Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hayward Gordon ULC: Start-Up Checklist Page 1 of 2

Caricato da

blackhand20xxDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hayward Gordon ULC: Start-Up Checklist Page 1 of 2

Caricato da

blackhand20xxCopyright:

Formati disponibili

Hayward Gordon ULC Start-up Checklist

Page 1 of 2

CUSTOMER INFORMATION

Name: Address:

Contact: Phone: Fax:

MIXER DRIVE INFORMATION

Mixer Size/Type: SONO#

Gear Oil Type: Manufacturer: Grease Type: Manufacturer:

PRESENT DURING START-UP

Engineer: Owner: Contractor:

HGL Sales Rep: HGL Service Rep: Date:

CAUTION

WHEN PERFORMING START-UP, CONSIDERATIONS ABOUT DOING THE JOB SAFELY MUST BE FULLY

INTEGRATED INTO YOUR APPROACH TO THE WORK. PLEASE READ AND BECOME FAMILIAR WITH ALL

SAFETY AND CAUTION STATEMENTS OUTLINED IN THE SERVICE INSTRUCTION MANUAL BEFORE ANY

WORK IS TO BE PERFORMED.

PROCEDURE

Note: These procedural steps are typical for all standard drives. Any steps that do not apply to the mixer being serviced may be skipped.

REFERENCES: ODD - Outline Dimension Drawing MAN - Service Instruction Manual

Notes

Notes

See

See

N/A

N/A

OK

OK

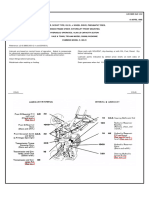

1. Disconnect power to prime mover by locking out 18. Remove low speed flexible coupling inspection

motor control center. cover. Check grease in grid of low speed flexible

coupling and replace if necessary. (Q units only)

2. Does equipment appear to have been stored 19. Inspect for proper oil level and oil grade (MAN)

properly?

3. Is drive mounted properly? (ODD) 20. Add correct type of oil if necessary.

4. Anchor/hold-down bolts Tight? 21. Regrease all output shaft & motor bearings.

(ODD)

5. Check paint (note any peeling or chipping). 22. Replace all inspection covers & coupling/v-belt

guards.

6. Check mixer for external rust & corrosion. 23. Recheck torque on all external mixer fasteners.

(ODD)

7. Check impeller location (ODD) 24. Check installation of breather.

8. Are blades on correct side of hub? (ODD) 25. Unlock motor control center.

9. Bolt torques of impeller blades correct? (MAN) CAUTION: If mixer is equipped with an external lube system, consult

Service Manual now to determine operating pressure before continuing

10. Set screw torques on hub correct? (MAN)

with start-up procedure.

11. Rigid coupling bolts torqued correctly? (MAN) 26. Jog mixer to check for proper rotation. (ODD)

12. Remove V-belt guard. 27. Do ODD & rotation tag agree?

13. Remove high speed coupling guard or cover. 28. Start mixer.

14. Rotate high speed coupling or drive sheave by 29. Check oil pressure of external lubrication pump,

hand & check for binding - mixer should rotate if applicable. (MAN)

freely.

15. Remove high speed coupling housing, if 30. Check for unusual noise (>85 dBA at 5 ft).

applicable.

16. Check alignment of high-speed flexible coupling 31. Check for unusual vibration.

or belt sheaves. (MAN - for maximum allowable

parallel and angular offset). 32. Check output shaft speed. (ODD)

17. Repack grid of high speed flexible coupling and 33. Check power draw (Note: impeller will draw

replace housing, if applicable more power in water &/or process than air).

Hayward Gordon ULC, Halton Hills, ON CanadaDoc: 03-41

mixers@haywardgordon.com November 2004

www.haywardgordon.com Supersedes N/A

Hayward Gordon ULC Start-up Checklist

Page 2 of 2

ITEM # NOTES

Based on my inspection, upon the Customer’s past and future compliance with all Hayward Gordon’s storage

installation and operating procedures, and upon the Customer’s agreement to successfully complete all work

shown in “NOTES”, I find that the referenced mixer is ready for full time operation. Hayward Gordon’s

contractual warranty is confirmed on the same basis.

.

Sign & Print Name

Customer Representative Date

Title Company Name

Hayward Gordon ULC, Halton Hills, ON CanadaDoc: 03-41

mixers@haywardgordon.com November 2004

www.haywardgordon.com Supersedes N/A

Potrebbero piacerti anche

- MPM 312 01 50Documento2 pagineMPM 312 01 50Mousa PetrolNessuna valutazione finora

- Transformer Check ListDocumento2 pagineTransformer Check ListKanhiya Prasad100% (3)

- Forte Camera, Exchanger & Table Planned Maintenance: (Checklists and Logs)Documento11 pagineForte Camera, Exchanger & Table Planned Maintenance: (Checklists and Logs)Julio Cesar Lugo RuizNessuna valutazione finora

- HJ110-2 Service Manual PDFDocumento170 pagineHJ110-2 Service Manual PDFJuan Barrera0% (1)

- trw800 PDFDocumento39 paginetrw800 PDFDev RaneNessuna valutazione finora

- Landrover Freelander 2 Maintenance ScheduleDocumento2 pagineLandrover Freelander 2 Maintenance Schedulevincent_devine777dNessuna valutazione finora

- Nor30p Serv ManDocumento187 pagineNor30p Serv Manjason_meyer_14100% (2)

- Maintenance-Log-Mud PumpDocumento4 pagineMaintenance-Log-Mud PumpSarah RavikumarNessuna valutazione finora

- Manual AEGP018 DMADocumento11 pagineManual AEGP018 DMAFelix MelendezNessuna valutazione finora

- Timberwolf TW 190TVGTR Wood Chipper Instruction ManualDocumento56 pagineTimberwolf TW 190TVGTR Wood Chipper Instruction ManualthuanNessuna valutazione finora

- FM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectionDocumento2 pagineFM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectiondavidburkepsNessuna valutazione finora

- Auxiliary Blower Instruction ManualDocumento35 pagineAuxiliary Blower Instruction ManualdigardbrandNessuna valutazione finora

- Induction Motors/ GeneratorsDocumento35 pagineInduction Motors/ GeneratorsJavier HernandezNessuna valutazione finora

- 3.2 Design & Procure Ment DataDocumento8 pagine3.2 Design & Procure Ment DataBhaumik BhuvaNessuna valutazione finora

- DGW200MS/UK: Operator'S ManualDocumento36 pagineDGW200MS/UK: Operator'S ManualthuanNessuna valutazione finora

- Service Manual Diesel Engine DB33ADocumento78 pagineService Manual Diesel Engine DB33ADVHHTC100% (4)

- Torque-Hub Planetary Final Drive S12A4 & 6 Series Service ManualDocumento58 pagineTorque-Hub Planetary Final Drive S12A4 & 6 Series Service Manualrafasel otubo guatia100% (1)

- General Information: Section 1ADocumento325 pagineGeneral Information: Section 1Atallerr.360Nessuna valutazione finora

- Maintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesDocumento2 pagineMaintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesCristiano DellazariNessuna valutazione finora

- Lowlander MK4 Manure Spreader - Bunning Owners Manual PDFDocumento120 pagineLowlander MK4 Manure Spreader - Bunning Owners Manual PDFДима ЧернеевNessuna valutazione finora

- Manual Transmission: Click On The Applicable Bookmark To Selected The Required Model YearDocumento21 pagineManual Transmission: Click On The Applicable Bookmark To Selected The Required Model YearUgratara AutoNessuna valutazione finora

- DSR Ex 125Documento120 pagineDSR Ex 125hugocalero4Nessuna valutazione finora

- MN1630-2012 TXT-R499353 PDFDocumento8 pagineMN1630-2012 TXT-R499353 PDFRyusuke IshikawaNessuna valutazione finora

- ABL-74T Machine MaintenanceDocumento1 paginaABL-74T Machine MaintenanceChris McNairNessuna valutazione finora

- CT26C Service ManualDocumento72 pagineCT26C Service ManualedwinNessuna valutazione finora

- Case IH Eng AGT PDI SheetDocumento4 pagineCase IH Eng AGT PDI SheetahmedNessuna valutazione finora

- Manual Chipeadora 18XP (059-119)Documento61 pagineManual Chipeadora 18XP (059-119)Mantenimiento BiocicloNessuna valutazione finora

- Timberwolf TW 150VTR Wood Chipper Instruction ManualDocumento64 pagineTimberwolf TW 150VTR Wood Chipper Instruction ManualthuanNessuna valutazione finora

- Maintenance Manual - AUMA PDFDocumento2 pagineMaintenance Manual - AUMA PDFPre TshuksNessuna valutazione finora

- Ops Maintenance PDFDocumento45 pagineOps Maintenance PDFanggie100% (1)

- Cut82hr Manual Parts (Cr9b-) 130712siDocumento43 pagineCut82hr Manual Parts (Cr9b-) 130712si2222222222222-242735Nessuna valutazione finora

- Band Saw2Documento2 pagineBand Saw2Piyush VyasNessuna valutazione finora

- Honda XR70R Service ManualDocumento218 pagineHonda XR70R Service ManualDerekNessuna valutazione finora

- Jadwal Weekly MaintanaceDocumento8 pagineJadwal Weekly Maintanaceardy ansyahNessuna valutazione finora

- 163-120 - Falk Drive One Type DH2, Sizes M1130-M1210 Shaft Drives - Parts ManualDocumento4 pagine163-120 - Falk Drive One Type DH2, Sizes M1130-M1210 Shaft Drives - Parts ManualCagNessuna valutazione finora

- Related: ChooseDocumento33 pagineRelated: Choosecengiz kutukcuNessuna valutazione finora

- Buyer: OwnerDocumento27 pagineBuyer: OwnerDaniel TostaNessuna valutazione finora

- 1ZSE 5492-104 en Rev 12 - Technical Guide UZ - Pdfx1aDocumento40 pagine1ZSE 5492-104 en Rev 12 - Technical Guide UZ - Pdfx1amojsic6313Nessuna valutazione finora

- Manual PDS55S - 5B2 - E1 - (2) (39600 - 78420)Documento22 pagineManual PDS55S - 5B2 - E1 - (2) (39600 - 78420)singoNessuna valutazione finora

- HHI Ballast Service LetterDocumento43 pagineHHI Ballast Service LetterDmitrii PustoshkinNessuna valutazione finora

- Total Task-Hr Total Task-Hr: Card 1 of 2Documento6 pagineTotal Task-Hr Total Task-Hr: Card 1 of 2SteveNessuna valutazione finora

- JLR 18 27 10 - 2E - Maintenance Check Sheet - Range Rover Sport (LW) - UK & EU - From 14MY - MilesDocumento2 pagineJLR 18 27 10 - 2E - Maintenance Check Sheet - Range Rover Sport (LW) - UK & EU - From 14MY - MilesmunNessuna valutazione finora

- Presentation Slide showQJ341 QJ241..ppsxDocumento120 paginePresentation Slide showQJ341 QJ241..ppsxdaniel100% (1)

- HP Service Manual R2A4 English Specs Rev6!4!2014Documento64 pagineHP Service Manual R2A4 English Specs Rev6!4!2014maconhu100% (1)

- Pm. Dozer d85ssDocumento20 paginePm. Dozer d85ssIqmal WahabNessuna valutazione finora

- Maintenance Checklist Shekar AugerDocumento1 paginaMaintenance Checklist Shekar Augershamsheer ikramNessuna valutazione finora

- Manual Servicio FZ-16 PDFDocumento267 pagineManual Servicio FZ-16 PDFaxpel calzadoNessuna valutazione finora

- CBX Eng 1Documento78 pagineCBX Eng 1ЮрийNessuna valutazione finora

- Manual de Operacio Dgw201Documento34 pagineManual de Operacio Dgw201Amando FuentesNessuna valutazione finora

- Rolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceDocumento36 pagineRolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceFranny Alexandra Tamayo RiocampoNessuna valutazione finora

- Cascade Fork Pos 55h ServiceDocumento34 pagineCascade Fork Pos 55h Servicejcardy1985Nessuna valutazione finora

- 22sPACE WAGONDocumento16 pagine22sPACE WAGONrafaelcruzgjaNessuna valutazione finora

- 029934Documento3 pagine029934Хелфор УкраинаNessuna valutazione finora

- GB RockBreaker Manual PDFDocumento84 pagineGB RockBreaker Manual PDFSerkanAl100% (4)

- QMB 10-25 - Mar 91 - Version A - 50033-100Documento19 pagineQMB 10-25 - Mar 91 - Version A - 50033-100Nelia ShkutNessuna valutazione finora

- Shindaiwa DGW400DM-ANZ-Owners-Manual-1Documento40 pagineShindaiwa DGW400DM-ANZ-Owners-Manual-1Guruh SuprayitnoNessuna valutazione finora

- Vetus M4.15 OperationDocumento72 pagineVetus M4.15 Operationchristian vergaray gonzalesNessuna valutazione finora

- Rep 24Documento330 pagineRep 24ArturNessuna valutazione finora

- 31733030Documento28 pagine31733030sunthron somchaiNessuna valutazione finora

- The Effect OfAdditional Nanoparticles Supplementation of Indonesian Bay Leaf (SyzigiumPolyanthum) On Blood Pressure in Pregnancy HypertensionDocumento4 pagineThe Effect OfAdditional Nanoparticles Supplementation of Indonesian Bay Leaf (SyzigiumPolyanthum) On Blood Pressure in Pregnancy HypertensionInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Ne XT ProtDocumento2 pagineNe XT Protwilliam919Nessuna valutazione finora

- EESC 111 Worksheets Module 5Documento5 pagineEESC 111 Worksheets Module 5Keira O'HowNessuna valutazione finora

- Aquamine 50.01Documento17 pagineAquamine 50.01Armando RelajoNessuna valutazione finora

- Stanford-Binet Test Scoring Explained - Stanford-Binet IQ TestDocumento3 pagineStanford-Binet Test Scoring Explained - Stanford-Binet IQ TestLM R50% (2)

- Foundation Engineering. 02 Soil CompressibilityDocumento63 pagineFoundation Engineering. 02 Soil Compressibilitysammy lopezNessuna valutazione finora

- Textbook of Dental Anatomy, Physiology and Occlusion, 1E (2014) (PDF) (UnitedVRG)Documento382 pagineTextbook of Dental Anatomy, Physiology and Occlusion, 1E (2014) (PDF) (UnitedVRG)Konstantinos Ster90% (20)

- Hiperparatiroidism SarcinaDocumento7 pagineHiperparatiroidism SarcinaClaudia IrimieNessuna valutazione finora

- Plastic As Soil StabilizerDocumento28 paginePlastic As Soil StabilizerKhald Adel KhaldNessuna valutazione finora

- People Vs CacayanDocumento2 paginePeople Vs CacayanAshley CandiceNessuna valutazione finora

- The Human Body: An Orientation: Part ADocumento10 pagineThe Human Body: An Orientation: Part ARoi Christoffer Jocson PeraltaNessuna valutazione finora

- Company Catalogue 1214332018Documento40 pagineCompany Catalogue 1214332018Carlos FrancoNessuna valutazione finora

- Written Assignment Unit 4 Health ScienceDocumento6 pagineWritten Assignment Unit 4 Health SciencesafsdaNessuna valutazione finora

- Planificare Săptămânală - Clasa A II-a (Fairyland 2)Documento6 paginePlanificare Săptămânală - Clasa A II-a (Fairyland 2)Oxy Oxy100% (1)

- Preservative MaterialsDocumento2 paginePreservative MaterialsmtcengineeringNessuna valutazione finora

- Soft Tissue SarcomaDocumento19 pagineSoft Tissue SarcomaEkvanDanangNessuna valutazione finora

- Plastic Omnium 2015 RegistrationDocumento208 paginePlastic Omnium 2015 Registrationgsravan_23Nessuna valutazione finora

- HOPE 3-Module 8-Week 5-6Documento9 pagineHOPE 3-Module 8-Week 5-6Freya SalorNessuna valutazione finora

- Industrial Visit ReportDocumento8 pagineIndustrial Visit ReportAnuragBoraNessuna valutazione finora

- Cross Rate and Merchant RateDocumento26 pagineCross Rate and Merchant RateDivya NadarajanNessuna valutazione finora

- Full Carrino Plaza Brochure and Application (General)Documento8 pagineFull Carrino Plaza Brochure and Application (General)tanis581Nessuna valutazione finora

- Rate Break Up 15500Documento1 paginaRate Break Up 15500Yash Raj Bhardwaj100% (1)

- Epoxy Data - AF35LVE TDS - ED4 - 11.17Documento8 pagineEpoxy Data - AF35LVE TDS - ED4 - 11.17HARESH REDDYNessuna valutazione finora

- An Enhanced Model of Thermo Mechanical Loading On A Vaccum Insulated GlazingDocumento29 pagineAn Enhanced Model of Thermo Mechanical Loading On A Vaccum Insulated GlazingNguyễn SơnNessuna valutazione finora

- Preparing Polymers For The Jar TestDocumento5 paginePreparing Polymers For The Jar Testarvin4dNessuna valutazione finora

- 1.8 SAK Conservations of Biodiversity EX-SITU in SITUDocumento7 pagine1.8 SAK Conservations of Biodiversity EX-SITU in SITUSandipNessuna valutazione finora

- Starbucks Reconciliation Template & Instructions v20231 - tcm137-84960Documento3 pagineStarbucks Reconciliation Template & Instructions v20231 - tcm137-84960spaljeni1411Nessuna valutazione finora

- 2015 4-H Show & Sale CatalogDocumento53 pagine2015 4-H Show & Sale CatalogFauquier NowNessuna valutazione finora

- House of Candy PresentationDocumento42 pagineHouse of Candy PresentationRohit JaroudiyaNessuna valutazione finora