reduction

the wheel hub. Distribution gearbox.......................................................... Cylindrical spur gear

When the planetary gears are forced to rotate against the ring Hub reduction............................................................Cylindrical planetary gear

Weight including driveshafts, hubs and drum brakes/disc brakes

gear, which is rigidly fixed to the rear axle casing, the rotation

Forward axle......................................................................................848/803 kg

speed is geared down. Rearward axle....................................................................................747/719 kg

The wheel bearings are in the form of maintenance-free unit bear- Crown wheel, diameter.......................................................................... 295 mm

ings. The entire hub with bearings can be removed and installed Driveshafts, diameter.................................................................................45 mm

simply and safely without affecting the bearing clearance. Maximum engine torque......................................................................3550 Nm

Max bogie loading................................................................................ 26000 kg

Max combination weight.................................................................. 100000 kg

Ratio with hub reduction............................................................................3.33:1

....................................................................................................................... 3.46:1

........................................................................................................................3.61:1

....................................................................................................................... 3.76:1

....................................................................................................................... 3.97:1

........................................................................................................................4.12:1

........................................................................................................................4.55:1

........................................................................................................................5.41:1

....................................................................................................................... 6.18:1

Ratio distribution gearbox................................................................................ 1:1

Oil change quantity:

Forward axle.................................................................................................. 26.5 l

Rearward axle............................... Air suspension 23 l/Leaf suspension 24 l

2014-03-10 ENG Version 02 2 (2)

Potrebbero piacerti anche

- Slides. Rear Axle RTS2370A. Texto PDFDocumento16 pagineSlides. Rear Axle RTS2370A. Texto PDFYery Cruz100% (2)

- 43 Design and Function InputshaftDocumento3 pagine43 Design and Function InputshaftYasin Noer Huda PNessuna valutazione finora

- Spec 1 Vt2009bDocumento5 pagineSpec 1 Vt2009bYasin Noer Huda PNessuna valutazione finora

- VT2814B Eng 01 953722Documento2 pagineVT2814B Eng 01 953722Memeng 51Nessuna valutazione finora

- Bodybuilder Module, Fault CodesDocumento2 pagineBodybuilder Module, Fault CodesIzz Bahar100% (1)

- Magnum Dxi13 Rocker Shaft and CamshaftDocumento110 pagineMagnum Dxi13 Rocker Shaft and CamshaftАлександр ГорбуновNessuna valutazione finora

- BrzdyDocumento206 pagineBrzdyLotfi Ben SlimNessuna valutazione finora

- D12A Refit Cylinder HeadDocumento26 pagineD12A Refit Cylinder HeadSherzad ChemNessuna valutazione finora

- Trainer Booklet PTDocumento33 pagineTrainer Booklet PTShane Lin0% (1)

- Tabela Óleo - Noguti CaminhãoDocumento2 pagineTabela Óleo - Noguti Caminhãodiego_egcaNessuna valutazione finora

- Diferencial Rs 1370 HV VOLVO FHDocumento3 pagineDiferencial Rs 1370 HV VOLVO FHEmerson Borges DelfinoNessuna valutazione finora

- Meritor Reman Caliper Catalogue - Web - 1Documento234 pagineMeritor Reman Caliper Catalogue - Web - 1SERVICIO AUTOMOTRIZNessuna valutazione finora

- 1349 052 004 - 6S1350 Caja de Cambios ZFDocumento56 pagine1349 052 004 - 6S1350 Caja de Cambios ZFchristian ULFFE HERNANDEZNessuna valutazione finora

- Caixas de Merchas Euro VDocumento28 pagineCaixas de Merchas Euro VJorge AlbertoNessuna valutazione finora

- GenspaDocumento373 pagineGenspaJulian Andres Zancajo100% (1)

- Voith 1Documento44 pagineVoith 1Branko AndricNessuna valutazione finora

- Control Unit, Gear Selector, ReplacementDocumento4 pagineControl Unit, Gear Selector, ReplacementHamilton MirandaNessuna valutazione finora

- D13A520Documento66 pagineD13A520DmitriyNessuna valutazione finora

- Engine Brake Design and Function PDFDocumento9 pagineEngine Brake Design and Function PDFRony CruzNessuna valutazione finora

- Jhbvokhvi0ebhb Y226379 1 en 000Documento2 pagineJhbvokhvi0ebhb Y226379 1 en 000ธีรพงษ์ นิตยบูรณ์Nessuna valutazione finora

- Service Bulletin Trucks: Unit Injectors, ReplacementDocumento23 pagineService Bulletin Trucks: Unit Injectors, ReplacementbabyNessuna valutazione finora

- RTH2610B - RT3210HV Carrier Catalogue PDFDocumento16 pagineRTH2610B - RT3210HV Carrier Catalogue PDFasdNessuna valutazione finora

- D13K460, EU6SCR - Eng - 09 - 310999631Documento3 pagineD13K460, EU6SCR - Eng - 09 - 310999631Justine GumboNessuna valutazione finora

- Main Shaft, Overhaul PDFDocumento21 pagineMain Shaft, Overhaul PDFEsam Phlipe100% (1)

- Product Academy 1: Corso Eurotronic II GE26Documento47 pagineProduct Academy 1: Corso Eurotronic II GE26SantosNegriNessuna valutazione finora

- Caixas de Merchas Euro V PDFDocumento24 pagineCaixas de Merchas Euro V PDFJorge Alberto100% (1)

- Iveco EMS 5120-6149Documento46 pagineIveco EMS 5120-6149PIKO MOBNessuna valutazione finora

- Wiring Diagram Index: Released ReleasedDocumento83 pagineWiring Diagram Index: Released ReleasedMc NanoNessuna valutazione finora

- Voith Service X-Change Manual 06-26-2020Documento17 pagineVoith Service X-Change Manual 06-26-2020Mohamed MohamedNessuna valutazione finora

- Adjust Valve FH v2Documento25 pagineAdjust Valve FH v2ekowahyuzulianto100% (1)

- Range Gear O.HDocumento26 pagineRange Gear O.HYasin Noer Huda P100% (1)

- Magnum Dxi13 Rocker and Valve AdjustmentDocumento24 pagineMagnum Dxi13 Rocker and Valve AdjustmentFranky FernandezNessuna valutazione finora

- Meritor D3 Service Manual - MM0265Documento23 pagineMeritor D3 Service Manual - MM0265LUKASNessuna valutazione finora

- AT2512C Eng 01 953804Documento2 pagineAT2512C Eng 01 953804Victor Hugo Benitez PaezNessuna valutazione finora

- 431-168 Input Shaft, Overhaul FM9, FM12, FH12, FH16, FH, FM PDFDocumento7 pagine431-168 Input Shaft, Overhaul FM9, FM12, FH12, FH16, FH, FM PDFautoeletricamalaquiaNessuna valutazione finora

- FM PDFDocumento660 pagineFM PDFEngkus KuswayaNessuna valutazione finora

- Fifth-Wheel Coupling JSK 38/50: Repair ManualDocumento38 pagineFifth-Wheel Coupling JSK 38/50: Repair ManualAbrar HussainNessuna valutazione finora

- Connecting Rod Bearings, Replace (All) D16Documento5 pagineConnecting Rod Bearings, Replace (All) D16Hamilton MirandaNessuna valutazione finora

- 21072-1 Engine, InstallDocumento6 pagine21072-1 Engine, InstallDeny Adi Irawan100% (1)

- Tapa de ValvulasDocumento6 pagineTapa de ValvulasJuan Jose Hernandez Jimenez100% (1)

- Scania: Pumpe Za Vodu I Ulje Water & Oil PumpsDocumento4 pagineScania: Pumpe Za Vodu I Ulje Water & Oil PumpsJasminM dooNessuna valutazione finora

- Cylinder Balancing, Fault TracingDocumento12 pagineCylinder Balancing, Fault TracingHamilton MirandaNessuna valutazione finora

- Prueba Wabco Ecad VolvoDocumento3 paginePrueba Wabco Ecad VolvoAnonymous J1sELDp7100% (1)

- Coolant Pump ReplacementDocumento6 pagineCoolant Pump ReplacementRajan MullappillyNessuna valutazione finora

- Volvo FH Product Guide Euro3 5 en enDocumento26 pagineVolvo FH Product Guide Euro3 5 en enYuber Ccoa100% (1)

- 8090 I 04 - 12 en - Servocom - Servotest 100 - China - 8095 - 8097 - 8098Documento42 pagine8090 I 04 - 12 en - Servocom - Servotest 100 - China - 8095 - 8097 - 8098joe blow100% (1)

- ScaniaPartsSolutions2020Brochure A5 V13Documento21 pagineScaniaPartsSolutions2020Brochure A5 V13கோவி கோபால் ஆர்ட்ஸ்Nessuna valutazione finora

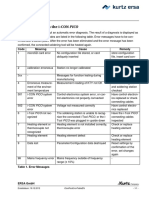

- Error Messages in The i-CON PICODocumento1 paginaError Messages in The i-CON PICOIvana Ika StankovicNessuna valutazione finora

- ACiencia para Ficar RicoDocumento67 pagineACiencia para Ficar RicoGlaudiston JblNessuna valutazione finora

- PV776 TSP142921Documento54 paginePV776 TSP142921Benjamin Miranda FloresNessuna valutazione finora

- Volvo: SR2000 - SRO2000 - SR2400 - SRO2400Documento6 pagineVolvo: SR2000 - SRO2000 - SR2400 - SRO2400عبدالغني القباطيNessuna valutazione finora

- ZF s6 1550Documento2 pagineZF s6 1550danielNessuna valutazione finora

- Volvo FL PDFDocumento19 pagineVolvo FL PDFBenNessuna valutazione finora

- Dss-Volvo Catalogue PDFDocumento182 pagineDss-Volvo Catalogue PDFOscar Bedregal100% (1)

- Meritor DownloadDocumento68 pagineMeritor DownloadShubham BhatiaNessuna valutazione finora

- Diagramas Fotos PDFDocumento30 pagineDiagramas Fotos PDFJonathan NuñezNessuna valutazione finora

- Factsheet Rearaxle PDFDocumento2 pagineFactsheet Rearaxle PDFJoãoPauloSouzaNessuna valutazione finora

- Factsheet - Rear Axle Rt2310Hv: Features and BenefitsDocumento2 pagineFactsheet - Rear Axle Rt2310Hv: Features and BenefitsJoãoPauloSouzaNessuna valutazione finora

- Slides. Puente Posterior RT3210HV. Texto PDFDocumento20 pagineSlides. Puente Posterior RT3210HV. Texto PDFLeonel Rojas100% (1)

- DPA5DualCAN - User - Manual - PDF 5Documento6 pagineDPA5DualCAN - User - Manual - PDF 5Miguel RamirezNessuna valutazione finora

- DPA5DualCAN - User - Manual - PDF 1Documento6 pagineDPA5DualCAN - User - Manual - PDF 1Miguel RamirezNessuna valutazione finora

- DPA5DualCAN - User - Manual - PDF 4Documento6 pagineDPA5DualCAN - User - Manual - PDF 4Miguel RamirezNessuna valutazione finora

- DPA5DualCAN - User - Manual - PDF 3Documento6 pagineDPA5DualCAN - User - Manual - PDF 3Miguel RamirezNessuna valutazione finora

- Manuales - T8240AP-19 - Fuse Specifications - Service ADVISOR™Documento2 pagineManuales - T8240AP-19 - Fuse Specifications - Service ADVISOR™Miguel RamirezNessuna valutazione finora

- DPA5DualCAN - User - Manual - PDF 2Documento6 pagineDPA5DualCAN - User - Manual - PDF 2Miguel RamirezNessuna valutazione finora

- MP Minicargadores 440 Serie 3 PDFDocumento1.942 pagineMP Minicargadores 440 Serie 3 PDFAndres Becerra86% (14)

- Cheroque 6 Cyl - XpsDocumento1 paginaCheroque 6 Cyl - XpsMiguel RamirezNessuna valutazione finora

- Crdi 300FDocumento22 pagineCrdi 300FvlahdacoromanNessuna valutazione finora

- Crdi 300FDocumento22 pagineCrdi 300FvlahdacoromanNessuna valutazione finora

- 2013-02-06 185812 Tl100a Clutch CalibrationDocumento9 pagine2013-02-06 185812 Tl100a Clutch CalibrationMiguel RamirezNessuna valutazione finora

- Division and Match of QQ Remote ControlsDocumento2 pagineDivision and Match of QQ Remote ControlsJhon Geimar Ortiz RodriguezNessuna valutazione finora

- Tightening Torques: Telephone: Fax: VAT Registration No.Documento1 paginaTightening Torques: Telephone: Fax: VAT Registration No.Miguel RamirezNessuna valutazione finora

- Opel 1.5Documento6 pagineOpel 1.5Miguel RamirezNessuna valutazione finora

- Opel 1.5Documento6 pagineOpel 1.5Miguel RamirezNessuna valutazione finora

- DTC Park Brake Presure NEW HOLLAND 4431Documento2 pagineDTC Park Brake Presure NEW HOLLAND 4431Miguel RamirezNessuna valutazione finora

- Opel 1.5Documento6 pagineOpel 1.5Miguel RamirezNessuna valutazione finora

- Stanadyne Ds PumpDocumento62 pagineStanadyne Ds Pumpvinnman87100% (5)

- Aurora Diesel Pump 913 - Dimensional DataDocumento72 pagineAurora Diesel Pump 913 - Dimensional DataHermantoro W. PradanaNessuna valutazione finora

- Bolero Pikup FB SC RHD Mdi TC 3200 Bsii Bsiii PS 2WD - Ver 1 - Sept 2007Documento114 pagineBolero Pikup FB SC RHD Mdi TC 3200 Bsii Bsiii PS 2WD - Ver 1 - Sept 2007maxmurshid100% (1)

- Blackmer LGLD3F Self Priming Specs Sheet PDFDocumento2 pagineBlackmer LGLD3F Self Priming Specs Sheet PDFRomnick Dela Cruz GasparNessuna valutazione finora

- Mounting of Pulley and Gear On ShaftDocumento14 pagineMounting of Pulley and Gear On Shaftrakesh wagh60% (5)

- Minor Project Report On Power Transmission in AutomobilesDocumento77 pagineMinor Project Report On Power Transmission in AutomobilesMohitt Thakur81% (16)

- Yanmar 3gm30eDocumento127 pagineYanmar 3gm30eYew LimNessuna valutazione finora

- Pettibone Parts Manual 204 S/N: 5664Documento343 paginePettibone Parts Manual 204 S/N: 5664Alberto Arietto De VidoNessuna valutazione finora

- Catlogo Motorreductores Boston Gears AlimenticioDocumento72 pagineCatlogo Motorreductores Boston Gears Alimenticiometalcernaw rodriguezNessuna valutazione finora

- 1812 05-07 6 0 12 V 5R110 Installation Manual PCS 11-2-12Documento34 pagine1812 05-07 6 0 12 V 5R110 Installation Manual PCS 11-2-12David BNessuna valutazione finora

- 93LH 2Documento72 pagine93LH 2prueba5Nessuna valutazione finora

- Paper MEIDEN Eaxle Coches Segmento CDocumento6 paginePaper MEIDEN Eaxle Coches Segmento CErnesto Capdepon CarvajalNessuna valutazione finora

- B2150 HSDDocumento310 pagineB2150 HSDJuan MayorgaNessuna valutazione finora

- 205-03 Front Drive Axle and Differential - Removal and Installation - Drive Pinion Flange and SealDocumento7 pagine205-03 Front Drive Axle and Differential - Removal and Installation - Drive Pinion Flange and SealCARLOS LIMADANessuna valutazione finora

- Sae2023 01 0446Documento7 pagineSae2023 01 0446Joanne WNessuna valutazione finora

- ClutchDocumento14 pagineClutchIwan CahyonoNessuna valutazione finora

- HYUNDAI Accent MANUAL DE SERVICIO AÑO 2003 AÑO 1.5LDocumento1.062 pagineHYUNDAI Accent MANUAL DE SERVICIO AÑO 2003 AÑO 1.5LManuel M100% (1)

- CBS-880 Instruction Manual 2013 DougCareDocumento39 pagineCBS-880 Instruction Manual 2013 DougCareMike PandeyNessuna valutazione finora

- Hagglunds CaDocumento19 pagineHagglunds CaJonathan Giraldo100% (1)

- 1998 Sec 7-Manual TransmissionDocumento25 pagine1998 Sec 7-Manual TransmissionAdal VeraNessuna valutazione finora

- Manual de Partes ST2DDocumento513 pagineManual de Partes ST2DJuan carlos Hernandez areas100% (2)

- 09 Manual Transaxle SystemDocumento29 pagine09 Manual Transaxle SystemMuhammad Eitch-BeeNessuna valutazione finora

- Jaguar XJ X350 WorkshopManualDocumento6.361 pagineJaguar XJ X350 WorkshopManualMaciek WiśniewskiNessuna valutazione finora

- Efficienza E Analisi Termica: Ing. Ivan SaltiniDocumento31 pagineEfficienza E Analisi Termica: Ing. Ivan SaltiniAnonymous kHYFVEONessuna valutazione finora

- LRL0096ENG - Land Rover Warranty Code Manual (1997)Documento26 pagineLRL0096ENG - Land Rover Warranty Code Manual (1997)Master XeotoNessuna valutazione finora

- Parts Manual: Truck Model: C20-33 35 L SERIAL NUMBER: P232L-0956 & Above-9645 KFDocumento176 pagineParts Manual: Truck Model: C20-33 35 L SERIAL NUMBER: P232L-0956 & Above-9645 KFJuan LaraNessuna valutazione finora

- PSCS Syz323 PDFDocumento3 paginePSCS Syz323 PDFTheo anggara kusumaNessuna valutazione finora

- 62st325 Civic 5 Door 99Documento197 pagine62st325 Civic 5 Door 99snstancuNessuna valutazione finora

- Centaflex - A: Highly Flexible CouplingsDocumento16 pagineCentaflex - A: Highly Flexible CouplingsBelmondo GiulioNessuna valutazione finora

- 07 Embragues de Levas PDFDocumento92 pagine07 Embragues de Levas PDFLuisNessuna valutazione finora

- Sm-Caterpillar Cat 950h Wheel Loader j5j01501Documento25 pagineSm-Caterpillar Cat 950h Wheel Loader j5j01501Daniel Vanegas100% (1)