Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mix Design C 35A - 50%

Caricato da

cecbCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mix Design C 35A - 50%

Caricato da

cecbCopyright:

Formati disponibili

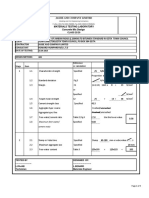

SATHUTA READY-MIX (PVT) LTD CONCRETE MIX DESIGN

No. 71, Negombo Road, Kurunegala - 60000 (Designed as per the BS 5328)

Tel: 0094 37 2221836 Fax: 0094 37 2221839

Email: readymix@sathuta.net URL: www.sathuta.net Ref # : SR-G30MD/OPC

Concrete Batching Plant: Sathuta Industrial Park, Alakoladeniya, Malkaduwawa. | Tel: 0094 37 312 4999

Project : Waste Water Treatment Plant at Elephant Opanage Pinnawala

Grade

Client :

Consultant :

35 N/mm2

Contractor : Central Engineering Services (Pvt.) Limited C - 35A

Reference or

Stage Item Values

Calculation

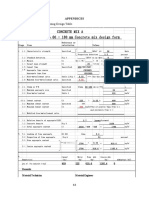

1 1.1 Characteristic Strength Specified 35 N/mm2 at = 28 Days

Proportion Defective = 5.0 %

2

1.2 Standard Deviation Fig. 3 5.0 N/mm or no Data = 5.0 N/mm2

1.3 Margin C1 (K=1.64) 1.64 × 5.0 = 8 N/mm2

1.4 Target mean Strength C2 35 + 8 = 43 N/mm2

1.5 Cement Type Specified (OPC/ SRPC / RHPC / PPC) = PPC

Cement Brand (Tokyo Super / Ultra Tech / Insee) =

1.6 Aggregate Type : Coarse Crushed Granite

Aggregate Type : Fine Uncrushed River Sand 50% Source : River Sand (Yan Oya)

Crushed Quarry Sand 50% Source : Galewala

}

1.7 Free Water / Cement Ratio Table 2, Fig. 4 0.44

Use the lower Value = 0.44

1.8 Maximum Free Water / Cement Ratio Specified 0.60

1.9 Air Content Not Specified = 0.00 %

2 2.1 Slump, Flow or Vebe time Specified Slump = 150+/-25mm

2.2 Maximum Aggregate Size Specified = 20 mm

2.3 Free Water Content Table 3 = 175 Kg/m3

3 3.1 Cement Content C3 175 ÷ 0.44 = 390 Kg/m3

3.2 Maximum Cement Content Not Specified = Kg/m3

3.3 Minimum Cement Content Not Specified = Kg/m3

Use 3.1 if ≤ 3.2

Use 3.3 if > 3.1 = 390 Kg/m3

3.4 Modified Free Water / Cement Ratio = 0.44 `

4 4.1 Relative Densities (SSD) Cement = 3.15

River Sand = 2.64

Quarry Sand = 2.27

Course Aggregate = 2.77

4.2 Concrete Density Fig. 5 = 2450 Kg/m3

4.3 Total Aggregate Content C4 2450 - 390 - 175 = 1885 Kg/m3

5 5.1 Grading of Fine Aggregate Percentage Passing 600 mm sieve Maximum 50 Minimum 30 Percent

5.2 Proportion of Fine Aggregate Fig. 6 44 to 50 Selected = 44%

5.3 Fine Aggregate Content C5 1885 × 44% = 829 Kg/m3

5.4 Coarse Aggregate Content C5 1885 - 829 = 1056 Kg/m3

6 6.1 Admixture 01 Type Superplacticizer / High Range Water Reducer

Brand / Admixture Chryso SL 92

Dosage Range 0.60 Ltr to 2.0 Ltr per 100 kg of Cement

Used Dosage 100 kg of Cement = 1.00 Ltr

6.2 Admixture 02 Type

Brand / Admixture

Dosage Range

Used Dosage

Cement Water Fine Aggregate / Kg Admixture 01 Admixture 02

Coarse

Items

Kg Kg River Sand Quarry Sand Aggregate / Kg Ltr Ltr

3

Quantities / m 390 175 415 415 1056 3.9 0.0

0.04 m3 Trial mix 15.60 7.00 16.60 16.58 42.24 0.16 0

Note: 1. Once retarder is added initial setting time of concrete mix is extended to about 3½ hours.

12/20/2018

Plant Manager Quality Assurance Manager Date

Potrebbero piacerti anche

- C35 A Concrete Mix DesignDocumento2 pagineC35 A Concrete Mix Designcecb100% (9)

- Concrete Mix Design: Stage Item Reference or Values CalculationDocumento8 pagineConcrete Mix Design: Stage Item Reference or Values Calculationmanish100% (1)

- Concrete Mix Design FormDocumento1 paginaConcrete Mix Design FormLAYLA SALIKIN CHE ROSMINNessuna valutazione finora

- Concrete Mix Design M-40 (RCC) GradeDocumento6 pagineConcrete Mix Design M-40 (RCC) GradeAshok amlapureNessuna valutazione finora

- M55 With GGBS and MicrosilicaDocumento1 paginaM55 With GGBS and MicrosilicaLegendary GamingNessuna valutazione finora

- Mix Design c40Documento13 pagineMix Design c40Jaime Manalili LandinginNessuna valutazione finora

- Strip Chart StructureDocumento5 pagineStrip Chart StructureBrijesh MishraNessuna valutazione finora

- Concrete Mix DesignDocumento5 pagineConcrete Mix DesignGlyn A. Brinquez100% (2)

- Mix Design For M35 Grade of ConcreteDocumento3 pagineMix Design For M35 Grade of ConcreteRajesh PentapalliNessuna valutazione finora

- Mix Design For M35 Grade of ConcreteDocumento2 pagineMix Design For M35 Grade of ConcreteLambu Sampath100% (2)

- Effect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete MixDocumento44 pagineEffect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete Mixshiva5059100% (1)

- Procedure For Concrete Mix Design of M25 Grade ConcreteDocumento10 pagineProcedure For Concrete Mix Design of M25 Grade ConcretedineshNessuna valutazione finora

- Analisis KonkritDocumento2 pagineAnalisis KonkritSuper Awesome PersonNessuna valutazione finora

- Mix Design To ACI 211.1-91 and BREDocumento11 pagineMix Design To ACI 211.1-91 and BREMbayo David Godfrey100% (1)

- Concrete Mixed Design MethodDocumento11 pagineConcrete Mixed Design Methodabdicasis rashidNessuna valutazione finora

- Concrete Mixed Design For C30Documento2 pagineConcrete Mixed Design For C30raju_420034520Nessuna valutazione finora

- Info On Paver BlocksDocumento6 pagineInfo On Paver BlocksGaneshNessuna valutazione finora

- Mix Design M30 PDFDocumento4 pagineMix Design M30 PDFDharmendra SahuNessuna valutazione finora

- C15....... Concrete Mix DesignDocumento18 pagineC15....... Concrete Mix DesignAbu FalasiNessuna valutazione finora

- Mix DESIGN IN .DOC FORMATDocumento2 pagineMix DESIGN IN .DOC FORMATthak49100% (2)

- BM LetterDocumento3 pagineBM LetterKasun Hewagama100% (2)

- Design of Cement Concrete Mix For M30 Grade ConcreteDocumento8 pagineDesign of Cement Concrete Mix For M30 Grade ConcreteNarendra BokreNessuna valutazione finora

- Concrete Mix Design C30 - ACI METHODDocumento4 pagineConcrete Mix Design C30 - ACI METHODMitendra Kumar ChauhanNessuna valutazione finora

- Cement TEST FORMATDocumento8 pagineCement TEST FORMATmanishjonw100% (1)

- Grout Volume CalculationDocumento3 pagineGrout Volume CalculationGEOLOGICS100% (1)

- M-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeDocumento3 pagineM-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeSai CharanNessuna valutazione finora

- 10262-2009 (Is Code For Concrete Mix Design)Documento18 pagine10262-2009 (Is Code For Concrete Mix Design)krishna kumar100% (2)

- Design MixDocumento7 pagineDesign MixMohammad Hafiz MahadzirNessuna valutazione finora

- 3812 1 PDFDocumento14 pagine3812 1 PDFइंजि कौस्तुभ पवारNessuna valutazione finora

- Concrete Mix Design C40/20-400 KG MSRC: Combined GradingDocumento1 paginaConcrete Mix Design C40/20-400 KG MSRC: Combined GradingkamakshiNessuna valutazione finora

- Mix Design As Per BSDocumento10 pagineMix Design As Per BSChetan SohalNessuna valutazione finora

- DoE Mix Design ExamplesDocumento8 pagineDoE Mix Design Examplesعابد خواجہNessuna valutazione finora

- Concrete Grade 30 Design MixDocumento1 paginaConcrete Grade 30 Design MixLallama100% (2)

- C-35 Mix Design by Estimate of MassDocumento26 pagineC-35 Mix Design by Estimate of MassTewodros TadesseNessuna valutazione finora

- Interlocking Concrete Block Pavement ICBDocumento24 pagineInterlocking Concrete Block Pavement ICBAbhishek RanaNessuna valutazione finora

- T.58 - Design Mix For Cement Grout G30Documento1 paginaT.58 - Design Mix For Cement Grout G30Tony James100% (1)

- Mix Design For M35 Grade of ConcreteDocumento4 pagineMix Design For M35 Grade of ConcretePaulos Wodajenehe TessemaNessuna valutazione finora

- Concrete Mix Design (Grade M60)Documento2 pagineConcrete Mix Design (Grade M60)புருஷோத்தமன் சரவணன்Nessuna valutazione finora

- Concrete Mix Design (Notes) PDFDocumento11 pagineConcrete Mix Design (Notes) PDFMohamad Khaled Nordin100% (1)

- Specification For Suppliers PDFDocumento7 pagineSpecification For Suppliers PDFalep azizNessuna valutazione finora

- Design Mix G30PDocumento1 paginaDesign Mix G30Psaffririzal4237Nessuna valutazione finora

- In This Article We Shall Discuss Three Important Points About Wet Mix Macadam (WMM)Documento6 pagineIn This Article We Shall Discuss Three Important Points About Wet Mix Macadam (WMM)RAMPALLI GATTAIAHNessuna valutazione finora

- Is 16720 Product Manual Fuel AshDocumento7 pagineIs 16720 Product Manual Fuel AshKolkata PIUNessuna valutazione finora

- Mix Design M40Documento3 pagineMix Design M40D21Nessuna valutazione finora

- Concrete Mix Design Final 7654Documento11 pagineConcrete Mix Design Final 7654talatzahoorNessuna valutazione finora

- Clay Bricks BS 3921Documento2 pagineClay Bricks BS 3921balgit100% (3)

- Concrete Cube ProjectDocumento22 pagineConcrete Cube ProjectluckywaysNessuna valutazione finora

- Concrete Mix Design - ExcelDocumento1 paginaConcrete Mix Design - ExcelTijani MohammedNessuna valutazione finora

- Concrete Mix DesignDocumento7 pagineConcrete Mix DesignUma MaheshwaraNessuna valutazione finora

- Prime CoatDocumento4 paginePrime CoatAnonymous YHcvra8Xw6Nessuna valutazione finora

- BS 812-102 - 1989Documento12 pagineBS 812-102 - 1989ماقوريNessuna valutazione finora

- High Slump Concrete Mix Design 2Documento68 pagineHigh Slump Concrete Mix Design 21man1bookNessuna valutazione finora

- Paving Blocks Results Report.Documento5 paginePaving Blocks Results Report.patrick munyaoNessuna valutazione finora

- PPT-Marshal Mix DesignDocumento19 paginePPT-Marshal Mix DesignAshok Kumar Rajanavar100% (1)

- Concrete Mix Design: Structural Element VARIOUSDocumento28 pagineConcrete Mix Design: Structural Element VARIOUSAlfred PatrickNessuna valutazione finora

- BS 5075-2-1982 - Concrete Admixtures - Specification For Air Entraining AdmixturesDocumento19 pagineBS 5075-2-1982 - Concrete Admixtures - Specification For Air Entraining AdmixturesRaviranjan kumarNessuna valutazione finora

- CLASS 25/20: Maximum Free-Water/ Cement RatioDocumento4 pagineCLASS 25/20: Maximum Free-Water/ Cement RatioHema Chandra IndlaNessuna valutazione finora

- Concrete Mix Design Proposal Mix - 33Documento3 pagineConcrete Mix Design Proposal Mix - 33Ruwan Sampath WickramathilakaNessuna valutazione finora

- Concrete Mix Design For M35 W-C Ratio 0.45Documento1 paginaConcrete Mix Design For M35 W-C Ratio 0.45James ChikabadwaNessuna valutazione finora

- Concrete Mixing DesignDocumento15 pagineConcrete Mixing DesignChris ArtecoNessuna valutazione finora

- Tm5 - 620 - Facilities Engineering Maintanane and Repair of Architectural and Structural Elements of Building and StructuresDocumento231 pagineTm5 - 620 - Facilities Engineering Maintanane and Repair of Architectural and Structural Elements of Building and StructurescecbNessuna valutazione finora

- BOQ PreperationDocumento2 pagineBOQ Preperationcecb100% (1)

- How To Design Concrete Structures Using Eurocode 2Documento104 pagineHow To Design Concrete Structures Using Eurocode 2Adil Javed Chaudhary97% (36)

- CCIP Concrete Building SchemeDocumento140 pagineCCIP Concrete Building Schemedimitrios2588% (16)

- Theater of Operations: Roads, Airfields, and Heliports-Road DesignDocumento402 pagineTheater of Operations: Roads, Airfields, and Heliports-Road DesigncecbNessuna valutazione finora

- Ccip Concise Ec2Documento118 pagineCcip Concise Ec2Sanka Seneviratne100% (9)

- Bill SampleDocumento2 pagineBill SamplececbNessuna valutazione finora

- BOQ PreperationDocumento2 pagineBOQ Preperationcecb100% (1)

- Masimo BasicsDocumento31 pagineMasimo BasicscecbNessuna valutazione finora

- Shengli Bauxite Product BrochureDocumento8 pagineShengli Bauxite Product BrochurececbNessuna valutazione finora

- Cross Checking The Quantity Accuracy in A BOQDocumento1 paginaCross Checking The Quantity Accuracy in A BOQcecbNessuna valutazione finora

- CFD BS 8110 97Documento52 pagineCFD BS 8110 97structuralengineersNessuna valutazione finora

- Cross Checking The Quantity Accuracy in A BOQDocumento1 paginaCross Checking The Quantity Accuracy in A BOQcecbNessuna valutazione finora

- Wall Art in SLDocumento1 paginaWall Art in SLcecbNessuna valutazione finora

- Kartandtinki1 Desktop-Wallpapers 02Documento1 paginaKartandtinki1 Desktop-Wallpapers 02cecbNessuna valutazione finora

- Building Design and Construction: See Victor Olgay (1963) Design With Climate and Mazria (1979)Documento15 pagineBuilding Design and Construction: See Victor Olgay (1963) Design With Climate and Mazria (1979)Bryle James NangleganNessuna valutazione finora

- Ka1 Ka102 A 3.02 en ProdDocumento1 paginaKa1 Ka102 A 3.02 en Prodirina_makedonijaNessuna valutazione finora

- Diseño Articulados Icpi AmericanoDocumento21 pagineDiseño Articulados Icpi AmericanoHugo Arenas LozanoNessuna valutazione finora

- Mebs6000 1011 03 Cold and Hot Water DesignDocumento82 pagineMebs6000 1011 03 Cold and Hot Water DesignSocratis SocratousNessuna valutazione finora

- 6075429Documento5 pagine6075429Dhurai Rajiv GandhiNessuna valutazione finora

- National PVC Technical Guide BookDocumento128 pagineNational PVC Technical Guide Bookasdthu100% (3)

- Hand RailDocumento1 paginaHand RailcecbNessuna valutazione finora

- Engineering Consultancy Services Professional Fee StructureDocumento12 pagineEngineering Consultancy Services Professional Fee StructureSuhas SahakariNessuna valutazione finora

- Ancient SiwhelaDocumento1 paginaAncient SiwhelacecbNessuna valutazione finora

- Ceylon & Portuguese PDFDocumento324 pagineCeylon & Portuguese PDFcecbNessuna valutazione finora

- DanceDocumento1 paginaDancececbNessuna valutazione finora

- Formulas and Functions in Excel - Easy Excel TutorialDocumento2 pagineFormulas and Functions in Excel - Easy Excel TutorialcecbNessuna valutazione finora

- Combine Text From Two or More Cells Into One Cell - ExcelDocumento3 pagineCombine Text From Two or More Cells Into One Cell - ExcelcecbNessuna valutazione finora

- OccupSftyAndHealthRegs1996 07 f0 00Documento400 pagineOccupSftyAndHealthRegs1996 07 f0 00FilipNessuna valutazione finora

- Basis of DesignDocumento1 paginaBasis of DesignRajaImranNessuna valutazione finora

- Design of Slabs To EC2Documento12 pagineDesign of Slabs To EC2smartman35100% (2)

- 2019 Summer Model Answer Paper (Msbte Study Resources)Documento7 pagine2019 Summer Model Answer Paper (Msbte Study Resources)Prasad ArsulNessuna valutazione finora

- Thesis On Construction Technology and Management PDFDocumento8 pagineThesis On Construction Technology and Management PDFpsmxiiikdNessuna valutazione finora

- Loading Summary For A Slab On Girder Bridge According To The CAN/CSA-S6Documento27 pagineLoading Summary For A Slab On Girder Bridge According To The CAN/CSA-S6Muntasir Billah100% (1)

- Cable Identification/Types: InstructorDocumento34 pagineCable Identification/Types: InstructorAzeta RobertNessuna valutazione finora

- Hydraulic Bench OperationDocumento2 pagineHydraulic Bench OperationAneeqMustafa GhumroNessuna valutazione finora

- Belzona 4521Documento2 pagineBelzona 4521Bobby SatheesanNessuna valutazione finora

- Data Sheet For Fire HydrantsDocumento2 pagineData Sheet For Fire HydrantsSohail AzharNessuna valutazione finora

- Résumé Projet Mise en Place de Procédures de Sécurité en AnglaisDocumento16 pagineRésumé Projet Mise en Place de Procédures de Sécurité en Anglaisgildas assandeNessuna valutazione finora

- House - Contract AgreementDocumento5 pagineHouse - Contract Agreementshashikiran divateNessuna valutazione finora

- TC51SC Cone Crusher Parts Manual TC51-441-AU1156Documento31 pagineTC51SC Cone Crusher Parts Manual TC51-441-AU1156Justice Machiwana100% (1)

- Aci SP-17Documento260 pagineAci SP-17Sarkis Masis100% (2)

- MB Brochure EN 2020Documento20 pagineMB Brochure EN 2020Yaman mNessuna valutazione finora

- Description Si Units Unit Aashto LRFD 2017 8thDocumento1 paginaDescription Si Units Unit Aashto LRFD 2017 8thmcatakulNessuna valutazione finora

- 聚氯乙烯 - 中国石化化工销售有限公司Documento3 pagine聚氯乙烯 - 中国石化化工销售有限公司Zhong LiNessuna valutazione finora

- Izon L : Technical Data Sheet: Izonil Hard - Renovation and Waterproof Plaster (Revision - February 2018)Documento4 pagineIzon L : Technical Data Sheet: Izonil Hard - Renovation and Waterproof Plaster (Revision - February 2018)AcingEdogawaNessuna valutazione finora

- TECOM Pressure RegulatorDocumento4 pagineTECOM Pressure RegulatorRagu RajanNessuna valutazione finora

- Staad - Pro V8i-Dynamic Response Sesmic Analysis-Course ContentsDocumento3 pagineStaad - Pro V8i-Dynamic Response Sesmic Analysis-Course ContentsSmartlearning TechnologyNessuna valutazione finora

- PR-SG-103 108 Standard Details-PR-SG-105Documento1 paginaPR-SG-103 108 Standard Details-PR-SG-105ahmad fauziNessuna valutazione finora

- 38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsDocumento7 pagine38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsMarjan SubanNessuna valutazione finora

- Im-015-16 Siemens 4500335983 (Col)Documento1 paginaIm-015-16 Siemens 4500335983 (Col)Gustaavo Caarvaajal HeerreraNessuna valutazione finora

- FXZ1 (FRT, ZH) : Halogen FreeDocumento4 pagineFXZ1 (FRT, ZH) : Halogen FreeMario LuvineriNessuna valutazione finora

- Ultratech TDS Leaflet Powergrout NS1 PDFDocumento1 paginaUltratech TDS Leaflet Powergrout NS1 PDFArpan GhoshNessuna valutazione finora

- Grundfos Submersible Waste Water Pump - AP-KPDocumento96 pagineGrundfos Submersible Waste Water Pump - AP-KPFerdy Syahreza100% (1)

- Installation Qudos 28h Installation and Service ManualDocumento59 pagineInstallation Qudos 28h Installation and Service ManualdraxnwNessuna valutazione finora

- HXR5 Series User ManualDocumento24 pagineHXR5 Series User ManualSANTIAGO VIDAL MIRANessuna valutazione finora

- Materials Select Torsionally Stressed ShaftDocumento7 pagineMaterials Select Torsionally Stressed ShaftJuan Diego Garcia EsquenNessuna valutazione finora

- Anexo #2 - Memoria de Calculo Muro de ContencionDocumento7 pagineAnexo #2 - Memoria de Calculo Muro de ContencionTres G Ingenieria Civil TopografiaNessuna valutazione finora