Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DA200 Operating Instructions PDF

Caricato da

Darwin Zuni RosadoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DA200 Operating Instructions PDF

Caricato da

Darwin Zuni RosadoCopyright:

Formati disponibili

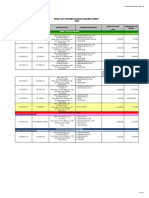

–OPERATING INSTRUCTIONS– BULLETIN 234

MODEL 200 SERIES AUG 2013

CONTOUR PROBES

The 200 Series Contour Probes are rugged high performance instruments for Magnetic Particle

inspection to accepted Nondestructive testing standards. Certain operating procedures and safety

precautions should be observed.

INSTRUMENT DESCRIPTION: Basically, the Contour Probe is an electromagnet producing a

strong magnetic field. Placement of the two poles (legs) upon ferrous metal provides a path for the

intense magnetic field to pass from one pole to the other. The part completes the flux path and

becomes highly magnetized. Models A210, A210S and A48 produce strong constant AC fields.

Electronic circuitry contained within the molded housing of the DA200 and DA200S models permits

selection of a strong constant AC field, or a high intensity half wave rectified (DC) field. All Parker

Contour Probes are designed with flexible legs that allow the field to be “focused” at a precise area

of inspection. The maximum leg spacing is 12 in. (304.8mm). All 200 series Contour Probes come

equipped with a 10’ (3.048 m) power cord.

The DA200 and A210 are for use on 115VAC 50-60 Hz, single phase grounded power source.

Using an approved GFCI is recommended.

The DA200S and A210S are for use on 230VAC 50-60 Hz, single phase grounded power source.

The DA200S and A210S are sold without a power cord plug. Only locally approved plugs should

be used and installed by certified personnel. Using an approved GFCI is recommended.

The A48 is for use on 42-48VAC 50-60 Hz, single phase grounded low voltage power source.

The A48 is sold without a power cord plug. Only locally approved plugs should be used and

installed by certified personnel. Using an approved GFCI is recommended.

SPECIFICATIONS

POWER

MODEL FIELD WEIGHT

REQUIREMENTS

117 VAC ±10%

8 lbs.

DA200 50-60 Hz AC OR DC

(3.6 kg)

6 AMPS

230 VAC ±10%

9 lbs.

DA200S 50-60 Hz AC OR DC

(4.1 kg)

4 AMPS

117 VAC ±10%

8 lbs.

A210 50-60 Hz AC ONLY

(3.6 kg)

9.5 AMPS

230 VAC ±10%

8 lbs.

A210S 50-60 Hz AC ONLY

(3.6 kg)

4 AMPS

42-48 VAC

8 lbs.

A48 50-60 Hz AC ONLY

(3.6 kg)

12-14 AMPS

FIG. 1

-2-

GENERAL SAFETY RULES

Please read all instructions. Failure to follow all instructions listed below may result in injury. If the

equipment is used in a manner other than as specified in these operating instructions, the

protection provided by the equipment may be impaired. Always wear eye protection.

DO NOT OPERATE unit from a DC power source.

Warning: Do not change the AC/DC selector switch with the probe on.

Do not abuse the power cords. Never carry the instrument by the cord or attempt to unplug the

instrument using the cord. Always operate the instrument with the standard installed cord.

Changing or using a damaged cord can increase the risk of electrical shock. The cord should be

checked periodically for any damage.

Do not position the instrument such that it would be difficult to operate the disconnect device (plug)

on the end of the power cord.

The outside housing should remain intact and solid. Any damage, chipping, or separating exposing

internal wires is a hazard. Instruments should not be used in this condition. The outside housing

should be periodically checked for damage.

Duty Cycle: The 200 series are designed for a 50% duty cycle, or approximately two minutes on

and two minutes off. Continuous operation may cause overheating and damage the Contour

Probe.

Operating Environment: Temperature: 32° to 104°F (0° to 40°C). Relative humidity: 10% to 95%,

non-condensing.

Shipping and Storage Environment: Temperature: 40° to 140°F (4.44° to 60°C). Relative

humidity: 5% to 95%. Vibration and shock: As encountered in normal shipping and handling with

no degradation.

General Cleaning

The outside surface of the instrument can be periodically

wiped clean with a clean cloth and a mild general purpose

cleaner. Avoid using cleaners such as lacquer thinner, or

mineral spirits that could damage the outside housing.

Never attempt field service. All 200 series Contour Probes

should be returned to the factory for repairs.

OPERATION: Connect the instrument plug into a

Grounded power outlet of proper voltage. Place the

Contour Probe legs upon the work surface with the

suspected defect at right angles to the legs (Good contact

will produce the best results). Push the test switch to

energize the instrument. Lightly dust or float dry magnetic

inspection powder over the area being inspected. Defect

indications will be revealed in a direction shown on figure 2.

Turn the Probe 90 degrees from the first test and repeat the

process. This method may also be utilized when applying a

wet medium. Check all procedures and standards for FIG. 2

further details involving inspection specifics.

-3-

DEMAGNETIZATION: Small pieces, which have become residually magnetized, may be easily

demagnetized by the following procedure: Energize the Probe and pass small parts through the

area between the leg ends “feet” and withdraw to a distance of approximately two feet. On large

pieces, place the Probe in the same position as inspection, energize the Probe and lift from the

work surface to a distance of approximately two feet. This procedure may need to be performed

more than once to remove the residual field.

AC MAGNETIZATION: An AC magnetic field induced into a part is a “skin” or surface field and

does not penetrate the cross section of the material. A by-product of AC is in the form of eddy

currents. These eddy currents tend to guide or direct the magnetic field in a narrow pattern

between the poles. Another by-product is a vibratory action, which adds mobility to the inspection

particles to form a more highly defined powder build-up at the defect. For these reasons, an AC

magnetic field is the most desirable for the detection of surface breaking defects.

HALF WAVE RECTIFIED (DC) MAGNETIZATION: A DC field induced into a small work piece penetrates a

larger cross section of the part and is inclined to spread out of each side of the line between the poles. The

field energy is dispersed over a greater area. Thus, DC provides greater penetration for the detection of

near-surface defects in small parts.

CAUTION: Small parts may become magnetically saturated due to excessive field application. This

may cause a masking effect to the point where it is impossible to define a defect.

WARRANTY: The Parker 200 series are warranted against malfunction due to defective material

and or workmanship. The defective unit will be repaired or replaced (less incoming freight charges)

for a period of one year from the date of sale. This repair warranty does not apply to altered units.

Repair or replacement of the defective unit will be made at the discretion of Parker Research

Corporation. Repaired or replacement unit(s) will be returned to the original customer prepaid.

The obligation of Parker Research Corporation is limited to the repair or replacement of the

defective unit. No other obligation is expressed or implied. Parker Research Corporation assumes

no liability from any claims arising from the use of this equipment.

CAUTION: For the correct and safe use of this equipment, training of operating personnel is

required. Use of proper inspection procedures, standards compliance and safety requirements is

the obligation of the user.

ALWAYS WEAR SAFETY GLASSES WHEN USING THIS EQUIPMENT

PARKER RESEARCH CORP.

2642 ENTERPRISE ROAD WEST

CLEARWATER, FL 33763

Potrebbero piacerti anche

- Hager Electrical Installation SystemsDocumento796 pagineHager Electrical Installation SystemsDavi VunschelNessuna valutazione finora

- Da400 PDFDocumento4 pagineDa400 PDFhcliffordpaNessuna valutazione finora

- Manual Del Compresor de AireDocumento3 pagineManual Del Compresor de AireEmiliano CamarenaNessuna valutazione finora

- Tool Mate Parker Yoke MSDSDocumento2 pagineTool Mate Parker Yoke MSDSJuan Pablo Sierra RamirezNessuna valutazione finora

- Parker Yoke ManualDocumento4 pagineParker Yoke ManualShahbaz KhanNessuna valutazione finora

- Parker B300S Product Data SheetDocumento6 pagineParker B300S Product Data SheetBonnie Fajrie AmrilNessuna valutazione finora

- Guia de ReciclajeDocumento1 paginaGuia de ReciclajeMadd000Nessuna valutazione finora

- Parker Research Corp.: INSTRUMENT DESCRIPTION: Basically, The Contour Probe Is An Electromagnet Producing ADocumento4 pagineParker Research Corp.: INSTRUMENT DESCRIPTION: Basically, The Contour Probe Is An Electromagnet Producing APedro MendozaNessuna valutazione finora

- 10KV, 12 KV & 15KV Surge Comparison Tester: Model 7010K, 7012K & 7015KDocumento2 pagine10KV, 12 KV & 15KV Surge Comparison Tester: Model 7010K, 7012K & 7015KAmorsolo CostalesNessuna valutazione finora

- Installation Guide for EVA-HF325/525 X-Ray MachineDocumento23 pagineInstallation Guide for EVA-HF325/525 X-Ray MachineAbu Bakr M. SaeedNessuna valutazione finora

- Time Mark 263 3 Phase MonitorDocumento2 pagineTime Mark 263 3 Phase MonitorDavid Marquez ErpelNessuna valutazione finora

- 870 ManualDocumento7 pagine870 ManualRafa TejedaNessuna valutazione finora

- 2608 Analog MultimeterDocumento1 pagina2608 Analog Multimeterneurofuzzy7393Nessuna valutazione finora

- Portable DC Hipot Testers for Field Testing up to 300 kVDocumento3 paginePortable DC Hipot Testers for Field Testing up to 300 kVElio PenaNessuna valutazione finora

- LSM200 Series: Load Sharing ModulesDocumento11 pagineLSM200 Series: Load Sharing ModulesHernando luis Fang pedrozaNessuna valutazione finora

- HARS-X Series: High Accuracy Decade Resistance SubstituterDocumento2 pagineHARS-X Series: High Accuracy Decade Resistance Substituterb4tipibeNessuna valutazione finora

- Catalogo Gral Kyoritsu 2010 PDFDocumento60 pagineCatalogo Gral Kyoritsu 2010 PDFsamaelkelebraNessuna valutazione finora

- Pib1002 Esd5500eDocumento5 paginePib1002 Esd5500eAnonymous M0OEZEKoGiNessuna valutazione finora

- 2.ross CatalogDocumento185 pagine2.ross CatalogFlavio BrunettiNessuna valutazione finora

- Interlocks General Areas Catalogue PagesDocumento16 pagineInterlocks General Areas Catalogue PagesPablo MarajNessuna valutazione finora

- 11kV Surge Arrestor HE-12Documento2 pagine11kV Surge Arrestor HE-12shabbir4Nessuna valutazione finora

- 13Q2094624 - 10 - Data ScheduleDocumento1 pagina13Q2094624 - 10 - Data Schedulejoao luyeyeNessuna valutazione finora

- Xtender series inverters and battery chargers overviewDocumento1 paginaXtender series inverters and battery chargers overviewZain BhinderNessuna valutazione finora

- Miniature Intermediate Power Relay Spec SheetDocumento4 pagineMiniature Intermediate Power Relay Spec SheetAji SiregarNessuna valutazione finora

- Peras de NivelDocumento2 paginePeras de NivelmarianaNessuna valutazione finora

- Baker AT101-ZTX: Expands Testing Capabilities To Include DC Motors and Other Low Impedance CoilsDocumento2 pagineBaker AT101-ZTX: Expands Testing Capabilities To Include DC Motors and Other Low Impedance CoilsSergio PereiraNessuna valutazione finora

- Young-Hwa: (Model No.: Yhass)Documento8 pagineYoung-Hwa: (Model No.: Yhass)Diki NugrahaNessuna valutazione finora

- Instructions: Automatic Voltage Regulator AVC63-12 AVC125-10Documento4 pagineInstructions: Automatic Voltage Regulator AVC63-12 AVC125-10yao nestorNessuna valutazione finora

- Hojas Técnicas y Dimensiones de Supresores de PicosDocumento8 pagineHojas Técnicas y Dimensiones de Supresores de PicosCrissCarreraNessuna valutazione finora

- Subminiature High Power Relay Features Under 40 CharactersDocumento2 pagineSubminiature High Power Relay Features Under 40 CharactersRoberto MendesNessuna valutazione finora

- 440L Series AC Line Rated Disc CapacitorsDocumento6 pagine440L Series AC Line Rated Disc CapacitorsBashir MtwaklNessuna valutazione finora

- Ups Kstar-1-3kva 120V 0.9PFDocumento5 pagineUps Kstar-1-3kva 120V 0.9PFoscar mauricio caballero camachoNessuna valutazione finora

- 1HID1-1-4047-E728 Lightning ArrestersDocumento12 pagine1HID1-1-4047-E728 Lightning ArrestersAbdan HDNessuna valutazione finora

- VS-6CWQ06FN-M3: Vishay SemiconductorsDocumento7 pagineVS-6CWQ06FN-M3: Vishay SemiconductorsSolihin iingNessuna valutazione finora

- Duogen Product Bulletin PDFDocumento2 pagineDuogen Product Bulletin PDFAnonymous VNu3ODGavNessuna valutazione finora

- SpecificationsDocumento3 pagineSpecificationsvictor laraNessuna valutazione finora

- Avc63 4a PDFDocumento2 pagineAvc63 4a PDFFernando AlegriaNessuna valutazione finora

- Brochure Equipos ATDocumento8 pagineBrochure Equipos ATCerduardo Chanchisco Roga RojasNessuna valutazione finora

- Price List Vs Online Welding Machine Expert 050423Documento1 paginaPrice List Vs Online Welding Machine Expert 050423Deta PutraNessuna valutazione finora

- Siemens Mobilett Plus HP Prospekt enDocumento2 pagineSiemens Mobilett Plus HP Prospekt enNathaniel Imade100% (1)

- Manual Hipot High Voltage - (ALT-120)Documento33 pagineManual Hipot High Voltage - (ALT-120)kennethNessuna valutazione finora

- Specification: Constant Current Discharge Characteristics: A (25)Documento2 pagineSpecification: Constant Current Discharge Characteristics: A (25)DavidBenaventeNessuna valutazione finora

- Regulador Basler VR6Documento4 pagineRegulador Basler VR6Manuel OteroNessuna valutazione finora

- Detector Falta Fase 3F 440VDocumento1 paginaDetector Falta Fase 3F 440VPedro MartinezNessuna valutazione finora

- Service Manual SBOL100KTIII 3HVDocumento57 pagineService Manual SBOL100KTIII 3HVOUAGUENOUNINessuna valutazione finora

- CA10 CAD11 CAD12 Ver2Documento1 paginaCA10 CAD11 CAD12 Ver2spurscoukNessuna valutazione finora

- Form Spesifikasi: Detailed SpecificationsDocumento4 pagineForm Spesifikasi: Detailed Specificationsheru pratiknoNessuna valutazione finora

- Harman Kardon Avr-2600 SMDocumento216 pagineHarman Kardon Avr-2600 SMCarollyne SabioniNessuna valutazione finora

- Manual Basler Avr Aec42 7Documento4 pagineManual Basler Avr Aec42 7Raul E. SoliNessuna valutazione finora

- Crouzet Corporation Industrial Control 7937100Documento1 paginaCrouzet Corporation Industrial Control 7937100IsabelRodriguezNessuna valutazione finora

- AgeaKull SeriesResonanceReactorDocumento2 pagineAgeaKull SeriesResonanceReactorShamik PurkayasthaNessuna valutazione finora

- Western Instruments Inc. Western Instruments Inc. Western Instruments Inc. Western Instruments IncDocumento3 pagineWestern Instruments Inc. Western Instruments Inc. Western Instruments Inc. Western Instruments IncMohammed Mosaad LyricsNessuna valutazione finora

- CURRENT TRANSFORMER SPECIFICATIONS COMPARISONDocumento2 pagineCURRENT TRANSFORMER SPECIFICATIONS COMPARISONHamada RagehNessuna valutazione finora

- Model RM-ST120: AC Distribution Panel UnitDocumento2 pagineModel RM-ST120: AC Distribution Panel UnitDanyNessuna valutazione finora

- SPARK QUENCHERS TITLEDocumento2 pagineSPARK QUENCHERS TITLEJerwei WooNessuna valutazione finora

- STD CapacDocumento4 pagineSTD Capacjignesh_sp2003Nessuna valutazione finora

- Enhanced ceramic resistors for circuitry with surges and high peak powerDocumento3 pagineEnhanced ceramic resistors for circuitry with surges and high peak powerAkashNessuna valutazione finora

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaDa EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNessuna valutazione finora

- Ensayo de Ultrasonido Industrial Astm1444 PDFDocumento12 pagineEnsayo de Ultrasonido Industrial Astm1444 PDFBetzabethZuñigaNessuna valutazione finora

- BGS guide to evaluating diatomite resourcesDocumento46 pagineBGS guide to evaluating diatomite resourcesDarwin Zuni Rosado100% (1)

- Interpreting SNT TC 1A PDFDocumento36 pagineInterpreting SNT TC 1A PDFavinash_k00794% (16)

- Microsoft Word - ACCUR-1 Catalogue PDFDocumento4 pagineMicrosoft Word - ACCUR-1 Catalogue PDFDarwin Zuni RosadoNessuna valutazione finora

- 1 s2.0 S2214031X16302674 MainDocumento13 pagine1 s2.0 S2214031X16302674 MainDarwin Zuni RosadoNessuna valutazione finora

- Portable Pressure Sprayer Product Data Sheet EnglishDocumento2 paginePortable Pressure Sprayer Product Data Sheet EnglishDarwin Zuni RosadoNessuna valutazione finora

- AC/DC Contour Probe: Product Data SheetDocumento2 pagineAC/DC Contour Probe: Product Data SheetDarwin Zuni RosadoNessuna valutazione finora

- 1 s2.0 S0102695X15002069 MainDocumento6 pagine1 s2.0 S0102695X15002069 MainDarwin Zuni RosadoNessuna valutazione finora

- Magnetic Field Indicators Product Data Sheet EnglishDocumento2 pagineMagnetic Field Indicators Product Data Sheet EnglishDarwin Zuni RosadoNessuna valutazione finora

- Art 2Documento12 pagineArt 2Darwin Zuni RosadoNessuna valutazione finora

- The Parker TB-10 (10-Pound) Weight Lift Test Bar and Associated Calibration ToolsDocumento2 pagineThe Parker TB-10 (10-Pound) Weight Lift Test Bar and Associated Calibration ToolsDarwin Zuni RosadoNessuna valutazione finora

- Antimicrobial ChitosanDocumento7 pagineAntimicrobial ChitosanMiftah WiryaniNessuna valutazione finora

- Pie Field Indicator Product Data Sheet EnglishDocumento1 paginaPie Field Indicator Product Data Sheet EnglishDarwin Zuni RosadoNessuna valutazione finora

- Asme V 2013 Cri-1-2003 PDFDocumento45 pagineAsme V 2013 Cri-1-2003 PDFFernando SalvatierraNessuna valutazione finora

- SKC S Aerosol Safety Data Sheet EnglishDocumento6 pagineSKC S Aerosol Safety Data Sheet EnglishDarwin Zuni RosadoNessuna valutazione finora

- PXS v2 22 Full-CalDocumento35 paginePXS v2 22 Full-CalDarwin Zuni Rosado100% (1)

- 1 s2.0 S0102695X15002069 MainDocumento6 pagine1 s2.0 S0102695X15002069 MainDarwin Zuni RosadoNessuna valutazione finora

- HiscbidbcidDocumento9 pagineHiscbidbcidGustavo NascimentoNessuna valutazione finora

- Uebung7 MSII 2009 Und LoesungenDocumento5 pagineUebung7 MSII 2009 Und LoesungenDarwin Zuni RosadoNessuna valutazione finora

- 1 s2.0 S0102695X15002069 MainDocumento6 pagine1 s2.0 S0102695X15002069 MainDarwin Zuni RosadoNessuna valutazione finora

- AutoCAD 2014 Tutorial 3DDocumento26 pagineAutoCAD 2014 Tutorial 3DseleneletoNessuna valutazione finora

- Volver Al Futuro III - Train Time MachineDocumento8 pagineVolver Al Futuro III - Train Time MachineCyJu08Nessuna valutazione finora

- Resbond® 907 GFDocumento1 paginaResbond® 907 GFDarwin Zuni RosadoNessuna valutazione finora

- Who Is SheDocumento1 paginaWho Is SheDarwin Zuni RosadoNessuna valutazione finora

- Expo CeramicosDocumento13 pagineExpo CeramicosDarwin Zuni RosadoNessuna valutazione finora

- EE082-Fault Finding in Electrical Control Systems-Th-Inst PDFDocumento78 pagineEE082-Fault Finding in Electrical Control Systems-Th-Inst PDFSameera Kodikara100% (2)

- Bosch GKF 600Documento194 pagineBosch GKF 600Mustafa KutanisNessuna valutazione finora

- IC60HDocumento9 pagineIC60HJan SebastianNessuna valutazione finora

- ALU UMTS Macrocell Indoor Site Preparation GuidelinesDocumento111 pagineALU UMTS Macrocell Indoor Site Preparation GuidelinesRobb RobinsonNessuna valutazione finora

- PEC Definition of Terms FOR ESDDocumento2 paginePEC Definition of Terms FOR ESDkelleyNessuna valutazione finora

- Classic 300 D Perkins: Operator'S ManualDocumento92 pagineClassic 300 D Perkins: Operator'S ManualCoordinador - MantenimientosNessuna valutazione finora

- General Safety Induction Manual 2014Documento22 pagineGeneral Safety Induction Manual 2014Eugen MatheNessuna valutazione finora

- Cub Cadet 34ABA2CS710 (EN)Documento64 pagineCub Cadet 34ABA2CS710 (EN)Gisell ZapataNessuna valutazione finora

- Nema Gfci StudyDocumento112 pagineNema Gfci StudyfedericodecrNessuna valutazione finora

- User Manual For HT33X 60-500kVA Tower UPS - V1.3 PDFDocumento76 pagineUser Manual For HT33X 60-500kVA Tower UPS - V1.3 PDFshlashmed100% (1)

- Magnum Manual Mmg320can6 OpsDocumento52 pagineMagnum Manual Mmg320can6 Opsbalajiboss005Nessuna valutazione finora

- Phoenix Contact Type 2 Surge Arrester - VAL-CP-RCD-3S - 40 - 0.03Documento7 paginePhoenix Contact Type 2 Surge Arrester - VAL-CP-RCD-3S - 40 - 0.03micaNessuna valutazione finora

- CERa Issue 21 Instruction ManualDocumento24 pagineCERa Issue 21 Instruction Manualخالد علىNessuna valutazione finora

- COP E 2020 UpdatedDocumento373 pagineCOP E 2020 UpdatedRay WongNessuna valutazione finora

- TN System - Protection Against Indirect Contact - Electrical Installation GuideDocumento4 pagineTN System - Protection Against Indirect Contact - Electrical Installation GuideRajendra Prasad ShuklaNessuna valutazione finora

- TechDaten Man 7SJ85 V0700 EnUSDocumento154 pagineTechDaten Man 7SJ85 V0700 EnUSMJNessuna valutazione finora

- Analysis of Changes 2017 NECDocumento18 pagineAnalysis of Changes 2017 NECAnonymous FocUHPwNessuna valutazione finora

- TE 50 / TE 50-AVR: Hilti CorporationDocumento16 pagineTE 50 / TE 50-AVR: Hilti CorporationRendy FahleviNessuna valutazione finora

- Types of Receptacles (For Prints)Documento8 pagineTypes of Receptacles (For Prints)yannie isananNessuna valutazione finora

- Y0720c1609 PDFDocumento256 pagineY0720c1609 PDFSiska BintariNessuna valutazione finora

- Wetstone Sharpener: Selling Points Optional AccessoriesDocumento83 pagineWetstone Sharpener: Selling Points Optional AccessoriesGustavo Gonzalez ToledoNessuna valutazione finora

- Maintenance ManualDocumento28 pagineMaintenance ManualnestoriussNessuna valutazione finora

- NHPNTUMCBNZESGDocumento12 pagineNHPNTUMCBNZESGErvin SmithNessuna valutazione finora

- Uline 20 PR AppletonDocumento10 pagineUline 20 PR AppletonAlex RamirezNessuna valutazione finora

- Acti9 Disbo - DSP1ROW8Documento2 pagineActi9 Disbo - DSP1ROW8Elias_jamhour9101Nessuna valutazione finora

- Ground FaultDocumento60 pagineGround FaultkrcdewanewNessuna valutazione finora

- ETEK IoT Smart Devices 2023Documento24 pagineETEK IoT Smart Devices 2023ELECTROSTATIC SPRAYERS GREECENessuna valutazione finora

- GFCI E320934 TestRecord Ul943Documento36 pagineGFCI E320934 TestRecord Ul943Alejandro CoronelNessuna valutazione finora

- PEC 2017 Quiz 1Documento10 paginePEC 2017 Quiz 1Jae RiondangaNessuna valutazione finora