Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Top259en PDF

Caricato da

Jose BenavidesTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Top259en PDF

Caricato da

Jose BenavidesCopyright:

Formati disponibili

DI-182 Design Idea

®

TOPSwitch-HX

Standard 65 W Notebook Adapter Which Meets

Requirements for Energy Star 2.0 (ES 2.0)

Application Device Power Output Input Voltage Output Voltage Topology

Notebook TOP259EN 65 W 90 – 265 VAC 19 V ±5% Flyback

Design Highlights Operation

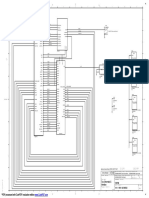

• Very compact, low part-count The power supply design shown in Figure 1 utilizes the

• Low profile eSIP-7C Single-Inline package TOP259EN. The TOPSwitch-HX products integrate a 700 V

• Same thermal impedance characteristics as standard MOSFET with a multi-function PWM controller in one device. The

TO-220 package optimized combination of switching MOSFET and integrated driver

• Allows lower overall height and smaller board footprint present for low switching loss enable a highly efficient and

• Clip mounted eSIP package easily passes shock and compact 65 W notebook power supply able to safely operate in a

vibration test to IEC60068 sealed enclosure up to an ambient temperature of 40 °C.

• Highly energy efficient

• Very low no-load input power: <250 mW at 230 VAC The bridge rectifier BR1, at the input of the power supply, rectifies

• High average efficiency: >87.5% meeting ENERGY STAR the line input; electrolytic capacitor C2 filters the input. Fuse F1

v2.0 draft requirements (measured at the end of cable: 1.8 m, protects against catastrophic failure. Common mode EMI is

18 AWG, 100 mΩ impedance) filtered by L1, L2, L3, C3, and C11. Common-mode choke L2

• 132 kHz operation allows small transformer (EE28) filters lower frequencies while L3 filters higher frequencies.

• Internal current-limit reduction vs line-voltage increase removes Differential filtering is provided by the leakage inductance of L2

need for secondary side current limiting used to meet power- and X capacitor C1. As C1 has a capacitance greater than 0.1 μF,

limited source requirements discharge resistors R1 and R2 are required to discharge C1 after

• Accurate hysteretic thermal shutdown protection removal of AC. To reduce differential EMI generation C5 provides

• Timed over-load protection with automatic recovery decoupling for the primary switching current.

• Meets CISPR-22/EN55022 B conducted EMI limits

C11 C12

2.2 nF 1 nF R16

250 VAC 100 V 33 7

C4 C13 C14

2.2 nF T1 470 MF 470 MF

1 kV 25 V 25 V 19 V, 3.42 A

1 EE28 FL1

BR1 D6

3KBP08M R5 MBR20100CT

100 k7 FL2

R6 1/2 W

C10 R10 RTN

33 7 VR1

22 MF 301 7 1N5248B

3 50 V 1%

4 18 V

R3 R7 D5 C8

2.0 M7 5.1 M7 BAV 100 nF

D1 19WS

DL4937 5 50 V

R11

2 M7

L3 R22 C19

12 mH R4 R8 R18

20 k7 470 pF 680 7

2.0 M7 6.8 M7 50 V

C2

L2 120 MF R12

200 MH 400 V 5.1 k7

C5

100 nF D3

400 V BAV19WS

U3A

C9 ISP817C

100 nF U3B

R1 R2 TOPSwitch-HX 25 V ISP817C

2.2 M7 2.2 M7 U1

D V TOP259EN

F1 C1 CONTROL R19

C

4A 330 nF C17 68.1 k7

275 VAC 100 nF

L R15

S X F

C6 6.8 7 R21

E

100 nF 1 k7

C3 R9 50 V C7

N 470 pF 14 k7 47 MF

250 VAC 1% 16 V

90 - 265 U2

VAC LM431 R20

L1 2% 10 k7

Ferrite Bead 1%

PI-5023-071408

Figure 1: Schematic of a 65 W Notebook Adapter Power Supply Using TOPSwitch-HX TOP259EN.

www.powerint.com July 2008

The TOP259EN, with its integrated multi-mode controller, is used Key Design Points

in a flyback configuration. It maintains output regulation by • Verify that the maximum drain voltage does not exceed 650 V

changing the duty cycle as a function of the control pin current. at high line and maximum overload. Adjust the values of C4 and

To maintain high efficiency across the whole load range, the multi- R5 as necessary.

mode controller changes between pulse width modulation and • Resistor R6 dampens high frequency ringing and improves EMI.

fixed on-time variable frequency control. To provide constant • Select the value of VR1 such that it does not falsely trigger OVP.

output overload power with changing line voltage, as line voltage VR1 should be chosen above the bias-winding voltage mea-

increases, resistors R7, R8, and R9 reduce the internal current sured under low line and full load conditions.

limit of the TOP259EN. This allows the supply to limit the output • If latching OVP is desired, select R12 as 20 Ω.

overload power to <100 VA at high line, while still delivering the • U1 does not require an insulating pad for reduced EMI. It has a

rated output at low line. tab connected to the electrically “quiet” source.

80

PI-5049-032508

The primary side’s output overvoltage protection (OVP) senses the

bias-winding voltage using Zener diode VR1. This is used to 70

provide both open-loop protection and output-overload protection QP

60

under a single-fault condition. Resistors R10 and R11 with

AV

capacitor C8 determine the delay before shutdown is triggered. 50

This prevents false triggering during startup and load transients.

40

The value of R12 selects the hysteretic shutdown behavior of U1.

dBMV

Capacitor C9 helps to filter high frequency noise that may appear 30

on the V pin.

20

The output is rectified by diode D6 which has an RC snubber (C12 10

and R16) to dampen leakage inductance ringing and reduce

0

radiated EMI. The output is filtered by capacitors C13 and C14.

-10

Feedback is derived from the output via optocoupler U3A.

-20

Resistor R18 sets the DC gain. Shunt regulator U2 has an 0.15 1.0 10.0 100.0

accurate internal voltage reference, and with resistors R19 and

MHz

R20, sets the output voltage to 19 V.

Figure 3. Conducted EMI, EN55022 B Limits. Measurements Made at 230 VAC

With 5.6 Ω Resistive Load (Output Grounded).

Diode D3 prevents loading of the V pin by the OVP circuit and also

isolates the line sense circuit from the OVP circuit. Transformer Parameters

EE28, TDK or equivalent, gapped for ALG of

Core Material

299 nH/t²

320 Bobbin Vertical 10 pin, pin 6 to pin 10 are to be removed

PI-5048-032508

Bias: 5T × 3, 30 AWG

280

Primary 1: 17T × 2, 26 AWG

240 Shield: 1T Cu foil, 1 mil thick

Input Power (mW)

Winding Details

Secondary: 6T × 4, 26 AWG-TIW

200 Shield: 1T Cu foil, 1 mil thick

Primary 2: 17T × 2, 25 AWG

160 Bias (4–5), Primary-1 (3–2), Shield (1–NC),

Winding Order Secondary (FL1–FL2), Shield (1–NC),

120 Primary-2 (2–1)

80 Primary Inductance 343 μH, ±5% at 132 kHz

Primary Resonant 1.1 MHz (minimum)

40 Frequency

0 Leakage

Inductance 4 μH (maximum)

90 115 140 165 190 215 240 265

Table 1. Transformer Parameters. (AWG = American Wire Gauge,

Input Voltage (VAC) TIW = Triple Insulated Wire, NC = No Connection)

Figure 2. No Load Input Power vs. Line Voltage.

Power Integrations Power Integrations reserves the right to make changes to its products at any time to improve reliability or manufacturability. Power

5245 Hellyer Avenue Integrations does not assume any liability arising from the use of any device or circuit described herein. POWER INTEGRATIONS

San Jose, CA 95138, USA. MAKES NO WARRANTY HEREIN AND SPECIFICALLY DISCLAIMS ALL WARRANTIES INCLUDING, WITHOUT LIMITATION, THE IMPLIED

Main: +1 408-414-9200 WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF THIRD PARTY RIGHTS.

Customer Service The products and applications illustrated herein (transformer construction and circuits external to the products) may be covered by

Phone: +1-408-414-9665 one or more U.S. and foreign patents or potentially by pending U.S. and foreign patent applications assigned to Power Integrations.

Fax: +1-408-414-9765 A complete list of Power Integrations' patents may be found at www.powerint.com. Power Integrations grants

Email: usasales@powerint.com its customers a license under certain patent rights as set forth at http://www.powerint.com/ip.htm.

The PI logo, TOPSwitch, TinySwitch, LinkSwitch, DPA-Switch, PeakSwitch, EcoSmart, Clampless, E-Shield, Filterfuse, StackFET,

On the Web PI Expert and PI FACTS are trademarks of Power Integrations, Inc. Other trademarks are property of their respective companies.

www.powerint.com ©2008, Power Integrations, Inc.

A

07/08 DI-182

Potrebbero piacerti anche

- Di22 HP 70 W 19 V External Laptop Adapter Schematic DiagramDocumento2 pagineDi22 HP 70 W 19 V External Laptop Adapter Schematic DiagramTonpitonpi Ton Pi75% (4)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Sony Play Station 2 Laser Calibration Using OscilloscopeDocumento10 pagineSony Play Station 2 Laser Calibration Using OscilloscopeH3liax100% (1)

- North China Research Institute 13m Ka-Band AntennaDocumento5 pagineNorth China Research Institute 13m Ka-Band Antennaanon_142925513Nessuna valutazione finora

- SQ11 Manual Ord-InfoDocumento4 pagineSQ11 Manual Ord-InfoMahmoud Saeed100% (4)

- DatasheetDocumento2 pagineDatasheetRyanz Nayrz100% (1)

- Di-187 Design Idea Topswitch-Hx: 35 W LCD MonitorDocumento2 pagineDi-187 Design Idea Topswitch-Hx: 35 W LCD MonitorIvanê FonsecaNessuna valutazione finora

- TNY278PNDocumento4 pagineTNY278PNJose BenavidesNessuna valutazione finora

- Di-91 Design Idea Tinyswitch-Iii: 12 W Universal Input CV AdapterDocumento2 pagineDi-91 Design Idea Tinyswitch-Iii: 12 W Universal Input CV Adapterahmed chaouki ChamiNessuna valutazione finora

- Di146 0Documento2 pagineDi146 0amitNessuna valutazione finora

- Di-123 Design Idea Tinyswitch-Iii: 9.65 W, Dual Output Power Supply For Residential Heating ControlDocumento2 pagineDi-123 Design Idea Tinyswitch-Iii: 9.65 W, Dual Output Power Supply For Residential Heating Controlahmed chaouki ChamiNessuna valutazione finora

- Di-198 Design Idea Linkswitch-Cv: Wide Range DVD Player Multiple Output Power Supply Without Need For OptocouplerDocumento2 pagineDi-198 Design Idea Linkswitch-Cv: Wide Range DVD Player Multiple Output Power Supply Without Need For OptocouplerAllyfranhy Nunes AlvesNessuna valutazione finora

- TNY264PNDocumento6 pagineTNY264PNJose Benavides100% (1)

- Constant Current/Constant Power Regulation Circuits For: TopswitchDocumento16 pagineConstant Current/Constant Power Regulation Circuits For: TopswitchBharat Singh AhluwaliaNessuna valutazione finora

- Application Note An-45 Linkswitch-Cv Family: Design GuideDocumento18 pagineApplication Note An-45 Linkswitch-Cv Family: Design Guidebharath prabhuNessuna valutazione finora

- Slyt 391Documento5 pagineSlyt 391deedeeNessuna valutazione finora

- Tops WithDocumento8 pagineTops Withtiburcio2000Nessuna valutazione finora

- Topswitch: Flyback Transformer Design For Power SuppliesDocumento12 pagineTopswitch: Flyback Transformer Design For Power SuppliesShirish BhagwatNessuna valutazione finora

- 45W Ac-Dc Adapter With Standby Function: AN1134 Application NoteDocumento9 pagine45W Ac-Dc Adapter With Standby Function: AN1134 Application NoteGrzegorz WegnerNessuna valutazione finora

- LNK364PNDocumento2 pagineLNK364PNJose Benavides100% (2)

- Halogen 12vDocumento17 pagineHalogen 12veryNessuna valutazione finora

- An2001 Application Note: Vipower™: The Viper53-E Single Output Reference Board With 90 To 264 Vac Input, 24 W OutputDocumento6 pagineAn2001 Application Note: Vipower™: The Viper53-E Single Output Reference Board With 90 To 264 Vac Input, 24 W OutputamitNessuna valutazione finora

- 1.5A Switch Step Down Switching Regulator: 1 General FeaturesDocumento11 pagine1.5A Switch Step Down Switching Regulator: 1 General FeaturesRene gNessuna valutazione finora

- Datasheet PDFDocumento6 pagineDatasheet PDFMichael DavenportNessuna valutazione finora

- Mc34063 Led DriverDocumento7 pagineMc34063 Led Driverelcomandante100% (1)

- Pdiol 2008dec24 Supply An 01Documento3 paginePdiol 2008dec24 Supply An 01Roberto De Mesa PNessuna valutazione finora

- H2PToday2207 Design Innovatia Part5Documento9 pagineH2PToday2207 Design Innovatia Part5juanNessuna valutazione finora

- L 5973 DDocumento17 pagineL 5973 DahmedcoNessuna valutazione finora

- Obsolete Product(s) - Obsolete Product(s) : EVL6562A-TM-80WDocumento6 pagineObsolete Product(s) - Obsolete Product(s) : EVL6562A-TM-80Wkamran moradiNessuna valutazione finora

- Half Bridge Driver With IR2153 IGBT PDFDocumento4 pagineHalf Bridge Driver With IR2153 IGBT PDFShibu Kumar SNessuna valutazione finora

- Documentatie Corector de Ton Cu 3 BenziDocumento7 pagineDocumentatie Corector de Ton Cu 3 BenziNicoleta NiţăNessuna valutazione finora

- dn359f PDFDocumento2 paginedn359f PDFo penNessuna valutazione finora

- FAN7314 LCD Backlight Inverter Drive IC: Features DescriptionDocumento3 pagineFAN7314 LCD Backlight Inverter Drive IC: Features DescriptionJúnior Da Silva SantanaNessuna valutazione finora

- dn359f PDFDocumento2 paginedn359f PDFo penNessuna valutazione finora

- 23V 3A 650KHz Synchronous Step-Down DC/DC ConverterDocumento13 pagine23V 3A 650KHz Synchronous Step-Down DC/DC ConverterwalmirNessuna valutazione finora

- 2 UkDocumento2 pagine2 UkJosé ManuelNessuna valutazione finora

- Tps 61197Documento22 pagineTps 61197Sahaly RandNessuna valutazione finora

- TNY268PNDocumento2 pagineTNY268PNJose BenavidesNessuna valutazione finora

- FR9886Documento12 pagineFR9886abrkNessuna valutazione finora

- Off-Line Quasi-Resonant Switching Regulators: STR-Y6763, STR-Y6765, and STR-Y6766Documento13 pagineOff-Line Quasi-Resonant Switching Regulators: STR-Y6763, STR-Y6765, and STR-Y6766Renato Luther escalanteNessuna valutazione finora

- FAN7314A - : LCD Backlight Inverter Drive ICDocumento3 pagineFAN7314A - : LCD Backlight Inverter Drive ICКОРЮН ГАБРИЕЛЯНNessuna valutazione finora

- DM0265R ONSemiconductorDocumento16 pagineDM0265R ONSemiconductorAdriano HenriqueNessuna valutazione finora

- 40V 4.5A Quad Power Half Bridge: Multipower BCD TechnologyDocumento9 pagine40V 4.5A Quad Power Half Bridge: Multipower BCD TechnologyDelcu MarinicaNessuna valutazione finora

- IrsolwibDocumento4 pagineIrsolwibleko17100% (2)

- Data Sheet: Stereo Cassette Head Preamplifier and EqualizerDocumento16 pagineData Sheet: Stereo Cassette Head Preamplifier and EqualizerahmedNessuna valutazione finora

- DE1 Lab ReportDocumento7 pagineDE1 Lab ReportRuth Abegail de VeraNessuna valutazione finora

- MP2225GJ-Z Circuito IntegratoDocumento20 pagineMP2225GJ-Z Circuito IntegratoMimmo FracchiollaNessuna valutazione finora

- EEN360: Electronics Circuits Lab Assignment 1 BJT Amplifiers Frequency RespondDocumento6 pagineEEN360: Electronics Circuits Lab Assignment 1 BJT Amplifiers Frequency RespondMohammed ShifulNessuna valutazione finora

- One-Shot Phase Control IC U490B: FeaturesDocumento7 pagineOne-Shot Phase Control IC U490B: FeaturesIulian Cristian AvramovNessuna valutazione finora

- Evaluation and Finding of Isolated Flyback Converter: © 2016 ROHM Co.,LtdDocumento29 pagineEvaluation and Finding of Isolated Flyback Converter: © 2016 ROHM Co.,LtdNhatNessuna valutazione finora

- STA508A: 45V 4.5A Quad Power Half BridgeDocumento11 pagineSTA508A: 45V 4.5A Quad Power Half BridgeJosue GarciaNessuna valutazione finora

- DatasheetDocumento11 pagineDatasheetGeorges TaradauxNessuna valutazione finora

- L 6928D - ReguladorDocumento9 pagineL 6928D - ReguladorTiago LeonhardtNessuna valutazione finora

- 23V DC-DC Converter with Adjustable OutputDocumento15 pagine23V DC-DC Converter with Adjustable OutputJuan Carlos VillegasNessuna valutazione finora

- ECE - 304L - Lab - 8 - Square - Wave - Generation - 1Documento2 pagineECE - 304L - Lab - 8 - Square - Wave - Generation - 1irfanNessuna valutazione finora

- An 0373 Env 130Documento13 pagineAn 0373 Env 130Danio RerioNessuna valutazione finora

- 2.5A Switch Step Down Switching Regulator: DescriptionDocumento10 pagine2.5A Switch Step Down Switching Regulator: DescriptionVictor CuaicalNessuna valutazione finora

- KSGER 96W 24V 5A Electric Power Supply Unit For STM32 STC OLED T12 Digital DIY Soldering Station ControllerDocumento1 paginaKSGER 96W 24V 5A Electric Power Supply Unit For STM32 STC OLED T12 Digital DIY Soldering Station ControllerTom Tom100% (3)

- Data Sheet: Low-Voltage Variable Capacitance Double DiodeDocumento8 pagineData Sheet: Low-Voltage Variable Capacitance Double Diodevladimir tomicNessuna valutazione finora

- Reference Design - 1 STR-A6151 Universal-Input, 10 W Power SupplyDocumento2 pagineReference Design - 1 STR-A6151 Universal-Input, 10 W Power Supplygary omanaNessuna valutazione finora

- LM3500 Synchronous Step-Up DC/DC Converter For White LED ApplicationsDocumento26 pagineLM3500 Synchronous Step-Up DC/DC Converter For White LED ApplicationsIngenieria MultifuncionalNessuna valutazione finora

- Tps 650250Documento36 pagineTps 650250Jaime SaliganNessuna valutazione finora

- Induction Cooktop: Cooking PerformanceDocumento2 pagineInduction Cooktop: Cooking PerformanceJose BenavidesNessuna valutazione finora

- Pioneer Plasma Top10 Repair Tips pdp-433cmx 434 4300 4304 4310 4314hd 4330 4340 502mx 505hd 504 5004 5014 5030 5031 5040 Pro-800 810 910 1000 1010 1110Documento6 paginePioneer Plasma Top10 Repair Tips pdp-433cmx 434 4300 4304 4310 4314hd 4330 4340 502mx 505hd 504 5004 5014 5030 5031 5040 Pro-800 810 910 1000 1010 1110Daniboy1994Nessuna valutazione finora

- Design Example Report: TitleDocumento19 pagineDesign Example Report: TitleJose BenavidesNessuna valutazione finora

- TNY268PNDocumento2 pagineTNY268PNJose BenavidesNessuna valutazione finora

- Bluetooth antenna connector padsDocumento1 paginaBluetooth antenna connector padsJose BenavidesNessuna valutazione finora

- Printed circuit boards main/crt componentsDocumento1 paginaPrinted circuit boards main/crt componentsJose BenavidesNessuna valutazione finora

- NT-R60 Plus SAMSUNG Laptop - Notebook 06. Electrical Part ListDocumento22 pagineNT-R60 Plus SAMSUNG Laptop - Notebook 06. Electrical Part ListJose BenavidesNessuna valutazione finora

- How to print large block diagrams in sectionsDocumento2 pagineHow to print large block diagrams in sectionsJose BenavidesNessuna valutazione finora

- The Ultimate DVD Region Hack Guide Book LIBROS de DVDDocumento143 pagineThe Ultimate DVD Region Hack Guide Book LIBROS de DVDlondon335Nessuna valutazione finora

- TNY264PNDocumento6 pagineTNY264PNJose Benavides100% (1)

- Di-117 Design Idea Tinyswitch-Iii: 15 W, 12 V Adapter With 100 MW No-Load ConsumptionDocumento8 pagineDi-117 Design Idea Tinyswitch-Iii: 15 W, 12 V Adapter With 100 MW No-Load ConsumptionJose BenavidesNessuna valutazione finora

- TNY277PNDocumento2 pagineTNY277PNJose BenavidesNessuna valutazione finora

- LNK362 PDFDocumento16 pagineLNK362 PDFJose BenavidesNessuna valutazione finora

- Di-18 Design Idea Linkswitch: Low Cost 2.75 W CV/CC Charger or AdapterDocumento4 pagineDi-18 Design Idea Linkswitch: Low Cost 2.75 W CV/CC Charger or AdapterJose Benavides100% (1)

- LNK302P Der-92Documento14 pagineLNK302P Der-92Jose BenavidesNessuna valutazione finora

- LNK364PNDocumento2 pagineLNK364PNJose Benavides100% (2)

- TOP261LNDocumento50 pagineTOP261LNJose BenavidesNessuna valutazione finora

- China 17-Lcd-power-Inverter Oz9938 Top245 SCHDocumento2 pagineChina 17-Lcd-power-Inverter Oz9938 Top245 SCHRicardo Chaman ChavezNessuna valutazione finora

- TOP244PDocumento112 pagineTOP244PJose BenavidesNessuna valutazione finora

- Design Example Report: TitleDocumento63 pagineDesign Example Report: TitleJose BenavidesNessuna valutazione finora

- Design Example Report: Title Specification Application Author Document Number Date RevisionDocumento40 pagineDesign Example Report: Title Specification Application Author Document Number Date RevisionJose Benavides100% (1)

- TOP258PNDocumento46 pagineTOP258PNJose BenavidesNessuna valutazione finora

- TOP233YDocumento24 pagineTOP233YJose BenavidesNessuna valutazione finora

- Datasheet B985Documento4 pagineDatasheet B985Jose BenavidesNessuna valutazione finora

- Di-143 Design Idea Topswitch-Hx: High Effi Ciency Inkjet Power Supply Provides Up To 80 Watts of Peak PowerDocumento2 pagineDi-143 Design Idea Topswitch-Hx: High Effi Ciency Inkjet Power Supply Provides Up To 80 Watts of Peak PowerJose BenavidesNessuna valutazione finora

- TOP250YNDocumento38 pagineTOP250YNJose BenavidesNessuna valutazione finora

- TOP257ENDocumento34 pagineTOP257ENJose BenavidesNessuna valutazione finora

- ACL LabDocumento30 pagineACL LabPaola Andrea Beniz NaipánNessuna valutazione finora

- IAC-18B217x45506 Revision 1Documento16 pagineIAC-18B217x45506 Revision 1Pablo Andres CartesNessuna valutazione finora

- Vivitek NovoTouch EK750i Preliminary Datasheet V6 07122019 PDFDocumento1 paginaVivitek NovoTouch EK750i Preliminary Datasheet V6 07122019 PDFPusparajahNessuna valutazione finora

- Introduction To Teletraffic TheoryDocumento8 pagineIntroduction To Teletraffic Theoryjeet259Nessuna valutazione finora

- Cebek I 208 User ManualDocumento4 pagineCebek I 208 User ManualAbu Bakr M. SaeedNessuna valutazione finora

- En 300 330 V2.1.0 PDFDocumento74 pagineEn 300 330 V2.1.0 PDFSosialNessuna valutazione finora

- Samsung CS29A5HT8XBWT PDFDocumento53 pagineSamsung CS29A5HT8XBWT PDFHootOwl IDNessuna valutazione finora

- DSP Chapter 4 Sampling of Continuous-time SignalsDocumento29 pagineDSP Chapter 4 Sampling of Continuous-time SignalsShah HussainNessuna valutazione finora

- s7300 PDFDocumento238 pagines7300 PDFLong HuynhNessuna valutazione finora

- Configuring A DC Sweep Analysis in Multisim - National InstrumentsDocumento4 pagineConfiguring A DC Sweep Analysis in Multisim - National InstrumentsDina Alagić GolužaNessuna valutazione finora

- G5725 1MHz 1A Synchronous Step-Down RegulatorDocumento2 pagineG5725 1MHz 1A Synchronous Step-Down RegulatorM. M.Nessuna valutazione finora

- ACS-AP Control PanelsDocumento22 pagineACS-AP Control PanelsAdrián ValenzuelaNessuna valutazione finora

- Shannon-Weaver Model of Communication - 7 Key Concepts (2020)Documento10 pagineShannon-Weaver Model of Communication - 7 Key Concepts (2020)Afif Kim100% (1)

- Part I ADocumento206 paginePart I AsenthilkumaranvNessuna valutazione finora

- Enhancement of ALSA Firewire Stack: AcknowledgementDocumento65 pagineEnhancement of ALSA Firewire Stack: AcknowledgementBNessuna valutazione finora

- Novatek nt96655 Data SheetDocumento56 pagineNovatek nt96655 Data Sheetapi-432313169Nessuna valutazione finora

- Huawei S3700 Naming Rules and Device StructureDocumento6 pagineHuawei S3700 Naming Rules and Device StructureElizabeth RichNessuna valutazione finora

- DTFT Review1Documento10 pagineDTFT Review1Abhishek Joshi100% (1)

- Instruction Manual: CT10X Barcode ScannerDocumento75 pagineInstruction Manual: CT10X Barcode ScannerLuis Y.M.Nessuna valutazione finora

- Mortek - EKKXO Cabinet - Installation Manual v1.1Documento4 pagineMortek - EKKXO Cabinet - Installation Manual v1.1Vasilis TserosNessuna valutazione finora

- DSP Lab # 8 Sampling in Time Domain: QuestionsDocumento3 pagineDSP Lab # 8 Sampling in Time Domain: QuestionsnoumanNessuna valutazione finora

- Design and Implementation of Hamming Code Using VHDL & DSCH: Divya Mokara, Sushmi Naidu, Akash Kumar GuptaDocumento8 pagineDesign and Implementation of Hamming Code Using VHDL & DSCH: Divya Mokara, Sushmi Naidu, Akash Kumar GuptaAbdulrahman behiryNessuna valutazione finora

- Manual Caixas JBL N24Documento4 pagineManual Caixas JBL N24Reilton AzeredoNessuna valutazione finora

- 50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDDocumento3 pagine50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDshyhuNessuna valutazione finora

- ManualDocumento100 pagineManualstephen dinopolNessuna valutazione finora

- Monte Carlo Simulation:: Figure 1: UMTS Coverage DisplayDocumento2 pagineMonte Carlo Simulation:: Figure 1: UMTS Coverage DisplaySulis Setiawati FirdausNessuna valutazione finora

- Ethos Overdrive Amp Spec Sheet RevBDocumento2 pagineEthos Overdrive Amp Spec Sheet RevBmikletNessuna valutazione finora

- LICDocumento5 pagineLICSandesh RSNessuna valutazione finora