Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Structural Notes

Caricato da

noelCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Structural Notes

Caricato da

noelCopyright:

Formati disponibili

REPUBLIC OF THE PHILIPPINES

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

H

OFFICE OF THE BUILDING OFFICIAL

MANDAUE CITY

ISSUANCE RECOMMENDED

H

GENERAL STRUCTURAL/CONSTRUCTION NOTES AND SPECIFICATIONS

H

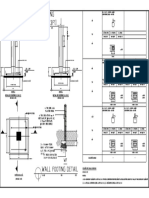

CRITICAL SECTION

(INTERIOR FACE OF HEAD STRUCTURAL DATE

SUPPORT)

(A) GENERAL REQUIREMENTS SECTION

ISSUED BY:

1. ALL STRUCTURAL MATERIALS AND WORK SHALL CONFORM TO THE REQUIREMENTS 6. MAINTAIN MINIMUM CONCRETE COVER FOR REINFORCING STEEL AS FOLLOWS:

OF THE LATEST EDITION OF THE NATIONAL STRUCTURAL CODE OF THE PHILIPPINES

FOOTINGS (CAST AGAINST & EXPOSED TO EARTH) . . . . . 75MM (3")

(NSCP 2010).

WHERE CONCRETE IS EXPOSED TO BUILDING OFFICIAL DATE

2. VERIFY ALL DIMENSIONS, ELEVATIONS AND SITE CONDITIONS BEFORE STARTING

EARTH BUT POURED AGAINST FORMS . . . . . . . . . . . . . . . . 50MM (2") WHERE:

WORK. NOTIFY THE ENGINEER IMMEDIATELY OF ANY DISCREPANCIES. Ldh = DEVELOPMENT LENGTH FOR

40MM ( 1 1/2") STANDARD HOOK NOTE:

SLAB ON GRADE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. NOTES AND DETAILS ON THE DRAWINGS TAKE PRECEDENCE OVER THE GENERAL H H = EXTENSION

This drawing is property of Archiglobal, Inc. whether the object for which they are

NOTES AND TYPICAL DETAILS IN CASE OF CONFLICT. COLUMN TIES OR SPIRALS AND BEAM STIRRUPS . . . . . . . 40MM ( 1 1/2") Ldh

r = INSIDE RADIUS OF BEND

made is executed or not. Do not reproduce and disclose this drawing to any

*ONLY WHEN USED AS COMPRESSION MEMBER IN FOOTING, unauthorized person without the written consent of Archiglobal, Inc.

4. WHERE CONSTRUCTION DETAILS ARE NOT SHOWN OR NOTED FOR ANY PART OF THE SUSPENDED SLABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20MM ( 3/4") SPLICED WITH DOWELS OR WHEN LAP SPLICED

WITH SMALLER BAR.

WORK, SUCH DETAILS SHALL BE THE SAME AS FOR SIMILAR WORK SHOWN ON THE Do not scale this drawing. All dimensions have to be verified on site. All

DRAWINGS. 7. SPLICES SHALL BE SECURELY WIRED TOGETHER AND SHALL LAP AT LEAST 40 TIMES STANDARD HOOKS discrepancies have to be clarified with the Project Architect.

DIAMETER OR 600MM WHICHEVER IS GREATER. STAGGER BOTTOM AT LEAST 1.50M STIRRUPS AND TIE HOOKS

All dimensions are in millimeters unless otherwise specified.

5. PIPES, DUCTS, SLEEVES, CHASES, ETC. SHALL NOT BE PLACED IN SLABS, BEAMS, OR FROM SPLICES IN OTHER BOTTOM REINFORCEMENT. STAGGER SPLICES FOR TOP

WALLS UNLESS SPECIFICALLY SHOWN OR NOTED NOR SHALL ANY STRUCTURAL

MEMBER BE CUT FOR PIPES, DUCTS, ETC. UNLESS SPECIFICALLY SHOWN. OBTAIN

REINFORCEMENT SIMILARLY. TABLE OF LAP SPLICE All levels indicated are finish floor levels in meters unless otherwise specified.

PRIOR WRITTEN APPROVAL FROM THE ENGINEER FOR INSTALLATION OF ANY 8. ALL ANCHOR BOLTS, DOWELS, AND OTHER INSERTS SHALL BE PROPERLY

ADDITIONAL PIPES, DUCTS, ETC. POSITION AND SECURED IN PLACE PRIOR TO PLACING OF CONCRETE. PARAMETERS

LOCATE AND PROTECT UNDERGROUND OR CONCEALED CONDUIT, PLUMBING OR 9. ALL CONCRETE SHALL BE KEPT MOIST FOR A MINIMUM OF 7 CONSECUTIVE DAYS MATERIAL psi MPa ACI 318-05

OTHER UTILITIES WHERE NEW WORK IS BEING PERFORMED. IMMEDIATELY AFTER POURING BY THE USE OF CURING COMPOUNDS, OR OTHER f'c 5000 34.5 DEV'T & SPLICE LENGTH

6. LOCATE AND PROTECT UNDERGROUND OR CONCEALED CONDUIT, PLUMBING OR APPROVED METHODS.

fy 60000 414 16mm & HIGHER

OTHER UTILITIES WHERE NEW WORK IS BEING PERFORMED. 10. STRIPPING OF FORMS AND SHORES: fyh 40000 276 12mm & LOWER

7. TAKE NECESSARY PRECAUTIONS TO MAINTAIN AND INSURE THE INTEGRITY OF THE FOUNDATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 HRS. tie Ø 10 stirrup Ø 10

STRUCTURE DURING CONSTRUCTION. NEITHER THE OWNER NOR SUSPENDED SLAB EXCEPT WHEN fyt 40000 fyt 40000

ARCHITECT/ENGINEER WILL ENFORCE SAFETY MEASURES OR REGULATIONS. IT ADDITIONAL LOADS ARE IMPOSED . . . . . . . . . . . . . . . . . . . . . . . . 8 DAYS

SHALL BE THE CONTRACTORS RESPONSIBILITY TO PROVIDE ADEQUATE SHORING WALLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 HRS STANDARD HOOK (mm) TENSION LAP SPLICE (mm)

BARØ ANCHORAGE BEAM COMP.

AND BRACING OF THE STRUCTURE FOR ALL THE LOADS THAT MAYBE IMPOSED BEAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 DAYS (mm) LENGTH (mm)

Ldh(mm)

SPLICE (mm)

UNIT WT.

BEAM COLUMN (kg/m)

DURING CONSTRUCTION. FURTHER, THE CONTRACTOR SHALL DESIGN, CONSTRUCT (E) CAMBER REQUIREMENTS 90° 180° 135°-90° LAP CLASS

TOP BAR BOTTOM BAR TIED SPIRAL

AND MAINTAIN ALL SAFETY DEVICES AND SHALL BE SOLELY RESPONSIBLE FOR

A 300 300

CONFORMING TO ALL SAFETY AND HEALTH STANDARDS, LAWS AND REGULATIONS. 1. UNLESS OTHERWISE NOTED ON THE PLANS OR SPECIFICATIONS CAMBER ALL RC 10 600 150 160 110 120~120 300 300 300 0.616

B 390 390

BEAMS AT LEAST 10mm FOR EVERY 4000mm OF CLEAR SPAN EXCEPT CANTILEVERS

8. OBTAIN PRIOR WRITTEN APPROVAL FROM THE ENGINEER IN CASE OF CHANGES TO A 530 410

WHICH WHICH SHALL BE 50mm FOR EVERY 3000mm OF CLEAR SPAN. 12 600 200 200 120 130~130 350 410 410 0.888

THE WORKING DRAWINGS. B 690 530

A 700 540

2. UNLESS OTHERWISE NOTED ON THE PLANS OR SPECIFICATIONS CAMBER ALL SLABS 16 740 270 260 130 160~160 460 540 540 1.579

B 910 700

(B) DESIGN CRITERIA 8mm PER 3000mm OF SHORTER SPAN AND 14mm FOR EVERY 2000mm OF SLABS

A 880 680

CANTILEVER SPAN. 20 920 340 320 160 200~320 580 680 680 2.466

B 1140 880

- - - REFER TO STRUCTURAL COMPUTATIONS

A 1370 1060

25 1150 430 400 200 250~400 720 1060 1060 3.854

(F) MASONRY AND CONCRETE BLOCKS B 1780 1380

(C) FOUNDATION A 1540 1180

1. CONCRETE HOLLOW BLOCKS, UNLESS OTHERWISE SPECIFIED SHALL BE 150MM 28 1300 480 480 260 810 1180 1180 4.833

B 2000 1530

1. FOOTINGS SHALL BEAR ON SOLID UNDISTURBED EARTH (CONTROLLED, COMPACTED THICK. LOAD BEARING BLOCKS SHALL HAVE A MINIMUM COMPRESSIVE STRENGTH OF A 1760 1350

STRUCTURAL FILL OR BOTH) AT LEAST 600MM BELOW LOWEST ADJACENT FINISHED 750 PSI (5.175 MPa) WHILE NON-LOAD BEARING SHALL HAVE A MINIMUM 32 1700 540 550 290 930 1350 1350 6.313

B 2290 1760

GRADE. COMPRESSIVE STRENGTH OF 400 PSI (2.76 MPa). A 1980 1520

2. FOUNDATION DESIGN IS BASED ON THE SOIL EXPLORATION AND GEOTECHNICAL 36 2150 610 650 360 1040 1520 1520 7.991

2. PROVIDE 1-16MMØ VERTICAL BARS AT CORNERS, INTERSECTIONS, END OF WALLS, B 2570 1980

EVALUATION PREPARED BY INDUSTRIAL INSPECTION (INT'L) INC. DATED JANUARY

EACH SIDE OF OPENINGS. NOTES:

07-19, 2013

3. SUB-GRADE PREPARATION INCLUDING DRAINAGE, EXCAVATION, COMPACTION, 3. LINTEL BEAMS SHALL BEAR AT LEAST 200MM (8") ON EACH SIDE OF MASONRY WALL 1. DEVELOPMENT LENGTH OF INDIVIDUAL BARS WITHIN A BUNDLE, IN TENSION OR COMPRESSION, SHALL BE THAT FOR INDIVIDUAL BARS,

INCREASED 20% FOR THREE-BUNDLED AND 33% FOR FOUR-BUNDLED BARS.

AND FILLING REQUIREMENTS, SHALL CONFORM STRICTLY WITH THE OPENING. 2. FOR COLUMNS AT ANY LEVEL, NO MORE THAN ALTERNATE BARS SHOULD BE SPLICED, NOTMORE THAN 33% OF THE BARS SHALL BE SPLICED WITHIN

RECOMMENDATIONS GIVEN IN THE SOILS REPORT OR AS DIRECTED BY THE SOILS THE REQUIRED LAP LENGTH, MINIMUM DISTANCE BETWEEN TWO ADJACENT SPLICED SHALL BE 600mm.

ENGINEER. 4. WALL REINFORCEMENTS SHALL BE AS FOLLOWS: 3. TOP BARS ARE HORIZONTAL BARS WITH MORE THAN 300mm DEPTH OF CONCRETE CAST BELOW REINFORCEMENT.

WALL THICKNESS VERTICAL BARS HORIZONTAL BARS 4. LAP SPLICE SHALL BE "CLASS B" TENSION LAP SPLICE IF MORE THAN ONE HALF OF THE BARS WERE SPLICED AT ANY SECTION, WHILE "CLASS A"

4. THE CONTRACTOR SHALL NOTIFY THE ENGINEER AFTER FOOTING EXCAVATION TENSION LAP SPLICE IF HALF OR FEWER THAN HALF OF BARS WERE SPLICED.

HAVE BEEN COMPLETED AND PRIOR TO CONCRETING TO CONFIRM THE DESIGN 8 IN. (200 mm) . . . . . . . . . . 12MMØ @ 400 mm 10MMØ @ 600 mm 5. TOP BARS SPLICE FOR BEAMS, SHOULD BE "BEAM COMPRESSIVE SPLICE x1.3"

SOIL BEARING CAPACITY. 6 IN (150 mm) . . . . . . . . . . . 10MMØ @ 400 mm 10MMØ @ 600 mm

4 IN. (100 mm) . . . . . . . . . . 10MMØ @ 400 mm 10MMØ @ 600 mm

5. ROOF AND AREA DRAINAGE SHALL BE DIRECTED AWAY FROM THE FOUNDATIONS. PARAMETERS

5. BLOCK WALL REINFORCING BARS SHALL BE LAPPED OF 30 BAR DIAMETERS WHERE

6. EXCAVATIONS SHALL BE PROPERLY BACKFILLED. BACKFILL FOR WALLS SHALL BE MATERIAL psi MPa ACI 318-05

SPLICED, HORIZONTAL/VERTICAL DOWELS FROM FOOTINGS, COLUMNS/WALLS OR

PERVIOUS MATERIAL ACCEPTABLE TO THE GEOTECHNICAL ENGINEER. DO NOT PLACE f'c 3000 20.7 DEV'T & SPLICE LENGTH

SLABS SHALL EXTEND INTO THE BLOCK WALL A MINIMUM OF 30 BAR DIAMETERS OR A

BACKFILL BEHIND WALLS BEFORE THEY HAVE ATTAINED THEIR DESIGN STRENGTH.

MINIMUM OF 400MM WHICHEVER IS LONGER AND DOWELS TO MATCH VERTICAL fy 60000 414 16mm & HIGHER

SHORE AND PROTECT WALLS FROM LATERAL LOADS UNTIL THE SUPPORTING

REINFORCEMENTS OF WALL. fyh 40000 276 12mm & LOWER

MEMBERS ARE IN PLACE AND HAVE DEVELOPED SPECIFIED STRENGTHS.

tie Ø 10 stirrup Ø 10

(G) STRUCTURAL STEEL

fyt 40000 fyt 40000

(D) REINFORCED CONCRETE

1. ALL STRUCTURAL STEELS SUCH AS ANGLES, WIDE FLANGE SECTIONS, PIPES, STANDARD HOOK (mm) TENSION LAP SPLICE (mm)

1. CONCRETE SHALL BE MIXED, PROPORTIONED, CONVEYED AND PLACED IN STIFFENER PLATES, BASE PLATES, ETC. SHALL CONFORM TO ASTM A-36. BARØ ANCHORAGE

Ldh(mm)

BEAM COMP.

UNIT WT.

ACCORDANCE WITH THE PROVISIONS SET BY THE NSCP 2010. (mm) LENGTH (mm) SPLICE (mm) BEAM COLUMN

90° 180° 135°-90° LAP CLASS (kg/m)

2. ALL STRUCTURAL STEEL SHALL BE DETAILED, FABRICATED AND ERECTED BASED ON TOP BAR BOTTOM BAR TIED SPIRAL

2. ALL CONCRETE SHALL DEVELOP A MINIMUM COMPRESSIVE STRENGTH AT 28 DAYS THE SPECIFICATION FOR DESIGN, FABRICATION, AND ERECTION OF STRUCTURAL A 380 300

STEEL GIVEN BY THE NATIONAL STRUCTURAL CODE OF THE PHILIPPINES (NSCP). 10 600 150 160 110 120~120 300 300 300 0.616

WITH CORRESPONDING MAXIMUM SLUMP AND MAXIMUM SIZE AGGREGATE AS B 490 390

FOLLOWS: 3. CONNECTION BOLTS (34 ROUND, UNLESS SHOWN OTHERWISE) SHALL CONFORM TO A 680 520

12 710 260 200 120 130~130 350 520 520 0.888

ASTM A-325. ANCHOR BOLTS (EMBEDDED IN MASONRY OR CONCRETE) SHALL B 880 680

STRUCTURAL MEMBER 28 DAY STRENGTH MAX. SLUMP MAX. SIZE AGG. A 910 700

CONFORM TO ASTM A307 UNLESS NOTED OTHERWISE ON THE DRAWINGS. 16 950 350 260 130 160~160 460 700 700 1.579

A. SLAB ON GRADE 21 MPa (3,000 PSI) 100MM (4") 25MM (1") B 1180 910

B. FOOTINGS & RETAINING WALLS 35 MPa (5,000 PSI) 100MM (4") 19MM (3/4") 4. ALL STRUCTURAL STEEL SHALL BE CLEAN, RUST FREE AND SHOP COATED WITH THE A 1140 870

APPROPRIATE PAINT. STRUCTURAL STEEL AND ANCHOR BOLTS SHALL BE MINIMUM 20 1180 440 320 160 200~320 580 870 870 2.466

C. COLUMNS / SHEARWALLS 35 MPa (5,000 PSI) 100MM (4") 19MM (3/4") B 1480 1130

D. BEAMS & SLABS 35 MPa (5,000 PSI) 100MM (4") 19MM (3/4") ASTM A-36 DOMESTIC, LATEST REVISION. A 1780 1370

25 1900 550 400 200 250~400 720 1370 1370 3.854

5. NON - SHRINK GROUT - PRE-MIXED, NON-METALLIC, CEMENT-BASED GROUT, MEETING B 2310 1780

3. ALL REINFORCING STEEL BARS SHALL CONFORM TO ASTM A615 GRADE 40 FOR THE REQUIREMENT OF ASTM C827, ASTM C109 & CRD-C621, WITH A MINIMUM A 1990 1530

28 2190 620 480 260 810 1530 1530 4.833

12MMØ AND SMALLER BARS WHILE BARS 16MMM Ø AND LARGER SHALL BE GRADE 60. COMPRESSIVE STRENGTH OF 7000psi AT 28 DAYS. B 2590 1990

A 2270 1750

6. PROVIDE MISCELLANEOUS PLATES, ANGLES AND ANCHORS AS SHOWN OR NOTED ON 32 2590 700 550 290 930 1750 1750 6.313

4. ALL FABRICATION, DETAILING AND PLACING SHALL CONFORM TO THE PROVISIONS DRAWINGS. B 2950 2280

SET BY THE NSCP 2010 EDITION. A 2560 1970

7. ALL CUTTING AND BLOCKING OF STEEL SHALL BE SHOWN ON SHOP DRAWINGS AND 36 2990 790 650 360 1040 1970 1970 7.991

B 3330 2560

5. CLEAR DISTANCE SPACING BETWEEN PARALLED BARS IN A LAYER SHALL NOT BE PERFORMED IN SHOP.

LESS THAN 1.50 TIMES THE NOMINAL DIAMETER OF THE BAR, OR 1.33 TIMES MAXIMUM NOTES:

8. PROVIDE TEMPORARY BRACING AS REQUIRED FOR A SAFE STRUCTURE UNTIL ALL

1 1. DEVELOPMENT LENGTH OF INDIVIDUAL BARS WITHIN A BUNDLE, IN TENSION OR COMPRESSION, SHALL BE THAT FOR INDIVIDUAL BARS,

SIZE AGGREGATE, NOR LESS THAN 38MM (1 2"). FINAL CONNECTIONS ARE MADE.

INCREASED 20% FOR THREE-BUNDLED AND 33% FOR FOUR-BUNDLED BARS.

2. FOR COLUMNS AT ANY LEVEL, NO MORE THAN ALTERNATE BARS SHOULD BE SPLICED, NOTMORE THAN 33% OF THE BARS SHALL BE SPLICED WITHIN

THE REQUIRED LAP LENGTH, MINIMUM DISTANCE BETWEEN TWO ADJACENT SPLICED SHALL BE 600mm.

3. TOP BARS ARE HORIZONTAL BARS WITH MORE THAN 300mm DEPTH OF CONCRETE CAST BELOW REINFORCEMENT.

4. LAP SPLICE SHALL BE "CLASS B" TENSION LAP SPLICE IF MORE THAN ONE HALF OF THE BARS WERE SPLICED AT ANY SECTION, WHILE "CLASS A"

FOR CONSTRUCTION PURPOSES TENSION LAP SPLICE IF HALF OR FEWER THAN HALF OF BARS WERE SPLICED.

5. TOP BARS SPLICE FOR BEAMS, SHOULD BE "BEAM COMPRESSIVE SPLICE x1.3"

- - -

DATE ISSUED: 03-19-2018 BY: GGSE

REV. DATE DESCRIPTION

R.A.9266 Section 33 ARCHITECTURAL: STRUCTURAL:

SEAL ARCHIGLOBAL, INC. GITAMONDOC-GOPAOCO

PROJECT TITLE: APPROVED BY: DRAWING TITLE: SCALE: DATE: 3/21/2018 SHEET NUMBER: REVISION:

Drawing and specifications and other

contract documents signed, stamped or PROJECT IN CHARGE:

GITAMONDOC-GOPAOCO RAMON M. GITAMONDOC sealed, as instruments of service, are the ELECTRICAL: ELECTRONICS:

OAKRIDGE REALITY BUILDING 2 N

S-100.0 R00

intellectual property and documents of the JONATHAN A. VILLAFLOR VICTOR C. NAVARRO 1 : 150 A1 JOHN

STRUCTURAL ENGINEERING COMPANY

www.ggstructural.com

STRUCTURAL ENGINEER

architect, whether the object for which

they are made is executed or not, it shall MECHANICAL:

be unlawful for any person to duplicate or L.M PARAGSA DESIGN &

FIRE PROTECTION:

L.M PARAGSA DESIGN &

A PROPOSED MIXED-USE DEVELOPMENT DEVELOPMENT CORPORATION GENERAL STRUCTURAL AND

REG. NO.: 92466 DATE : 01/15/2002

WOOLBRIGHT DRIVE, LAHUG, CEBU CITY,

to make copies of said documents for use

in the repetition of and for other projects CONSULTANCY CONSULTANCY OWNER CONSTRUCTION NOTES DRAFTED BY:

PTR NO. : 6632275 DATE : 01/08/2016 of building, whether executed partly in PLUMBING: SITE DEVELOPMENT: -

PHILIPPINES whole, without the written consent of JOHN

TIN : 135-446-443 architect or author of said documents. J.M SALERA CONSTRUCTION LOCATION: 880 - A.S FORTUNA STREET, BANILAD, MANDAUE CITY, CEBU ADDRESS: 880 - A.S FORTUNA STREET, BANILAD, MANDAUE CITY, CEBU PROJECT CODE: P11_C0M_126

Potrebbero piacerti anche

- General Structural / Construction Notes and Specifications: Wall Footing Details (Where Applicable)Documento5 pagineGeneral Structural / Construction Notes and Specifications: Wall Footing Details (Where Applicable)anon_181338447Nessuna valutazione finora

- General Notes & SpecificationsDocumento6 pagineGeneral Notes & SpecificationsDon Santos100% (1)

- Covered Basketball (ST)Documento7 pagineCovered Basketball (ST)Angel Lisette LaoNessuna valutazione finora

- ESTIMATESDocumento13 pagineESTIMATESmelvin bautistaNessuna valutazione finora

- Type-1 - Structural Plan - 2013-02-16 PDFDocumento3 pagineType-1 - Structural Plan - 2013-02-16 PDFjremptymak0% (1)

- Standard school building structural detailsDocumento1 paginaStandard school building structural detailsSuranga Gayan100% (1)

- Proposed 5 Storey Building with Roof Deck Structural DesignDocumento4 pagineProposed 5 Storey Building with Roof Deck Structural DesignAlvin SantosNessuna valutazione finora

- Steel NewDocumento19 pagineSteel NewMark Jendel TomoNessuna valutazione finora

- 2 Storey Residential BuildingDocumento9 pagine2 Storey Residential BuildingBleasy CepedaNessuna valutazione finora

- Structural Calculation for 4-Storey Residential BuildingDocumento8 pagineStructural Calculation for 4-Storey Residential BuildingJake CortezNessuna valutazione finora

- General Structural/Construction Notes and Specifications: Proposed 4-Storey Residential Building W/FenceDocumento1 paginaGeneral Structural/Construction Notes and Specifications: Proposed 4-Storey Residential Building W/FenceWilbert ReuyanNessuna valutazione finora

- Steel HandbbokDocumento420 pagineSteel HandbbokMJ100% (1)

- Detail Detail Detail: Schedule of Truss MembersDocumento6 pagineDetail Detail Detail: Schedule of Truss MembersSharmane BurlazaNessuna valutazione finora

- SpecificationDocumento15 pagineSpecificationRichard TagleNessuna valutazione finora

- 2-Storey Glenn FernandezDocumento66 pagine2-Storey Glenn Fernandezclarkgagui100% (1)

- Timber Design of A Two Storey HouseDocumento92 pagineTimber Design of A Two Storey HouseEmmanuel Lazo80% (5)

- Slabs Problem PDFDocumento23 pagineSlabs Problem PDFChesley MoralesNessuna valutazione finora

- Plumbing diagram layout and labeling guideDocumento1 paginaPlumbing diagram layout and labeling guideKwammy BrownNessuna valutazione finora

- NBCPDocumento9 pagineNBCPSharamay NavarroNessuna valutazione finora

- General Notes and Standard Details: Rafter DetailDocumento1 paginaGeneral Notes and Standard Details: Rafter DetailLiza MarieNessuna valutazione finora

- Revised National Plumbing Code HistoryDocumento225 pagineRevised National Plumbing Code HistoryJames Bryan Hije100% (1)

- Plumbing Notes Material Specifications:: Plan SectionDocumento2 paginePlumbing Notes Material Specifications:: Plan Sectionmichaelmtadeo100% (1)

- Fascia Frame Details: Foundation PlanDocumento1 paginaFascia Frame Details: Foundation PlanRod NajarroNessuna valutazione finora

- Table 2-1. Allowable Stress On Fasteners, Mpa: G V E, IDocumento4 pagineTable 2-1. Allowable Stress On Fasteners, Mpa: G V E, ILouie Jay CabunocNessuna valutazione finora

- S3 PDFDocumento1 paginaS3 PDFarkitravel onthegoNessuna valutazione finora

- Structural PlansDocumento13 pagineStructural Plansapi-294439854Nessuna valutazione finora

- NSCP 2015: NSCP: Free Download, Borrow, and Streaming ..Documento3 pagineNSCP 2015: NSCP: Free Download, Borrow, and Streaming ..godofredo dumaliNessuna valutazione finora

- Temporary Facility Floor Plan and ElevationsDocumento1 paginaTemporary Facility Floor Plan and Elevationskhraieric16Nessuna valutazione finora

- Beam Schedule: 250 3Rd FloorDocumento1 paginaBeam Schedule: 250 3Rd FloorNhel AlbrechtNessuna valutazione finora

- Design of a Five-Storey Reinforced Concrete Seminary Main BuildingDocumento117 pagineDesign of a Five-Storey Reinforced Concrete Seminary Main BuildingjedsclementNessuna valutazione finora

- AR1Documento1 paginaAR1erwin sarmientoNessuna valutazione finora

- Footing Schedule: 4" THCK (100mm) CHB WALL With 10mmø Vert. & Hort. Bars Spaced at 0.40M & Every 2-Layers Property LineDocumento1 paginaFooting Schedule: 4" THCK (100mm) CHB WALL With 10mmø Vert. & Hort. Bars Spaced at 0.40M & Every 2-Layers Property LineVerna Balang Martinez100% (1)

- Structural Beam ComputationsDocumento12 pagineStructural Beam ComputationsJustine LedesmaNessuna valutazione finora

- Design rectangular beam reinforced for tensionDocumento8 pagineDesign rectangular beam reinforced for tensionaltavanoarNessuna valutazione finora

- NSCP 2010Documento758 pagineNSCP 2010Chelle Sujetado De Guzman95% (21)

- M2 Cw2a Attempt 2Documento8 pagineM2 Cw2a Attempt 2Ryan JuanNessuna valutazione finora

- DPWH Building PlansDocumento5 pagineDPWH Building PlansHelp DACNessuna valutazione finora

- Wind Loads NSCP 2001 ProvisionsDocumento22 pagineWind Loads NSCP 2001 ProvisionsMonde Nuylan75% (4)

- A 402 Escalator Plans and SectionsDocumento1 paginaA 402 Escalator Plans and SectionsrrrwwwNessuna valutazione finora

- Drainage A 1Documento1 paginaDrainage A 1akositeodoroNessuna valutazione finora

- c1f1 c1f1 WFDocumento4 paginec1f1 c1f1 WFsicnarfoyamat1977100% (1)

- Service Apartel Building Structural Plan - Edited PDFDocumento17 pagineService Apartel Building Structural Plan - Edited PDFHeliosNessuna valutazione finora

- Reinforced concrete slab details with traverse and longitudinal layoutsDocumento1 paginaReinforced concrete slab details with traverse and longitudinal layoutsJoseph Cloyd LamberteNessuna valutazione finora

- Construction of Multi-Level ParkingDocumento13 pagineConstruction of Multi-Level Parkingdunknown15Nessuna valutazione finora

- Sewer & Drainage Layout: IsometricDocumento1 paginaSewer & Drainage Layout: IsometricAubrey ManelleNessuna valutazione finora

- Construction notes and details for reinforced concrete structuresDocumento14 pagineConstruction notes and details for reinforced concrete structuresBilly Joe BreakfastNessuna valutazione finora

- Reinforced Concrete DesignDocumento19 pagineReinforced Concrete DesignAlexander ChuaNessuna valutazione finora

- Canal II Layout1Documento1 paginaCanal II Layout1Xan KulitzNessuna valutazione finora

- Technical Specifications-PlumbingDocumento52 pagineTechnical Specifications-Plumbingpandey71087100% (1)

- NSCP 2010Documento758 pagineNSCP 2010Cherish Taguinod Aliguyon100% (2)

- Asep Steel SectionsDocumento87 pagineAsep Steel SectionsGilven Beamond MedinaNessuna valutazione finora

- Marces Osmeña General SpecificationsDocumento5 pagineMarces Osmeña General SpecificationsAlexander Osmeña IINessuna valutazione finora

- FP 01 PDFDocumento1 paginaFP 01 PDFJeralyn NoynayNessuna valutazione finora

- Plan 1 BuildingDocumento1 paginaPlan 1 BuildingcimpstazNessuna valutazione finora

- 2Nd Floor Lighting Layout 2Nd Floor Power Layout: Electrical NotesDocumento1 pagina2Nd Floor Lighting Layout 2Nd Floor Power Layout: Electrical NotesKristel Grace OgtipNessuna valutazione finora

- Front Elevation Right Side Elevation: A B C D E 5 4 3 2 1Documento1 paginaFront Elevation Right Side Elevation: A B C D E 5 4 3 2 1ArjelyNessuna valutazione finora

- Building Plans and DrawingsDocumento1 paginaBuilding Plans and DrawingsJem CapistranoNessuna valutazione finora

- 2022 10 19 ODESSA GRANTVILLE-A3Documento1 pagina2022 10 19 ODESSA GRANTVILLE-A3Mary Gen ReynesNessuna valutazione finora

- 2022 10 19 ODESSA GRANTVILLE-A2Documento1 pagina2022 10 19 ODESSA GRANTVILLE-A2Mary Gen ReynesNessuna valutazione finora

- Instant Assessments for Data Tracking, Grade 1: Language ArtsDa EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNessuna valutazione finora

- Tabulation Process - 2019Documento1 paginaTabulation Process - 2019noelNessuna valutazione finora

- Structural NotesDocumento1 paginaStructural NotesnoelNessuna valutazione finora

- AISC-15th-Steel-Construction-Manual-pdf_34Documento1 paginaAISC-15th-Steel-Construction-Manual-pdf_34noelNessuna valutazione finora

- AISC-15th-Steel-Construction-Manual-pdf_33Documento1 paginaAISC-15th-Steel-Construction-Manual-pdf_33noelNessuna valutazione finora

- Back PageDocumento1 paginaBack PagenoelNessuna valutazione finora

- Revised 5thDocumento1 paginaRevised 5thnoelNessuna valutazione finora

- Tabulation Process - 2019Documento1 paginaTabulation Process - 2019noelNessuna valutazione finora

- Tabulation Process - 2019Documento1 paginaTabulation Process - 2019noelNessuna valutazione finora

- Tabulation Process - 2019Documento1 paginaTabulation Process - 2019noelNessuna valutazione finora

- 5TH 5 PDFDocumento1 pagina5TH 5 PDFnoelNessuna valutazione finora

- How To Limit ExpensesDocumento2 pagineHow To Limit ExpensesnoelNessuna valutazione finora

- Back Page PDFDocumento1 paginaBack Page PDFnoelNessuna valutazione finora

- Tabulation Process - 2019Documento1 paginaTabulation Process - 2019noelNessuna valutazione finora

- Bolt Sizes PresentationDocumento1 paginaBolt Sizes PresentationnoelNessuna valutazione finora

- 5TH 1Documento1 pagina5TH 1noelNessuna valutazione finora

- Tutorials Risa 3DDocumento160 pagineTutorials Risa 3DCapacitacion TecnicaNessuna valutazione finora

- Table of Fees and Rates - MB Classic MasterCard-VisaDocumento4 pagineTable of Fees and Rates - MB Classic MasterCard-VisanoelNessuna valutazione finora

- Front PageDocumento1 paginaFront PagenoelNessuna valutazione finora

- TheStockMarketJumpstarter PDFDocumento43 pagineTheStockMarketJumpstarter PDFedmondNessuna valutazione finora

- Structural EngineeringDocumento1 paginaStructural EngineeringnoelNessuna valutazione finora

- Structural NotesDocumento1 paginaStructural NotesnoelNessuna valutazione finora

- Wall Footing Typical DetailDocumento1 paginaWall Footing Typical DetailnoelNessuna valutazione finora

- FE Handbook 4Documento1 paginaFE Handbook 4noelNessuna valutazione finora

- Motorcycle Parking FabricationDocumento1 paginaMotorcycle Parking FabricationnoelNessuna valutazione finora

- Requirement For Provision of Professional ServicesDocumento1 paginaRequirement For Provision of Professional ServicesnoelNessuna valutazione finora

- Pmi - 017 RequantifyDocumento6 paginePmi - 017 RequantifynoelNessuna valutazione finora

- RC Link BeamDocumento1 paginaRC Link BeamnoelNessuna valutazione finora

- Fellenius-Basics Foundation Design 1 PDFDocumento1 paginaFellenius-Basics Foundation Design 1 PDFnoelNessuna valutazione finora

- Guidelines On How To Become A Specialist PDFDocumento1 paginaGuidelines On How To Become A Specialist PDFAnonymous I4c7llBfNessuna valutazione finora

- BMVIT 327120 0060 10 ANP Micropile SAS 550 EnglishDocumento30 pagineBMVIT 327120 0060 10 ANP Micropile SAS 550 EnglishakajsiNessuna valutazione finora

- Docslide.us Upload Login / Signup Cost Estimate GuidelinesDocumento62 pagineDocslide.us Upload Login / Signup Cost Estimate GuidelinesNhiel DazaNessuna valutazione finora

- Calculation For Base Plate ConnectionDocumento85 pagineCalculation For Base Plate ConnectionpriantomoNessuna valutazione finora

- Construction Notes Beam ReinforcementDocumento9 pagineConstruction Notes Beam Reinforcementvishalbhardwa12Nessuna valutazione finora

- Lecture 3 Bending and Shear in Beams PHG A8 2oct16Documento30 pagineLecture 3 Bending and Shear in Beams PHG A8 2oct16HarithSilvaNessuna valutazione finora

- Reinforcing SteelDocumento5 pagineReinforcing SteelStraus WaseemNessuna valutazione finora

- Precast Concrete ConstructionDocumento71 paginePrecast Concrete ConstructionMahad AbdiNessuna valutazione finora

- TANK FOUNDATION CalculationDocumento30 pagineTANK FOUNDATION CalculationMahmoud SalahNessuna valutazione finora

- I Structural Terminologies: Architectural Preboard ExaminationDocumento41 pagineI Structural Terminologies: Architectural Preboard ExaminationAr Agner O. BatuigasNessuna valutazione finora

- 1Documento20 pagine1Sir PocoyoNessuna valutazione finora

- Trans Proj ProfileDocumento9 pagineTrans Proj ProfileGeronimo Rigor D. CapariñoNessuna valutazione finora

- Standard Practice For Design and Construction of Concrete Silos and Stacking Tubes For Storing Granular Materials (ACI 313-97)Documento19 pagineStandard Practice For Design and Construction of Concrete Silos and Stacking Tubes For Storing Granular Materials (ACI 313-97)nathanNessuna valutazione finora

- IIW Doc III-1445-07Documento13 pagineIIW Doc III-1445-07Marjan SubanNessuna valutazione finora

- ACI RAP-4 - Surface Repair Using Form-and-Pour Techniques - 2011Documento8 pagineACI RAP-4 - Surface Repair Using Form-and-Pour Techniques - 2011ilo88Nessuna valutazione finora

- Development of Cylindrical Shear Connector Inserted in Perforated Steel Plate and Apply To The Hybrid StructureDocumento12 pagineDevelopment of Cylindrical Shear Connector Inserted in Perforated Steel Plate and Apply To The Hybrid Structureerky arkvathonejhNessuna valutazione finora

- MD1 0 T 052 05 00114 CDocumento20 pagineMD1 0 T 052 05 00114 Chunkenx01100% (1)

- Sika Carbodur Plates: Pultruded Carbon Fiber Plates For Structural StrengtheningDocumento7 pagineSika Carbodur Plates: Pultruded Carbon Fiber Plates For Structural StrengtheningJet ToledoNessuna valutazione finora

- Steel FixerDocumento2 pagineSteel FixerivanaNessuna valutazione finora

- Assignment 2Documento10 pagineAssignment 2Karl Andre CabañeroNessuna valutazione finora

- Rebar - WikipediaDocumento12 pagineRebar - WikipediaglennNessuna valutazione finora

- INSPECTION TEST PLAN For Pole Production - Doc1Documento8 pagineINSPECTION TEST PLAN For Pole Production - Doc1OGBONNAYA MARTINSNessuna valutazione finora

- L-2 Steel SectionsDocumento23 pagineL-2 Steel SectionsRukhsar JoueNessuna valutazione finora

- Anclajes PeikkoDocumento28 pagineAnclajes PeikkopablopelaNessuna valutazione finora

- Bellows Compensators GB 2Documento9 pagineBellows Compensators GB 2faisalnadimNessuna valutazione finora

- Beme For DamDocumento5 pagineBeme For DamOladunni Afolabi50% (2)

- Sika Anchorfix®-3001: Product Data SheetDocumento5 pagineSika Anchorfix®-3001: Product Data SheetPramuditha SuraweeraNessuna valutazione finora

- WARDHA Tender BOQ 13-12-2013 For TenderDocumento23 pagineWARDHA Tender BOQ 13-12-2013 For TenderSai BabaNessuna valutazione finora

- Ductile Building DesignDocumento3 pagineDuctile Building DesignroseNessuna valutazione finora

- 01 Bar Schedule Pile Cap & ColumnDocumento7 pagine01 Bar Schedule Pile Cap & Columnorode franklynNessuna valutazione finora