Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

174-175 Technical A Boring Calculation of Cutting Forces PDF

Caricato da

Mohammed AlnasharDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

174-175 Technical A Boring Calculation of Cutting Forces PDF

Caricato da

Mohammed AlnasharCopyright:

Formati disponibili

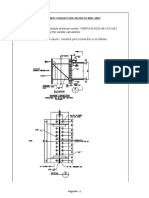

Tools with ISO elements | Technical appendix | Calculation of cutting forces, boring

Calculation of cutting forces, boring

(simplified)

ø 72 pre-drilled

ø 80

Example calculation: Boring tool ø 80 mm; Material: EN-GJL-250

Z = 5; pre-drilled ø 72 mm κ = 90° kc1.1* = 1160 mc = 0.26

vc 200 m/min fz= 0.2 mm

Blunting 30 %

Basic formula Calculation Result

Vc · 1000 200 · 1000

1. Spindle speed n = –––––––– n = –––––––– n = 800 1/min

�·D � · 80

(D – d) (80 – 72)

2. Cutting depth ap = –––––––– ap = –––––––– ap = 4 mm

2 2

3. Cutting cross section A = ap · f · z A = 4 mm · 0,2 mm · 5 A = 4 mm2

4. Chipping thickness h = fz · sin κ h = 0,2 mm · sin90º h = 0,2 mm

kc1.1 1160

5. Specific cutting kc = –––––––– kc = –––––––– kc = 1763 N/mm2

force h mc 0,2 0,26

without blunting with 30 % blunting:

factor

1763 N/mm2 × 1,3 =

2292 N/mm2

6. Cutting force Fc = A · kc = b · h · kc Fc = 4 mm2 · 2292 N/mm2 Fc = 9,17 kN

7. Cutting torque dm 0,076 m

dm = average Mc = Fc ––––– Mc = 9167,3 N ––––––– Mc = 348,3 Nm

diameter in metres 2 2

2 · � · n · Mc 2 · � · 800 min-1 · 348,3 Nm

8. Cutting power Pc = ––––––––––– Pc = ––––––––––––––––––––––– Pc = 29,2 kW

60s 60s

* Value for cutting force calculation, WTO GmbH Note: The efficiency of the main spindle drive is not taken into account.

Appropriate power calculations can be made by MAPAL.

174

Tools with ISO elements | Technical appendix | Calculation of cutting forces, boring

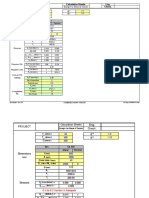

Machine tool selection:

Comparison with torque and output power of the machine tool Motor spindle (Figure 1)

Torque (Nm) Power (kW)

There follow two spindle speed/power diagrams.

The number of teeth and cutting parameters are to be defined as a 35 kW 100%

function of the machine. 40

630

400 30

In the example calculation the machine with the motor spindle is

200 187 Nm 100% 20

unsuitable, as here at a spindle speed of 800 1/min a torque of

10

187 Nm and a power of approx. 20 kW is achieved (Figure 1).

160 8

100 5

3,15

40 2

10

5 1000 0,6

1600

4000

10.000

Torque curve in Nm Spindle speed (1/min)

Power curve in kW

Line to assist on reading the diagram

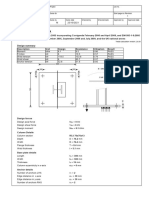

Solution: Geared spindle (Figure 2)

Either reduce number of teeth, reduce cutting speed and feed,

Torque (Nm) Power (kW)

divide cut between two tools or select more powerful machine

(e.g. with geared spindle, (Figure 2). 42 kW 100%

40

630 400 Nm 100%

400 30

200 20

10

160 8

100 5

3,15

40 2

10

5 0,6

1000

1600

4000

10.000

The example diagrams are shown in a simplified form. Spindle speed (1/min)

Technical

appendix

175

Potrebbero piacerti anche

- Problem Analysis TechniquesDocumento10 pagineProblem Analysis TechniquesIRMTraining100% (5)

- Unbraced RC Circular Column Design - Sample Calculation (AS3600)Documento4 pagineUnbraced RC Circular Column Design - Sample Calculation (AS3600)Tiam MarapeNessuna valutazione finora

- Calculation Coconut Dehusking and Decorticating MachineDocumento10 pagineCalculation Coconut Dehusking and Decorticating MachineJakeNessuna valutazione finora

- University of Sheffield Advanced Concrete Design Excel SheetsDocumento60 pagineUniversity of Sheffield Advanced Concrete Design Excel SheetsChetan ChikkannaswamyNessuna valutazione finora

- EEE8155 Design and Analysis of Electrical Machines and DrivesDocumento13 pagineEEE8155 Design and Analysis of Electrical Machines and DrivesstephenNessuna valutazione finora

- 174-175 Technical A Boring Calculation of Cutting Forces PDFDocumento2 pagine174-175 Technical A Boring Calculation of Cutting Forces PDFMohammed AlnasharNessuna valutazione finora

- 174-175 Technical A Boring Calculation of Cutting ForcesDocumento2 pagine174-175 Technical A Boring Calculation of Cutting Forcesjanaaidaas1996100% (2)

- Amp 2021-09Documento10 pagineAmp 2021-09Renata OsunaNessuna valutazione finora

- AMP Exam Solution 10 09 2021Documento10 pagineAMP Exam Solution 10 09 2021Dhanush YoganandhanNessuna valutazione finora

- CK 2 CM CK 2 2 CTM 2 CK 2 2/3 2 CM 2 CM 2 0.3 2 Cu2 Cu3: Project Job NoDocumento3 pagineCK 2 CM CK 2 2 CTM 2 CK 2 2/3 2 CM 2 CM 2 0.3 2 Cu2 Cu3: Project Job NorameshkaaNessuna valutazione finora

- Desingn of U.G TANK WALLDocumento5 pagineDesingn of U.G TANK WALLnileshNessuna valutazione finora

- Calculation Chechking Void 600x600 On SlabDocumento5 pagineCalculation Chechking Void 600x600 On SlabDamar BudiNessuna valutazione finora

- HMWK 3 Problem SolutionsDocumento6 pagineHMWK 3 Problem SolutionsMD Al-AminNessuna valutazione finora

- Beam DesignDocumento9 pagineBeam Designujaval shah100% (1)

- Base Slab & Crack Width Check - ACI CodeDocumento6 pagineBase Slab & Crack Width Check - ACI CodensureshbabuNessuna valutazione finora

- Beam DesignDocumento9 pagineBeam Designمحمد شاويNessuna valutazione finora

- Beam-Column Moment ConnectionDocumento10 pagineBeam-Column Moment Connectionrammohan100% (3)

- 30m Anchor and Base Plate MonopoleDocumento6 pagine30m Anchor and Base Plate MonopoleEhtesham AliNessuna valutazione finora

- Turning Problems - DR Saqib 2018Documento11 pagineTurning Problems - DR Saqib 2018254Nessuna valutazione finora

- MMB411-Tutorial Gears04 SpurGears-Bending&Fatigue PDFDocumento26 pagineMMB411-Tutorial Gears04 SpurGears-Bending&Fatigue PDFNdivhuwo NdivhuwoNessuna valutazione finora

- Verificare Grinda MetalicaDocumento2 pagineVerificare Grinda MetalicaVirginia Elena IordacheNessuna valutazione finora

- RC Beam DesignDocumento1 paginaRC Beam DesignshiruhanNessuna valutazione finora

- (Calculation To Check The Capacity of Pci Girder H-170) : Beam SlabDocumento33 pagine(Calculation To Check The Capacity of Pci Girder H-170) : Beam SlabDavid SinambelaNessuna valutazione finora

- Perhitungan Shaft Pulley ConveyorDocumento5 paginePerhitungan Shaft Pulley ConveyorRiska DamayantiNessuna valutazione finora

- Design of Beam: Effective Depth, D D' D'/D Mu/bd2 Me1 Mu, LimDocumento8 pagineDesign of Beam: Effective Depth, D D' D'/D Mu/bd2 Me1 Mu, LimVhârÆt Ķħâptäđi KhàdkâNessuna valutazione finora

- Mat Foundation Y Dir Rebar DesignDocumento4 pagineMat Foundation Y Dir Rebar DesignGaneshalingam Ramprasanna2Nessuna valutazione finora

- Beam Design With Crackwidth CalculationDocumento16 pagineBeam Design With Crackwidth CalculationFazilat Mohammad ZaidiNessuna valutazione finora

- EA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Documento2 pagineEA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Imaduddin KhajaNessuna valutazione finora

- Beam Design by SP 16 PDFDocumento1 paginaBeam Design by SP 16 PDFRafeeq khanNessuna valutazione finora

- Braced RC Circular Column Design - Sample Calculation (As 3600)Documento5 pagineBraced RC Circular Column Design - Sample Calculation (As 3600)Tiam MarapeNessuna valutazione finora

- 4.10. Pier Pile Cap Design: BR - CP7-5B (KTM) CH 39+884 To CH 39+954Documento3 pagine4.10. Pier Pile Cap Design: BR - CP7-5B (KTM) CH 39+884 To CH 39+954saubhagya majhiNessuna valutazione finora

- Design of T-BeamDocumento6 pagineDesign of T-BeamDineshNessuna valutazione finora

- Maxon RE25 Precious Metal Brushes 10wattDocumento1 paginaMaxon RE25 Precious Metal Brushes 10wattElectromateNessuna valutazione finora

- Shaft DesignDocumento18 pagineShaft DesignWest100% (1)

- Koluna C700.700 Office - PDF 1Documento2 pagineKoluna C700.700 Office - PDF 1jo fernandezNessuna valutazione finora

- DTS 10.2 Problems in Clutch DesignDocumento32 pagineDTS 10.2 Problems in Clutch Designr nilakandan100% (1)

- Pipe Guide and Welding Connection - h150x125x14x8.5Documento13 paginePipe Guide and Welding Connection - h150x125x14x8.5BenchNessuna valutazione finora

- Slab Reinforcement Considering 1m-StripDocumento2 pagineSlab Reinforcement Considering 1m-StripAnonymous ya6gBBwHJFNessuna valutazione finora

- 09 P Example Shear (Lecturenotes)Documento5 pagine09 P Example Shear (Lecturenotes)Matteo SoruNessuna valutazione finora

- Sci - Lift Calculation - 1Documento6 pagineSci - Lift Calculation - 1Simon LsmNessuna valutazione finora

- Design of Singly Reinf BeamsDocumento5 pagineDesign of Singly Reinf BeamsharsharanmannNessuna valutazione finora

- Section Properties: Left Beam Member MC 400: Major MinorDocumento12 pagineSection Properties: Left Beam Member MC 400: Major MinorshaimenneNessuna valutazione finora

- All TutorialsDocumento37 pagineAll TutorialsSimphiweNessuna valutazione finora

- Ref. Calculations Output: The Capacity of The Slab Basic MeshDocumento3 pagineRef. Calculations Output: The Capacity of The Slab Basic MeshOmar MokhtarNessuna valutazione finora

- Design of Pile and Pile Cap BeamDocumento4 pagineDesign of Pile and Pile Cap Beamshivendra kumarNessuna valutazione finora

- COLUMNDocumento3 pagineCOLUMNGaneshalingam Ramprasanna2Nessuna valutazione finora

- Project Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionDocumento2 pagineProject Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionmaheshbandhamNessuna valutazione finora

- Steel Structure DesignDocumento12 pagineSteel Structure DesignTalha tahirNessuna valutazione finora

- 3 1Documento3 pagine3 1Mark Arvin VelascoNessuna valutazione finora

- Design of PierDocumento18 pagineDesign of PierMrinal kayalNessuna valutazione finora

- LANDINGDocumento2 pagineLANDINGGaneshalingam Ramprasanna2Nessuna valutazione finora

- Beam Column - IS 800Documento2 pagineBeam Column - IS 800parishith0% (1)

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Documento5 pagineInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNessuna valutazione finora

- Turning Moment Diagram1Documento25 pagineTurning Moment Diagram1Bibin BabyNessuna valutazione finora

- Calculation and Design of Critical Speed and Power AgitatorDocumento4 pagineCalculation and Design of Critical Speed and Power AgitatorFrendy RianNessuna valutazione finora

- Deflection Due To Creep and ShrinkageDocumento3 pagineDeflection Due To Creep and ShrinkagekarthiNessuna valutazione finora

- Beam DesignDocumento15 pagineBeam Designravi kumarNessuna valutazione finora

- Project Job No.: Ed Ed EdDocumento5 pagineProject Job No.: Ed Ed EdUnknown_unknown_unknownNessuna valutazione finora

- HANDRAILDocumento3 pagineHANDRAILGaneshalingam Ramprasanna2Nessuna valutazione finora

- EC - Max 30 30 MM, Brushless, 60 Watt: Part NumbersDocumento1 paginaEC - Max 30 30 MM, Brushless, 60 Watt: Part NumbersfurkanfurkanfurkanNessuna valutazione finora

- Beam Referance Solving Units: Existing ConditionsDocumento5 pagineBeam Referance Solving Units: Existing ConditionsSUBHA JNessuna valutazione finora

- Routine Press Maintenance Routine Press Maintenance Routine Press Maintenance Routine Press MaintenanceDocumento42 pagineRoutine Press Maintenance Routine Press Maintenance Routine Press Maintenance Routine Press MaintenanceMorshedNessuna valutazione finora

- Project Planning: Jesper LarsenDocumento19 pagineProject Planning: Jesper LarsenMohammed AlnasharNessuna valutazione finora

- Silo - Tips Table of ContentDocumento18 pagineSilo - Tips Table of ContentMohammed AlnasharNessuna valutazione finora

- FT0511 1192 AbsDocumento1 paginaFT0511 1192 AbsMohammed AlnasharNessuna valutazione finora

- Outline: Spring Functions & Types Helical SpringsDocumento46 pagineOutline: Spring Functions & Types Helical SpringsMohammed AlnasharNessuna valutazione finora

- Steel Silos With Different Aspect Ratios: I - Behaviour Under Concentric DischargeDocumento25 pagineSteel Silos With Different Aspect Ratios: I - Behaviour Under Concentric DischargeBayari ArNessuna valutazione finora

- Programme Specification (Master) : A-GeneralDocumento33 pagineProgramme Specification (Master) : A-GeneralMohammed AlnasharNessuna valutazione finora

- Feeds and SpeedsDocumento1 paginaFeeds and SpeedsMohammed AlnasharNessuna valutazione finora

- The Discrete Element Method For The Simulation of Ball MillsDocumento7 pagineThe Discrete Element Method For The Simulation of Ball MillsMohammed AlnasharNessuna valutazione finora

- تقرير برنامج ماجستيرDocumento6 pagineتقرير برنامج ماجستيرMohammed AlnasharNessuna valutazione finora

- FintoriaDocumento1 paginaFintoriaMohammed AlnasharNessuna valutazione finora

- To Study The Analysis, Design and Behavior of Corrugated Steel SiloDocumento7 pagineTo Study The Analysis, Design and Behavior of Corrugated Steel SiloMohammed AlnasharNessuna valutazione finora

- ScreeningDocumento16 pagineScreeningMohammed AlnasharNessuna valutazione finora

- Module ListDocumento24 pagineModule ListMohammed AlnasharNessuna valutazione finora

- DR A CombinedDocumento14 pagineDR A CombinedArief SaladdinNessuna valutazione finora

- Obram Cheese LineDocumento16 pagineObram Cheese LineMohammed AlnasharNessuna valutazione finora

- Content in Revit - Families: Bill KnittleDocumento12 pagineContent in Revit - Families: Bill KnittleMohammed AlnasharNessuna valutazione finora

- Min PDFDocumento1 paginaMin PDFMohammed AlnasharNessuna valutazione finora

- CC-S1 SaleCNC ManualDocumento44 pagineCC-S1 SaleCNC ManualMohammed AlnasharNessuna valutazione finora

- v1 AB4013 DillonDocumento12 paginev1 AB4013 DillonMohammed AlnasharNessuna valutazione finora

- Numerical Analysis of Impact Events in A Centrifugal Impact Pin MillDocumento5 pagineNumerical Analysis of Impact Events in A Centrifugal Impact Pin MillMohammed AlnasharNessuna valutazione finora

- 4977 96eeDocumento3 pagine4977 96eeMohammed AlnasharNessuna valutazione finora

- Fire Water Tank ModelDocumento1 paginaFire Water Tank ModelMohammed AlnasharNessuna valutazione finora

- Thompson - Comparativa Entre Sist. de GuiadoDocumento10 pagineThompson - Comparativa Entre Sist. de GuiadoalexNessuna valutazione finora

- Ch3 Steps in FEMDocumento39 pagineCh3 Steps in FEMMohammed AlnasharNessuna valutazione finora

- Portfolio Management Professional Reference ListDocumento1 paginaPortfolio Management Professional Reference ListMohammed AlnasharNessuna valutazione finora

- TS A Plant FinalDocumento10 pagineTS A Plant FinalSaurabh TyagiNessuna valutazione finora

- Holex 2017-2018Documento8 pagineHolex 2017-2018Krakovchi LorandNessuna valutazione finora

- PCI MeteorTS900V ENDocumento2 paginePCI MeteorTS900V ENHX WEINessuna valutazione finora

- Unit - 8: CNC ProgrammingDocumento21 pagineUnit - 8: CNC ProgrammingVarshaNessuna valutazione finora

- 420SS Johnson - Cook - ConstantsDocumento8 pagine420SS Johnson - Cook - ConstantsKrishnaDuttPandeyKdpNessuna valutazione finora

- Using Tutorials Tutorial 1in MM Tutorial 1in Inch Tutorial 2Documento55 pagineUsing Tutorials Tutorial 1in MM Tutorial 1in Inch Tutorial 2patel_vicky87100% (1)

- Taladro 20inDocumento32 pagineTaladro 20inMari LozanoNessuna valutazione finora

- Laser Cutting - First Principles PaperDocumento6 pagineLaser Cutting - First Principles PaperSiddaraju V Hodekal100% (2)

- Current Trends in High-Speed Machining: S SmithDocumento3 pagineCurrent Trends in High-Speed Machining: S SmithJuanLuisEsquivelNessuna valutazione finora

- Handbook Prototyp Threading UsDocumento124 pagineHandbook Prototyp Threading UsRobotNessuna valutazione finora

- Gaylee Saws / Bitner Tooling TechnologiesDocumento36 pagineGaylee Saws / Bitner Tooling TechnologiesPuneeth KumarNessuna valutazione finora

- Catálogo Corte Láser Ulf-3015 1500WDocumento16 pagineCatálogo Corte Láser Ulf-3015 1500WMulti MaqNessuna valutazione finora

- Cutter GuideDocumento1 paginaCutter GuideCarlos RamirezNessuna valutazione finora

- Productivity Improvement of Conventional Drilling MachineDocumento38 pagineProductivity Improvement of Conventional Drilling MachineHarshad_S50% (2)

- VF HVRBDocumento12 pagineVF HVRBNAHRUDIN KOLIĆNessuna valutazione finora

- Series: Ultra High Performance Vertical Machining CenterDocumento20 pagineSeries: Ultra High Performance Vertical Machining Centerwataneta valveNessuna valutazione finora

- VC 430 VC 510 EnglishDocumento20 pagineVC 430 VC 510 EnglishValdair Jose De SouzaNessuna valutazione finora

- انتاج ٢Documento9 pagineانتاج ٢khaledfarrag281Nessuna valutazione finora

- 280 Zy 0 Uxx 5 Okr 0 VaDocumento28 pagine280 Zy 0 Uxx 5 Okr 0 VaJeffreyNessuna valutazione finora

- CMSP Handbook 12-Nov-2020Documento13 pagineCMSP Handbook 12-Nov-2020Cathode RayNessuna valutazione finora

- ASSAB Vanadis 8 SuperClean enDocumento12 pagineASSAB Vanadis 8 SuperClean enAre Soo YantoNessuna valutazione finora

- 741045revp Cosasco Hot Tap Kit-WIDocumento22 pagine741045revp Cosasco Hot Tap Kit-WIjonathan marin navarroNessuna valutazione finora

- Laser Cutting of Thick Sheet MetalsDocumento6 pagineLaser Cutting of Thick Sheet MetalsTolga TanrıseverNessuna valutazione finora

- Lathe, Drilling MachineDocumento42 pagineLathe, Drilling MachineSaroj100% (1)

- CNC 3018 To 3040 Upgrade With 500W Spindle Motor - TechydiyDocumento5 pagineCNC 3018 To 3040 Upgrade With 500W Spindle Motor - TechydiyDer Schleich KanalNessuna valutazione finora

- Drill PressDocumento12 pagineDrill PressRPShepherdNessuna valutazione finora

- Question Bank Set - 2 PDFDocumento69 pagineQuestion Bank Set - 2 PDFsayhigaurav07Nessuna valutazione finora

- Maintenance Ane Operation Manual For TNC-30N NLDocumento166 pagineMaintenance Ane Operation Manual For TNC-30N NLKien Nguyen TrungNessuna valutazione finora

- H 2000 6223 00 B Contact ToolsettingDocumento66 pagineH 2000 6223 00 B Contact Toolsettingssenn02Nessuna valutazione finora

- YSS Die Casting Die MaterialDocumento14 pagineYSS Die Casting Die MaterialVishal BalkwadeNessuna valutazione finora

- TurningDocumento9 pagineTurningAhmed RexNessuna valutazione finora