Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Filter Press HPHT 175R PDF

Caricato da

Hamed NazariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Filter Press HPHT 175R PDF

Caricato da

Hamed NazariCopyright:

Formati disponibili

Drilling Fluids & Oil Well Cements

Fann Instrument Company Product Information

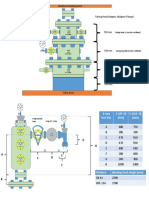

HPHT Filter Press

Model 175CT

Description

HPHT Filter Press, Model 175CT simulates filtration

against a permeable formation at high temperatures

and pressures. Each 175 ml HPHT Filter Press consists

of the following components and operating supplies:

• Stainless steel cell with CellTell™Positive Pressure

Indicator

• Aluminum heating jacket

• Pressurization System (Nitrogen or CO2)

• Back Pressure Receiver, 15 ml

• Graduated cylinder

Application

Measuring filtration and cake-building properties is

fundamental to treatment and control of drilling fluids.

Studying filtrate characteristics, oil, water, or emulsion

content, is also essential.

For a drilling fluid, the quantity, type and size of solid

particles, emulsified water, and properties of the liquid

phase affect the filtration characteristics. Temperature

and pressure may influence the interactions of these

various components. Therefore, filtration tests are

often performed at ambient and high temperatures, HPHT Filter Press, Model 175CT, CO2 Pressurized

providing data for comparison. Maximum Pressure: 1800 psig

Backpressure: 750 psig

Advantages Maximum Temperature: 350°F

• Wide range of customizing configurations for your

specific needs Safety Features

• HPHT safety features that help protect from Each HPHT Filter Press cell is furnished

hazards with a CellTell™Positive Pressure Indicator.

• Heavy-duty components and materials that This new safety feature gives feedback

withstand HPHT conditions about the pressure status of any HPHT

cell. CellTell™Positive Pressure Indicator is

• Pilot light on heating jacket that signals when unaffected by temperature and resistant to

temperature reaches thermostat setting motion caused by vibration and rotation.

• Single or double opening cells that accept various

filter media choices, such as API standard filter

paper, ceramic discs of various porosities, and

screens of various mesh sizes

• Choice of 115 volt AC or 230 volt AC heating jacket

• Pressurization alternatives, such as CO2 cartridges,

nitrogen, or in-house source

HPHT Filter Press, Model 175CT

Specifications

Cell: 1800 psig (12.4 MPa)

Maximum Working Pressure

Backpressure: 750 psig (5.17 MPa)

Maximum Temperature 350°F (177°C)

Sample Cell Volume 175 ml

Receiver Volume 15 ml

Filtering Area 3.5 in2 (22.6 cm2)

Heating Capacity 400 watts

Power Requirement 115/230 VAC, Frequency 50/60 Hz

Ordering Information

HPHT Filter Presses are available in various configuration as shown in the following tables.

HPHT Filter Press 115 Volts

CO2 Pressurization Nitrogen Pressurization

HPHT Filter Press

No. 101571371 No. 101571372 No. 101565554 No. 101565556

Assembly

Cell Configuration 175 ml, dual 175 ml, single 175 ml, dual 175 ml, single

openingb opening openingb opening

No. 209585 No. 209584 No. 209585 No. 209584

Cap & Screen 1 Cap No. 209536 Cap No. 209532 1 Cap No. 209536 Cap No. 209532

Configuration w/Detachable 60 Mesh Screena w/Detachable 325 60 Mesh Screena

Screen, 325 Mesh/ No. 207232 Mesh Screen, No. 207232

60 Mesh Backup, 1 Cap No. 209568

1 Cap No. 209568

Pressurization CO2 Assembly No. 209471 Dual Nitrogen Assembly No. 209545

Backpressure

15 ml, CO2, No. 209503 15 ml, Nitrogen, No. 209502

Receiver

Heating Jacket 115 Volts, 400 Watts, No. 209492

Note: Items listed for each assembly part number are included.

a

Screen is installed in the cap.

b

Both ends are open.

Phone: 281-871-4482 Web: www.fann.com Email:fannmail@fann.com

Copyright © 2013 Fann Instrument Company All Rights Reserved. Effective Date: August 2013

HPHT Filter Press, Model 175CT

HPHT Filter Press 230 Volts

CO2 Pressurization Nitrogen Pressurization

HPHT Filter Press

No. 101571373 No. 101571374 No. 101565558 No. 101565560

Assembly

Cell 175 ml, dual 175 ml, single 175 ml, dual 175 ml, single

Configuration openingb opening openingb opening

No. 209585 No. 209584 No. 209585 No. 209584

Cap & Screen 1 Cap No. 209536 Cap No. 209532 1 Cap No. 209536 Cap No. 209532

Configuration w/Detachable 60 Mesh Screena w/Detachable 325 60 Mesh Screena

Screen, 325 Mesh/ No. 207232 Mesh Screen, No. 207232

60 Mesh Backup, 1 Cap No. 209568

1 Cap No. 209568

Pressurization CO2 Assembly, No. 209471 Dual Nitrogen Assembly, No. 209545

Backpressure

15 ml, CO2, No. 209503 15 ml, Nitrogen, No. 209502

Receiver

Heating Jacket 230 Volts, 400 Watts, No. 209506

Note: Items listed for each assembly part number are included.

a

Screen is installed in the cap.

b

Both ends are open.

Recommended Safety Equipment

Fann Filter Press Cell Clamps are available as a separate purchase.

• P/N 232207 — Filter Press Cell Clamp for 175 ml cell

• P/N 232208 — Filter Press Cell Clamp for 500 ml cell

Optional Equipment

Fann offers a complete line of replacement parts, accessories,

and tools for all HPHT Filter Presses. Filter Press Cell Clamp,175ml

Cell Carrying Tool, Cap Removal Tool, Valve Reseat-

ing Tool, Screens, Ceramic Discs, and Filter Paper

Fann Instrument Company offers a complete line of equipment, materials, and supplies for analyzing various

drilling fluids and oil well cements in accordance with API Specifications and API Recommended Practices.

Phone: 281-871-4482 Web: www.fann.com Email:fannmail@fann.com

Copyright © 2013 Fann Instrument Company All Rights Reserved. Effective Date: August 2013

Potrebbero piacerti anche

- Ebook V9 10 2017-ReduxDocumento247 pagineEbook V9 10 2017-ReduxBilboNessuna valutazione finora

- Schlumberger: PIPESIM Open Link - Gas Lift Design & DiagnosticsDocumento16 pagineSchlumberger: PIPESIM Open Link - Gas Lift Design & DiagnosticsnvnvNessuna valutazione finora

- 50W Monocrystalline Solar Panels: Electrical SpecificationsDocumento1 pagina50W Monocrystalline Solar Panels: Electrical SpecificationsCloue DeriadaNessuna valutazione finora

- Sucker Rod Pump and Accessories-Huaming EnergyDocumento9 pagineSucker Rod Pump and Accessories-Huaming EnergyKevin XuNessuna valutazione finora

- UniDocumento21 pagineUnisparda94Nessuna valutazione finora

- He-E10 Well MontageDocumento1 paginaHe-E10 Well MontageSaeid OrangiNessuna valutazione finora

- Drilling Engineering and OperationsDocumento30 pagineDrilling Engineering and Operationsreza khNessuna valutazione finora

- Innovative Through-Tubing Cement Packer PDFDocumento2 pagineInnovative Through-Tubing Cement Packer PDFFe Maligi100% (1)

- 1.8 Casing Design1.9 Burst, Collapse, TensionDocumento19 pagine1.8 Casing Design1.9 Burst, Collapse, TensionMobeen MurtazaNessuna valutazione finora

- NA OG: Cable Reheading Made Simple (After GOI)Documento4 pagineNA OG: Cable Reheading Made Simple (After GOI)RoyNessuna valutazione finora

- DRLG Exam 2023Documento12 pagineDRLG Exam 2023Essam AnanyNessuna valutazione finora

- Natural Gas DehydrationDocumento29 pagineNatural Gas DehydrationMaulana Syamil BasayevNessuna valutazione finora

- Slim Hole Drilling TechnologyDocumento11 pagineSlim Hole Drilling TechnologyMuhammad MohtashimNessuna valutazione finora

- Spe 70027 02 PDFDocumento9 pagineSpe 70027 02 PDFairlinemembershipNessuna valutazione finora

- IWCF Formula Sheet - API Field UnitsDocumento4 pagineIWCF Formula Sheet - API Field Unitsak80ak80Nessuna valutazione finora

- Cementing: Habiburrohman, B.Eng, M.EngDocumento52 pagineCementing: Habiburrohman, B.Eng, M.EngNamwangala Rashid NatinduNessuna valutazione finora

- Mainan DewasaDocumento153 pagineMainan DewasaHeris SitompulNessuna valutazione finora

- Drilling String DesignDocumento13 pagineDrilling String DesignMiguel Angel TiconaNessuna valutazione finora

- PerforationDocumento3 paginePerforationTeguh Akbar HarahapNessuna valutazione finora

- Hole Conditioning Before Running Casing or LinerDocumento1 paginaHole Conditioning Before Running Casing or LinerYougchu LuanNessuna valutazione finora

- API Example No. 1 100 100 1000 0.465 78 130 178 0.650 4000 544 7000 1030 8000 12 0.094 25.0 EDocumento3 pagineAPI Example No. 1 100 100 1000 0.465 78 130 178 0.650 4000 544 7000 1030 8000 12 0.094 25.0 EashrafsaberNessuna valutazione finora

- ACPI 6 3 Final Jan30Documento512 pagineACPI 6 3 Final Jan30Imagine MiracleNessuna valutazione finora

- Fill Only The Yellow Cells !: Pump Rate Pump RateDocumento3 pagineFill Only The Yellow Cells !: Pump Rate Pump RateCristian BarbuceanuNessuna valutazione finora

- Stress Check and Casing SeatDocumento19 pagineStress Check and Casing Seatمحمد كريم زهير حبيب 49Nessuna valutazione finora

- Model A Hydro TripDocumento1 paginaModel A Hydro TripFernando OlaveoNessuna valutazione finora

- Lecture 3 - Mud ProgramDocumento16 pagineLecture 3 - Mud ProgramhuutaiphamNessuna valutazione finora

- Well Completion and Its TypesDocumento14 pagineWell Completion and Its TypesJagdish annayaNessuna valutazione finora

- ENPE 515 W 2013 Assignment 3.313Documento2 pagineENPE 515 W 2013 Assignment 3.313ench501Nessuna valutazione finora

- Right Torque at The Connection 5Documento4 pagineRight Torque at The Connection 5Shafiqa AlhobaishyNessuna valutazione finora

- Lesson 3. Wellbore PressuresDocumento64 pagineLesson 3. Wellbore Pressuresbon1ngNessuna valutazione finora

- Kimray - Glycol PumpsDocumento29 pagineKimray - Glycol Pumpsafsuarezco100% (1)

- 2 Bridge PlugsDocumento9 pagine2 Bridge PlugsmahsaNessuna valutazione finora

- Amoco - Drilling Fluid ManualDocumento45 pagineAmoco - Drilling Fluid ManualMehrnoosh ArefNessuna valutazione finora

- 2441 Unit 23Documento42 pagine2441 Unit 23mahaveen100% (1)

- Petani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)Documento30 paginePetani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)handokoNessuna valutazione finora

- Well Completions 2111Documento2 pagineWell Completions 2111muturabu87Nessuna valutazione finora

- 02 Drill Bit Hydraulics CalculationsDocumento61 pagine02 Drill Bit Hydraulics CalculationsArkhatTompakovNessuna valutazione finora

- Pressure TraverseDocumento10 paginePressure TraverseFabianIrsyadNessuna valutazione finora

- Calculate Influx Height PDFDocumento3 pagineCalculate Influx Height PDFShoaib KhalilNessuna valutazione finora

- DRLG 451 - Assignment #3 Well ControlDocumento6 pagineDRLG 451 - Assignment #3 Well ControlnijamediaNessuna valutazione finora

- Carbonate Acidizing AHDocumento79 pagineCarbonate Acidizing AHMarrry Florencia100% (1)

- Drilling Engineering NotesDocumento28 pagineDrilling Engineering NotesshanecarlNessuna valutazione finora

- University of Tripoli Faculty of Engineering Petroleum EngineeringDocumento8 pagineUniversity of Tripoli Faculty of Engineering Petroleum EngineeringRoba SaidNessuna valutazione finora

- Wellhead HeightDocumento2 pagineWellhead HeightPranjal PatilNessuna valutazione finora

- Well Testing MilisDocumento40 pagineWell Testing Milisdrg100% (1)

- Cement Plug CalculationDocumento7 pagineCement Plug CalculationEmad JamshidiNessuna valutazione finora

- Successfully Drills Through Total Losses Zones, Saves 17.6 DaysDocumento2 pagineSuccessfully Drills Through Total Losses Zones, Saves 17.6 DaysAriel Della TorreNessuna valutazione finora

- Conversion Factors & Pressure Test & Casing and DPDocumento4 pagineConversion Factors & Pressure Test & Casing and DPhaoues23Nessuna valutazione finora

- Well Test Analysis - Math + Data + Python CodeDocumento10 pagineWell Test Analysis - Math + Data + Python CodeAllah bakhsh BakhshNessuna valutazione finora

- BKDocumento1 paginaBKmbloexNessuna valutazione finora

- Smith Nozzles PDFDocumento2 pagineSmith Nozzles PDFrangga1000Nessuna valutazione finora

- Cementing Job PlanDocumento13 pagineCementing Job PlanBrihaspati VermaNessuna valutazione finora

- Part 7 - Wellbore Storage EffectsDocumento5 paginePart 7 - Wellbore Storage EffectsChai CwsNessuna valutazione finora

- Well CementingDocumento11 pagineWell CementingSuleiman BaruniNessuna valutazione finora

- Kick Tolerance Calculations For Well Design and Drilling OperationsDocumento2 pagineKick Tolerance Calculations For Well Design and Drilling Operationsi oNessuna valutazione finora

- Filter Press HPHT 175RDocumento3 pagineFilter Press HPHT 175RJosé RodriguezNessuna valutazione finora

- Hitachi ChillerDocumento8 pagineHitachi Chillertrantrunghoa1984Nessuna valutazione finora

- Delvac PumpsDocumento8 pagineDelvac PumpsudhaiiNessuna valutazione finora

- Quotation On 5 Gallon and 7L Pet Bottle Blow Mould MachinesDocumento20 pagineQuotation On 5 Gallon and 7L Pet Bottle Blow Mould MachinesAni Mercedes SalazarNessuna valutazione finora

- Manual Rooftop On-OffDocumento73 pagineManual Rooftop On-OffGerman CiclonNessuna valutazione finora

- Mehrdad Mohammadpour MD Resume: OphthalmologyDocumento15 pagineMehrdad Mohammadpour MD Resume: OphthalmologyHamed NazariNessuna valutazione finora

- Mehdi Soltani: Curriculum VitaeDocumento3 pagineMehdi Soltani: Curriculum VitaeHamed NazariNessuna valutazione finora

- 4 5963071420547203453Documento85 pagine4 5963071420547203453Hamed NazariNessuna valutazione finora

- Daily Drilling ReportDocumento3 pagineDaily Drilling ReportHamed NazariNessuna valutazione finora

- DDR1402 02 09Documento26 pagineDDR1402 02 09Hamed Nazari100% (1)

- MD-1 NPT-Farvardin 1400: DescriptionDocumento5 pagineMD-1 NPT-Farvardin 1400: DescriptionHamed NazariNessuna valutazione finora

- Daily Drilling ReportDocumento25 pagineDaily Drilling ReportHamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Da13 DDR N1 14000305 254 0Documento3 pagineDa13 DDR N1 14000305 254 0Hamed NazariNessuna valutazione finora

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud PumpDocumento26 pagineDaily Drilling Report: Bha Tally Bit Record Mud Report Mud PumpHamed NazariNessuna valutazione finora

- Da14 DDR N2 14000103 175 0Documento3 pagineDa14 DDR N2 14000103 175 0Hamed NazariNessuna valutazione finora

- غزالDocumento1 paginaغزالHamed NazariNessuna valutazione finora

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocumento25 pagineDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Da DDR N1 1Documento3 pagineDa DDR N1 1Hamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocumento25 pagineDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariNessuna valutazione finora

- Da13 DDR N1 14000229 247 0Documento3 pagineDa13 DDR N1 14000229 247 0Hamed NazariNessuna valutazione finora

- Full Field Study & MDP Preparation For Asmari Reservoir of Parsi FieldDocumento60 pagineFull Field Study & MDP Preparation For Asmari Reservoir of Parsi FieldHamed NazariNessuna valutazione finora

- Da13 DDR N1 13991207 164 0Documento3 pagineDa13 DDR N1 13991207 164 0Hamed NazariNessuna valutazione finora

- Da13 14000103 190 0Documento3 pagineDa13 14000103 190 0Hamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocumento25 pagineDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariNessuna valutazione finora

- Daily Drilling ReportDocumento3 pagineDaily Drilling ReportHamed NazariNessuna valutazione finora

- Da13 DDR N1 14000104 191 0Documento3 pagineDa13 DDR N1 14000104 191 0Hamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Course Material Fees: Terms 1190 - 1193Documento8 pagineCourse Material Fees: Terms 1190 - 1193Frances Ijeoma ObiakorNessuna valutazione finora

- Mumbai BylawsDocumento110 pagineMumbai BylawsLokesh SharmaNessuna valutazione finora

- BMW X4 (2019-2022) Vs Audi Q5 Vs Land Rover Discovery Sport Vs Mercedes-Benz GLE - CarWaleDocumento1 paginaBMW X4 (2019-2022) Vs Audi Q5 Vs Land Rover Discovery Sport Vs Mercedes-Benz GLE - CarWaleSahil GoyalNessuna valutazione finora

- MS3XV30 Hardware 1.3Documento229 pagineMS3XV30 Hardware 1.3Colton CarmichaelNessuna valutazione finora

- 2ND 3RD Typical Floor Plan PDFDocumento1 pagina2ND 3RD Typical Floor Plan PDFSamuel ZaraNessuna valutazione finora

- GIT CloudDocumento20 pagineGIT CloudGyanbitt KarNessuna valutazione finora

- tt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFDocumento20 paginett130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFelmek jayaNessuna valutazione finora

- TT2223 Week 12a Z-TransformDocumento39 pagineTT2223 Week 12a Z-TransformAjiMaulanaNessuna valutazione finora

- RDBMS and HTML Mock Test 1548845682056Documento18 pagineRDBMS and HTML Mock Test 1548845682056sanjay bhattNessuna valutazione finora

- SP-2069 Specification For Pressure VesselsDocumento68 pagineSP-2069 Specification For Pressure Vesselsarjunprasannan7Nessuna valutazione finora

- VULCAN Instruction Manual ALL-A4Documento94 pagineVULCAN Instruction Manual ALL-A4Ayco DrtNessuna valutazione finora

- Astm F 30 - 96 R02 - RJMWDocumento5 pagineAstm F 30 - 96 R02 - RJMWphaindikaNessuna valutazione finora

- Bomba FlightDocumento2 pagineBomba FlightGustavo HRNessuna valutazione finora

- CS 303e, Assignment #10: Practice Reading and Fixing Code Due: Sunday, April 14, 2019 Points: 20Documento2 pagineCS 303e, Assignment #10: Practice Reading and Fixing Code Due: Sunday, April 14, 2019 Points: 20Anonymous pZ2FXUycNessuna valutazione finora

- EM000039Rev1 PDFDocumento1 paginaEM000039Rev1 PDFGustavo RiveraNessuna valutazione finora

- CPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFDocumento51 pagineCPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFMar SolNessuna valutazione finora

- Advanced Lathe Milling Report Batch 2Documento3 pagineAdvanced Lathe Milling Report Batch 2Tony SutrisnoNessuna valutazione finora

- Programmable Safety Systems PSS-Range: Service Tool PSS SW QLD, From Version 4.2 Operating Manual Item No. 19 461Documento18 pagineProgrammable Safety Systems PSS-Range: Service Tool PSS SW QLD, From Version 4.2 Operating Manual Item No. 19 461MAICK_ITSNessuna valutazione finora

- Dnvgl-Ru-Ships (2015) Part 3 Ch-10 TrolleyDocumento7 pagineDnvgl-Ru-Ships (2015) Part 3 Ch-10 TrolleyyogeshNessuna valutazione finora

- Features: 833H - 1A - F - CDocumento3 pagineFeatures: 833H - 1A - F - CDaniboy1994Nessuna valutazione finora

- Shock AbsorberDocumento0 pagineShock AbsorberSahaya GrinspanNessuna valutazione finora

- Desmophen 1200 - en - 00134597 17947398 20766463Documento3 pagineDesmophen 1200 - en - 00134597 17947398 20766463Sabri AeroChemNessuna valutazione finora

- University of Mumbai: Syllabus For Sem V & VI Program: B.Sc. Course: PhysicsDocumento18 pagineUniversity of Mumbai: Syllabus For Sem V & VI Program: B.Sc. Course: Physicsdbhansali57Nessuna valutazione finora

- 1.5SMC Series-1864824 PDFDocumento8 pagine1.5SMC Series-1864824 PDFRizwan RanaNessuna valutazione finora

- Treatment Processes: Coagulation and Filtration: Draft Guidelines For Drinking-Water QualityDocumento25 pagineTreatment Processes: Coagulation and Filtration: Draft Guidelines For Drinking-Water QualityAbsharinaNessuna valutazione finora

- Content Beyond SyllabusDocumento3 pagineContent Beyond SyllabusRahul PolNessuna valutazione finora

- Student Manual of Damped & Un DampedDocumento3 pagineStudent Manual of Damped & Un DampedaqibNessuna valutazione finora

- Civ-Su-6001-C - Design of BuildingsDocumento37 pagineCiv-Su-6001-C - Design of BuildingsBolarinwaNessuna valutazione finora

- Exterity g44 Serie 1.2 ManualDocumento87 pagineExterity g44 Serie 1.2 Manualruslan20851Nessuna valutazione finora

- Acids and Bases Part 3 (Weak Acids) EdexcelDocumento2 pagineAcids and Bases Part 3 (Weak Acids) EdexcelKevin The Chemistry TutorNessuna valutazione finora