Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

F765-150SHP, 2.5", 3-Way ANSI Class 150 Butterfly Valve: Reinforced Teflon Seat, 316 Stainless Steel

Caricato da

tariqTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

F765-150SHP, 2.5", 3-Way ANSI Class 150 Butterfly Valve: Reinforced Teflon Seat, 316 Stainless Steel

Caricato da

tariqCopyright:

Formati disponibili

F765-150SHP, 2.

5”, 3-Way ANSI Class 150 Butterfly Valve

Reinforced Teflon Seat, 316 Stainless Steel

Application

These valves are designed to meet the needs of HVAC and commercial

applications requiring bubble tight shut-off for liquids. Typical applications

include chiller insolation, cooling tower isolation, change-over systems, large

air handler coil control, bypass and process control applications. The large

Cv values provide for an economical control valve solution for larger flow

applications.

Jobsite Note

Valve assembly should be stored in a weather protected area prior to

installation. Reference the butterfly valve installation instruction for additional

information.

Flow/Cv

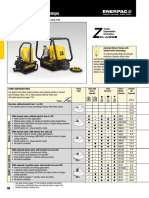

Cv 10° Cv 20° Cv 30° Cv 40° Cv 50° Cv 60° Cv 70° Cv 80° Cv 90°

2.2 8.8 20 37 55 80 110 142 146

Dimensions (Inches [mm])

Technical Data 1935

A B C D E F

Service chilled or hot water, up to 60% glycol, steam 12.78” 11.88” 23” [584] 20” [508] 7.38” [187] 9.26” [234]

Flow Characteristic modified linear, unidirectional [325] [302]

Controllable Flow Range Quarter turn, mechanically limited

Size [mm] 2.5” [65]

End Fitting For use with ASME/ANSI B16.5 flanges

Body carbon steel full lug (ASME B16.34)

Seat RPTFE

Shaft 17-4 PH stainless steel

Bushings glass backed PTFE

Disc 316 stainless steel

Body Pressure Rating [psi] ASME/ANSI Class 150

ANSI Class ANSI 150

Number of Bolt Holes 4

Date created, 01/19/2017 - Subject to change. © Belimo Aircontrols (USA), Inc.

Lug Threads 5/8-11 UNC

Maximum Steam Inlet 50 psi (345 kPa)

(Rotary actuators)

Media Temperature Range -22°F to 400°F [-30°C to 204°C]

(Water)

Close-Off Pressure 285 psi

Rangeability 100:1

Maximum Velocity 32 FPS

Cv 146

Weight 46.1 lb [20.9 kg]

Leakage 0%

Servicing maintenance free

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA / CARIBBEAN

SY2-220

On/Off Floating Point, Non-Spring Return, 220 V

Technical Data 2366

Power Supply 120 VAC ± 10%, 50/60 Hz

Power Consumption Running 100 W

Transformer Sizing 115 VA (class 2 power source)

Electrical Connection terminal block

Overload Protection thermally protected 135°C cut-out

Operating Range Y on/off, floating point

Angle of Rotation 90°

Torque 801 in-lbs [90 Nm] minimum

Duty cycle 30%

Direction of Rotation (Motor) reversible with built-in switch

Position Indication top mounted domed indicator

Manual Override hand wheel

Running Time (Motor) 16 sec

Internal Humidity Control resistive heating element

Ambient Humidity 5 to 100% RH (UL Type 4)

Ambient Temperature Range -22°F to 150°F [-30°C to 65°C]

Storage Temperature Range -40°F to 176°F [-40°C to 80°C]

Date created, 09/12/2017 - Subject to change. © Belimo Aircontrols (USA), Inc.

Housing NEMA 4X, IP66/67, UL Enclosure Type 4

Housing Material die cast aluminum alloy

Gear Train high alloy steel gear sets, self locking

Agency Listings† ISO, CE, cCSAus

Noise Level (Motor) <45 dB (A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 26.2 lb [11.9 kg]

Auxiliary Switch 2 x SPDT 3A resistive (0.5A inductive) @ 250

VAC, one set at +10° and one set at 85°

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA / CARIBBEAN

SY2-220

On/Off Floating Point, Non-Spring Return, 220 V

Wiring Diagrams

INSTALLATION NOTES 60 61 62 63

Do not change sensitivity or dip switch setting with power applied.

G G Ground

60

Power supply Common/Neutral and Control Signal “-”wiring to a N L1 1 Common

61 Open

common is prohibited. Terminals 4 and 6 need to be wired separately. 3 Open

H L2

Isolation relays must be used in parallel connection of multiple 4 Closed

62 Close

actuators using a common control signal inputs. The relays should be

5 Connect to #1 for fully

DPDT. open indication

6

Isolation relays are required in parallel applications. The reason parallel

63 7

applications need isolation relays is that the motor uses two sets of HTR

windings, one for each direction. When one is energized to turn the

actuator in a specific direction a voltage is generated in the other due to A

LS3

the magnetic field created from the first. It’s called back EMF. This is not B

A-C (Open Indication)

an issue with one actuator because the voltage generated in the second C

winding isn’t connected to anything so there is no flow. On parallel

applications without isolation, this EMF voltage energizes the winding it D

LS4

is connected to on the other actuators in the system, the actuators are E

tying to turn in both directions at once. The EMF voltage is always less D-F (Closed Indication)

F

than the supply voltage due to the resistance of the windings, so while Contact Rating: 5A 250 VAC Max.

the actuator still turns in the commanded direction, the drag from the SY2…12-120V or 230V

other reduces the torque output and causes overheating.

110/120V or 220/230VC AC/DC

! WARNING! LIVE ELECTRICAL COMPONENTS!

During installation, testing, servicing and troubleshooting of this

product, it may be necessary to work with live electrical components. 60 61 62 63

Have a qualified licensed electrician or other individual who has been G G Ground

Actuator B

properly trained in handling live electrical components perform these

tasks. Failure to follow all electrical safety precautions when exposed to N L1 1 Common

live electrical components could result in death or serious injury. Open K1

3 Open

H L2

4 Closed

Close K1-B

5

6

7 HTR

Date created, 09/12/2017 - Subject to change. © Belimo Aircontrols (USA), Inc.

A LS3

B

A-C (Open Indication)

C

D

LS4

E

D-F (Closed Indication)

F

Contact Rating: 5A 250 VAC Max.

SY2…12-110 (220)

G Actuator A

G Ground

1 Common

3 Open

4 Closed

K1-A

5

6

7 HTR

A LS3

B

A-C (Open Indication)

C

D

LS4

E

D-F (Closed Indication)

F

Contact Rating: 5A 250 VAC Max.

SY2…12-110 (220)

110/120 or 220/230 VAC

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA / CARIBBEAN

Potrebbero piacerti anche

- Valvula Belimo F780hdu - GMX24-MFT-X1Documento5 pagineValvula Belimo F780hdu - GMX24-MFT-X1Lionel ZacharonokNessuna valutazione finora

- 3-Way Valve - Belimo - F7100HD - PRBUP-3-TDocumento4 pagine3-Way Valve - Belimo - F7100HD - PRBUP-3-TDaniel FigueiredoNessuna valutazione finora

- Valvula Belimo F7150hdu - 2 - GMX24-MFT-X1Documento4 pagineValvula Belimo F7150hdu - 2 - GMX24-MFT-X1Lionel ZacharonokNessuna valutazione finora

- Valvula de Aislamiento f6100hd - drcx24-3-tDocumento5 pagineValvula de Aislamiento f6100hd - drcx24-3-tErikaNessuna valutazione finora

- Squif Single FansDocumento10 pagineSquif Single FansRavirayanpeterNessuna valutazione finora

- GFMJ-1500 en (V2.0 20200418)Documento2 pagineGFMJ-1500 en (V2.0 20200418)Jose Iván RamosNessuna valutazione finora

- Technical Information and Variances.: Spec/Feature Vst-Se VST-Mini CommentsDocumento1 paginaTechnical Information and Variances.: Spec/Feature Vst-Se VST-Mini CommentsAhmadNessuna valutazione finora

- Service Operating - Model 8329 ALEMITEDocumento19 pagineService Operating - Model 8329 ALEMITEMorales EduardoNessuna valutazione finora

- Masoneilan 80000 Data SheetDocumento24 pagineMasoneilan 80000 Data SheetGloria HamiltonNessuna valutazione finora

- Intelligent Plus: Installation ManualDocumento54 pagineIntelligent Plus: Installation ManualAle LatroNessuna valutazione finora

- VCA™ Series 5-YEAR LIMITED 5-YEAR LIMITEDDocumento12 pagineVCA™ Series 5-YEAR LIMITED 5-YEAR LIMITEDShouzab AbbasNessuna valutazione finora

- Series 2200 TechBro 041812Documento8 pagineSeries 2200 TechBro 041812GianniNessuna valutazione finora

- ITAP SpA's Technical Catalogue for Automatic Air-Vent ValvesDocumento14 pagineITAP SpA's Technical Catalogue for Automatic Air-Vent ValvesCarlos EspNessuna valutazione finora

- Electronic Pressure Independent Valve (ePIV) : ePIV With Non-Spring Return and Electronic Fail-Safe Actuators RT DDocumento14 pagineElectronic Pressure Independent Valve (ePIV) : ePIV With Non-Spring Return and Electronic Fail-Safe Actuators RT DHussein AkilNessuna valutazione finora

- File - 1918 - File0120 (1) .PDF - AeroserviciosDocumento2 pagineFile - 1918 - File0120 (1) .PDF - AeroserviciosKazem QarebeiglooNessuna valutazione finora

- Honeywell EA79 SpecsDocumento6 pagineHoneywell EA79 SpecsNestor PerezNessuna valutazione finora

- Installation, Operation, and Maintenance Manual Magnitude Magnetic Bearing Centrifugal Chillers IOM 1210-7Documento70 pagineInstallation, Operation, and Maintenance Manual Magnitude Magnetic Bearing Centrifugal Chillers IOM 1210-7MNessuna valutazione finora

- Service & operating manual for Alemite model 8329 air-operated double diaphragm pumpDocumento19 pagineService & operating manual for Alemite model 8329 air-operated double diaphragm pumpCesar Marcello Cordova GuerreroNessuna valutazione finora

- Dust Collector Main Pulse Valves: FeaturesDocumento4 pagineDust Collector Main Pulse Valves: FeaturesQuân TrịnhNessuna valutazione finora

- 44778.0 HPB Auxiliary Valve Operation: FeaturesDocumento3 pagine44778.0 HPB Auxiliary Valve Operation: FeaturesMOHAMED ABD ELGHANYNessuna valutazione finora

- VENTILADOR INDUSTRIAL enDocumento4 pagineVENTILADOR INDUSTRIAL enFelipe BarrientosNessuna valutazione finora

- Valvula YarwayDocumento12 pagineValvula YarwayRobert VillavicencioNessuna valutazione finora

- Product BrochuresDocumento6 pagineProduct BrochuresTanjong Minyak Car Wash Sdn BhdNessuna valutazione finora

- Reliable 12V industrial battery for security systemsDocumento4 pagineReliable 12V industrial battery for security systemsGA16DETNessuna valutazione finora

- Service Manual and Instructions For Continued Airworthiness For The Wipaire Model 8750 Amphibious/Seaplane Float On The Cessna Model 208/208B CaravanDocumento104 pagineService Manual and Instructions For Continued Airworthiness For The Wipaire Model 8750 Amphibious/Seaplane Float On The Cessna Model 208/208B CaravanStefanoNessuna valutazione finora

- ZE-Series Electric Pumps EN-GBDocumento6 pagineZE-Series Electric Pumps EN-GBjølle jølleNessuna valutazione finora

- In Line Pumps BrochureDocumento8 pagineIn Line Pumps BrochurerafaelberaldiNessuna valutazione finora

- 2463248Documento12 pagine2463248Dexter Hawkins100% (1)

- CPVS 40Documento24 pagineCPVS 40Luciano Lemos100% (1)

- Zuec Ventilation SolutionsDocumento8 pagineZuec Ventilation SolutionsAllen EspeletaNessuna valutazione finora

- 3-Way Valve LongLifeDocumento4 pagine3-Way Valve LongLifesconquest ETONessuna valutazione finora

- K 100 XL Sileo: Centrifugal Circular Duct Fan, 125WDocumento9 pagineK 100 XL Sileo: Centrifugal Circular Duct Fan, 125WPeroMentoroNessuna valutazione finora

- P6250S-110, 2-1/2", Electronic Pressure Independent Valve: Stainless Steel Ball, ANSI 125 FlangeDocumento4 pagineP6250S-110, 2-1/2", Electronic Pressure Independent Valve: Stainless Steel Ball, ANSI 125 FlangeJeffery OsvoldNessuna valutazione finora

- Hoja de Especificaciones RL94 InteriorDocumento2 pagineHoja de Especificaciones RL94 InteriormrspokebcsNessuna valutazione finora

- Turbair Blower (Type RT)Documento2 pagineTurbair Blower (Type RT)Amir AbbaszadehNessuna valutazione finora

- CVS 1000L Electro-Pneumatic Linear Positioner: Product ManualDocumento12 pagineCVS 1000L Electro-Pneumatic Linear Positioner: Product Manualmhidayat108Nessuna valutazione finora

- Installation and Maintenance InstructionsDocumento16 pagineInstallation and Maintenance InstructionsMonim KhanNessuna valutazione finora

- Advanced Electrode Steam Humidifier: Tools NeededDocumento28 pagineAdvanced Electrode Steam Humidifier: Tools NeededlaboratorioNessuna valutazione finora

- Delco 55SI Sheet 6 20Documento2 pagineDelco 55SI Sheet 6 20Richard SanchezNessuna valutazione finora

- B339 - Arb24 SR TDocumento4 pagineB339 - Arb24 SR TFernando PerdomoNessuna valutazione finora

- Champion Screw Compressors 30-45Documento6 pagineChampion Screw Compressors 30-45Uroš VučkovićNessuna valutazione finora

- WHA-1260XL Water Hammer ZurnDocumento2 pagineWHA-1260XL Water Hammer ZurnJeffry GabilanNessuna valutazione finora

- Flygt 4320 MixersDocumento4 pagineFlygt 4320 MixersEder Callejas PerezNessuna valutazione finora

- CV300 2Documento13 pagineCV300 2Achariya ParpromNessuna valutazione finora

- GK247D KDocumento3 pagineGK247D KRodney SilvaNessuna valutazione finora

- Flow Control August 2019 PDFDocumento37 pagineFlow Control August 2019 PDFAlberto Fernández MarínNessuna valutazione finora

- HIGH FLOW PULSE VALVESDocumento4 pagineHIGH FLOW PULSE VALVESFelipe SalvatierraNessuna valutazione finora

- Festo Electovalvulas Guia de SeleccionDocumento2 pagineFesto Electovalvulas Guia de SeleccionhomeroNessuna valutazione finora

- Yawmc 0414 UsDocumento12 pagineYawmc 0414 UsNaser JahangiriNessuna valutazione finora

- CSM - Modular ValvesDocumento2 pagineCSM - Modular Valvesramon slepickaNessuna valutazione finora

- The Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410ADocumento12 pagineThe Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410AcarlosNessuna valutazione finora

- GFMJ2000 VRLA Gel BatteryDocumento2 pagineGFMJ2000 VRLA Gel BatteryAllamNessuna valutazione finora

- DS2300 2300 8802 Yg Eu enDocumento16 pagineDS2300 2300 8802 Yg Eu enLucas Vinícius CostaNessuna valutazione finora

- Alternador Avi128 PDFDocumento2 pagineAlternador Avi128 PDFPascual MtzNessuna valutazione finora

- Yarway Series 7100Documento12 pagineYarway Series 7100Cecep AtmegaNessuna valutazione finora

- Gear Pumps: Product RangeDocumento4 pagineGear Pumps: Product RangeEng-Mohammed SalemNessuna valutazione finora

- Air Handling Unit Installation, Operation and Maintenance ManualDocumento19 pagineAir Handling Unit Installation, Operation and Maintenance ManualAnita MoyaNessuna valutazione finora

- FFGDocumento8 pagineFFGFernando RomoNessuna valutazione finora

- Single Check Filler Valves For Storage Tanks With Supplementary Back Check Valves 3174C, 3194C and 6584CDocumento1 paginaSingle Check Filler Valves For Storage Tanks With Supplementary Back Check Valves 3174C, 3194C and 6584CLPG Equipment Consulting and ServicesNessuna valutazione finora

- Digital Power Electronics and ApplicationsDa EverandDigital Power Electronics and ApplicationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Kavr159 en M G11Documento118 pagineKavr159 en M G11Indra AryanaNessuna valutazione finora

- UR Relay Series: Revision 1.60 Release NotesDocumento6 pagineUR Relay Series: Revision 1.60 Release NotesNima MahmoudpourNessuna valutazione finora

- Electric ContactsDocumento34 pagineElectric ContactsYelu GonzalezNessuna valutazione finora

- 01 Dist BasicsDocumento22 pagine01 Dist BasicsAshok KumarNessuna valutazione finora

- Field Installation and IP 16-13-1 Testing of Electrical EquipmentDocumento8 pagineField Installation and IP 16-13-1 Testing of Electrical EquipmentOrlando E Cabrera RojasNessuna valutazione finora

- PartLow MRC7700 Operqating ManualDocumento74 paginePartLow MRC7700 Operqating ManualLeandro CostaNessuna valutazione finora

- Hach Sc100 Controller User ManualDocumento64 pagineHach Sc100 Controller User ManualAndreea TrandafirNessuna valutazione finora

- Smart Street LightDocumento15 pagineSmart Street LightSaurabh BiswasNessuna valutazione finora

- BREAKDOWN COMPONENT FOR TERMINAL JAWA PHASE-1 PANELSDocumento4 pagineBREAKDOWN COMPONENT FOR TERMINAL JAWA PHASE-1 PANELSsswahyudiNessuna valutazione finora

- 101 - 200 Transistor CircuitsDocumento119 pagine101 - 200 Transistor CircuitsrichardNessuna valutazione finora

- 700-HB Square Base Relay: - Wiring Diagrams Coil Voltage Cat. No. U.S./Canada InternationalDocumento1 pagina700-HB Square Base Relay: - Wiring Diagrams Coil Voltage Cat. No. U.S./Canada InternationalArif KhanNessuna valutazione finora

- Configure 8200 SMD Frequency InverterDocumento8 pagineConfigure 8200 SMD Frequency InverterIranXavier Dos AnjosNessuna valutazione finora

- BMW 4HP22, 4HP24 Transmission No Upshift, Stuck in 1st Gear, Limp Mode Troubleshooting GuideDocumento5 pagineBMW 4HP22, 4HP24 Transmission No Upshift, Stuck in 1st Gear, Limp Mode Troubleshooting GuidegoogleheadNessuna valutazione finora

- TeSys LRD Overload Relays - LRD21Documento3 pagineTeSys LRD Overload Relays - LRD21Giau Ngoc HoangNessuna valutazione finora

- mi-SK983A100 v3Documento6 paginemi-SK983A100 v3alinmuieNessuna valutazione finora

- Sup-Ec8.0 Ec Controller User ManualDocumento24 pagineSup-Ec8.0 Ec Controller User Manualjaime hernandezNessuna valutazione finora

- Certification of Engineering Calculation 2: I-FormDocumento69 pagineCertification of Engineering Calculation 2: I-FormParantap RahaNessuna valutazione finora

- Manual de Instalacion CrimeStopper SP 500Documento32 pagineManual de Instalacion CrimeStopper SP 500emaffeiNessuna valutazione finora

- P140 AppsDocumento66 pagineP140 AppsDipankar MukherjeeNessuna valutazione finora

- 1.EEE304 Power System Protection TechniquesDocumento2 pagine1.EEE304 Power System Protection TechniquesVijay VenkatNessuna valutazione finora

- Wny 210 157 Part 6Documento222 pagineWny 210 157 Part 6lamondbrownNessuna valutazione finora

- NEX 24KV CatalogueDocumento42 pagineNEX 24KV CatalogueThức VõNessuna valutazione finora

- Coordinations Type 1&2Documento4 pagineCoordinations Type 1&2naderezzNessuna valutazione finora

- SIPROTEC Numerical Protection Relays Catalog Features 7RW600 UV/OV & Frequency ProtectionDocumento20 pagineSIPROTEC Numerical Protection Relays Catalog Features 7RW600 UV/OV & Frequency Protectionrajinipre-1Nessuna valutazione finora

- Safety Light Curtain BasicsDocumento7 pagineSafety Light Curtain BasicsShanmugamNessuna valutazione finora

- Self & Dual Powered Overcurrent Relays: Technical Data SheetDocumento17 pagineSelf & Dual Powered Overcurrent Relays: Technical Data SheetrelayteamNessuna valutazione finora

- Irdh265 TGHDocumento48 pagineIrdh265 TGHDecebal ScorilloNessuna valutazione finora

- Ect161 PDFDocumento16 pagineEct161 PDFMinhthien NguyenNessuna valutazione finora

- New Holland CX8070, CX8080, CX8090 Combine Harvesters Service Repair ManualDocumento31 pagineNew Holland CX8070, CX8080, CX8090 Combine Harvesters Service Repair ManualggjjjjotonesNessuna valutazione finora

- Power Management System PMA 300: SIEMENS Marine Solutions Automation On ShipsDocumento20 paginePower Management System PMA 300: SIEMENS Marine Solutions Automation On ShipshamzehNessuna valutazione finora