Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1st S: Sort Through/sort Out

Caricato da

paknejadDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1st S: Sort Through/sort Out

Caricato da

paknejadCopyright:

Formati disponibili

5S EVALUATION SHEET

5S EVALUATION SHEET

1st S: Sort through/sort out

Eliminate what is unneeded and decide what is needed INITIAL SITUATION FIRST IMPROVEMENTS DEVELOPMENT INTEGRATED SYSTEM EXCELLENCE

NO DISTINCTION BETWEEN NEEDED ELIMINATION OF UNNEEDED ITEMS IS IN UNNEEDED AND NEEDED ITEMS HAVE CLEAR LOCATION FOR ALL NEEDED LOCATIONS FOR ALL NEEDED ITEMS

Check item Question AND UNNEEDED PROGRESS BEEN SEPARATED ITEMS ARE CLEAR AND VISUAL

Is the workplace cluttered with Unneeded raw materials, packaging The necessary quantities of materials, All locations for finished products, materials,

Large quantities of finished products and There are no unneeded drums or pallets in

Unneeded pallets / boxes / raw unnecessary pallets, raw materials, materials, inventory and finished products packaging or pallets have been defined. The packaging materials, are visually indicated.

raw materials are stored in the work area the work and storage areas. All products,

materials / consumables / finished drums, inventory or finished products? have been eliminated from the workplace. areas for boxes, pallets and finished Minimum and maximum levels have been

and in corridors instead of being stored in consumables and materials have specific

1. products in the workplace Are there any obsolete products in the The work area only includes materials used products around the machines or in the work defined, with a visual system for

the warehouse or in a specific area. There locations defined on the basis of a 5S flow

workplace? Have chemicals and on a daily basis. Corridors and safety exits area are defined. Dangerous products and replenishment. An area for tagged products

are pallets, drums, packaging materials in map (which identifies the best locations to

consumables been sorted according to are clear. Chemical products, scrap consumables have been sorted according to (with no clearly defined usage) has been

the work areas and in corridors. Safety e reduce motion waste), and they are kept in

their use and their nature? materials and their n clearly

1 2 3-4 5 6

Unneeded tools, jigs and accessories lie Tools/items on shelves, in cupboards have No unneeded items can be found in the Only tools and items used regularly for

There are only the needed tools in the

Are there any unneeded tools, jigs, dies, about in the workplace, in drawers, on been partly sorted and put away, and workplace: the items with no specific daily/shift production can be found in the

workplace: a list has been established.

Unneeded tools, jigs, support material moulds or accessories (wrenches, machines, drums, or on the worktables. tagging of unneeded items is in progress. location are clearly identified for action. workplace: their locations are clearly

There are only clearly identified items in

2. or accessories scrapers, gloves...) in the work area? Is it Shelves and cupboards are filled with Machine tooling is put away in specific Machine toolings and jigs have been sorted marked, together with necessary quantities.

cupboards or on shelves. There are no more

possible to distinguish between needed useless tools and other old items. Machine spaces. There are still a few non-defined out and put away in a specific place. Cupboards have been completely cleared of

personal toolboxes, except for specific uses.

and unneeded items? tools are put away in a jumble. Some tools tools or items on cupboards, machines or Screws, electric and mechanical pieces are useless items. There are no tools in

The tagging process is carried out every tim

are in perso about. being sorte personal l

1 2 3-4 5 6

All machines in the area have a specific use, All equipment in the work area has a specific

All equipment in the area has a specific use.

There is some unused equipment in the and all unneeded items have been removed. use and a clear location. Forklift trucks have

Are there any unused machines or other Unneeded machines have been removed. They have defined locations and their

Unneeded machine or other workplace, in the aisles or in the storage Forklift trucks have a defined location. specific allocated spaces everywhere they

3. equipment in the workplace? (worktables, There are still a couple of unused or very names are displayed. All forklift trucks have

equipment areas. Forklift trucks have no specific Sporadically used machines/equipment are are used. All machines or equipment used

shelving, packing machine, etc). rarely used equipment in the workplace. a clearly defined location in every area

locations. put away in a specific location. The machine sporadically have a specific location, well

where they can be used.

and protection guards have been identifi indicated, and anybody can get them

1 2 3-4 5 6

Are there any unneeded or obsolete The workplace (workstation/monitoring All unneeded papers, documents and files All procedures and notes are up-to-date and

Instructions on the desks or workstation are Only the documents necessary for daily

instructions, procedures, memos, room) contains documents/files that are have been discarded, and the necessary forms/instructions are related to current

Unneeded documentation, visual not all related to current work. A few old production activities and process monitoring

4 drawings or visual displays in the file unneeded or that have been kept in the documents have been sorted depending on work. A location has been defined for the

displays, books, drawings memos. Drawers are still full of papers and can be found in the workplace, in specific

cabinets, on the workstation and on the wrong place (old calendars, memos, files, how frequently they are used. Teams have support documentation necessary for all

each team runs its own document system. and visually indicated locations.

walls? drawings, catalogues…). standardized their documents. operators.

1 2 3-4 5 6

(*) PPE: Personal protection Yellow tagging for undefined items -

Suggested methodologies:

equipment Tagging list and action plan.

Saint-Gobain HPM Sector

28/06/05 Productivity Group Europe

2nd S: Set in order

Define a specific location for every item needed INITIAL SITUATION FIRST IMPROVEMENTS DEVELOPMENT INTEGRATED SYSTEM EXCELLENCE

WORKPLACE ORGANIZATION IS IN LOCATIONS ARE BEING VISUALLY A VISUAL CONTROL SYSTEM IS BEING

Check item Question LACK OF ORGANIZATION AND ORDER

PROGRESS IDENTIFIED IMPLEMENTED

A VISUALLY ORGANIZED WORKPLACE

All units, lines and machines are identified

Are production units, workshops, There are no (or very limited) visual with a name or a number that is clearly There are visual markings for all equipment, All equipment, their functioning conditions,

Identification of production units Production units, machine names, as well as

machines, piping, production lines and indications of the names of the production indicated and visible from a distance. silos, supplying inlets, and a system has and the safety conditions that are to be

1. ,piping, machines, running condition process types, are indicated. All machine

processes clearly identified and visually units, nature of processes, areas, names or Machines and workstations are well-lit. been implemented to identify when they are respected are clearly marked with a visual

and flow guards are in place,

displayed? numbers of lines and machines. Piping contents and direction of flow have functioning. control system.

been identified.

1 2 3-4 5 6

Tools have a defined location, with a clear

A list of the necessary tools is displayed at

Are accessories, jigs and tools arranged The locations for the tools necessary to the labeling and color codes. Tooling, machine Tools are actually in the right place, and

Tools have a defined location, but they are every workstation. Equipment accessories

Organization of tools, jigs, support and ordered rationally, in order that they workstation are not visible. Tools have no accessories and jigs are organized they are visible at once. Tools locations are

not always in that location. Fixtures, toolings are well-defined. Codes and colors indicate

2. materials and machine accessories. can be easily taken and returned into allocated space. Machines tooling and according to size and frequency of use. The visually controlled, with clear and legible

and machine accessories are stored in where they are to be put away. A standard

Location for PPE* and safety material place, depending on how often and where fixtures are in a jumble in dark, unidentified tools necessary in each point of use have markings of their dimensions or conditions

specific areas. for arranging tools and accessories has

they are used? areas. been supplied and have a specific location, for use.

been created and is displayed.

cle

1 2 3-4 5 6

Are there any markings to clearly identify Storage areas, pedestrian areas, exits, Storage areas, pedestrian areas, aisles and Materials, packaging and finished products

Delimitation of floor areas, aisles, There are no signs to indicate floor areas, Storage areas, pedestrian areas and

floor areas, aisles, walkways, scrap and safety issues and passageways are passageways are well indicated. locations, as well as flow directions and

storage areas for materials and passageways and pedestrian areas. Areas passageways are visualized or painted with

storage spaces? Are there labels identified, but not respected. Markings are Passageways are clear. All storage is hazardous areas, can be identified at a

finished products. Location and for storage and scrap, safety issues are not specific colors. All storage are carried out in

3. indicating all items location and their not always clear, or there are a few location carried-out as indicated. Forklift trucks glance.

supplies of items in shelves/on indicated or have disappeared. The labels the areas indicated. Passageways are clear,

quantities on shelves? Are PPE* and indicators, but they are not always respected locations are identified. Items in cupboards A list of contents is displayed on all

storage racks (consumables, bottles, indicating locations in cupboards or shelves and dangerous areas as well as forklift

safety materials arranged rationally and or not precise enough. PPE* have a specific or on racks are well-identified, marked and cupboards and shelves. A visual system has

rolls, tapes, etc). are nonexistent, spoiled or cannot be r trucks, ramps paths can be identified at a g

easily-accessible? l labeled. M been set up for the replenishment of the

1 2 3-4 5 6

Presence of the necessary documents All necessary documents (SHE* documents, SHE* documents and job instructions are Job instructions, batch forms, order forms, Instructions, standard operating procedures

All SHE* documents and other documents

in the production unit and at the Are all documents essential to the activity batch forms, quality forms, etc) cannot be well organized and visible, and specific quality forms and other documents (specific and safety instructions can be identified at a

4 have an allocated space and are available

workstation (SHE* documents, job well-arranged and clearly identified? found on the workstation, or they are in a spaces with color codes corresponding to operating procedures) are visually marked, glance on each workstation, and globally in

on the workstation

forms, work instructions, etc) jumble and difficult to identify and read. the nature of documents have been defined. codified with well-defined sequences. all areas of the workplace.

1 2 3-4 5 6

(*) PPE: Personal protection

Suggested methodologies: 5S flow map

equipment

(*) SHE: Safety, Human, Environment Color codes / addresses codes

Photos

Saint-Gobain HPM Sector

28/06/05 Productivity Group Europe

3rd S: Shine and sweep

Keep the workplace clean and eliminate abnormalities INITIAL SITUATION FIRST IMPROVEMENTS DEVELOPMENT INTEGRATED SYSTEM EXCELLENCE

CONDITIONS FOR A CLEAN

CLEANING AND INSPECTING BECOME A CLEANING AND INSPECTING ARE PART

Check item Question ENVIRONMENT NOT CLEAN CLEANLINESS IS IN PROGRESS ENVIRONMENT ARE BEING

HABIT OF THE CULTURE

ESTABLISHED

Cleaning tools, materials and equipment are

The necessary tools (shovel, clothes, There are clearly defined and visualized

clearly identified in well-defined areas: their

brushes), products (detergents) and Cleaning tools and materials have been Cleaning tools, materials and equipment are locations for cleaning instruments, materials

Cleaning tools, materials and Are cleaning tools, equipment materials list has been established in every production

1. equipment (vacuum cleaners) for everyday identified, they have been allocated a space, available and they have a specific allocated and equipment, with available material

equipment available, accessible and adapted? unit and the operators in charge of their

cleaning are not all available or in a good but they are not all in that space. space. everywhere it is needed, in different points of

maintenance and replenishment are

state, or they have no defined location. the workplace. All addresses are marked.

indicated.

1 2 3-4 5 6

Machines are not very clean: all overflows, Machines are moderately clean: there are Machines are quite clean, and hard-to-reach

Workstations, machines are dirty: there are leaks and dust are not under control. still cables, PPE and areas difficult to reach. Workstations , machines and piping are areas have been removed or adjusted.

Cleanliness of workstations, Are machines, workstations, piping,

overflows, swarm, leakages, dust, Workstations (drawers, cupboards, shelves) Workstations are clean. clean. equipment, machine accessories, Workstations are perfectly clean, there are

machines, equipment, accessories cabinets, shelves clean? Have

2. fingerprints. Dirt and contamination sources are not completely clean. Some The main contamination sources are tools and racks are clean. no fingerprint or dust. All contamination

and piping. Elimination of sources for contamination and dirt causes (leaks,

are not treated: there are oil leaks, dust and contamination sources are identified with identified with tags and they are being All identified contamination sources are sources are being improved. Some

dirt and contamination dust) been identified and treated?

overflows. tags. Some of them have been treated or improved or a team is analyzing the being improved or are planned to be. improvements projects are still going on and

are being treated problem. are displa

1 2 3-4 5 6

Floors and all the workplace areas are

Floors and passageways are rather clean, perfectly clean and markings are in a very

Floors are dirty; there is dust, oil and product Floors are quite clean, even nearby or under

Are floors, aisles and scraps, scrap areas but floors in the work areas are dirty, soiled Floors are clean, bin/scraps areas and good condition. A team is responsible for

3. Cleanliness of floors and scrap areas stains. Containers and bins are dirty and machines and piping, and in all work and

clean? with oil and dust. Containers and bins are containers are clean and emptied regularly. every area in the plant. Responsibilities are

they sometimes overflow. storage areas.

emptied regularly. defined for control of cleaning and extraction

systems.

1 2 3-4 5 6

The planned cleaning activities are carried

The workplace is divided into areas, and

out according to schedule. Working clothes

Cleaning programs are nonexistent, not teams are responsible for them. The

Is cleanliness a usual team concern? Is Cleaning programs are displayed. They are The cleaning activities planned at the are clean. Cleanliness criteria are on display

4 Cleanliness behaviors and rules regular or not applied; weekly cleaning has planned cleaning activities are carried out

cleaning an ongoing team activity? not always completed for lack of time. workstation are adhered to. on every machines. Changing-rooms,

not been done; clothes are dirty. according to the programs. Working clothes

similarly to all the workplaces, are quite

are clean.

clean and well-kept.

1 2 3-4 5 6

Suggested methodologies: Red tags - Cleaning program - Photo showing a cleaning standard - Map of the setting with divided areas

Saint-Gobain HPM Sector

28/06/05 Productivity Group Europe

4th S: Standardize

Create a visually managed workplace INITIAL SITUATION FIRST IMPROVEMENTS DEVELOPMENT INTEGRATED SYSTEM EXCELLENCE

Check item Question LACK OF STANDARDS A FEW STANDARDS ARE ESTABLISHED STANDARDS ARE BEING DEVELOPED A VISUAL CONTROL SYSTEM IS IN PLACE ALL SITUATIONS ARE UNDER CONTROL

Tools are marked with defined color codes: A visual system has been defined for tools,

Standard colors have been defined for floor locations are identified according to color equipment and accessories organization

Are there existing standards and a shared Colors, coding systems for tools , jigs and

Visual standards for marking, Marking rules and color codes are not markings (raw materials, finished products, standards and to an established codification and management. A reference book has

1 coding system for areas, tools ,pipes and pipes have been defined and are

signboarding and tools management clearly defined for the site. bins, etc) and are implemented in all system. Moulds, fixtures and machine been created with all the standard operating

equipment markings? implemented.

workplaces. accessories are marked out with defined procedures for cleaning and organization of

codes. moulds, dies and jig storage, et).

1 2 3-4 5 6

The standards to avoid dirt have been

defined by teams and displayed where dirty

Each team manages its own cleaning

Have cleaning routines, Orderliness There are no cleanliness standards. There are a few cleaning rules or operations take place. Cleaning and Cleanliness and cleaning standards are

schedule and inspections, has a checklist of

2 Orderliness and cleaning standards standards and inspection routines been Cleaning and inspection programs are instructions for some workstations, but they inspection routines, as well as cleanliness displayed and integrated into daily team

specific control points, and all areas are

visually standardized? neither visible nor clearly formalized. are incomplete. criteria, are displayed. All disposal recipients activities.

clean and under control.

have been identified, and all discarded

mater

1 2 3-4 5 6

Some rules are formalized, operators are Instructions are clear and visually indicated Quality parameters and standard operating

Are production rules operating Operating rules and procedures are not

trained and work according to habits. There on all workstations: production and process procedures are displayed at each The process is defined by clear, visual

procedures and safety standards, clear clear; the process is uncertain or it results

Production operating procedures, are instruction and quality forms at the parameters (weight, pressure, temperature) workstation. standards which are adhered to. Process

and accessible? Are there dangerous from a habit. There are no traces of quality

3 safety and quality standards workstation. are visually indicated. Visual standards for hazardous activities are malfunctions will be seen at a glance.

activities in the workplace that have not forms or specific instructions. There are no

safety instructions are displayed where All rules for dangerous activities have been clearly displayed where hazardous Mistake-proofing systems are developed to

been defined and visualized by a appropriate and visualized safety rules for

hazardous actions take place. Displays and standardized and displayed where operations take place, and they are adhered prevent dangerous operations.

standard? hazardous operations. No visible saf

visual controls of safety condit operations take plac to.

1 2 3-4 5 6

The management of consumables/ various Teams have a checklist that they can refer

There are no standards for the management Systems have been set up with warehouses

Are there standards for the management kinds of products is under the responsibility to for a regular checking of reorder levels.

Consumables, supplies and raw of consumables, cleaning products and Minimum and maximum quantities for or suppliers (FIFO, Kanban system) for the

4 and supplying of consumables and raw of teams operators: a visual standard allows Checklists are displayed and integrated into

materials management materials in the workplace. There are products used regularly have been defined. regular replenishment of products necessary

materials? to see at a glance when products need teams routines, and replenishment

occasional stock shortage situations. to the teams, and they are fully respected.

resupplying. standards are fully respected.

1 2 3-4 5 6

Saint-Gobain HPM Sector

28/06/05 Productivity Group Europe

5th S: Sustain

Sustain improvements and make further company wide

INITIAL SITUATION FIRST IMPROVEMENTS DEVELOPMENT INTEGRATED SYSTEM EXCELLENCE

improvements

INTENSIVE CONTINUOUS

CONTINUOUS IMPROVEMENT A CONTINUOUS IMPROVEMENT

Check item Question NO REGULAR 5S ACTIVITY REGULAR 5S ACTIVITIES ARE STARTING

ACTIVITIES ARE BEING DEPLOYED CULTURE IS ESTABLISHED

IMPROVEMENT ACTIVITIES ALL OVER

THE PLANT

The 5S are not integrated into the activity.

The Steering Committee has started audits

Is there a formal 5S program with No formal program . Management is not

and performance meetings, but they are not The Steering Committee audits are part of Steering Committee audit programs and

1. 5S project with management management commitment? Is the 5S aware of the benefits. The Steering The Steering Committee audits are

carried out regularly. 5S achievements are the reporting system and teams priorities are results for all production units and all the

1 commitment and a Steering vision shared in the plant? Are targets Committee members do not carry out any scheduled on a regular basis in the

amongst the managerial staff priorities and regularly defined with the managerial staff teams priorities are displayed in a place

Committee clearly communicated? Are there an audit audits. The nature and the objectives of the workshops. 5S are part of team activities.

they are followed during workshop meetings. and the Steering Committee. shared by all personnel

system and a reporting system in place? 5S project are not displayed and known by

everyone.

1 2 3-4 5 6

All workshop operators have been trained in

A large part of workshop operators have Everyone takes part in the 5S activities and Each team is responsible for an area in the

5S. Each team is responsible for an area,

All workshop operators have not been been trained to the 5S, the 5S team activity each team is responsible for an area. Some workplace. The activity board is a regular

Have all operators been trained to the 5S and a meeting point with an activity board

trained to the 5S and there is no evidence of board is set up, but regular team activities time is allocated to the 5S activities. Team and systematic meeting for the team;

5S training and team activities. and is there a continuous 5S team activity has been set up. Regular meetings and

2. team activity. have not started yet. All documents are not members photos are displayed on activity documents are up-to-date. There is a 5S

Audits and follow-up all over the plant, with a regular audit plan teams are developing.

up-to-date. Some audits have been boards together with team action plans. coordinator in each team. The planning of

clearly defined for all the teams?

scheduled, but they are irregular, and the team audits as well as all the elements of

Audits are made by the whole team,

last Audits are made regularly and lead to im the te

supervisors and operators, as

1 2 3-4 5 6

All identified issues are subject to A process for the treatment of abnormalities

Several improvement ideas have been put

Have improvement suggestions, projects A couple of recent improvement ideas and a improvement projects and displayed on (problem solving methodology) and the

forward, they are recent and well displayed

Ideas for improvement, problems and action plans been structured and There are no recent improvement couple of issues have been targeted for an activity boards. Abnormalities are subject to follow-up of improvement ideas has been

3. on the team activity board. Meetings aimed

solving and action projects visually displayed, and are they visible to suggestions, or visible action projects. improvement project and are displayed in a clear improvement process. Action plans set up. Teams have set up a very efficient

at solving some particular issues have been

everyone? the workshop. are shared out between team members and and shared organization for problem

scheduled.

displayed on the team activity board. analysis and action plans follow-up.

1 2 3-4 5 6

The workplace performance indicators are

There are a few performance indicators, but displayed and up-to-date. The results for 5S The performance indicators are followed by

There is no displayed indicator of the

Is everyone informed of the workplace they are not up-to-date, they are still too audits and indicators related to the teams and the 5S action plans progress All teams develop their own action projects,

4 Performance indicators production unit performance and of the 5S

past and present achievements? global or do not reflect correctly the improvements due to the 5S are displayed are being related to a process indicator and process and performance indicators.

progress.

production unit performance. on the activity board or in the production to a financial indicator.

unit.

1 2 3-4 5 6

Saint-Gobain HPM Sector

28/06/05 Productivity Group Europe

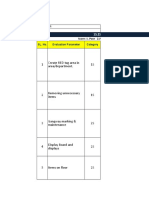

OFFICE 5S CHECK LIST

OFFICE 5S CHECK LIST

1st S: Sort through/sort out Eliminate what is unneeded and decide what is needed

Check item Question 1 2 3-4 5 6

SCORE

FIRST INTEGRATED

INITIAL SITUATION DEVELOPMENT EXCELLENCE

IMPROVEMENTS SYSTEM

Are there any unneeded things (newspapers, samples,

1. Unneeded objects

various items) on shelves and in file cabinets? 0

2. Unneeded files Are there any files requiring specific archiving? 0

Are there any computer cables and wires lying about on

3. Cables and wires

the floor? 0

Are walls, machines or boards covered in unneeded

4, Walls, equipment and partitions

calendars and posters? 0

0

Total S1

Saint-Gobain - HPM Sector 28/06/2005 Productivity Group Europe

2nd S: Set in order Define a specific location for every item needed

Check item Question 1 2 3-4 5 6

FIRST INTEGRATED

INITIAL SITUATION

IMPROVEMENTS

DEVELOPMENT

SYSTEM

EXCELLENCE SCORE

Are shelves and filing cabinets identified with labels,

1. Shelves and filing cabinets

markings and visible codes? 2

Documents, files and binders Is there any indication of title, number, name of person in

2.

identification charge, and/or date on file or binders? 2

Are documents, stationery, materials well-ordered and

3. Easiness of use

easy to reach and return to their location? 1

Are the various areas, cabinets, and offices clearly

4, Areas indication

identified? 2

7

Total S2

Saint-Gobain - HPM Sector 28/06/2005 Productivity Group Europe

3rd S: Shine and sweep Keep the workplace clean and eliminate abnormalities

Check item Question 1 2 3-4 5 6

FIRST INTEGRATED

INITIAL SITUATION

IMPROVEMENTS

DEVELOPMENT

SYSTEM

EXCELLENCE SCORE

Are floors, carpets and walls clean, do paintworks need

1. Cleanliness of floors and walls re-doing? Are windows, shelves and plants regularly 0

dusted and cleaned?

Is there a specific person in charge of keeping files up-to-

2. Updating tasks

date for each subject? 0

Are wastebaskets and destroyer bins regularly emptied

3. Wastebaskets

before they overflow? 0

4, Feeling of tidiness and cleanliness Offices are clean, few documents are not filed. 0

0

Total S3

4th S: Standardize Create a visually managed workplace

Check item Question 1 2 3-4 5 6

SCORE

FIRST INTEGRATED

INITIAL SITUATION DEVELOPMENT EXCELLENCE

IMPROVEMENTS SYSTEM

The location of files, books, articles and stationary can be

1, Visualization seen at a glance. All cabinets are visually defined with 0

their contents.

Is there a procedure for dealing with confidential

2, Confidential documents and archiving

documents and archives? 0

Have team defined a shared filing system in the computer

3, Shared filing system and are the work-in-process files managed with a 0

visual system indicating progress level and things to do?

4, Stationary Are minimum supplies levels clearly indicated? 0

0

Total S4

Sustain improvements and make further company wide

5th S: Sustain improvements

Check item Question 1 2 3-4 5 6

FIRST INTEGRATED

INITIAL SITUATION

IMPROVEMENTS

DEVELOPMENT

SYSTEM

EXCELLENCE SCORE

Do team members carry out regular meetings in a

1, Meetings

specific area? 0

Are activity scheduling, departments tasks and

2. Work schedules and performance

performance indicators clear and visualized? 0

Are meetings and traveling schedules clearly visualized

3. Schedules

and displayed? 0

Have dates been set within the team for audits, and to

4, Audits and updating

update and dispose of documents? 0

0

Total S5

TOTAL SCORE 7

% of ultimate target 5.83%

Saint-Gobain - HPM Sector 28/06/2005 Productivity Group Europe

Potrebbero piacerti anche

- 5S - Excellence Assessment PDFDocumento2 pagine5S - Excellence Assessment PDFAshokNessuna valutazione finora

- 5S Checklist OfficeDocumento1 pagina5S Checklist Officetoxicity23Nessuna valutazione finora

- 5S Audit Checklist - Workplace EvaluationDocumento7 pagine5S Audit Checklist - Workplace EvaluationNenad DeusicNessuna valutazione finora

- 5s ChecklistDocumento8 pagine5s ChecklistMohini MaratheNessuna valutazione finora

- Audit ChecklistDocumento12 pagineAudit Checklistjohnoo7Nessuna valutazione finora

- MSE507 Lean Manufacturing: 5S and The Visual WorkplaceDocumento85 pagineMSE507 Lean Manufacturing: 5S and The Visual WorkplaceSAYFUDDINSG100% (1)

- Basic 5S Audit ChecklistDocumento1 paginaBasic 5S Audit Checklistbasha1900Nessuna valutazione finora

- 5s AuditchecklistDocumento15 pagine5s AuditchecklistChristian PaulsenNessuna valutazione finora

- 5S CFT Audit Checklist-FY 2014-15Documento2 pagine5S CFT Audit Checklist-FY 2014-15arunbiswal100% (1)

- 5s Audit ChecklistDocumento22 pagine5s Audit ChecklistJeevaAJAnanthanNessuna valutazione finora

- 5 S - A PresentationDocumento38 pagine5 S - A Presentationpbalawin43900% (1)

- BF Area - 5S Check ListDocumento30 pagineBF Area - 5S Check ListVi KraNessuna valutazione finora

- 5S Audit Checklist - Workplace EvaluationDocumento5 pagine5S Audit Checklist - Workplace EvaluationDaniel2116Nessuna valutazione finora

- HR - 15 Operator Observance Check SheetDocumento2 pagineHR - 15 Operator Observance Check SheetRavi YadavNessuna valutazione finora

- Non-Conformity Report & Corrective Action: Description of Non-ConformanceDocumento1 paginaNon-Conformity Report & Corrective Action: Description of Non-Conformanceazadsingh1Nessuna valutazione finora

- 6s Evaluation FormDocumento3 pagine6s Evaluation FormDhananjay PatilNessuna valutazione finora

- 5s Workstation AuditchecklistDocumento10 pagine5s Workstation AuditchecklistJamal AbdullahNessuna valutazione finora

- Equipment People: The ISO 9001:2015 Implementation Handbook": Turtle DiagramDocumento3 pagineEquipment People: The ISO 9001:2015 Implementation Handbook": Turtle DiagramTatiana Rilo0% (1)

- Introduction To 5SDocumento98 pagineIntroduction To 5SnahomNessuna valutazione finora

- GLC - 5 S Presentation PDFDocumento118 pagineGLC - 5 S Presentation PDFVenkatesanNessuna valutazione finora

- Supplier Name Auditors: Vendor Attendees:: JudgmentDocumento4 pagineSupplier Name Auditors: Vendor Attendees:: Judgment3A System SolutionNessuna valutazione finora

- 5S Audit ChecklistDocumento12 pagine5S Audit Checklistmogul_hunkNessuna valutazione finora

- Performance Review TemplateDocumento6 paginePerformance Review TemplateDrAnand ShankarNessuna valutazione finora

- 5S Audit Checklist and Report PDFDocumento2 pagine5S Audit Checklist and Report PDFshahiraNessuna valutazione finora

- 8DDocumento117 pagine8DLokesh NarasimhaiahNessuna valutazione finora

- 5S Implementation ProcedureDocumento18 pagine5S Implementation Procedurehim123verNessuna valutazione finora

- 6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1Documento5 pagine6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1stylish eagleNessuna valutazione finora

- WF 2012aug 5s Red Tagging Process Flow LEANDocumento1 paginaWF 2012aug 5s Red Tagging Process Flow LEANGaneshan Mathan RajNessuna valutazione finora

- Draft Site Operating Manual - HUL HO Mumbai (For Joint Discussion With UL Team)Documento1 paginaDraft Site Operating Manual - HUL HO Mumbai (For Joint Discussion With UL Team)Subhranshu ChakrabortyNessuna valutazione finora

- Cis-Sp-18-Customer Complaints HandlingDocumento5 pagineCis-Sp-18-Customer Complaints HandlingVaibhav Gadhawe100% (1)

- Anand Kumar ResumeDocumento3 pagineAnand Kumar ResumeArun ShishodiaNessuna valutazione finora

- Quality Manual With Two Sections of PreDocumento1 paginaQuality Manual With Two Sections of Pretheanjum1980Nessuna valutazione finora

- SPC Training Material - 18!04!2018Documento34 pagineSPC Training Material - 18!04!2018Rajesh KumarNessuna valutazione finora

- 9001 Audit Checklist-Monitoring Measurement and ImprovDocumento7 pagine9001 Audit Checklist-Monitoring Measurement and ImprovAmer RahmahNessuna valutazione finora

- Certification and Certified Forest Products Markets: DR Ruth Nussbaum ProforestDocumento17 pagineCertification and Certified Forest Products Markets: DR Ruth Nussbaum Proforesthalalisan1Nessuna valutazione finora

- One Day Training On KAIZEN: Hilton HotelDocumento74 pagineOne Day Training On KAIZEN: Hilton HotelyinueNessuna valutazione finora

- Non-Conformity Report: Commercial Aircraft GroupDocumento2 pagineNon-Conformity Report: Commercial Aircraft GroupLalit Bom MallaNessuna valutazione finora

- Equipment Name Theme Division TPM Pillar Pilllar Step Basic Work Minor Classification Classification No: Major ClassificationDocumento1 paginaEquipment Name Theme Division TPM Pillar Pilllar Step Basic Work Minor Classification Classification No: Major ClassificationGiö GdlNessuna valutazione finora

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Documento11 pagineISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351100% (1)

- ISO 9001 Lead AuditorDocumento20 pagineISO 9001 Lead AuditorAmer MakenNessuna valutazione finora

- Needs and Expectations RegisterDocumento6 pagineNeeds and Expectations RegisterrrharshaNessuna valutazione finora

- 5S Audit Checklist FactoryDocumento2 pagine5S Audit Checklist FactoryGaneshNessuna valutazione finora

- 5S Audit Checklist and Report 1663039107Documento2 pagine5S Audit Checklist and Report 1663039107Ashish R. SinghNessuna valutazione finora

- ISO 9001:2015 Preparation Steps: No Activities Deadline Person in Charges 1 CommitmentDocumento3 pagineISO 9001:2015 Preparation Steps: No Activities Deadline Person in Charges 1 CommitmentRhisnaErdyDianaNessuna valutazione finora

- 5S Production Area Audit: Location: Date: Scored By: Score: Previous ScoreDocumento2 pagine5S Production Area Audit: Location: Date: Scored By: Score: Previous ScoreGeeTheWhizz100% (1)

- LP LA N: Control PlanDocumento26 pagineLP LA N: Control PlanSyed ShabbirNessuna valutazione finora

- Implement 5 "S" System: Visual FactoryDocumento47 pagineImplement 5 "S" System: Visual FactoryAnil Maurya100% (1)

- Implementation & Monitoring: (Work Place Improvement)Documento112 pagineImplementation & Monitoring: (Work Place Improvement)Sonika SinghNessuna valutazione finora

- ISO 9001:2000 IN A NUTSHELL (First Revision)Documento5 pagineISO 9001:2000 IN A NUTSHELL (First Revision)nallasivam v100% (1)

- 5s Checklist OperationDocumento1 pagina5s Checklist OperationDian PeshevNessuna valutazione finora

- 4M Changing Point ManagementDocumento7 pagine4M Changing Point ManagementKumaravelNessuna valutazione finora

- 5 S ProgramDocumento118 pagine5 S ProgramNatarajan RajNessuna valutazione finora

- Format Issue RecordDocumento4 pagineFormat Issue RecordBharatNessuna valutazione finora

- ZED PresentationDocumento13 pagineZED PresentationSatbir SinghNessuna valutazione finora

- OPL Knowladge SharingDocumento4 pagineOPL Knowladge SharingRakesh TigadiNessuna valutazione finora

- VERIFICATION / CHECK POINTS (Implementation of Countermeasures in Process & Documentation With Date)Documento1 paginaVERIFICATION / CHECK POINTS (Implementation of Countermeasures in Process & Documentation With Date)amritanshuNessuna valutazione finora

- HR Finance Supply Chain Sales Warehouse CRM Quality Manufact UringDocumento1 paginaHR Finance Supply Chain Sales Warehouse CRM Quality Manufact UringPriyankka PRNessuna valutazione finora

- 5S ChecklistDocumento8 pagine5S Checklistx_imranNessuna valutazione finora

- 5S Audit SheetDocumento1 pagina5S Audit SheetSiddharth GuptaNessuna valutazione finora

- WPO Audit - Auditoria WPODocumento2 pagineWPO Audit - Auditoria WPOFabian BenítezNessuna valutazione finora

- MRTS25 Steel Reinforced Precast Concrete PipesDocumento23 pagineMRTS25 Steel Reinforced Precast Concrete Pipeswhutton11Nessuna valutazione finora

- So 01 Struktur OrganisasiDocumento2 pagineSo 01 Struktur Organisasiadry tusangNessuna valutazione finora

- SuperchargerDocumento27 pagineSuperchargerRamachandran SubburathinamNessuna valutazione finora

- Slope Site SolutionsDocumento2 pagineSlope Site SolutionspolyplopNessuna valutazione finora

- 3 Nelson - Up, Up, and Away! - AnswersDocumento3 pagine3 Nelson - Up, Up, and Away! - Answersdmccloy28Nessuna valutazione finora

- Working Method For Piping Installation - Add Method For Boom Lift 227KgDocumento58 pagineWorking Method For Piping Installation - Add Method For Boom Lift 227KgPhát NguyễnNessuna valutazione finora

- JT Series Miter Gearbox: Jacton Electromechanical Co.,LtdDocumento32 pagineJT Series Miter Gearbox: Jacton Electromechanical Co.,LtdWarren LeeNessuna valutazione finora

- RECENT Engineer Hamza Akhtar's CVDocumento2 pagineRECENT Engineer Hamza Akhtar's CVHamza Akhtar100% (1)

- DPW LGM Large Ground MountDocumento2 pagineDPW LGM Large Ground MountArshia GhNessuna valutazione finora

- Form and Position: LubricationDocumento72 pagineForm and Position: LubricationSavoNessuna valutazione finora

- Warranty Certificate NO:: Customer Name & AddressDocumento1 paginaWarranty Certificate NO:: Customer Name & AddressCursed PalzNessuna valutazione finora

- Agro Process Flowchart CG and Seed - May 17 - FinalDocumento26 pagineAgro Process Flowchart CG and Seed - May 17 - FinalMarkandeya SatyanarayanaNessuna valutazione finora

- Electrical Engineering PortalDocumento25 pagineElectrical Engineering Portalraul_bsuNessuna valutazione finora

- Lifts & Escalators: (Transportation System in Buildings)Documento43 pagineLifts & Escalators: (Transportation System in Buildings)ShubhaNessuna valutazione finora

- "Shear Sensation Plus" All-Purpose Grease: Trust Omega TODocumento2 pagine"Shear Sensation Plus" All-Purpose Grease: Trust Omega TOchem KhanNessuna valutazione finora

- IS 15183 2002 Part-3 Guidelines For Maintenance Management of Buildings, Part 3 LabourDocumento10 pagineIS 15183 2002 Part-3 Guidelines For Maintenance Management of Buildings, Part 3 LabourShree Krishna GroupNessuna valutazione finora

- AKA Company ProfileDocumento25 pagineAKA Company ProfileFahim ChapraNessuna valutazione finora

- Construction Finance Management NCP 29Documento28 pagineConstruction Finance Management NCP 29Kavvindra MehraNessuna valutazione finora

- Sport KingDocumento7 pagineSport KingPoorti GargNessuna valutazione finora

- ISO Observation Points by AuditorsDocumento2 pagineISO Observation Points by Auditorsvishwas salunkheNessuna valutazione finora

- Best Practices For Global MES RolloutsDocumento8 pagineBest Practices For Global MES RolloutsCognizantNessuna valutazione finora

- PSC Girder Over River Surma - Bangladesh - Good Construction ExampleDocumento6 paginePSC Girder Over River Surma - Bangladesh - Good Construction ExampleAnand Shah100% (1)

- Tubes Properties Arcelor MittalDocumento20 pagineTubes Properties Arcelor Mittalanil-kumar-singh-6674Nessuna valutazione finora

- Project Report Ultratech CemntDocumento149 pagineProject Report Ultratech CemntNirav Parmar80% (5)

- Data Lake For HadoopDocumento12 pagineData Lake For Hadoopg17_ram100% (2)

- The History of Space DebrisDocumento13 pagineThe History of Space DebrisMukesh KarunanethyNessuna valutazione finora

- Building Decision Support System User InterfaceDocumento24 pagineBuilding Decision Support System User InterfacePostolache Adina IulianaNessuna valutazione finora

- DAIRY FARM GROUP - Redesign of Business Systems and Processes - Case AnalysisDocumento5 pagineDAIRY FARM GROUP - Redesign of Business Systems and Processes - Case Analysisbinzidd007Nessuna valutazione finora

- Procedure For Positive Material Identification PmiDocumento2 pagineProcedure For Positive Material Identification PmiMohamed NabilNessuna valutazione finora