Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DIN 7162-1965x

Caricato da

Antonio Maestre LorenzoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DIN 7162-1965x

Caricato da

Antonio Maestre LorenzoCopyright:

Formati disponibili

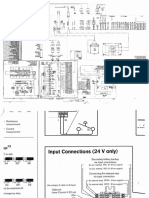

UDC 621.75J.

2 (100) DEUTSCHE NORMEN December 1965)(

-

.------..,

u

Q)

Q.

"'

')

Plain Workshop and Inspection Gauges

Manufacturing Tolerances and Permissible Wear 7162

DIN

c.,

~~D

~ . Q g~

·00 r-

--------------------

-~ ~ ~~ ..--------------------Herstelltoleranzen

Arbeits- --------------------

Frtiflehren fUr LangenmaBe1

und zulassige Abnutzung

--------------------~L.--------------------~

und

-

Q)

..a

oo

0 0~

c 'l; i Dimensions in,.um

~ ... ~f

c -:; .3.1: Gauges for internal dimensions (holes) dimensions (shafts)

u:;:

., ...

==

!~

CL) ..... .! ...

cc 0 :1

-.,

~

V

i~

0 M

Nominal size

:I u mruup to

Cl 'i

0 .!

z

~ ~

0

" 'tl....."

'tl

.... ....'tl"' <: ..

...."'" ..... .....s

II

"' "'0 "'0 .0......"'

"

0

"" ..... ,.0

~ "'

0

l!J

a >C

i!~

0 "I <!>

~

""'

: I I

r · ·~· -· ~~

I ~" Inspection

I

"' """...

"'""

<:

..., 0

!! Workpiece gauge :.:

;;

"'

a·

M

....

~~~-= ~~:/

~

"" Nominal size

~pver

::;

1

-g"

:>

~

0

...0 . ::t:~....

.

.

0

c ..

II C

E

:; " .....en

z .....

'tl "' a .,

c

.. "'.,"

.....

co

0 0 0

0

.....

"'""'

'tl

.....

] ... f ~~ "I """

..

c"

0

:2 Inspection """

ll.Oll<:

"'a "'z..,

;

... I I gauge ... 0

"'c

·e"D> Manufacturing tolerances Perm.wear Tolerance on workpiece Illustrated for quality 5 to 8;

... Internal. External

.z;

Inspection Workshop Workshop !or quality 9 onwards y and y 1

c gauge gauge gauge dimension dimenaion

~

are equal to 0

·e

5c

[I ~ ~ For meaning o! symbols, see

page 3

.:

~

Formulae for determining gauge dimensions

0, Nominal size r8.llge

"5

N

Gauges Side of

up to 180mm over 180 ma

0

for gauge Workshop gauge Inspection gauge Workshop gauge Inspection gauge

-ti rW111fec-

Design Manufacturing Design IManufac•

turing Design

.

~!anufac turing Des~gn turing

"'

0

iS. size tolerance size tolerance size tolerance size tole.rarce

i;" H HI)

-ti

D

Not go G ± 2H or ±i not

G-.:x ± i-(

2

or ±2

not

z Int•rnal defined defined

+!!_ K+z ±H or ±H.

dimen- new K+z -2 "f 2

sion Go

worn K-y - K-y+.:x -

worn G+y, - G+yl ± nP lo+y,-cx,

2

- G+y1 -cx 1 ± HP

2

External Go

dimen- new G- z1 ± H, G- z1 ±HP G- ZJ ±11 G- z1 ± Hr>

sion 2 2 2 2

~~ '

:~ ±HI ± HP ±HI /( + (WI + Hr>

..liO,,

..5

M

~

•

I Not go /(

7

/(

2

K+<X, 2 -2

...

~

~ 0

_.:: E

1

) B/2 applies only it spherical end measuring rods are not used.

0 •

For ISA system of !ita, introduction, gauges, see DIN 7150 Sheet 2

.-

M

.. '6 ...

g.: .

0

Continued on pages 2 to 5

;~" Explanations on page 6

-" ...

~i i

~ ... % ~----------------- ------------------

Alleinverkauf der Normblcitter durdl Beuth-Venrieb GmbH, Berlin 30 und K<iln ------------------

------------------ -------~~~~~~~--~~

DIN 7162 engl. l'reisgr.~~--~5

Vertr.·Nr, 0106

.

01 91

Copyright by the DIN Deutsches Institut Fur Normung E V

Mon May

Print12to13:53:11 2014

PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

Page 2 DIN 7162

Gauges for lnternal dlmens1ons (holes)

Nominal ~uality of workpiece according to I SO tolerance group

siz e range Symbol

mm 6 7 I 8 9 I 10 11 I 12 13 I 14 15 I 16

T 6 10 14 25 l 40 60 l 100 140 I 250 400 1 60o

from 1 H/2 0,6 1 1 2 5 5

to 3 y 1 1,5 3 0 0 0 0

z 1 1,5 2 5 10 20 40

T 8 12 18 30 I 48 75 I 120 180 I 300 480 J 750

over 3 Hf2 0,75 1,25 1,25 2,5 6 6

·-

to 6 y 1 1,5 3 0 0 0 0

z 1,5 2 3 6 12 24 48

r 9 15 22 36 I 58 90 I 150 220 l 360 580 l 900

H/2 0,75 1,25 1,25 3 7,5 7,5

over 6

H5 /2 0,75 0,75 0,75 2 4,5 4,5

to 10

y 1 1,5 3 0 0 0 0

z 1,5 2 3 7 14 28 56

T 11 18 27 43 I 70 110 I 180 270 l 430 700 l 1100

H/2 1 1,5 1,5 4 9 9

over I 0

H,/2 1 1 1 2,5 5,5 5,5

to 18

y 1,5 2 ~ 0 0 0 0

l 2 2,5 4 8 16 32 64

T 13 21 33 52 l 84 130

l 210 330 l 520 840 J1300

H/2 1,25 2 2 4,5 10,5 10,5

over 'a H,/2 1,25 1,25 1,25 3 6,5 6,5

to 30

y 1,5 3 ~ 0 0 0 0

z 2 3 5 9 19 36 72

r 16 25 39 62 1 100 160

J 250 390 1 620 1000 l 1600

H/2 1,25 2 2 5,5 12,5 12,5

o ver 30

HJ2 1,25 1,25 1,25 3,5 8 8

to so

y 2 3 5 0 0 0 0

z 2,5 3,5 6 11 22 42 80

T 19 30 46 74 l 120 190 l 300 46o 1 740 12oo 1 19oo

H/2 1,5 2,5 2,5 6,5 15 15

over 50

HJ2 1,5 1,5 1,5 4 9,5 9,5

to 80

y 2 3 5 0 0 0 0

z 2,5 4 7 13 25 48 90

T 22 35 54 87 I 140 220

l 350 540 l 870 1400 j2200

H/2 2 3 3 7,5 17,5 17,5

over SO

H,/2 2 2 2 5 11 11

to 120

y 3 4 6 0 0 0 0

z 3 5 8 15 28 54 100

T 25 40 63 100 1 160 250 l 400 630 j1ooo 1600 12500

Hf'l 2,5 4 4 9 20 20

over 120 2,5 2,5 2,5 6 12,5 12,5

H,/2

t o 180

y 3 4 6 0 0 0 0

z 4 6 9 18 32 60 110

~-

Copyright by the DIN Deutsches Institut Fur Normung E V

Mon May

Print12to13:53:37 2014

PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

DIN 7162 Page 3

Gau~es for internal dimensions (holes) (continued)

Nominal. Quality of workpiece according to ISO tolerance group

Symbol

eize range

I a I 10 11 I 12 13 I 14 15 I 16

mm

r

6

29

7

46 72 '

115 185 290 460 720 1150 1850 2900

H/2 3,5 5 5 10 23 23

over 180 H,/2 3,5 3,5 3,5 7 U,5 U,5

to 250 y 4 6 7 0 0 0 0

z 5 7 12 21 24 40 45 80 100 170 210

(): 2 3 4 4 7 10 15 25 45 70 110

T 32 52 81 130 210 320 520 810 1300 2100 3200

H/2 4 6 6 11,5 26 26

over 250 H,/2 4 4 4 B 16 16

to 315 y 5 7 9 0 0 0 0

z 6 8 14 24 27 45 50 90 110 190 240

Cl< 3 4 6 6 9 15 20 35 55 90 140

T 36 57 89 140 230 360 570 890 1400 2300 3600

H/2 4,5 6,5 6,5 12,5 28,5 28,5

H,/2 4,5 4,5 4,5 9 18 18

over 315

to 400 y 6 8 9 0 0 0 0

z 7 10 16 28 32 50 65 100 125 210 280

Cl< 4 6 7 7 11 15 30 45 70 110 180

T 40 63 97 155 250 400 630 970 1550 2500 4000

H/2 5 7,5 7,5 13,5 31,5 31,5

HJ2 5 5 5 10 20 20

over 400

to 500 y 7 9 11 0 0 0 0

z 8 11 18 32 37 55 70 110 145 240 320

(): 5 7 9 9 1.4 20 35 55 90 140 220

Gauge dimensions for workpieces whose tolerances "T" are not contained in the above Table are

evaluated bY" the data given for the next larger ":£." in the same nominal size range.

Worked example 2 )

Gauge dimensions for gauge ~

The workpiece allowances are + 0,162} eee DIN 7161

+ 0.110

The size limits for the workpiece are therefore

G c 25.000 + 0,162 c 25.162 mm

K = 25.000 + 0.110 • 25.110 mm

for a workshop gause these values give the following:

Not go side s G~

H

'=

25,162 + 0,02 ~

Go side new .. (K+z) :t ~ .. (25.110 + 0.009):!: 0.02

.. ~± 0.02!!!!!!

Go side worn • K- y = 25.110- 0

= 25.110 mm

Meaning of symbols used

G • Maximum of workpiece

H c Manufacturing tolerance of workshop gauges for internal dimensions

(excluding spherical end measuring rode)

a Manufacturing tolerance of spherical end measuring rods

= Manufacturing tolerance of workshop gauges for external dimensions

= Manufacturing tolerance of inspection gauges

= Minimum of workpiece

Tolerance on workpiece (T = G - K)

= Quantity specifying wear limit

= Quantity specifying design size of go side

~ Safety allowance for metrological uncertainty

2

) For gauge dimensions and manufacturing tolerances for ISO fit sizes from 1 to 500 mm

nominal for workshop plug gauges and spherical end meaeuring rods, to be evaluated from

the gauge allowances, see DIN 7164

Copyright by the DIN Deutsches Institut Fur Normung E V

Mon May

Print12to13:53:37 2014

PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

Page 4 DIN 7162

. ~auges for external dimensions (shafts)

Nominal ~uality of workpiece according to ISO toler ance group

Srmbol

eize range

mm 5 6 l 7 8 9 I 10 11 I 12 13 _l 14 1s I 16

T 4 6 I 10 14 25 140 60 1 100 140 I 2so 400 1 600

Hd2 0,6 1 1,5 1,5 2 5 5

from 1 0,6 0,6 0,6 1 1

HJ2 0,4 0,4

to 3

y, 1 1,5 3 0 0 0 0

z, 1 1,5 2 5 10 20 40

T 5 8 1 12 18 30 I 48 75 1 120 18o I 3oo 48o 1 1so

H,/2 0,75 1,25 2 2 2,5 6 6

over 3 0,5 0,5 0,75 0,75 0,75 1,25 1,25

6

HJ2

to

y, 1 1,5 3 0 0 0 0

z, 1 2 3 6 12 24 48

T 6 9 115 22 36 I 58 90 I uo 22o I 360 sao I 900

H,/2 0,75 1,25 2 2 3 7,5 7,5

ove r 6 0,75 1,25 1,25

to 10

Hpl2 0,5 0,5 015 OlS

y, 1 1,5 3 0 0 0 0

z, 1 2 3 7 14 28 56

T 8 11 1 1a 27 43 I 70 110 1 no 21o 1 43o 700 11100

H1/2 1' 1,5 2,5 2,5 4 9 9

over 10 1 1 1,5 1,5

Hp/2 0,6 0,6 1

to 18

y, 1,5 2 4 0 0 0 0

z, 1,5 2,5 4 8 16 32 64

T 9 13 1 21 33 52 I 84 130 1 2ao 33o 1 s2o 140 {1300

H1/2 1,25 2 3 3 4,5 10,5 10,5

over 18 1,25 2 2

HJ2 0,75 075 1,25 1,25

to 30

y, 2 3 4 0 0 0 0

z, 1,5 3 5 9 19 36 72

T 11 16 I 25 39 62 1 1oo 16o 1 2so 39o 1 62o 1000 11600

H1/2 1,25 2 3,5 3,5 5,5 12,5 12,5

o ver 30 1,25 1,25 2 2

to 50 HJ2 075 0,75 1,25

y, 2 3 5 0 0 0 0

z, 2 3,5 6 11 22 42 80

T 13 19 l 30 46 74 l 120 190 1 300 460 1 740 1200 lt900

H./2 1,5 2,5 4 4 6,5 15 15

over 50 1,5 2,5 2,5

Hp/2 1 1 1,5 1,5

to 80

y, 2 3 5 0 0 0 0

!--'---~ ~ -

z, 2 4 7 13 25 48 90

T 15 22 I 35 54 87 1 140 220 1 3so s40 1 87o 1400 12200

Hd2 2 3 5 5 7,5 17,5 17,5

over 80

HJ2 1,25 1,25 2 2 2 3 3

to 120

y, 3 4 6 0 0 0 0

z, 2,5 5 8 15 28 54 100

Copyright by the DIN Deutsches Institut Fur Normung E V

Mon May

Print12to13:53:37 2014

PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

DIN 7162 Page 5

Gauges for external dimensions (shafts) (continued )

Nominal ~uality of workpiece according to ISO tolerance group

Symbol

size range

mm s 6 I 7 a 9 I 10 11 I 12 13 I 14 15 I 16

T 11 25 _I 40 63 100 160 250 400 630 1000 1600 2500

H1/2 2,5 4 6 6 9 20 20

over 120 1,75 1,75 2,5 2,5 2,5 .( 4

to

Hp/2

180 0 0 0

y, 3 4 6 0

z, 3 6 9 18 32 60 110

185 290 460 720 1850 2900

1150

T 20 29 I 46 72 115

23

H,/2 3,5 5 7 7 10 23

2,25 2,25 3,5 3,5 3,5 5 5

over 180 HP/2

0 0 0

to 250 y, 3 5 I 6 7 0

100 170 210

z, 4 7 12 21 24 40 45 80

1 2 _j 3 4 4 7 10 15 25 45 70 110

a,

810 .1300 2100 3200

T 23 32 52 I 81 130 210 320 520

26 26

HJ12 4 6 8 8 11,5

3 3 4 4 4 6 6

HP/2

over 250 0

0

to 315 y, 3 6 I 7 9 0

45

0

50 90 110 190 240

z, 5 8 14 24 '0

15 20 35 55 90 140

a, 1,5 3 I 4 6 6 9

570 890 1400 2300 3600

T 25 36 l 57 89 140

9

230 360

12,5 28,5 28,5

H,/2 4,5 6,5 9

Hp/2 3,5 3,5 4,5 4,5 4,5 6,5 6,5

over 315

0 0

to 400 y, 4 6 I 8 9 0 0

100 125 210 280

z, 6 10 16 28 32 50 65

70 110 180

a, 2,5 4 I 6 7 7 11 15 30 45

1550 2500 4000

250 630 970

T 27 40 I 63 97 155 400

31,5

H,j2 5 7,5 10 10 13,5 31,5

HP/2 4 4 5 5 5 7,5 7,5

over 400

0 0

to 500 y, 4 7 I 9 II 0 0

70 110 145 240 320

z, 7 11 18 32 37 55

1.4 55 90 140 220

"''

3 5

I 7 9 9 20

Table

35

Gauge dimensions for workpieoes whose tolerances "T" are not contained in the above

range,

are evaluated by the data given for the next larger "!" in the same nominal size

Worked example;)

Gauge dimensions for gauge l1Q - 0.05

The workpiece allowances are:

G = 270.000 mm

K = 270 - 0,05 = 269.950 mm

for a workshop gauge these values give the following:

Go side worn • G + y 1 - « 1 • 270.000 + 0.007 - 0.004

270,003 DUD

H1

Go side new = (G-z 1 ):!; 2 (270.000- 0,008) ± 0.006

= 269.992 ! o.oo6 me

H1

Not go side "'(K+a 1 ):!: 2 .. (269.950 + 0.004) + 0.006

= 269.954 ! 0.006 ~-

)) For gauge dimensions and manufa cturing tolerances for ISO fit ~izes from 1

to 500 mm nominal for

eee DIN 716)

workshop gap gauges and inspection gauges, to be evaluated from th e gauge allowances,

Copyright by the DIN Deutsches Institut Fur Normung E V

Mon May

Print12to13:53:37 2014

PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

Page 6 DIN 7162

E:xplana ti ona

DI N 7162 is used for determining gauge dimensions. In t he case of gauges for internal dimensions

the tabulated values apply to workpiece qualities from IT 6 to IT 16, and in the case of

external dime nsions to workpiece qualities from IT 5 to IT 16. The present issue takes account

of ISO tolerances according to ISO Recommendation ISO/R 286 - 1962, Compared with the October

1936 issue of DIN 7162 some alterations have been made to gauge dimensions as a result of

modification of certain basic tolerances (see DIN 7151, Issue of November 1964) and of certain

basic allowances (see DIN 7152, Issue of July 1965). For the fixed gauges affected by these

changes the new ISO values are compared with the previous ISA values in the Tables below.

Basic tolerance Basic allowance on tolerance zone position or tolerance zone

Nominal IT f g i n p r s X % xb XC F G J

size range 6 7

mm

s 6 7 12 Sa. 7 8 8

6

4 6 10 100 -6 -2 -2 -4 -6 +4 +6 +10 +14 +20 +26 +60 +6 +2 +2 +4 + 6

from 1

to 3

ISO

ISA 5 7 9 90 -7 -3 -1 -2 -7 +6 +9 +12 +15 +22 +28 +50 +7 +9 +3 +3 - + 7

~3 -2 -4 +50 +80 +5 +6 +10

to 6 ~

ISO

- - - - - - -1 -3

- - - - - - - +53 +69

- +4 +5 - + 9

Basic allowance on t olerance zone position or tolerance zone

Nominal

&ize range M N p R s u X z ZA ZB zc

6a 8 8 9 to 6a.7 trom8 .rc:m8 6a,7 from8 6a.1 fum8 fum8 6 a,7 6 7 6 7

' mm 7 11

from 1 ISO -2 -2 -4 -4 -6 -6 -10 -14 -14 -18 -20 -26 -32 -40 -40 -60 -60

to 3 ISA 0 +3 -1 0 -7 -9 -12 -13 -15 -16 -22 -28 -30 -38 -38 -48 -48

-77 -76

ove r 3

to 6

ISO

ISA

- - - -

;

- - - - - - - - - -47 -46

-58 -61 -74 -77

According to ISO, in the nominal size range over 6 and up to 10 tne basic allowances are as

follows: for zb T67 instead of +70 previously, for ZB 6 -64 instead of -76 previously,

for ZB 7 -61 instead or -79 previously and for ZC 7 -91 instead of -93 previously.

In the range over 400 and up to 450 the basic allowance 2400 instead of 2~50pm applies to

zc for all qualities and to ZC !rom and including quality 8 and in tne range over 450 and

up to 500 the basic allowance 2100 instead of 2050j£m applies to zb for all qualities and

to ZB from and including quality 8.

The gauge manufacturing tolerances H, He, H and H are correlated with workpiece tolerances.

The correlation adopted in the ISA system ot

fits ~see DIN 7150 Sheet 2, Issue of July 1938x)

has been retained. In the qualities used for gauge manufacture the ISO basic tolerances have

undergone extensive changes compared with the ISA values. These changes are shown in the

Table below on the right.

Order of magnitude of IT

Nominal Gauge manufacturing tolerance ! ~ of

gauge manufacturing size range

Workpiece toleranc tolerance mm IT6 IT7

IT for IT 1 IT2 IT3 Ill ITS

T H H, HP H• !rom 1 ISO o,.c 0,6 1 1,5 2 3 5

4,5

ITS - 1 -

2 to 3 ISA 0;15 1

0,75

1,5

1,25

2 2,5 3,5

0,5

IT6 2 2

2

1

1

3

3

over

to 10

3 ISO

ISA 0;15 1 1,5

- - - -

IT7 3 1---

ISO 0,6

IT 8 to IT 10 3 2 2

2

4

5

over 10

to 18 ISA 0,75

-- - - - -

IT 11 to IT 12 5 4

over 18 ISO 1,25

IT 13 to IT 16 7 6 l 7

to 30 isA

- 1-1 - - - - -

~-~ ---,-

over 30 ISO 0,75 1,25

to 50 ISA I 1,5

- - - - -

80 ISO 1,25

over

to 120 ISA 1,5

- - - - - -

over 120 ISO 1;15

to 180 ISA 2

- - - - - -

- -- ·- ·----- - - f-cc ~ - ·

ISO 2,25

over 180

to 250 ISA 2,5

- - - - - -

Copyright by the DIN Deutsches Institut Fur Normung E V

Mon May

Print12to13:53:38 2014

PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

Potrebbero piacerti anche

- Formosa Ldpe Data SheetDocumento5 pagineFormosa Ldpe Data SheetBasant AGarwalNessuna valutazione finora

- Threads-External Thread NOGO RulesDocumento3 pagineThreads-External Thread NOGO RulesdchannarongNessuna valutazione finora

- DIN 6930-2 Stamped Steel Parts Part 2 General TolerancesDocumento17 pagineDIN 6930-2 Stamped Steel Parts Part 2 General TolerancespopoNessuna valutazione finora

- Din 6930 Octobre 2011Documento18 pagineDin 6930 Octobre 2011Franck Savignard100% (1)

- Thermal Friction Drilling: Parameters For Metric Thread ToolsDocumento2 pagineThermal Friction Drilling: Parameters For Metric Thread Tools69x4Nessuna valutazione finora

- VW 011 03Documento22 pagineVW 011 03Alexandre UrquizaNessuna valutazione finora

- Thread Gauge ISO1502 PDFDocumento5 pagineThread Gauge ISO1502 PDFBaldev SinghNessuna valutazione finora

- Bench Top Dial Hardness Tester User ManualDocumento20 pagineBench Top Dial Hardness Tester User ManualPeter KlassenNessuna valutazione finora

- DIN EN 10277: ICS 77.140.60 Supersedes: See BelowDocumento55 pagineDIN EN 10277: ICS 77.140.60 Supersedes: See BelowEmersonNessuna valutazione finora

- Calypso 05 DMIS InputDocumento22 pagineCalypso 05 DMIS InputDragu StelianNessuna valutazione finora

- TL 256 en 2022Documento8 pagineTL 256 en 2022Michal BílekNessuna valutazione finora

- VW 01055 - Regra RpsDocumento18 pagineVW 01055 - Regra RpsMarcos Roberto BarbosaNessuna valutazione finora

- nx5 KeyboardcommandsDocumento1 paginanx5 KeyboardcommandsShaheen ArihaNessuna valutazione finora

- Din 6173-2Documento10 pagineDin 6173-2Rudiney TrombettaNessuna valutazione finora

- Din 2393-2Documento0 pagineDin 2393-2Yalavarthi ChandrasekharNessuna valutazione finora

- Autoliv Material Specification: Flat Hot Rolled Steel For Safety Products - E116088Documento4 pagineAutoliv Material Specification: Flat Hot Rolled Steel For Safety Products - E116088krishnamartial8269Nessuna valutazione finora

- The Most Important Topics of The Program GEOPAKDocumento416 pagineThe Most Important Topics of The Program GEOPAKYnomata RusamellNessuna valutazione finora

- Norma ISO 13385Documento24 pagineNorma ISO 13385jorge_t_71100% (3)

- Surface Roughness Tester Work InstructionDocumento8 pagineSurface Roughness Tester Work InstructionSadikAhmed0% (2)

- Q7 Gear&Geartools 2007Documento45 pagineQ7 Gear&Geartools 2007M.NatarajanNessuna valutazione finora

- As ISO 14978-2007 Geometrical Product Specifications (GPS) - General Concepts and Requirements For GPS MeasurDocumento10 pagineAs ISO 14978-2007 Geometrical Product Specifications (GPS) - General Concepts and Requirements For GPS MeasurSAI Global - APAC50% (2)

- ISO-10664Documento10 pagineISO-10664Daniel Quijada LucarioNessuna valutazione finora

- BasicCAM2 SmartInspect Basic v1.2 - FaroArm and FARO Gage Training Workbook - November 2014Documento166 pagineBasicCAM2 SmartInspect Basic v1.2 - FaroArm and FARO Gage Training Workbook - November 2014raseen pNessuna valutazione finora

- Threads-Setting Adjustable Ring Gages Per ASME B1.2Documento3 pagineThreads-Setting Adjustable Ring Gages Per ASME B1.2Muhammad Nadeem AzamNessuna valutazione finora

- General Tolerances For MTB: July 2012 Accuracy of ShapeDocumento9 pagineGeneral Tolerances For MTB: July 2012 Accuracy of ShapeAkmal NizametdinovNessuna valutazione finora

- Calypso 03 SimulationDocumento62 pagineCalypso 03 SimulationDragu StelianNessuna valutazione finora

- DIN Fittings and TubesDocumento92 pagineDIN Fittings and TubesJosé A. RamírezNessuna valutazione finora

- Iso 14660 2 1999Documento6 pagineIso 14660 2 1999LipikaNessuna valutazione finora

- Measuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)Documento1 paginaMeasuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)SudhagarNessuna valutazione finora

- VDI 3400 Surface Finish Grade Definition PDFDocumento1 paginaVDI 3400 Surface Finish Grade Definition PDFdbaNessuna valutazione finora

- Calypso 09 VAST NaviogatorDocumento32 pagineCalypso 09 VAST NaviogatorDragu StelianNessuna valutazione finora

- MBN 10317-1 2006-07Documento17 pagineMBN 10317-1 2006-07Parameswaran MurugesanNessuna valutazione finora

- OpenDMIS V6 EnhancementsDocumento4 pagineOpenDMIS V6 EnhancementsasndmpNessuna valutazione finora

- Gear and Spline InspectionDocumento12 pagineGear and Spline InspectionAtulNessuna valutazione finora

- Ford We 910 - 2001Documento6 pagineFord We 910 - 2001Jason-chungNessuna valutazione finora

- Din 16901Documento9 pagineDin 16901CarlaOliveiraNessuna valutazione finora

- Astm A254Documento4 pagineAstm A254dai.nh100% (2)

- BA DuraMax REV 3 0 Online en PDFDocumento235 pagineBA DuraMax REV 3 0 Online en PDFbeto206123100% (1)

- Vdocuments - MX Din 405 Universo For Knuckle Thread Din 405Documento7 pagineVdocuments - MX Din 405 Universo For Knuckle Thread Din 405wauwio1906Nessuna valutazione finora

- DN Iso 5817Documento13 pagineDN Iso 5817Phani Sridhar ChNessuna valutazione finora

- Aiag Ppap4Documento75 pagineAiag Ppap4tamtom75Nessuna valutazione finora

- Plug-Snap Gauge PDFDocumento2 paginePlug-Snap Gauge PDFasifNessuna valutazione finora

- SPC 001 PDFDocumento240 pagineSPC 001 PDFSalah BennourNessuna valutazione finora

- Summary of Evidence Report: - Hydraulic Brake Hoses (FMVSS 106)Documento13 pagineSummary of Evidence Report: - Hydraulic Brake Hoses (FMVSS 106)MarsellusProbstNessuna valutazione finora

- Tabela Tol Din861 BPDocumento1 paginaTabela Tol Din861 BPDeimos PhobosNessuna valutazione finora

- Calypso 07 OVCMMDocumento20 pagineCalypso 07 OVCMMDragu StelianNessuna valutazione finora

- 535 CatDocumento1 pagina535 CatHubertNessuna valutazione finora

- Meenakshi Molding Private Limited Process FMEA: O C C U RDocumento4 pagineMeenakshi Molding Private Limited Process FMEA: O C C U Rilaya raja100% (1)

- Faro ManualDocumento256 pagineFaro ManualEvka AkováNessuna valutazione finora

- MCOSMOS Rack Alignment v3.2 - SCR200 Jul11Documento22 pagineMCOSMOS Rack Alignment v3.2 - SCR200 Jul11sensacje100% (1)

- GRR Studies On CMM Accuracy HexDocumento31 pagineGRR Studies On CMM Accuracy HexSylvia FischerNessuna valutazione finora

- Parameters Mahr Roughness PDFDocumento19 pagineParameters Mahr Roughness PDFCarlos RamirezNessuna valutazione finora

- GD&T Symbols - GD&T Terms - Geometric Dimensioning and Tolerancing Glossary - GD&T Free ResourceDocumento5 pagineGD&T Symbols - GD&T Terms - Geometric Dimensioning and Tolerancing Glossary - GD&T Free Resourcebbbsample0% (1)

- Daimler MBN 10317 Eng 09-09Documento27 pagineDaimler MBN 10317 Eng 09-09gültekin gökNessuna valutazione finora

- Din 862Documento4 pagineDin 862068999100% (1)

- Laporan Review JSADocumento1 paginaLaporan Review JSAAndrianoNessuna valutazione finora

- สัตวานุกรมวิธานพร้อมตัวอย่างการศึกษาของไรDocumento104 pagineสัตวานุกรมวิธานพร้อมตัวอย่างการศึกษาของไรOrmphipod WongkamhaengNessuna valutazione finora

- DIN 630 EN-1993 Double Row Self-Aligning Ball BearingsDocumento4 pagineDIN 630 EN-1993 Double Row Self-Aligning Ball BearingsthachpnNessuna valutazione finora

- 6786-Article Text PDF-10544-1-10-20130718Documento11 pagine6786-Article Text PDF-10544-1-10-20130718Alpine.designNessuna valutazione finora

- Electrical InstructionsDocumento45 pagineElectrical InstructionssfsdffdsdfsdfsdfNessuna valutazione finora

- Valuable Customer: Air Torque S.P.ADocumento1 paginaValuable Customer: Air Torque S.P.AAntonio Maestre LorenzoNessuna valutazione finora

- Grundfos Irrigation Pump HandbookDocumento104 pagineGrundfos Irrigation Pump HandbookGrundfosEgypt100% (2)

- Fundamentos Neumatica Electroneumatica FESTODocumento1 paginaFundamentos Neumatica Electroneumatica FESTOAntonio Maestre LorenzoNessuna valutazione finora

- NEOTI 4051 Neoseal Pressure Test O2PDocumento3 pagineNEOTI 4051 Neoseal Pressure Test O2PAntonio Maestre LorenzoNessuna valutazione finora

- Flange ChartDocumento4 pagineFlange ChartAntonio Maestre LorenzoNessuna valutazione finora

- Ecs448 Chapter 5a ArchDocumento28 pagineEcs448 Chapter 5a Archdixn__Nessuna valutazione finora

- Desai, Park - 2005 - Recent Developments in Microencapsulation of Food Ingredients PDFDocumento36 pagineDesai, Park - 2005 - Recent Developments in Microencapsulation of Food Ingredients PDFIoanaCarlanNessuna valutazione finora

- Is.11921.1993 Fuel Efficiency StandardDocumento12 pagineIs.11921.1993 Fuel Efficiency StandardParminder SinghNessuna valutazione finora

- Opsis Technique Eng 2007Documento4 pagineOpsis Technique Eng 2007sukumariicbNessuna valutazione finora

- NuPolar Quality Testing and ComparisonsDocumento12 pagineNuPolar Quality Testing and Comparisonsou82muchNessuna valutazione finora

- Binary Dependent VarDocumento5 pagineBinary Dependent VarManali PawarNessuna valutazione finora

- Dwnload Full Physics 3rd Edition Giambattisata Solutions Manual PDFDocumento35 pagineDwnload Full Physics 3rd Edition Giambattisata Solutions Manual PDFmarcusquyepv100% (12)

- Dayton Miller's Ether-Drift ExperimentsDocumento33 pagineDayton Miller's Ether-Drift Experimentsxreader0Nessuna valutazione finora

- Mathematical Model of Transportation ProblemDocumento14 pagineMathematical Model of Transportation ProblemwasimghghNessuna valutazione finora

- Third Space Learning - Fluent in Five - Spring Term 2 Week 5Documento11 pagineThird Space Learning - Fluent in Five - Spring Term 2 Week 5ZoonieFRNessuna valutazione finora

- Mathematics IDocumento1 paginaMathematics IYadav MaheshNessuna valutazione finora

- Geometry and Trigonometry PDFDocumento46 pagineGeometry and Trigonometry PDFnewspaperNessuna valutazione finora

- Spring State Machine TransitionsDocumento6 pagineSpring State Machine TransitionsGroza CristiNessuna valutazione finora

- Che 243 Fluid Dynamics: Problem Set #4 Solutions: SolutionDocumento9 pagineChe 243 Fluid Dynamics: Problem Set #4 Solutions: SolutionKyungtae Park100% (2)

- Design of Absorber: 5.1 AbsorptionsDocumento13 pagineDesign of Absorber: 5.1 AbsorptionsNaya Septri HanaNessuna valutazione finora

- Person Name: NDT Management CoordinatorDocumento4 paginePerson Name: NDT Management CoordinatorDendy PratamaNessuna valutazione finora

- An Adaptive Hello Messaging Scheme For Neighbor Discovery in On-Demand MANET Routing ProtocolsDocumento4 pagineAn Adaptive Hello Messaging Scheme For Neighbor Discovery in On-Demand MANET Routing ProtocolsJayraj SinghNessuna valutazione finora

- Bearing FitsDocumento9 pagineBearing Fitsm2110Nessuna valutazione finora

- Physics: FiitjeeDocumento1.319 paginePhysics: FiitjeeBISWAJEET100% (2)

- Buck Boost IN7900Documento12 pagineBuck Boost IN7900Adam StroufNessuna valutazione finora

- Important Notes of 10th Class Math Exercise 3.2Documento12 pagineImportant Notes of 10th Class Math Exercise 3.2Tayyabah ShahNessuna valutazione finora

- K.T. Chau, R.H.C. Wong, T.-f. Wong (Auth.), STAVROS K. KOURKOULIS (Eds.) - Fracture and Failure of Natural Building Stones_ Applications in the Restoration of Ancient Monuments-Springer Netherlands (2Documento581 pagineK.T. Chau, R.H.C. Wong, T.-f. Wong (Auth.), STAVROS K. KOURKOULIS (Eds.) - Fracture and Failure of Natural Building Stones_ Applications in the Restoration of Ancient Monuments-Springer Netherlands (2Daniel Ruperto CanoNessuna valutazione finora

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocumento18 pagineSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudNessuna valutazione finora

- Oxyacids of SulphurDocumento29 pagineOxyacids of SulphurSumaira Yasmeen100% (1)

- Conte R Fort WallDocumento30 pagineConte R Fort Wallmirko huaranccaNessuna valutazione finora

- Loan Pre Research PaperDocumento4 pagineLoan Pre Research PaperVaseem AkramNessuna valutazione finora

- GWRS5500Documento13 pagineGWRS5500Andrew HartNessuna valutazione finora

- Circuit Diagrams P160110 Rev.0Documento24 pagineCircuit Diagrams P160110 Rev.0tuyetden613Nessuna valutazione finora

- CS6411 Network Lab Manual - 2013 - Regulation PDFDocumento71 pagineCS6411 Network Lab Manual - 2013 - Regulation PDFjayaprasanna123Nessuna valutazione finora