Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler Installation

Caricato da

sebaversaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler Installation

Caricato da

sebaversaCopyright:

Formati disponibili

Model CB 15-100 HP Boilers

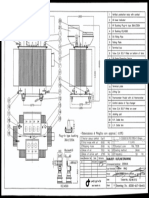

Figure A6-14. No. 2 Oil Piping, Multiple Boiler Installation

Section A6-28 Rev. 07-10

Model CB 15-100 HP Boilers

VENT

H OIL TRANSFER TANK AT

LOCATION NEAR BOILER

OIL LEVEL TEST OIL TRANSFER PUMP NEAR

VALVE STORAGE TANK

F.O.R. CHECK VALVE STRAINER

F.O.R.

F.O.S. GATE VALVE

SUPPLY TO BOILER F.O.S.

TERMINAL BLOCK OR

TO BOILER OIL PUMP

RELIEF VALVE GATE VALVE

UNION VACUUM

(100 PSIG)

GAUGE

ITEM SIZE DESCRIPTION

Connection to oil

A 1/2" NT

level switch S

See G 3/16"

B Return line to tank

Note B

Oil supply 2"

See 5"

C connection from

Note

transfer pump 3"

1/2" Tank drain 22"

D F

NPT connection

See C

E FOS connection 60"

Note

4" OR 6" STD

1/8" Oil level test valve 33"

F E BLACK PIPE

NPT connection

See

G FOR connection 3"

Note

H S

No.80 Oil level switch

McD

3/8" MTL D 3/16"

NOTE: Connections should be sized

using recommended sizes in oil line

sizing instructions.

Figure A6-15. No. 2 Oil Piping

(For elevated boiler room locations using an oil transfer pump and tank)

NOTE: OBSERVE ALL LOCAL AND NATIONAL

(EG. FIRE UNDERWRITERS) CODE

REQUIREMENTS GOVERNING THE

INSTALLATION OF FUEL OIL STORAGE

TANKS AND SUPPLY SYSTEMS

Figure A6-16. Typical Fuel Storage Tank Arrangement

Section A6-29 Rev. 07-10

Model CB 15-100 HP Boilers

Boiler Room Information

Figure A6-17 shows typical boiler room length requirements.

Figure A6-18 shows typical boiler room width requirements.

Figure A6-19 shows typical breeching arrangements.

Stack Support Capabilities

Cleaver-Brooks Firetube Boilers 15 hp through 100 hp can support up to 1,000 lbs

without additional support. Firetube boilers 125 hp through 800 hp can support up to

2,000 lbs without additional support.

Firetube sizes 250 hp through 800 hp can be reinforced to support 3,000 lbs.

Stack/Breeching Size Criteria

The design of the stack and breeching must provide the required draft at each boiler flue

gas outlet. Proper draft is critical to burner performance.

Although constant pressure at the flue gas outlet of the Model CB is not required, it is

necessary to size the stack/breeching to limit flue gas pressure variation. For boiler sizes

50 – 800 horsepower, the allowable pressure range is –0.5" W.C. to

+0.5" W.C. The maximum pressure variation at any firing rate for the boiler is 0.5" W.C.

For boiler sizes 15 – 40 horsepower, the allowable pressure range is –0.25" W.C. to

+0.25" W.C.

For additional information, please review Section I4, General Engineering Data (Stacks)

and Section F, Stacks. Stack and breeching sizes should always be provided by a

reputable stack supplier who will design the stack and breeching system based on the

above criteria. Your local Cleaver-Brooks authorized representative is capable of

assisting in your evaluation of the stack/breeching design.

Boiler Room Combustion Air

When determining boiler room air requirements, the size of the room, air flow, and

velocity of air must be reviewed as follows:

1. Size (area) and location of air supply openings in boiler room.

A. Two (2) permanent air supply openings in the outer walls of the boiler room are

recommended. Locate one at each end of the boiler room, preferably below a

height of 7 feet. This allows air to sweep the length of the boiler.

B. Air supply openings can be louvered for weather protection, but they should not

be covered with fine mesh wire, as this type of covering has poor air flow

qualities and is subject to clogging by dust or dirt.

C. A vent fan in the boiler room is not recommended, as it could create a slight

vacuum under certain conditions and cause variations in the quantity of

combustion air. This can result in unsatisfactory burner performance.

D. Under no condition should the total area of the air supply openings be less than

(1) square foot.

E. Size the openings by using the formula:

Area (sq-ft) = cfm/fpm

2. Amount of air required (cfm).

A. Combustion Air = Rated bhp x 8 cfm/bhp.

B. Ventilation Air = Maximum bhp x 2 cfm/bhp

Section A6-30 Rev. 07-10

Model CB 15-100 HP Boilers

C. Total recommended air, 10 cfm/bhp - up to 1000 feet elevation. Add 3 percent

more per 1000 feet of added elevation.

3. Acceptable air velocity in boiler room (fpm).

A. From floor to (7) foot height - 250 fpm.

B. Above (7) foot height - 500 fpm.

Example: Determine the area of the boiler room air supply openings for (1) 300 hp

boiler at 800 feet altitude. The air openings are to be 5 feet above floor level.

• Air required: 300 x 10 = 3000 cfm (from 2B above).

• Air velocity: Up to 7 feet = 250 fpm (from 3 above).

• Area Required: Area = cfm = 3000/250 = 12 Sq-ft total.

• Area/Opening: 12/2 = 6 sq-ft/opening (2 required).

Notice

Consult local codes, which may supersede these requirements.

Section A6-31 Rev. 07-10

Model CB 15-100 HP Boilers

FRONT

FEEDWATER

TANK

BOILER

FEEDWATER

PUMP

DRAIN

TRENCH

DWG A

DWG B

DWG C

1. Shortest boiler room length (Dwg A) is obtained by allowing for possible future tube replacement (from front or rear of boiler)

through a window or doorway. Allowance is only made for minimum door swing at each end of the boiler. This arrangement

provides sufficient aisle space at the front of the boiler but a "tight" space condition at the rear.

If space permits, approximately 1.5 additional feet should be allowed at the rear for additional aisle and working space.

2. Next shortest boiler room length (Dwg B) is obtained by allowing for possible future tube replacement from the front of the

boiler. Allowance is only made for minimum door swing at the rear.

If space permits, approximately 1.5 additional feet should be allowed at the rear for additional aisle and working space.

3. A slightly longer boiler room (Dwg C) is obtained by allowing for possible future tube replacement from the rear of the boiler.

Allowance for door swing at the front provides sufficient aisle and working space at the front.

Figure A6-17. Boiler Room Length (Typical Layout)

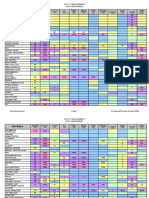

BOILER HP 15-40 50-100

Dimension A 75" 81"

A B FEEDWATER Dimension B 103" 115"

TANK

NOTES:

1. Recommended Minimum Distance Between Boiler and Wall.

BOILER Dimension "A" allows for a "clear" 42" aisle between the

FEEDWATER water column on the boiler and the wall. If space permits,

PUMP this aisle should be widened.

2. Recommended Minimum Distance Between Boilers.

Dimension "B" between boilers allows for a "clear" aisle of:

DRAIN

42" - 15-100 hp

TRENCH If space permits, this aisle should be widened.

Figure A6-18. Boiler Room Width (Typical Layout)

Section A6-32 Rev. 07-10

Potrebbero piacerti anche

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocumento5 pagineModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNessuna valutazione finora

- B10fuv NLDocumento20 pagineB10fuv NLBla BleNessuna valutazione finora

- Cozy Heater Installation Manual 9-24 PagesDocumento2 pagineCozy Heater Installation Manual 9-24 PagesChris McGovernNessuna valutazione finora

- Oil pump specificationDocumento2 pagineOil pump specificationmochammad RezaNessuna valutazione finora

- Model 4WI 100 - 800 HP Boilers: Figure A2-7. No. 2 Oil Piping, Multiple Boiler InstallationDocumento4 pagineModel 4WI 100 - 800 HP Boilers: Figure A2-7. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNessuna valutazione finora

- HD263Documento8 pagineHD263Ahamed IbrahimNessuna valutazione finora

- Bentone BG 100Documento22 pagineBentone BG 100mechanicalNessuna valutazione finora

- RC2-230B Screw Compressor: Standard Compressors Accessories PortsDocumento1 paginaRC2-230B Screw Compressor: Standard Compressors Accessories PortsPrashanth RavindranNessuna valutazione finora

- Installation-And Maintenance InstructionDocumento14 pagineInstallation-And Maintenance InstructionRafael PadillaNessuna valutazione finora

- HV 60/125 Manifolds/Collectors For 2 and 3 Heating CircuitsDocumento1 paginaHV 60/125 Manifolds/Collectors For 2 and 3 Heating CircuitsHutan CatalynNessuna valutazione finora

- 85kva Volvo 5312752662 Trafalgar (Essential Solar) GDS3117Documento1 pagina85kva Volvo 5312752662 Trafalgar (Essential Solar) GDS3117DEVRON VAN ASWEGENNessuna valutazione finora

- AM3 3 QF Flow-Regulator-Cetop-3Documento1 paginaAM3 3 QF Flow-Regulator-Cetop-3PitupyNessuna valutazione finora

- Ratio Controller: HD Fire Protect Pvt. Ltd. Technical DataDocumento8 pagineRatio Controller: HD Fire Protect Pvt. Ltd. Technical DataDarshAwadNessuna valutazione finora

- Bentoflex ST 133 Ka/K: Providing Sustainable Energy Solutions WorldwideDocumento24 pagineBentoflex ST 133 Ka/K: Providing Sustainable Energy Solutions Worldwidesameeh919Nessuna valutazione finora

- Fuel Oil Control Valve - KBSD Upgrade Installation GuideDocumento6 pagineFuel Oil Control Valve - KBSD Upgrade Installation Guideadnan ariNessuna valutazione finora

- Eaton Solenoid Valves - 02-167105 Overview - EatonDocumento2 pagineEaton Solenoid Valves - 02-167105 Overview - EatonDanielEscobarMontecinosNessuna valutazione finora

- Bentone ST133 ManualDocumento14 pagineBentone ST133 ManualAsron Ferdian FalaahNessuna valutazione finora

- Compact Heavy Duty: Function Model CodeDocumento2 pagineCompact Heavy Duty: Function Model CodeanandsubbiahNessuna valutazione finora

- D77003 enDocumento57 pagineD77003 enzliangNessuna valutazione finora

- Oil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-InDocumento2 pagineOil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-Inmochammad RezaNessuna valutazione finora

- Oil Pump Type Ta: For Fuel Oil #2 To #6 ApplicationsDocumento2 pagineOil Pump Type Ta: For Fuel Oil #2 To #6 Applicationsmochammad RezaNessuna valutazione finora

- Bentone Burner Operating InstructionsDocumento20 pagineBentone Burner Operating InstructionsVikk Suriya100% (2)

- SERVA Pumps C-Pumps 052918p en Screen 0711Documento50 pagineSERVA Pumps C-Pumps 052918p en Screen 0711Ilham Nugroho100% (2)

- Installing Vapor Recovery Units To Reduce Methane LossesDocumento29 pagineInstalling Vapor Recovery Units To Reduce Methane LossesandresNessuna valutazione finora

- Hanbell Spec Sheet RC2-230B PDFDocumento1 paginaHanbell Spec Sheet RC2-230B PDFDaniel Naoe FestinNessuna valutazione finora

- VÁLVULA 2VS3 06 Double Throttle Check Valves Sandwich Plates EngDocumento4 pagineVÁLVULA 2VS3 06 Double Throttle Check Valves Sandwich Plates Engadriana853Nessuna valutazione finora

- E Series: 40 - 10 Series Proportional Electro-Hydraulic Relief and Flow Control ValvesDocumento24 pagineE Series: 40 - 10 Series Proportional Electro-Hydraulic Relief and Flow Control ValvesSai Ganesh Techno SolutionNessuna valutazione finora

- P 16 SeriesDocumento17 pagineP 16 SeriesJas SumNessuna valutazione finora

- A-Manifolds 326e GB 0Documento2 pagineA-Manifolds 326e GB 0Gabriel OyedemiNessuna valutazione finora

- Ata - 28 (Nov-19)Documento2.663 pagineAta - 28 (Nov-19)saradeepsNessuna valutazione finora

- Axial Piston Pumps: Variable Displacement Worldcup Series P6, 7 & 8W Design BDocumento52 pagineAxial Piston Pumps: Variable Displacement Worldcup Series P6, 7 & 8W Design BSwaminathan KbNessuna valutazione finora

- TV en Mai2021Documento2 pagineTV en Mai2021negar adelniaNessuna valutazione finora

- Instr Bentone B40a en 0 PDFDocumento13 pagineInstr Bentone B40a en 0 PDFमेनसन लाखेमरूNessuna valutazione finora

- Head Calculation For Primary Variable Chilled Water PumpDocumento12 pagineHead Calculation For Primary Variable Chilled Water PumpRajeeth JaisonNessuna valutazione finora

- Test Report Englisch BlancoDocumento3 pagineTest Report Englisch BlancoElio DiazNessuna valutazione finora

- 25309912 - EATON VVA20R-CD-WW VANE PUMPSDocumento8 pagine25309912 - EATON VVA20R-CD-WW VANE PUMPSJohnatas GamaNessuna valutazione finora

- Xpi Fuel Circuit - 9 & 13 Litre Engine - 0314-06 Issue - 1Documento3 pagineXpi Fuel Circuit - 9 & 13 Litre Engine - 0314-06 Issue - 1NoeRtjahya AhmadNessuna valutazione finora

- TV US - Ed2 Nov2018Documento2 pagineTV US - Ed2 Nov2018sofyan_adekNessuna valutazione finora

- Oil Pump Type T GEAR SIZES 2-3-4-5Documento2 pagineOil Pump Type T GEAR SIZES 2-3-4-5Eden Ben100% (1)

- M326-d17.Rev1 (2000KVA-33-0.4)Documento1 paginaM326-d17.Rev1 (2000KVA-33-0.4)Karim RahmaniNessuna valutazione finora

- RC2-100B Screw Compressor: Standard Compressors Accessories PortsDocumento1 paginaRC2-100B Screw Compressor: Standard Compressors Accessories PortsPrashanth RavindranNessuna valutazione finora

- Schematic Layout Line Feeder System PTO - CópiaDocumento1 paginaSchematic Layout Line Feeder System PTO - CópiaRenato MagalhãesNessuna valutazione finora

- Prism Hydraulics Pvt. LTD: 2 - Way Flow Control Valve Model: 2FcvDocumento2 paginePrism Hydraulics Pvt. LTD: 2 - Way Flow Control Valve Model: 2FcvAnonymous eLOoTenWvQNessuna valutazione finora

- Oil Pump Type Ae GEAR SIZES 47-57-67-77-97Documento2 pagineOil Pump Type Ae GEAR SIZES 47-57-67-77-97mochammad RezaNessuna valutazione finora

- Hydac Axial Piston Pump Ppv100m LQDocumento32 pagineHydac Axial Piston Pump Ppv100m LQpeterNessuna valutazione finora

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocumento5 pagineModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNessuna valutazione finora

- Universal Service Pump Type Au V - Gear Size 47Documento2 pagineUniversal Service Pump Type Au V - Gear Size 47mochammad RezaNessuna valutazione finora

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Documento4 pagineS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Юрий ТрофимовNessuna valutazione finora

- 6.1 - SL2006-469 PDFDocumento15 pagine6.1 - SL2006-469 PDFValeriy DomashenkoNessuna valutazione finora

- Catalogo Compresores Hermeticos Piston MT MTZ NTZ Danfoss PDFDocumento8 pagineCatalogo Compresores Hermeticos Piston MT MTZ NTZ Danfoss PDFPablo Angel ToiaNessuna valutazione finora

- A Polyhydron Group Company: Pressure Compensated Flow Control Valve Model: 2PF 10Documento3 pagineA Polyhydron Group Company: Pressure Compensated Flow Control Valve Model: 2PF 10Rakesh SharmaNessuna valutazione finora

- Zexel VRZ Pump PDFDocumento12 pagineZexel VRZ Pump PDFalvarikokexNessuna valutazione finora

- 9161Documento5 pagine9161BaytolgaNessuna valutazione finora

- 05 VruDocumento17 pagine05 VruSergio RodriguezNessuna valutazione finora

- MAB100Documento2 pagineMAB100Sathish JonnalaNessuna valutazione finora

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SDa EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Working Guide to Reservoir Rock Properties and Fluid FlowDa EverandWorking Guide to Reservoir Rock Properties and Fluid FlowValutazione: 3 su 5 stelle3/5 (1)

- Model CB 15-100 HP BoilersDocumento5 pagineModel CB 15-100 HP BoilerssebaversaNessuna valutazione finora

- Model CB 15-100 HP BoilersDocumento5 pagineModel CB 15-100 HP BoilerssebaversaNessuna valutazione finora

- Efficient 15-100 HP Boilers for BuildingsDocumento5 pagineEfficient 15-100 HP Boilers for BuildingssebaversaNessuna valutazione finora

- 15-100 HP Boilers Dimensions SpecsDocumento5 pagine15-100 HP Boilers Dimensions SpecssebaversaNessuna valutazione finora

- Section A5: Model CBL 900-1800 HP BoilersDocumento5 pagineSection A5: Model CBL 900-1800 HP BoilerssebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocumento5 pagineModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocumento5 pagineModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocumento5 pagineModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocumento5 pagineModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: Sound LevelDocumento5 pagineModel CB 15-100 HP Boilers: Sound LevelsebaversaNessuna valutazione finora

- 900-1800 HP Boiler SpecsDocumento5 pagine900-1800 HP Boiler SpecssebaversaNessuna valutazione finora

- Features and Benefits: Model CB 15-100 HP BoilersDocumento5 pagineFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNessuna valutazione finora

- 81Documento5 pagine81sebaversaNessuna valutazione finora

- Model CBL 900-1800 HP BoilersDocumento5 pagineModel CBL 900-1800 HP BoilerssebaversaNessuna valutazione finora

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocumento5 pagineModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNessuna valutazione finora

- 75Documento5 pagine75sebaversaNessuna valutazione finora

- Model CBL 900-1800 HP Boilers: Engineering DataDocumento5 pagineModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNessuna valutazione finora

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDocumento5 pagine900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaNessuna valutazione finora

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocumento5 pagine125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocumento5 pagineModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocumento5 pagineModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNessuna valutazione finora

- Model CBR 125-800 HP BoilersDocumento5 pagineModel CBR 125-800 HP BoilerssebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Documento6 pagineModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNessuna valutazione finora

- 78Documento5 pagine78sebaversaNessuna valutazione finora

- Model ICB 100-800 HP BoilersDocumento4 pagineModel ICB 100-800 HP BoilerssebaversaNessuna valutazione finora

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocumento5 pagine125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNessuna valutazione finora

- High-efficiency boiler specifications for 100-800 HP modelsDocumento4 pagineHigh-efficiency boiler specifications for 100-800 HP modelssebaversaNessuna valutazione finora

- General: Model ICB 100-800 HP BoilersDocumento4 pagineGeneral: Model ICB 100-800 HP BoilerssebaversaNessuna valutazione finora

- Brittle Fracture and Reporting OverviewDocumento38 pagineBrittle Fracture and Reporting OverviewRaja HoneNessuna valutazione finora

- Comeval - Power - Business - UnitDocumento21 pagineComeval - Power - Business - UnitnamNessuna valutazione finora

- SCALE AND SLUDGE IN BOILERSDocumento20 pagineSCALE AND SLUDGE IN BOILERSUtsav Chovatia100% (1)

- Greenhouse Heating and Distribution SystemsDocumento22 pagineGreenhouse Heating and Distribution SystemsvickysimhaNessuna valutazione finora

- BP Shipping Questionnaire: New Build VesselDocumento15 pagineBP Shipping Questionnaire: New Build Vesselmr mrNessuna valutazione finora

- Boiler System - GEADocumento8 pagineBoiler System - GEAKhoaNguyenNessuna valutazione finora

- Summer Training Report On NTPCDocumento31 pagineSummer Training Report On NTPCRajeev Varanwal100% (1)

- Accomplishment Report MarkDocumento6 pagineAccomplishment Report MarkJoana Marie BuenoNessuna valutazione finora

- Utility Management Risk AssessmentDocumento4 pagineUtility Management Risk AssessmentMantho DeriztNessuna valutazione finora

- Axial Fan Brochure PFDocumento12 pagineAxial Fan Brochure PFhardik033Nessuna valutazione finora

- Combustion of Wood - Heat ValuesDocumento4 pagineCombustion of Wood - Heat Valuesags19941253Nessuna valutazione finora

- BoilersDocumento37 pagineBoilersSumaira KhanNessuna valutazione finora

- Hood Type Dishwasher with Guaranteed Rinse SystemDocumento3 pagineHood Type Dishwasher with Guaranteed Rinse SystemHibatulAwwalUlfaNessuna valutazione finora

- Gpsa - M05Documento21 pagineGpsa - M05mobywicaksonoNessuna valutazione finora

- Recent Changes To API 521 PDFDocumento23 pagineRecent Changes To API 521 PDFPablo R. Jimenez SalcesNessuna valutazione finora

- Ee Oral QB-1Documento26 pagineEe Oral QB-1Atharva RodgeNessuna valutazione finora

- Lestari Banten Energi Bab 2Documento7 pagineLestari Banten Energi Bab 2mandortajirNessuna valutazione finora

- Combustion Control System For A Marine BoilerDocumento2 pagineCombustion Control System For A Marine Boilermavericksailor100% (2)

- Hydrofixx Prospekt Eng 2011-12-29Documento12 pagineHydrofixx Prospekt Eng 2011-12-29Istvan MadacsyNessuna valutazione finora

- Screw Feeder CalculationDocumento5 pagineScrew Feeder CalculationHirenNessuna valutazione finora

- FM Global Property Loss Prevention Data Sheets: Oil-And Gas-Fired Multiple Burner BoilersDocumento24 pagineFM Global Property Loss Prevention Data Sheets: Oil-And Gas-Fired Multiple Burner BoilersAnonymous knICaxNessuna valutazione finora

- JKKP PMTDocumento14 pagineJKKP PMTarepNessuna valutazione finora

- Controlling CO Boilers: Kurt Kraus and Minwoo Kwon UOP CallidusDocumento5 pagineControlling CO Boilers: Kurt Kraus and Minwoo Kwon UOP CallidusAle SanzNessuna valutazione finora

- Third Party Inspection For Valve - ProcedureDocumento13 pagineThird Party Inspection For Valve - ProcedureAbhay Karande100% (1)

- Economic Operation Power SystemsDocumento100 pagineEconomic Operation Power SystemsGayan ShashiNessuna valutazione finora

- Training ReportDocumento33 pagineTraining ReportMayank KamnaniNessuna valutazione finora

- Rules For The Classification of Naval Ships: Part C - Machinery, Systems and Fire ProtectionDocumento444 pagineRules For The Classification of Naval Ships: Part C - Machinery, Systems and Fire Protectionguichen wangNessuna valutazione finora

- A Central University Government of IndiaDocumento2 pagineA Central University Government of IndiaMohammed Shaji E IMU KochiNessuna valutazione finora

- Apgenco - Se - Mechanical EngineeringDocumento23 pagineApgenco - Se - Mechanical EngineeringNEELAKANTHESWARNessuna valutazione finora

- Boiler ExplosionDocumento4 pagineBoiler Explosionmhd_bashiriNessuna valutazione finora