Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Duct Diag Wis 2003 PDF

Caricato da

calvin.bloodaxe4478Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Duct Diag Wis 2003 PDF

Caricato da

calvin.bloodaxe4478Copyright:

Formati disponibili

Duct Diagnostics February 2003

Duct Diagnostics: What’s Wrong with this System?

Duct Diagnostics: Topics Addressed in Session

Ductwork sizing discussion.

What’s Wrong with this System

Ductwork Specification: Consortium for Energy

Efficiency (CEE).

Smarter Buildings: Smarter Business Residential Conference

Tools for duct design and commissioning.

February 18, 2003

Some duct installation details.

Analysis of existing ductwork.

Rick Karg Ductwork trouble-shooting.

R.J. Karg Associates

www.karg.com

©2003 R.J. Karg Associates

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Ducted Distribution

Some Basics of Duct

Design and

Installation

3 4

Page 1

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Good Ducts Start With Good Design Duct Design Objective

Design - yeah, right! Duct delivery system provides year-around

What constitutes design comfort with:

is usually a mix of after-

Efficiency,

thought, what happens

to be on the truck at the Little noise,

moment, and the need No hazards to occupants,

for speed. Little maintenance.

5 6

Page 2

Rick Karg, R.J. Karg Associates 1

Duct Diagnostics February 2003

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Low Noise Levels are Important A Well Designed Duct System

Properly balanced.

Look good.

Be inexpensive to install.

Help create a comfortable environment.

Be very quiet while air handler is operating.

Be economical to operate.

Proper insulation, tight ducts, no pressure imbalance.

Be healthy for occupants (e.g., from pressure imbalances).

Be easy to maintain.

7 8

Page 3

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Duct Design Rules Duct System Pressures

Place air handler in central location.

Plan for symmetrical duct system.

Keep duct runs short.

Support ducts properly.

Use minimum number of fittings.

Keep aspect ratio low.

Select registers properly.

Install return in each room having a working door.

Etc.

9 10

Page 4 Page 5

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Measuring Temperature Rise & Design Standard is Manual D

Calculating CFM

Available from

ACCA

2800 Shirlington Road, Suite 300

Arlington, VA 22206

(703) 575-4477

www.acca.org

11 12

Page 6 Pages 47 and 35 - 49

Rick Karg, R.J. Karg Associates 2

Duct Diagnostics February 2003

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Manual D Procedure Manual D Procedure (con.)

Calculate DHL/DCL (Manual J, ACCA). Plan location of registers and grilles (Manual T).

Select blower (Manual S, ACCA & Man. Data). Determine the greatest Total Effective Length (TEL)

Determine External Static Pressure (ESP) from value for the duct system, supply and return sides.

manufacturer’s data. Include measured length and fitting equivalent length.

Determine device pressure losses (DPL) that are Calculate Friction Rate design value (FR).

added to distribution system.

FR = (ASP x 100)/TEL, or use friction chart.

Determine Available Static Pressure (ASP). Friction rate should be between 0.06” and 0.18” WG/100

ASP = ESP – DPL (Equal to about 0.2” WG, limits of range are feet of duct.

0.10” to 0.35” WG).

13 14

Pages 7 - 11 Pages 7 - 11

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

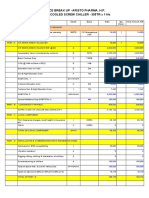

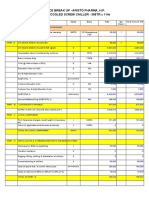

Manual D Procedure (con.) Ductwork Specification 1

Quick Reference for HVAC Installation Specification

Ducts and Air Handlers

Calculate heating and cooling airflow factors. Section/Specification Element

5. Ducts and Air Handlers

Specification Element Potential Benefits Verification Test or

Method

5.1 Duct Location - All ducts should be located within the conditioned spaces - Reduces conduction and air-leakage - Visual inspection.

HF = (blower CFM)/(Design heating load) whenever possible.

- No ducts in exterior wall cavities.

- Always install ducts, don’t use building cavities.

losses.

- No panned floor joists.

CF – (blower CFM)/(Sensible cooling design load) 5.2 Duct System Design

- Don’t use crawl spaces as plenums.

- Use Residential Duct System, Manual D, 1995 edition or later. - If ducts are not sized large enough to

permit adequate airflow, system efficiency

- Residential Duct System,

Manual D, 1995 edition or

can be adversely affected. later.

- 25 CFM of leakage for every 400 CFM of measured airflow, or - Can save 15% in energy costs per year for - Tests for Ensuring Proper Air

Calculate CFM for each register (room). 5.3 Allowable Duct Leakage, New Air

Distribution Systems - The sum of supply and return leakage divided by air handler

fan flow shall be a maximum of 6%.

new systems. Handler Airflow – 3.13 and 4.9.

- Total Duct Leakage and

Percentage Duct Leakage Test –

5.13.1.

Room CFM = HF or CF x Room DHL 5.3 Allowable Duct Leakage, Existing Air

Distribution Systems

- 40 CFM of leakage for every 400 CFM of measured airflow, or

- The sum of supply and return leakage divided by air handler

fan flow shall be a maximum of 10%.

- Can save 10% in energy costs per year for

existing systems.

- Tests for Ensuring Proper Air

Handler Airflow – 3.13 and 4.9.

- Total Duct Leakage and

Percentage Duct Leakage Test –

5.13.1.

Size branch ducts and trunks with use of duct 5.4 Duct Sealing Materials and Methods - Refer to Duct Installation and Sealing Specification. - Use of the proper materials and methods

extends the life of the ducted system,

retaining duct efficiency.

- Visual inspection.

5.5 Insulation, New and Existing Installations - Follow insulation manufacturer’s recommendations. - Duct insulation slows heat transfer, - Visual inspection.

calculator or friction chart. 5.5.2 Insulation, New Installations

- Refer to Duct Installation and Sealing Specification

- No insulation required for ducts in conditioned spaces, except

making the ducted distribution network

more efficient.

- Duct insulation slows heat transfer, - Visual inspection.

to prevent condensation. making the ducted distribution network

Check velocity. 5.5.3 Insulation, Existing Installations

- In unconditioned spaces a minimum R-value of 6 is required.

- Ducts located on the exterior of building require a minimum R-

value of 8.

- No insulation required for ducts in conditioned spaces, except

more efficient.

- Duct insulation slows heat transfer, - Visual inspection.

to prevent condensation. making the ducted distribution network

Select registers and grilles (Manual T, ACCA). - In unconditioned spaces a minimum R-value of 6 is required.

- Parts of ductwork that are not accessible do not require

insulation.

- If ducts are already insulated to R-4 or greater, no additional

more efficient.

insulation is needed.

Balance system with branch balancing dampers. - Ducts located on the exterior of building require a minimum R-

value of 8.

15 16

Pages 7 - 11 Page 16

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Ductwork Specification 2

Quick Reference for HVAC Installation Specification

Ducts and Air Handlers (continued)

Section/Specification Element Specification Element Potential Benefits Verification Test or

Method

5. Ducts and Air Handlers (continued)

5.6 Room Pressure Imbalances - While air handler is operating and house is closed up, pressure - High-pressure differences between spaces - Room Pressure Imbalances

differences between 1) closed room and the outdoors and 2) the in a house and the outdoors can increase air Test – 5.14.1.

main body of the house with all the interior doors closed should leakage to and from the outdoors.

Tools for Duct

be no more than 0.01 inches water gauge (3 Pascals), positive or Decreasing these pressures can save energy.

negative. - Room depressurization may cause

hazardous back drafting of combustion

gases.

5.7 Selection and Location of Supply Registers - At least one supply-air register should be installed in each - Proper selection and placement of supply- - Visual inspection.

conditioned room. air registers can increase occupant comfort.

- Each register should be able to handle the required heating and

cooling CFM and air velocity.

- Maximum velocity of 700 feet per minute.

- Select for proper throw, drop, and spread.

5.8 Selection and Location of Return Grilles - Return-air grilles should be located to provide pressure- - The proper placement of return-air grilles - Visual inspection.

Design & Testing

balanced air circulation during air handler operation. minimized indoor pressure imbalances

- Max. velocity of 500 feet per minute. during air handler operation, thereby

conserving energy lost due to forces air

leakage.

5.9 Duct Support - Ducts should be supported so as to prevent dislocation or - Supporting ducts in a proper and durable - Visual inspection.

damage. fashion helps maintain duct system

- Refer to Duct Installation and Sealing Specification. efficiency.

5.10 Volume Dampers - Supply branch ducts should be equipped with volume dampers - A properly balanced duct system increases - Visual inspection.

to allow for manual balancing of distribution airflow. occupant comfort and reduces occupant

- After installation, the ducted system should be properly complaints.

balanced.

5.11 Access for Installation and Maintenance - Adequate clearance should be provided on all sides of the - Adequate clearance for the maintenance of - Visual inspection.

equipment to allow for easy access for periodic maintenance. important equipment components allows

- All doors leading from the mechanical room to the outdoors the equipment to be serviced properly and

should be large enough to allow easy passage of equipment. regularly, thereby ensuring the maintenance

of maximum equipment efficiency.

5.12 Maintenance Items - Inspect the following items at servicing: - Proper maintenance of the forced-air - Visual inspection.

- Filters, distribution system will help retain system

- Duct obstructions and debris, efficiency.

- Duct leaks and disconnections,

- Volume dampers,

- Duct balancing,

- Duct insulation, and

- Room pressure imbalances.

17 18

Page 17 Page 18

Rick Karg, R.J. Karg Associates 3

Duct Diagnostics February 2003

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Duct Duct

Calculator Calculator

From ACCA From ACCA

19 20

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Duct Blower Digital Manometer

The Energy Conservatory

Duct Blaster™

21 22

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Duct Leakage Testing Blower Door

If you don’t test, you A blower door

is often needed

don’t know. for duct leakage

Duct leakage testing is testing.

essential to producing

comfort and efficiency.

23 24

Rick Karg, R.J. Karg Associates 4

Duct Diagnostics February 2003

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Pressure Pan & Flowbox Measuring Air Flow

The volumetric

capture bag.

AKA the garbage bag.

Works by timing how

long it takes to fill a

known volume with air.

25 26

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Some Duct

Installation Details

27 28

Page 19

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Try to Keep Duct Inside

Inside vs. outside Do not use

the air and duct tape

thermal barrier

of the house. on ducts!

If the ducts are

outside, more

work is required

But, it’s really

to make them good for many

efficient. other needs.

29 30

Rick Karg, R.J. Karg Associates 5

Duct Diagnostics February 2003

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Ducts Should Be Permanently Tight Love that Duct Mastic

Mechanical Fastening

Sealed with Mastic

Pay attention to gores

31 32

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Provide Ability to Adjust Airflow Temperature Measurements

If duct are large enough, Simple temperature

Cooling coil

airflow can be adjusted readings can help

to met individual locate leaks or loss

comfort levels or of cooling or heating

differences in heating energy in a ducted

and cooling loads system.

Cooling season

Balancing damper handle

33 34

Page 20

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Impact of an Air Handler Multiple Returns are Essential

What happens to air leakage Return air paths are

as a result of the closed

bedroom door?

critical to a good duct

system.

What if a return is installed A closed door can serve

in the basement return trunk?

as an air distribution

What if the supply trunk leaks damper!!

to the outdoors?

35 36

Page 21

Rick Karg, R.J. Karg Associates 6

Duct Diagnostics February 2003

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Return Side Retrofit

Analysis of Existing

Ductwork

For a furnace/AC to operate at maximum efficiency and capacity, the volume-

carrying capacity of the return air must equal that of the supply air. However,

many residential systems are undersized on the return side, causing pressure

imbalances and discomfort. To balance the return and supply sides, additional

Page 22 return grilles and ductwork might have to be added.

37 38

Source: Journal of Light Construction, 2/94, page 49

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Analysis of Existing Ductwork 1 Analysis of Existing Ductwork 2

Inspect air handler and ductwork for such things

Interview occupants about thermal comfort of as:

existing system. Anticipator setting.

Ask such things as: Duct leakage.

Uncomfortable rooms. Restricted returns.

Excessive noise. Panned floor joists.

Frequent cycling of air handler blower. Ducts in unconditioned spaces.

Balancing dampers.

39 40

Pages 23 - 26 Pages 23 - 26

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Analysis of Existing Ductwork 3 Analysis of Existing Ductwork 4

Do technical appraisal of duct system and Do pressure testing of existing system:

equipment: Room-to-room pressures.

Temperature rise. Duct leakage testing

Static pressure measurements. Blower door.

Blower CFM. Duct blower.

41 42

Pages 23 - 26 Pages 23 - 26

Rick Karg, R.J. Karg Associates 7

Duct Diagnostics February 2003

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Analysis of Existing Ductwork 5 Now, Perform the Work!

Determine strategies for duct repair:

Write down possible problems.

Check trouble-shooting list.

Determine required alterations to furnace/AC and

ductwork.

Decide on consumer education strategies.

43 44

Pages 23 - 26 Pages 23 - 26

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Ductwork Troubleshooting 1

Duct Trouble-

Shooting Tables

45 46

Pages 27 - 30 Pages 27 - 30

Duct Diagnostics: What’s Wrong with this System? Duct Diagnostics: What’s Wrong with this System?

Ductwork Troubleshooting 2 Ductwork Troubleshooting 3

47 48

Pages 27 - 30 Pages 27 - 30

Rick Karg, R.J. Karg Associates 8

Duct Diagnostics February 2003

Duct Diagnostics: What’s Wrong with this System?

Ductwork Troubleshooting 4

49

Pages 27 - 30

Rick Karg, R.J. Karg Associates 9

Potrebbero piacerti anche

- Underground Distribution System Design GuideDocumento461 pagineUnderground Distribution System Design Guidetruemack8295% (20)

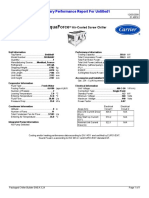

- Selection Sheet - 30XA452 Screw ChillerDocumento1 paginaSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478Nessuna valutazione finora

- Distributed Process Control ReportDa EverandDistributed Process Control ReportNessuna valutazione finora

- UT Thickness Digital 19-105 Rev.0 PDFDocumento10 pagineUT Thickness Digital 19-105 Rev.0 PDFUmair JavedNessuna valutazione finora

- Vibration Measurement Handbook MideDocumento14 pagineVibration Measurement Handbook MideJason DrakeNessuna valutazione finora

- ADRE System by GE - Orbit MagazineDocumento84 pagineADRE System by GE - Orbit MagazineMuhammad ImranNessuna valutazione finora

- (Subrayado) Predictive - Maintenance - For - Wind - Turbine - Diagnostics - Using - Vibration - Signal - AnalysisDocumento4 pagine(Subrayado) Predictive - Maintenance - For - Wind - Turbine - Diagnostics - Using - Vibration - Signal - Analysismerecis920Nessuna valutazione finora

- Air Conditioning Proposal for AuditoriumDocumento4 pagineAir Conditioning Proposal for Auditoriumcalvin.bloodaxe4478Nessuna valutazione finora

- Wireless Communications Design Handbook: Space Interference: Aspects of Noise, Interference and Environmental ConcernsDa EverandWireless Communications Design Handbook: Space Interference: Aspects of Noise, Interference and Environmental ConcernsValutazione: 5 su 5 stelle5/5 (1)

- Vibration Analysis of Rotating Machines With Case Studies PDFDocumento7 pagineVibration Analysis of Rotating Machines With Case Studies PDFShailesh Barbate100% (1)

- Daniel Tian Li: Circular Column Design Based On ACI 318-05Documento1 paginaDaniel Tian Li: Circular Column Design Based On ACI 318-05OswardMorenoNessuna valutazione finora

- Shubharambh Banquets HL - All Halls 26-5-2017Documento5 pagineShubharambh Banquets HL - All Halls 26-5-2017calvin.bloodaxe4478Nessuna valutazione finora

- AP CentacTraining Manual V2 PDFDocumento262 pagineAP CentacTraining Manual V2 PDFubaldo caraballo89% (9)

- Design and Analysis of Tune Mass Damper System IJERTV9IS100244Documento4 pagineDesign and Analysis of Tune Mass Damper System IJERTV9IS100244Gülçin TekinNessuna valutazione finora

- Nuclear Engineering Homework Solutions Due 16 February 2006Documento8 pagineNuclear Engineering Homework Solutions Due 16 February 2006Snakefistx100% (1)

- Optimization of Cable Insulation Eccentricity by Taguchi Robust DesignDocumento6 pagineOptimization of Cable Insulation Eccentricity by Taguchi Robust Design李庆森Nessuna valutazione finora

- Datwyler WP CoordinationDocumento2 pagineDatwyler WP Coordination2zeceNessuna valutazione finora

- Inspection Programs For Internal Corrosion in PipingDocumento6 pagineInspection Programs For Internal Corrosion in PipingsajimaliNessuna valutazione finora

- Considerations ForDocumento9 pagineConsiderations Forkiyong namNessuna valutazione finora

- Vibration Monitoring of BearingsDocumento22 pagineVibration Monitoring of Bearingsfaisal ali khanNessuna valutazione finora

- Tutorial: Environmental Vibration CriteriaDocumento2 pagineTutorial: Environmental Vibration CriteriadrdinglechengNessuna valutazione finora

- BR 821-045 BAUR Product Brochure Cable Testing Diagnostics ENDocumento11 pagineBR 821-045 BAUR Product Brochure Cable Testing Diagnostics ENthumbaibalaNessuna valutazione finora

- Accurate Defect Sizing Using Phased Array and Signal ProcessingDocumento10 pagineAccurate Defect Sizing Using Phased Array and Signal ProcessingfayyazdnvNessuna valutazione finora

- Bstract: A B D C EDocumento15 pagineBstract: A B D C EDavidNessuna valutazione finora

- Analysis and Optimization of 132KV Grid Using ETAP PDFDocumento6 pagineAnalysis and Optimization of 132KV Grid Using ETAP PDFAlejandro PalaciosNessuna valutazione finora

- 6 PDFDocumento4 pagine6 PDFAnonymous NHuqCVE1wNessuna valutazione finora

- CT Sim Commissioning ProcessDocumento11 pagineCT Sim Commissioning ProcessEskadmas BelayNessuna valutazione finora

- Issue 8 100822 White Paper - HLL System Critical Components - What You Need To KnowDocumento5 pagineIssue 8 100822 White Paper - HLL System Critical Components - What You Need To Knowsteve_jervis687Nessuna valutazione finora

- Is Fault Locating Killing Our Cable SystemsDocumento5 pagineIs Fault Locating Killing Our Cable SystemsJIGSNessuna valutazione finora

- Tremblay Et Al 2010 Effluent Decontamination Systems Addressing The Challenges of Planning Designing Testing andDocumento11 pagineTremblay Et Al 2010 Effluent Decontamination Systems Addressing The Challenges of Planning Designing Testing andAntonio Osante LeyvaNessuna valutazione finora

- Interview Questions and Answers On Safety Systems Instrumentation ToolsDocumento7 pagineInterview Questions and Answers On Safety Systems Instrumentation ToolsNGASSAKI ATONGUI Christ HubertNessuna valutazione finora

- E-Vaidya NewDocumento1 paginaE-Vaidya Newhash electrolabsNessuna valutazione finora

- InsightsGainedNPIC HMIT2012Documento11 pagineInsightsGainedNPIC HMIT2012waqar khanNessuna valutazione finora

- Emona Signals Systems R3 0Documento192 pagineEmona Signals Systems R3 0Erika AlexandraNessuna valutazione finora

- Electrodynamic Motor Distortion MechanismsDocumento15 pagineElectrodynamic Motor Distortion Mechanismsdonald141Nessuna valutazione finora

- EDS-80 Tape Extensometer R04Documento14 pagineEDS-80 Tape Extensometer R04davzuluetaNessuna valutazione finora

- Testing-and-Diagnostics-of-Reclosers-and-Sectionalizers-Brochure-ENUDocumento16 pagineTesting-and-Diagnostics-of-Reclosers-and-Sectionalizers-Brochure-ENUjagmcinquitosNessuna valutazione finora

- Workshop Transformer Residual Life EnhancementDocumento4 pagineWorkshop Transformer Residual Life EnhancementdevcharuNessuna valutazione finora

- Bridge Monitoring System Using IOTDocumento4 pagineBridge Monitoring System Using IOTsanaz shoaieNessuna valutazione finora

- Hitachi_Energy_MV_Surge_Arrester_Application_GuidelinesDocumento31 pagineHitachi_Energy_MV_Surge_Arrester_Application_GuidelinesAmany HamdyNessuna valutazione finora

- Deva, Azizi, (Hes Vs de 4200h)Documento16 pagineDeva, Azizi, (Hes Vs de 4200h)Omar MuqtharNessuna valutazione finora

- Property Risk Solutions: Electrical Maintenance and Testing GuidelinesDocumento6 pagineProperty Risk Solutions: Electrical Maintenance and Testing GuidelinesAndres RamirezNessuna valutazione finora

- Finished PosterDocumento1 paginaFinished Posterapi-396402491Nessuna valutazione finora

- Implementation of Locally Weighted Projection Regression Network For Condition Monitoring of A Steam TurbineDocumento4 pagineImplementation of Locally Weighted Projection Regression Network For Condition Monitoring of A Steam Turbinepurushothaman sinivasanNessuna valutazione finora

- Arduino-controlled UV-C disinfection binDocumento27 pagineArduino-controlled UV-C disinfection binAdelfa Mae BerdonNessuna valutazione finora

- Engineering Structures: Neil A. Hoult, W. Andy Take, Chris Lee, Michael DuttonDocumento9 pagineEngineering Structures: Neil A. Hoult, W. Andy Take, Chris Lee, Michael DuttonpaulkohanNessuna valutazione finora

- Condition Monitoring of Rotating EquipmeDocumento14 pagineCondition Monitoring of Rotating EquipmessshettyNessuna valutazione finora

- Vibration System For GT GeneratorDocumento5 pagineVibration System For GT GeneratorMayurNessuna valutazione finora

- Schneider Electric & Satron To Shorter Cleaning TimeDocumento4 pagineSchneider Electric & Satron To Shorter Cleaning TimeTHONG LAMNessuna valutazione finora

- A Floor Sensor System For Gait RecognitionDocumento6 pagineA Floor Sensor System For Gait RecognitionNasir HussainNessuna valutazione finora

- Add Control GKDocumento50 pagineAdd Control GKVangelis PapadogiannisNessuna valutazione finora

- Pipeline Corrosion MitigationDocumento19 paginePipeline Corrosion MitigationJinlin HanNessuna valutazione finora

- Experiment 4Documento13 pagineExperiment 4shawon_darkNessuna valutazione finora

- Johnson PDFDocumento9 pagineJohnson PDFJHON ANGEL VARGAS HUAHUASONCCONessuna valutazione finora

- 2018 COMP Report CPQR Technical Quality Control Guidelines Fo Gamma Knife RadiosurgeryDocumento3 pagine2018 COMP Report CPQR Technical Quality Control Guidelines Fo Gamma Knife RadiosurgerytuNessuna valutazione finora

- Tubrial Seftest: BuiihnDocumento10 pagineTubrial Seftest: BuiihnVLSISD36 Edwin DominicNessuna valutazione finora

- 17th Edition Testing GuideDocumento13 pagine17th Edition Testing GuideOdoch Herbert0% (1)

- Final Group Presentation 2022Documento16 pagineFinal Group Presentation 2022Job OkurutNessuna valutazione finora

- Vibration Analysis in Bearings For Failure PreventDocumento17 pagineVibration Analysis in Bearings For Failure PreventlayafoNessuna valutazione finora

- Four Factors Accurate Fiber Certification White Papers Books en - 903928Documento6 pagineFour Factors Accurate Fiber Certification White Papers Books en - 903928JOSE RAMOSNessuna valutazione finora

- Hydrotherapy Pools BrochureDocumento6 pagineHydrotherapy Pools BrochureVicktorNessuna valutazione finora

- 02 A 06 de Junho de 2003 / June 2 To 6 2003 Rio de Janeiro - RJ - BrasilDocumento16 pagine02 A 06 de Junho de 2003 / June 2 To 6 2003 Rio de Janeiro - RJ - Brasilfranklin84Nessuna valutazione finora

- AnritsuInfivis XRay 1017-UKDocumento4 pagineAnritsuInfivis XRay 1017-UK. .Nessuna valutazione finora

- 3300 16 MM High Temperature Proximity System: ManualDocumento48 pagine3300 16 MM High Temperature Proximity System: ManualLinh LyNessuna valutazione finora

- In 001318 HPLC Vanquish Core Ownership Cost Infographic In001318 Na enDocumento1 paginaIn 001318 HPLC Vanquish Core Ownership Cost Infographic In001318 Na enNowsathAliNessuna valutazione finora

- Extruded Cable Reliability-Life Estimation and Life ExtensionDocumento6 pagineExtruded Cable Reliability-Life Estimation and Life Extensionromany italianoNessuna valutazione finora

- Polycab Cables PricelistDocumento4 paginePolycab Cables Pricelistcalvin.bloodaxe4478Nessuna valutazione finora

- GO GREEN!!!!: My Role in Improving The Living Conditions of PuneDocumento7 pagineGO GREEN!!!!: My Role in Improving The Living Conditions of Punecalvin.bloodaxe4478Nessuna valutazione finora

- SIGuide ConversionsDocumento12 pagineSIGuide Conversionscalvin.bloodaxe4478Nessuna valutazione finora

- Vat Break UpDocumento2 pagineVat Break Upcalvin.bloodaxe4478Nessuna valutazione finora

- PURCHASES BY QUALITAIR ENGINEERSDocumento1 paginaPURCHASES BY QUALITAIR ENGINEERScalvin.bloodaxe4478Nessuna valutazione finora

- Contact ListDocumento3 pagineContact Listcalvin.bloodaxe4478Nessuna valutazione finora

- Harry Potter DetailsDocumento3 pagineHarry Potter Detailscalvin.bloodaxe4478Nessuna valutazione finora

- JMSOADN Enterprises GI Sheet Sales ReportDocumento1 paginaJMSOADN Enterprises GI Sheet Sales Reportcalvin.bloodaxe4478Nessuna valutazione finora

- Price Break Up in INR With Duties (04.06.08)Documento2 paginePrice Break Up in INR With Duties (04.06.08)calvin.bloodaxe4478Nessuna valutazione finora

- STPI - Equipment ListDocumento3 pagineSTPI - Equipment Listcalvin.bloodaxe4478Nessuna valutazione finora

- Evergreen Chiller Performance Outputs: Tag Name: 23XRV 350TRDocumento1 paginaEvergreen Chiller Performance Outputs: Tag Name: 23XRV 350TRcalvin.bloodaxe4478Nessuna valutazione finora

- Ciaq Webinar MullerDocumento56 pagineCiaq Webinar MullerAgozie AnosikeNessuna valutazione finora

- Dynapac - Equipment ScheduleDocumento1 paginaDynapac - Equipment Schedulecalvin.bloodaxe4478Nessuna valutazione finora

- Annexure - 1 Scope of Supply Rev (04.12.08)Documento1 paginaAnnexure - 1 Scope of Supply Rev (04.12.08)calvin.bloodaxe4478Nessuna valutazione finora

- AquaForce Air-Cooled Screw Chiller Performance ReportDocumento1 paginaAquaForce Air-Cooled Screw Chiller Performance Reportcalvin.bloodaxe4478Nessuna valutazione finora

- Factory Certificate On Chilled Water Pipe ConnectionsDocumento1 paginaFactory Certificate On Chilled Water Pipe Connectionscalvin.bloodaxe4478Nessuna valutazione finora

- Selection of Water Cooled Screw ChillerDocumento1 paginaSelection of Water Cooled Screw Chillercalvin.bloodaxe4478Nessuna valutazione finora

- Detailed Performance Summary For Untitled1(1) ChillerDocumento2 pagineDetailed Performance Summary For Untitled1(1) Chillercalvin.bloodaxe4478Nessuna valutazione finora

- Selection of Water Cooled Screw ChillerDocumento1 paginaSelection of Water Cooled Screw Chillercalvin.bloodaxe4478Nessuna valutazione finora

- Price Break Up in INR With Duties (04.06.08)Documento2 paginePrice Break Up in INR With Duties (04.06.08)calvin.bloodaxe4478Nessuna valutazione finora

- 30xa0452 FullloadDocumento1 pagina30xa0452 Fullloadcalvin.bloodaxe4478100% (1)

- Price Break Up in INR With Duties (04.12.08)Documento2 paginePrice Break Up in INR With Duties (04.12.08)calvin.bloodaxe4478Nessuna valutazione finora

- Data Sheet - Carrier ChillerDocumento4 pagineData Sheet - Carrier Chillercalvin.bloodaxe4478Nessuna valutazione finora

- Selection of Water Cooled Chiller - 221 TR PDFDocumento2 pagineSelection of Water Cooled Chiller - 221 TR PDFcalvin.bloodaxe4478Nessuna valutazione finora

- 30RB0262 Partload Chiller DataDocumento3 pagine30RB0262 Partload Chiller Datacalvin.bloodaxe4478Nessuna valutazione finora

- Detailed Performance Summary For Untitled1Documento3 pagineDetailed Performance Summary For Untitled1calvin.bloodaxe4478Nessuna valutazione finora

- Annexure - I Scope of SupplyDocumento1 paginaAnnexure - I Scope of Supplycalvin.bloodaxe4478Nessuna valutazione finora

- Product Information F737 OberonDocumento2 pagineProduct Information F737 OberonCosmic TitusNessuna valutazione finora

- Extended Essay Introduction - Thomas Jackson PDFDocumento2 pagineExtended Essay Introduction - Thomas Jackson PDFThomas JacksonNessuna valutazione finora

- Problem Set 1Documento2 pagineProblem Set 1JiiiNessuna valutazione finora

- Mn-Cu Alloying Improves Mechanical Properties of Ductile IronDocumento7 pagineMn-Cu Alloying Improves Mechanical Properties of Ductile IronabhiNessuna valutazione finora

- Final Exam "Intro To Optics": Problems & SolutionsDocumento7 pagineFinal Exam "Intro To Optics": Problems & SolutionsDavid SalahNessuna valutazione finora

- 9.1 Multiple-Choice and Bimodal QuestionsDocumento18 pagine9.1 Multiple-Choice and Bimodal QuestionsQuốc Thắng NguyễnNessuna valutazione finora

- NatureDocumento18 pagineNatureAs PNessuna valutazione finora

- Traversable Wormholes: Some Simple Examples: Matt VisserDocumento7 pagineTraversable Wormholes: Some Simple Examples: Matt VisserllapeyreNessuna valutazione finora

- Evaporacion y EvapotranspiracionDocumento50 pagineEvaporacion y EvapotranspiracionRaul Cordova Alvarado100% (1)

- Charged Particle Motion in Magnetic and Electric FieldsDocumento15 pagineCharged Particle Motion in Magnetic and Electric FieldsMariyam FarhanaNessuna valutazione finora

- Research GateDocumento34 pagineResearch GateMustafa ÇakırNessuna valutazione finora

- Laboratory Exercise 3: Atterberg Limits Test: ReferencesDocumento10 pagineLaboratory Exercise 3: Atterberg Limits Test: ReferencesmoNessuna valutazione finora

- Tablas SI - Moran & Shapiro - Fundamentals of Engineering Thermodynamics 5th Edition (Con R12)Documento53 pagineTablas SI - Moran & Shapiro - Fundamentals of Engineering Thermodynamics 5th Edition (Con R12)Yasir MumtazNessuna valutazione finora

- Introduction To Wellbore Positioning - V01.7.12 PDFDocumento157 pagineIntroduction To Wellbore Positioning - V01.7.12 PDFMiguelNessuna valutazione finora

- Experiment 1: Forces in A Roof Truss With A Central and Wind LoadDocumento5 pagineExperiment 1: Forces in A Roof Truss With A Central and Wind LoadAinur NasuhaNessuna valutazione finora

- Division 23 Hvac: 230548: Vibration Isolation / 230549: Seismic/Wind Restraints Section 230548: Vibration IsolationDocumento10 pagineDivision 23 Hvac: 230548: Vibration Isolation / 230549: Seismic/Wind Restraints Section 230548: Vibration IsolationTengku Azaha Tengku IsmailNessuna valutazione finora

- High-Performance Vertical Gate-All-Around Silicon Nanowire FET With High - Kappa Metal GateDocumento5 pagineHigh-Performance Vertical Gate-All-Around Silicon Nanowire FET With High - Kappa Metal GateForgot PasswordNessuna valutazione finora

- Changes in ACI 318 Code Provisions For Earthquake Resistant StructuresDocumento5 pagineChanges in ACI 318 Code Provisions For Earthquake Resistant StructuresTrầmLãngNessuna valutazione finora

- TitraDocumento8 pagineTitraAbdoul RahimNessuna valutazione finora

- 03 Chap 3 Membrane Preparation Phase InversionDocumento51 pagine03 Chap 3 Membrane Preparation Phase InversionRamanan NadarajanNessuna valutazione finora

- Liquid-crystal polymer properties and usesDocumento3 pagineLiquid-crystal polymer properties and usessheetalNessuna valutazione finora

- Chapter Ten Lecture Ten Thermodynamics: TemperatureDocumento16 pagineChapter Ten Lecture Ten Thermodynamics: TemperatureTony AtefNessuna valutazione finora

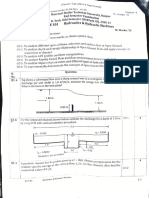

- 5th Semester ESE Paper... (CE)Documento16 pagine5th Semester ESE Paper... (CE)MOHD NAZIM - 33 HBTUNessuna valutazione finora

- Misc - Projectile MotionDocumento18 pagineMisc - Projectile Motionapi-3723453Nessuna valutazione finora

- Pages From Combined QP - Unit 1 Edexcel Physics A-Level-8Documento2 paginePages From Combined QP - Unit 1 Edexcel Physics A-Level-8ieswaheedNessuna valutazione finora

- Atomic Orbital (AO) Molecular Orbital (MO) MO LCAO (Linear Combination of Atomic Orbital)Documento17 pagineAtomic Orbital (AO) Molecular Orbital (MO) MO LCAO (Linear Combination of Atomic Orbital)Imroon de MadritistaNessuna valutazione finora