Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Segment 001 of CPA CHIG1101 Maintenance and TE of Hoists 111010

Caricato da

Adhe GedeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Segment 001 of CPA CHIG1101 Maintenance and TE of Hoists 111010

Caricato da

Adhe GedeCopyright:

Formati disponibili

Annex 5 – Typical In-service Maintenance Checklist

Construction Hoist

In-service Maintenance Checklist

Company Site

Date Hoist Type Serial No. Hour Clock O/S No.

KEY: A – in good order B – requires early attention C – requires immediate action D - Not applicable

A B C D A B C D

1. Side-panels 44. Mast sections

2. Cable basket(s) & trailing cable(s) 45. M ast bo l ts a nd nu ts

3. Electrical panel 46. Mast racks and bolts

4. Ultimate limit ramps 47. R a c k l u b r i ca t i o n

5. I s o l a t o r s 48. Cable guides standard

6. G a t e / d o o r 49. Cable guide device & trolley

7.

10.Foundation fixing

Gate, door entrance

50. Landing beams

51. Pipe supports

11. Ga te , do or e xi t

12. Side panels, roof and floor 52. Wall ties and fixings

13. Ladder and fixing 53. Ve r t i c a l p i p e s

54. L i m i t c a m s t o p

14. Limit switches for 60. L an di ng g a te s d oo r

gates/doors

0. Mechanical interlocks

15. Limit switch for trap door 61. Gate cam & switch

0. Ultimate limit switch assembly

1. U p l i m i t s w i t ch 63. Counterweight assembly

16. Do wn li mi t swi tch 64. Rope anchorages

17. Control switch/buttons 65. Cathead sheaves

18. Electrical equipment 66. Guide rollers

26. Guide roller, hook

assemblies 67. Buffer springs

27. Guide roller adjustment

68.

72. Support ropes

External call system

28. Guide roller wear 73. Emergency stop control

74. Alarm system

29. Sa fe ty de vi ce u ni t

30. Safety device resetting

75. Sto p n ext la nd in g

tool 76. Load sensing

31. Dr i ve mo tor s 77. H frame clips

32. Brakes 78. Em er ge n cy l ow er i ng

79. No undue noises

33. Brake adjustment 81. Load control test

34. G e a r b o xe s 84. L oa d te st

35. Gea rb o x oi l l eve l s 85. D ro p te st

36. Drive pinions 86. Site register signature

37. D r i ve p i n i o n w e a r 87. Report of thorough

Notes

Name Company Signature

Annex 6 - Daily Pre-use Checks

Construction Hoist

Daily Pre-use Checklist and Report

Maintenance, Inspection and Thorough Examination of Construction Hoists 1 October 2011

Week Commencing Company Site

Hoist Type Serial No. Plant No.

= in good order X = defect

Hoist Item Mon Tue Wed Thu Fri Sat Sun

Ropes correctly positioned on sheaves

Operation of cage flaps, gates & interlocks

Operation of landing flaps, gates & interlocks

Roof trapdoor & interlock (passenger hoist)

Base enclosure gates & interlocks

Hoistway clear of obstructions

Mast ties are secure (no undue movement)

Check operating controls

Emergency controls (except safety brake)

Mains isolator switch operation & condition

Operation of upper & lower limit switches

Operation of trailing cable storage system

Check cable guide springs are intact

Check brake operates normally

No unusual noises from motor, gearbox etc.

Notices - instruction, operating & warning

Leakage from any fuel system

Condition of fuel container & security of cap

Operation of audible or visual warning alarms

Communication system cage to ground level

Debris in base enclosure & on cage roof

Initials of person carrying out checks

Details of defects found & repairs

Name of Appointed Person Signature Company

Annex 7 - Weekly Inspections

Construction Hoist

Weekly Inspection Checklist and Report

Date Company Site

Maintenance, Inspection and Thorough Examination of Construction Hoists 2 October 2011

Hoist Type Serial No. Plant No.

All daily checks to be carried out prior to weekly inspection

4= in good order R = repaired fault 8 = defect

Hoist Item 4 , R or 8

Inspect structure for damage, e.g. bent mast bracings or ties, indentations on mast

guides, cracked welds, loose bolts & fasteners

Hoist rope for obvious signs of damage, excessive wear or corrosion

Wire rope terminations, pins & retaining devices for damage, correct position & security

Check sheaves, pulleys & drums for damage & that bushes are not worn or seized

Rack and pinion for engagement, undue wear, damage and lubrication

Inspect gearbox for leaks

Check that tie bolts are secure with undue movement

Check foundation bolts, rack retaining bolts and other bolts are fitted & secure

Check guide rollers are correctly positioned and operational

Check brake & clutch friction linings & drum paths for wear & that brakes are effective

Check hoistway protection & machinery guards & fastenings are in place & secure

Electrical cables - check for damage and bare wires

Plugs & sockets - check for condition, cracks, bent pins and debris or dirt in sockets

Cables - for taped or non-standard joints

Check that cable covering has not been pulled out of plug or equipment grips

Check casing of electrical equipment for damage & loose or missing parts & screws

Check electrical equipment for contamination by oil, grease, water or dirt

Check cables, plugs and equipment for overheating or burn marks

Check any RCD power breaker by operating test button

Visually check overspeed safety device

Details of defects found & repairs - inform appointed person

Contacted hoist supplier Yes No

Carried out by Signature Company

Annex 8 – Report of Thorough Examination

Construction Hoist

Report of Thorough Examination

(As required by Lifting Operations and Lifting Equipment Regulations 1998 - Schedule 1)

Date of thorough Date of report: Report No: Date of last thorough

examination: examination:

Maintenance, Inspection and Thorough Examination of Construction Hoists 3 October 2011

Name & address of hirer/user: Name & address of owner:

Description of equipment: Makers name:

Date of manufacture: Owners No & serial No: Location of equipment:

Mast height: Number of landing gates: Number of ties:

Safe Working Load: Test load applied: Drop test carried out with: Rated number of Safety device

persons: serial No:

Examination after installation/assembly State if any parts were inaccessible:

at a new location: Yes / No

Periodic examination 6 Monthly: Yes / No

Particulars of other tests carried out during this

Periodic examination 12 Monthly: Yes / No thorough examination:

Examination following alteration/repair

Or exceptional circumstances: Yes / No

Is the equipment installed correctly: NA / Yes / No Is the equipment safe to operate: Yes / No

Particulars of any defects, repair, renewal or alteration required which is or could Date (time) the defect must

become a danger to persons: be rectified:

I hereby declare that the equipment described in this report was thoroughly examined and was found to be free

from any defect likely to affect safety, (unless otherwise stated above) and that the particulars are correct.

Name of competent person: Signature: Job title/qualification:

Name of authenticating person: Signature: Job title:

Address of competent person or his employer:

The next thorough examination will be due on or before:

Maintenance, Inspection and Thorough Examination of Construction Hoists 4 October 2011

Annex 9 - Thorough Examination of Wire Ropes

The examination of wire ropes as part of the thorough examination of a construction

hoist should be based on the principles and requirements set out in BS ISO

4309:2010, Cranes. Wire ropes. Care, maintenance, installation, inspection and

discard

This document stresses the importance of examining critical areas of the rope such

as:-

· The termination points of both moving and stationary ropes;

· That part of the rope which passes through over sheaves or any

erection crane block;

· In the case of hoists performing a repetitive operation, any part of the

rope which lies over sheave(s) while the hoist is in a loaded condition;

· That part of the rope which lies over a compensating sheave;

· Any part of the rope which may be subject to abrasion by external

features.

When examining ropes on a construction hoist it is often quite difficult to examine

some parts of the rope, particularly those parts of the rope that are continually passing

over cathead and deflector sheaves. Consideration should be given to both the length

of time that the hoist will be erected on a particular site and the age of the rope. It may

well be appropriate to fit a new rope before erection to reduce the risk of rope failure.

During the planning of thorough examinations the following points should be taken

into consideration

1. Where it is not possible to carry out an effective examination of all parts

of a hoist or counterweight rope on an erected construction hoist, that part of

the rope that cannot be accessed should be examined by the competent

person on the ground before the winch is installed on the hoist. This will

provide confirmation that the rope is in good condition at the time of erection.

At the same time the state of lubrication of the rope should be assessed so that

any necessary remedial action can be taken before the rope is installed on

the hoist. Fitment of a new rope will negate the requirement for this

examination.

2. Where it is not possible to examine all parts of a hoist or counterweight

rope on an erected hoist the competent person must specify, following pre-

erection examination on the ground, the maximum period for which the rope

may remain in service before full examination or replacement. In the case of a

new rope fitted to the hoist at time of erection the period must not exceed

12 months.

3. The competent person must be provided with the hoist or counterweight

rope specification and history of usage before carrying out the thorough

examination.

4. If a hoist or counterweight rope is found to be excessively greased - and

hence not able to be properly examined, the rope must be cleaned prior to

examination.

5. All signs of external corrosion should be followed up by detailed

measurement of rope diameter in those parts of the rope where the corrosion is

observed to assess any reduction of rope diameter which may indicate

deterioration of the rope core.

6. The competent person should assess the state of rope lubrication and

Maintenance, Inspection and Thorough Examination of Construction Hoists 5 October 2011

detail any requirements for additional lubrication on his report.

The results of any examination of wire ropes should be recorded.

Maintenance, Inspection and Thorough Examination of Construction Hoists 6 October 2011

Annex 10 – Example of Pre-delivery Checklist

Pre-Delivery Inspection

Checksheet - Construction Hoist

Contract: Date:

Hoist Number Number of Hours

Serial Number: Plant Number

Hoist Type

TICK COLUMN UPON COMPLETION OF INSPECTION OR MARK N/A

1 Side Panels 31 Mast sections

2 Cable basket(s) & trailing cable(s) 32 Mast bolts and nuts

3 Gate/door 33 Mast racks and bolts

4 Foundation fixing 34 Rack lubrication

5 Buffer springs 35 Cable guides standard

6 Foundation plate 36 Cable guide arm device & trolley

7 37 Landing Beams

8 Gate door entrance 38 Main frames

9 Gate door exit 39 Wall ties, fixings & couplers

10 Side panels, roof and floor 40 Vertical pipes & pipe supports

11 Ladder and fixing 41 Erection crane and accessories

12 Safety notices/signs 42

13 Operator's Manual 43

14 44

15 Guide roller, hook assemblies 45 Landing gates

16 Guide roller adjustment 46 Mechanical interlocks

17 Guide roller wear 47

18 Safety device unit 48

19 Date to replace safety device 49 All electrical equipment

20 Safety device resetting tool 50 and limit switches

21 Gearboxes 51 as per HEC1-2

22 Gearbox oil levels 52

23 Drive pinions 53

24 Drive pinion wear 54 Drop test (100% WLL)

25 Drive pinion adjustment 55 Load test (100% WLL)

26 Safety pinion 56 Static Load Sensor Test (110%WLL)

27 Safety pinion wear 57

28 Safety pinion adjustments 58

29 59

30 60

Confirmation of Inspection

Name (Print): Signature:

Maintenance, Inspection and Thorough Examination of Construction Hoists 7 October 2011

Pre-Delivery Electrical Inspection

Checksheet - Construction Hoist

Contract Hoist Type Plant No. Serial No.

Wiring Diagram No. Cable Length Hour Meter Reading Date

Winding Resist Brake Resist Pad Thickness/Air Gap

Motor 1

Motot 2

Motor 3

Main Panel

Base Panel

Remote P/B Control

Main P/B Control

Mast Switches

Mast Cover Switches

Gate Switches

Ramp Switches

Car Light

All plugs/sockets

Safety Device Base Surround

Battery Charger Battery

Loadcell

Loadcell Amplifier

Mains Cable Insulation Value Earth Continuity

Faults Found

Parts Used

Person/Persons Responsible for Tests

Maintenance, Inspection and Thorough Examination of Construction Hoists 8 October 2011

Annex 11 - Example of Record of Competent Person Monitoring

Record of Stage 1 Monitoring of a Competent Person (Installation Supervisor)

Undertaking Thorough Examination of Goods Hoists with a Rated Capacity of 500kg

or less.

Competent Person: Employer:

Relevant Qualifications:

Relevant Experience:

Review of Thorough Examination Records

OK? Issues OK? Issues

TE Report TE Report

No. No.

On-site Review

Hoist Make and Model: Date of Original TE:

Date of Check TE:

Additional defects found

during check TE:

Satisfactory Review? Y/N Action taken:

Overall Stage 1 Review Outcome: Satisfactory/Unsatisfactory

Remedial Action Required:

Monitor's Name: Position:

Signature: Date:

Maintenance, Inspection and Thorough Examination of Construction Hoists 9 October 2011

Record of Stage 2 Monitoring of a Competent Person (Installation Supervisor)

Undertaking Thorough Examination of Goods Hoists with a Rated Capacity of 500kg

or less.

Competent Person: Employer:

Review of Thorough Examination Records

OK? Issues OK? Issues

TE Report TE Report

No. No.

Review of Maintenance and Breakdown Records and Comparison with Reports of Thorough Examination

Details of Discrepancies:

On-site Review

Hoist Make and Model: Date of Original TE:

Date of Check TE:

Additional defects

found during check TE:

Satisfactory Review? Y/N Action taken:

Overall Stage 2 Review Outcome: Satisfactory/Unsatisfactory

Remedial Action Required:

Monitor's Name: Position:

Signature: Date:

Maintenance, Inspection and Thorough Examination of Construction Hoists 10 October 2011

Record of Stage 3 Monitoring of a Competent Person (Installation Supervisor)

Undertaking Thorough Examination of Goods Hoists with a Rated Capacity of 500kg

or less.

Competent Person: Employer:

Review of Thorough Examination Records

OK? Issues OK? Issues

TE Report TE Report

No. No.

Review of Maintenance and Breakdown Records and Comparison with Reports of Thorough Examination

Details of Discrepancies:

On-site Review

Hoist Make and Model Date of Original TE

Date of Check TE

Additional defects

found during check TE

Satisfactory Review? Y/N Action taken

Overall Stage 3 Review Outcome: Satisfactory/Unsatisfactory

Remedial Action Required:

Monitor's Name: Position:

Signature: Date:

Maintenance, Inspection and Thorough Examination of Construction Hoists 11 October 2011

Potrebbero piacerti anche

- UT102 ManDocumento94 pagineUT102 ManSergey BadloNessuna valutazione finora

- Drilling Rig Inspection Checklist: (Day) (Month) (Year)Documento3 pagineDrilling Rig Inspection Checklist: (Day) (Month) (Year)Dusty PinkNessuna valutazione finora

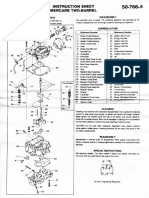

- Instruction Sheet Mercarb Two-Barrel: General Exploded View - DisassemblyDocumento3 pagineInstruction Sheet Mercarb Two-Barrel: General Exploded View - DisassemblyNNessuna valutazione finora

- Vehicle Inspection ChecklistDocumento2 pagineVehicle Inspection ChecklistJawad JadNessuna valutazione finora

- Checklist For CarDocumento4 pagineChecklist For Carsai sandipNessuna valutazione finora

- Ut803 English Manual PDFDocumento57 pagineUt803 English Manual PDFSUDHANSHU SINGHNessuna valutazione finora

- X-Ray Tube-Stand: A. General PrecautionsDocumento9 pagineX-Ray Tube-Stand: A. General PrecautionsrichartinNessuna valutazione finora

- UT107 English ManualDocumento63 pagineUT107 English ManualRafael MoralesNessuna valutazione finora

- Eot Ibl Crane Yearly ChecksheetDocumento3 pagineEot Ibl Crane Yearly ChecksheetAmit ThakurNessuna valutazione finora

- Final Report Ss 170 9 23 2014Documento85 pagineFinal Report Ss 170 9 23 2014Sanjay PhukanNessuna valutazione finora

- UT61 English ManualDocumento69 pagineUT61 English ManualJosé LaranjoNessuna valutazione finora

- UT71 English ManualDocumento73 pagineUT71 English ManualandreaNessuna valutazione finora

- Multimetro Tenma 72 - 10405Documento64 pagineMultimetro Tenma 72 - 10405João Oliveira BentesNessuna valutazione finora

- Eot Crane Monthly ChecksheetDocumento4 pagineEot Crane Monthly ChecksheetAmit ThakurNessuna valutazione finora

- UT61ABCDE Manual en PDFDocumento69 pagineUT61ABCDE Manual en PDFEverton DoradoNessuna valutazione finora

- 01 UT71B Eng Manual PDFDocumento72 pagine01 UT71B Eng Manual PDFPE TruNessuna valutazione finora

- 85-4085 Ut 804Documento69 pagine85-4085 Ut 804Jonatan JonatanBernalNessuna valutazione finora

- Solenoid Training ManualDocumento194 pagineSolenoid Training ManualASESOR para servirlesNessuna valutazione finora

- 42,0426,0202, EaDocumento72 pagine42,0426,0202, Eadjkgxn827mNessuna valutazione finora

- Crawler Crane Annual InspectionDocumento3 pagineCrawler Crane Annual InspectionMark SolmundsonNessuna valutazione finora

- Pfaff 1029 Sewing Machine Instruction ManualDocumento40 paginePfaff 1029 Sewing Machine Instruction ManualiliiexpugnansNessuna valutazione finora

- (A) Engine /cooling System (D) Centrifugals: Cbs-955/957 Stem Ii Check SheetDocumento3 pagine(A) Engine /cooling System (D) Centrifugals: Cbs-955/957 Stem Ii Check Sheetyao nestorNessuna valutazione finora

- UT804 Manual (110V)Documento70 pagineUT804 Manual (110V)Juan Guillermo CardenasNessuna valutazione finora

- Goodrich De-Icing & Specialty Systems Uniontown, OhioDocumento53 pagineGoodrich De-Icing & Specialty Systems Uniontown, OhioFrank JansenNessuna valutazione finora

- OK REV W.hse-014 F.02 Formulir Inspeksi Safety Crane (Monthly)Documento2 pagineOK REV W.hse-014 F.02 Formulir Inspeksi Safety Crane (Monthly)Ahfi Rizqi FajrinNessuna valutazione finora

- Electronic Circuit Devices - Frank HarrisDocumento284 pagineElectronic Circuit Devices - Frank Harrisnglok100% (1)

- 68 - Daily Inspection Checklist For Launching GirdersDocumento13 pagine68 - Daily Inspection Checklist For Launching GirdersankitNessuna valutazione finora

- DANFOSS TLX6 TLX8 TLX10 TLX12.5 TLX15kW Manual Referencia ENDocumento126 pagineDANFOSS TLX6 TLX8 TLX10 TLX12.5 TLX15kW Manual Referencia ENcarl clarkNessuna valutazione finora

- 8 Point Mooring - Attachment XxxiiDocumento5 pagine8 Point Mooring - Attachment XxxiiFaiqah AzmirNessuna valutazione finora

- 21-Crane Inspection Check ListDocumento2 pagine21-Crane Inspection Check ListKhuda Buksh100% (1)

- Job Sheet Stater Sepeda MotorDocumento8 pagineJob Sheet Stater Sepeda Motoraditya yudiantoro100% (1)

- Index 55 1Documento2 pagineIndex 55 1Hallex OliveiraNessuna valutazione finora

- How To Diagnose and Repair Automotive Electrical SystemsDocumento135 pagineHow To Diagnose and Repair Automotive Electrical Systemsgeorge74% (19)

- 123939-60a1 2 PDFDocumento84 pagine123939-60a1 2 PDFsmartravi222Nessuna valutazione finora

- Pfaff Performance 2054 Service ManualDocumento110 paginePfaff Performance 2054 Service ManualiliiexpugnansNessuna valutazione finora

- R Series PDFDocumento43 pagineR Series PDFMilan AleksićNessuna valutazione finora

- Sensors and Actuators (PDFDrive)Documento268 pagineSensors and Actuators (PDFDrive)chaitnayaNessuna valutazione finora

- Philips HEARTSTART MRX PDFDocumento7 paginePhilips HEARTSTART MRX PDFSERGIO PEREZ0% (2)

- Tenma Manual PDFDocumento58 pagineTenma Manual PDFkanchankonwarNessuna valutazione finora

- Service Manual: F2 SeriesDocumento36 pagineService Manual: F2 SeriesPramono DamarNessuna valutazione finora

- Military Engineering Services Estimating Data 07Documento148 pagineMilitary Engineering Services Estimating Data 07anandabalaji67% (6)

- Sussex Valve TesterDocumento68 pagineSussex Valve Tester21C1Nessuna valutazione finora

- DROPS - Reliable Securing Rev 04Documento67 pagineDROPS - Reliable Securing Rev 04Chris EasterNessuna valutazione finora

- Kagira Drawing Solution: Pipeline Stress AnalysingDocumento4 pagineKagira Drawing Solution: Pipeline Stress AnalysingKagira Drawing Soltuion0% (1)

- Manual Ut804Documento70 pagineManual Ut804Juan Guillermo CardenasNessuna valutazione finora

- Concord Infinity Residential Elevator Instal & Service SearchableDocumento141 pagineConcord Infinity Residential Elevator Instal & Service SearchableHongquan SuNessuna valutazione finora

- Form Inspeksi Tower CraneDocumento2 pagineForm Inspeksi Tower CraneAnnisa Agustina100% (1)

- Unit 01-03-1st Ed. RDS (IADC-PETEX) - Drill String and Drill CollarsDocumento119 pagineUnit 01-03-1st Ed. RDS (IADC-PETEX) - Drill String and Drill CollarsRoy67% (3)

- Line ProtectionDocumento173 pagineLine ProtectionMallikarjun ReddyNessuna valutazione finora

- DROPS InspectionDocumento67 pagineDROPS InspectionJoel CummingsNessuna valutazione finora

- 4862 Service Manual EnglishDocumento68 pagine4862 Service Manual EnglishChander Sharma100% (2)

- LEEA New Rigging ManualDocumento106 pagineLEEA New Rigging ManualAkramKassisNessuna valutazione finora

- 1947 US Navy WWII 8 Inch 3 Gun Turrets 220p.Documento220 pagine1947 US Navy WWII 8 Inch 3 Gun Turrets 220p.PlainNormalGuy2Nessuna valutazione finora

- Pfaff Expression 2014 Service ManualDocumento112 paginePfaff Expression 2014 Service ManualiliiexpugnansNessuna valutazione finora

- Transistor Switching and Sequential CircuitsDa EverandTransistor Switching and Sequential CircuitsValutazione: 5 su 5 stelle5/5 (1)

- Soal Uas Tek KoputasiDocumento1 paginaSoal Uas Tek KoputasiAdhe GedeNessuna valutazione finora

- Calculation of Air Receiver TankDocumento2 pagineCalculation of Air Receiver TankAdhe GedeNessuna valutazione finora

- Tanda Terima BarangDocumento1 paginaTanda Terima BarangAdhe GedeNessuna valutazione finora

- Materai 6.000 Tanda Tangan Dan Cap StempelDocumento1 paginaMaterai 6.000 Tanda Tangan Dan Cap StempelAdhe GedeNessuna valutazione finora

- Herc-Alloy 800 Hammerlok - CatDocumento1 paginaHerc-Alloy 800 Hammerlok - CatAdhe GedeNessuna valutazione finora

- Motor Grader TB 385-9 Safety Manual For Operating and Maintenance PersonnelDocumento7 pagineMotor Grader TB 385-9 Safety Manual For Operating and Maintenance PersonnelAdhe GedeNessuna valutazione finora

- PDF QLCM.Q6024..12.Ton 1339844525Documento4 paginePDF QLCM.Q6024..12.Ton 1339844525Adhe GedeNessuna valutazione finora

- Tank Emisiion CalcDocumento16 pagineTank Emisiion CalcAdhe GedeNessuna valutazione finora

- Past Question Papers Theory Solved Jan 12 To Jan 15 Capt. Saujanya SinhaDocumento282 paginePast Question Papers Theory Solved Jan 12 To Jan 15 Capt. Saujanya Sinhabasheer shaik100% (2)

- Gastric Feeding TubesDocumento10 pagineGastric Feeding Tubesapi-254470605Nessuna valutazione finora

- Hitachi ZX75USDocumento9 pagineHitachi ZX75US3man 9394Nessuna valutazione finora

- Behavior Intervention PlanDocumento22 pagineBehavior Intervention Planapi-343163369100% (1)

- Guidelines For Execution of Adapt-Pt: Structural Concrete Software SystemDocumento6 pagineGuidelines For Execution of Adapt-Pt: Structural Concrete Software SystemJoe IztadaNessuna valutazione finora

- Notes Microwave Engineering Unit 5 PDFDocumento14 pagineNotes Microwave Engineering Unit 5 PDFKujur RebecaNessuna valutazione finora

- Live IT Oct09Documento132 pagineLive IT Oct09indianebooksNessuna valutazione finora

- Tablet Coamoxiclave (Amoxicillin +clavulanic Acid) Indications and DosDocumento2 pagineTablet Coamoxiclave (Amoxicillin +clavulanic Acid) Indications and DosShumaila Iftikhar Iftikhar AhmadNessuna valutazione finora

- With Serverless ComputingDocumento9 pagineWith Serverless Computingmha1375.1635Nessuna valutazione finora

- "Some of Us May Never Die," by Kathleen SteinDocumento5 pagine"Some of Us May Never Die," by Kathleen SteinMark PlusNessuna valutazione finora

- M. Rahul Ananta - Rudito, BambangDocumento5 pagineM. Rahul Ananta - Rudito, BambangMuhammad Rahul AnantaNessuna valutazione finora

- Generic List - MOH PHCs-March-2023Documento11 pagineGeneric List - MOH PHCs-March-2023drabdulrabbNessuna valutazione finora

- Find The Best Location For Your Business or For Your Rice Retailing BusinessDocumento2 pagineFind The Best Location For Your Business or For Your Rice Retailing BusinessAAAAANessuna valutazione finora

- Lecture6-Design Expert Software - TutorialDocumento29 pagineLecture6-Design Expert Software - TutorialAzwan ShakraniNessuna valutazione finora

- AEM-Large Deformation AnalysisDocumento37 pagineAEM-Large Deformation AnalysisPinakin GoreNessuna valutazione finora

- Seed Health Testing in Field Crops Seeds........... AaaaaaaDocumento37 pagineSeed Health Testing in Field Crops Seeds........... AaaaaaaJagadish GowdaNessuna valutazione finora

- Thermodynamics QsDocumento3 pagineThermodynamics QsT Hari PrasadNessuna valutazione finora

- A Review of The Book That Made Your World. by Vishal MangalwadiDocumento6 pagineA Review of The Book That Made Your World. by Vishal Mangalwadigaylerob100% (1)

- SiteDocumento6 pagineSiteMikeNessuna valutazione finora

- Reheating and Preheating After Inflation: An IntroductionDocumento9 pagineReheating and Preheating After Inflation: An IntroductionSourav GopeNessuna valutazione finora

- Ladybug Reflection 10-14 NovDocumento2 pagineLadybug Reflection 10-14 Novapi-272157766Nessuna valutazione finora

- Backup of DB2Documento1.297 pagineBackup of DB2Kamakshigari SureshNessuna valutazione finora

- SyllabusDocumento3 pagineSyllabuspan tatNessuna valutazione finora

- Topic: Atoms and Molecules Sub-Topic: Mole: Lesson PlanDocumento4 pagineTopic: Atoms and Molecules Sub-Topic: Mole: Lesson PlanPushpa Kumari67% (3)

- Indra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043Documento28 pagineIndra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043AnhTuấnPhanNessuna valutazione finora

- 10 kVA - PI044E PDFDocumento9 pagine10 kVA - PI044E PDFYogi PurchasingNessuna valutazione finora

- Capitec Case StudyDocumento6 pagineCapitec Case StudyMpho SeutloaliNessuna valutazione finora

- Jurnal Kacang Hijau Dan MaduDocumento7 pagineJurnal Kacang Hijau Dan Madusri margiatiNessuna valutazione finora

- Retscreen International: Clean Energy Project AnalysisDocumento72 pagineRetscreen International: Clean Energy Project AnalysisAatir SalmanNessuna valutazione finora

- We Live in An Electromagnetic WorldDocumento7 pagineWe Live in An Electromagnetic Worlddocorof634Nessuna valutazione finora