Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MPI Communication

Caricato da

rafael charchabalCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MPI Communication

Caricato da

rafael charchabalCopyright:

Formati disponibili

MPI communikation

Chapter 1

Chapter 1

MPI communication

1.1 Introduction to MPI

MPI (Multipoint Interface) communication is a kind of simple and economical

communication method, which is adopted when the requirement of baud rate is not high and the

communication data quantity is not great.

MPI communication can exchange data by using PLC S7-200/300/400, operation panel

TP/OP and MPI/PROFIBUS communication card of host computer, such as CP5512/CP5611/

CP5613 etc.

MPI baud rate is 19.2Kbit/s~12Mbit/s, and usually the default setting is 187.5Kbit/s. Only

the MPI interface that can be configured as PROFIBUS interface can support 12Mbit/s.

MPI network, whose maximum communication distance is 50 meters, can link 32 nodes at

most. Besides, its length can be extended via repeaters.

1.2 MPI Network

1. MPI network structure

The RS485 interface in Siemens PLC S7-200/300/400 CPU is not only for programming,

but also for MPI communication. Without additional hardware investment, it can implement

communication functions such as PG/OP, global data communication and the S7

communication with a little data exchange etc.

The nodes of the network usually include network components such as S7 PLC, TP/OP,

PG/PC, intelligent ET200S and RS485 repeater etc. The network configuration structure is

shown in Figure 1-1.

Figure 1-1 MPI Network Structure

2. Extending the network length via repeaters

The MPI maximum communication distance is 50 meters. Also it can be extended via

RS485 repeaters, and there are two extension methods:

1) As shown in Figure 1-2, there is no other station between two stations.

version 1.0 page 1 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-2 Extending MPI network length via RS485 repeaters

The maximum communication distance between MPI station and repeater is 50 meters, and

the maximum distance between two repeaters is 1000 meters. As MPI can connect 10 repeaters

at most, so the maximum distance between two MPI stations is 9100 meters.

2) If other MPI stations exist between two repeaters, then each repeater can extend only 50

meters. MPI interface is RS485 interface, and it requires the PROFIBUS bus connector (with

terminal resistance) and PROFIBUS cable (see Figure 1-3). If using other cables and

connectors, then the communication quality and distance will not be guaranteed.

Figure 1-3 Standard PROFIBUS Cable And Bus Connector

There are 32 stations at most in MPI network, but repeaters also occupy MPI nodes when

used for extension. And the connection method is shown in Figure 1-4.

version 1.0 page 2 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-4 Connecting PROFIBUS Cable with Connector

1.3 MPI Configuration

1.3.1 Configuration of MPI parameters

It can be divided into two parts: MPI parameter configuration of PC side and PLC side.

1.Parameter configuration of PLC side

During hardware configuration, the user can click the "Properties" button (see in Figure 1-

5) to configure properties of MPI, including address and baud rate. The detailed operation refers

to Figure 1-5.

version 1.0 page 3 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-5 MPI Network Parameter Configurations

Suggestion: Do not change the MPI baud rate in normal application. Please note that baud

rate must be kept consistent in whole MPI network, and the MPI addresses cannot be conflicted.

2. Configuration of PC side parameters

MPI parameters should be also configured in the PC side. In the "control panel"→"Set

PG/PC Interface", select the using program card and "S7_ONLINE" as access point. For

instance, PC Adapter can be selected as the programming card, as shown in Figure 1-6. After

finishing configuration, download configured information in STEP 7 into CPU.

version 1.0 page 4 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-6 Configurations of MPI Programming Interface in PG/ PC

1.3.2 MPI communication card type of PC side

(1) PC Adapter One end is connected to RS232 port or universal serial bus (USB) port of

PC, while the other is connected to MPI interface of CPU. It has no network diagnostic

function, and its maximum baud rate is 1.5Mbit/s, with a lower price.

(2) CP55 11 PCMCIA TYPE II card, used for programming and communication of

notebook computer. It has network diagnosis function, and its maximum baud rate is 12Mbit/s,

with a comparatively higher price.

(3) CP55 12 PCMCIA TYPE II Cardbus (32 bit) card, used for programming and

communication of notebook computer. It has network diagnosis function, and its

maximum baud rate is 12Mbit/s, with a comparatively higher price.

(4) CP56 11 PCI card, used for programming and communication of the desk computer. It

has network diagnosis function, and the maximum baud rate is 12Mbit/s, with a proper price.

(5) The CP56 13 PCI card (replace the original CP5412card), used for programming and

communication of the desk computer. It has network diagnosis function, and the maximum baud

rate is 12Mbit/s. It has processor, which can maintain stability of communication with a large

amount of data. Usually it is used in PROFIBUS network, and it has MPI function, with a

comparatively higher price.

After figuring out functions mentioned above, it is easy to select the proper communication

card. In the code of CP communication card, ‘5’represents PCMCIA interface, ‘6’represents

PCI bus, ‘3’represents that it has processor.

version 1.0 page 5 of 38 04/04/2005

MPI communikation

Chapter 1

1.3.3 Remote programming via public telephone network

In addition to local connection, the telephone network can also be used for remote

programming. The detailed network structure refers to Figure 1-7.

Figure 1-7 Network Configurations via Remote Programming by Telephone Network

1. MPI of configuration programmer side

Click "Set PG/PC Interface" in the "control panel", select "S7ONLINE (STEP 7)" as

access point, and point to "TS Adapter", whose property configuration selection is shown in

Figure 1-8: Select communication interface and baud rate, which is easy to configure TS

Adapter, and the "Modem connection" can be selected automatically when dial-up (version

above the STEP 7 V5.2s).

Figure 1-8 TS Adapter Parameter Configurations

2. Configuring parameters of TS Adapter

1) Select "Direct connection" in "Set PG/PC Interface". One end of TS Adapter requires a

RS232 cable to connect PC serial port.

version 1.0 page 6 of 38 04/04/2005

MPI communikation

Chapter 1

2) The other end of TS Adapter connects to MPI interface of PLC, which enables CPU

supply power for TS Adapter.

Click the "Start"→"SIMATIC"→"STEP 7"→"TeleService", enter menu configuration.

On the left side of menu, create a new Folder, such as "test", then insert "Plant" and add

remote telephone number. As Figure 1-9 show, on the left side of menu, insert "test", then on

the right side, create "MY plant". In this case, it configures remote telephone number as 010

64721888.

Figure 1-9 TeleService Configuring-Creating New Project

Then the user click "MY plant" properties in Figure 1-9, and can modify project name and

telephone number, double-click project name to select the modem connected to programmer

side, as shown in Figure 1-10.

version 1.0 page 7 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-10 TeleService Configuring-Selecting Modem

As for dial-up access, considering system security, there are three methods that can avoid

unauthorized access:

Disconnect TS Adapter connected with PLC MPI interface.

Configure username and password in TS Adapter.

Add callback function.

After dialing through, TS Adapter verifies username and password, then disconnect

automatically, callback the user appointed number. That means if user want to modify the

program, after verification of username and password, he must dial the number TS Adapter

appointed to ensure the system security.

The latter two methods must use the TeleService for configuration.

Detailed is as follows:

Connect TS Adapter, click "Options" and "Assign adapter parameters" to enter menu

configuration as Figure 1-11.

version 1.0 page 8 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-11 TeleService Configuring-Configuring TS Adapter parameters

Configure MPI address of TS Adapter as shown in Figure 1-12.

version 1.0 page 9 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-12 Configuring MPI Address of TS Adapter

3) After configuration, connect the programmer and TS Adapter to public telephone

network, select project name, click the "Connection"→"Establish" or press shortcut key "F7",

and then establish dial-up connection for remote programming access, as Figure 1-13 show.

version 1.0 page 10 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-13 TeleService configuring-creating a connection

The new version of TS Adapter supports dial-up communication among PLC stations. First

PLC calls TeleService function function block FB47 to dial, then related MPI communication

function block (SFC65/66, SFC67/68) for communication.

Sample program refers to the CD, with the project name MPI-SFC-TS.

1.4 MPI Communication between PLC-PLC

There are three methods to implement communication between PLC-PLC via MPI: global

data package communication, non-configured connection communication, and configuration

connection communication.

1.4.1 Global data package communication

1.Introduction

As for data exchange between PLCs, only sending data area and receiving data area should

be concerned. Global data package communication mode means that in the process of

configuration of PLC hardware, it configures the sending data area and receiving data area

among communicating PLC stations, and need not any program processing. This mode can only

be applied to communication among S7-300/400 PLC stations. The detailed methods and steps

of global data package communication mode are given as follows.

2.Network configuration figuring

The network configuration of global data package communication mode is shown in Figure

1-14.

version 1.0 page 11 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-14 Network Configuration Graph

3.Hardware and software requirement

Hardware:

(1) CPU 315-2 DP.

(2) CPU 416-2 DP.

(3) MPI cable.

Software: STEP 7 V5.2 SP1.

4.Network and parameter configuration

(1) Creating MPI network Create a new project in STEP 7, for example MPI_GD. Insert

two PLC stations under this project, which are STATION1 (CPU416-2DP) and STATION2

(CPU315-2DP). Insert CPU separately to finish hardware configuration. Then create MPI

network, and configure MPI address and baud rate. In this case, MPI addresses are configured

as STATION2 and STATION4, baud rate 187.5Kbit/s.

(2) Sending data area and receiving data area As it is shown in Figure 1-15, pick out MPI

network, select "Options"→"Define Global Data" to enter menu configuration shown in Figure

1-16.

Figure 1-15 Entering Global Configuration Menu

version 1.0 page 12 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-16 Global Data Configuration Menu

(3) Inserting all CPUs required for communication Double-click the CPU column on the

right side of "GD ID" to select CPUs required for communication. Fill in sending data area and

receiving data area under each CPU column, for example: the sending data area of CPU416-

2DP is DB1.DBB0~DB1.DBB21, and can be filled as DB1.DBB0: 22 ("DB1.DBB0" represents

initial address, "22" represents data length), then under "Edit" menu, select "sender" and

configured as sending data area. While receiving data area of CPU315-2DP is DB1.DBB0~21,

and can be filled as DB1.DBB0: 22. After compiling and saving, download configuration data

into corresponding CPU. In this way, data communication can be processed, as shown in Figure

1-17.

Figure 1-17 Defining Data Sendting and Receiving Zone

The data area can be DB, M, I, Q , and the maximum length of S7-300 data area is 22 bytes,

while S7-400 54 bytes.

Sample program refers to the CD, with the project name MPI_GD (path name, file name).

version 1.0 page 13 of 38 04/04/2005

MPI communikation

Chapter 1

(4) Multiple CPU communication To implement multiple CPU communication, GD ID

parameters must be figured out first. After compiling, communication data area in each row has

a GD ID number, as shown in Figure 1-18.

Figure 1-18 Parameter Definition

1) Parameter A: cycle number of global data package. Each cycle number represents

communication with a CPU. For example, for S7-300 CPU, two transceiving processes is a

cycle, while for S7-400 CPU, three transceiving processes is a cycle.

The supported cycle number is related to CPU, the maximum number of S7-300 CPU is 4,

which means that it can communicate with 4 CPUs at most. While the maximum number of S7-

400 CPU 414-2 DP is 8, S7-400 CPU 416-2 DP is 16.

2) Parameter B: number of global data packages. It represents how many global data

packages are contained in one cycle. For example: there are two data packages in one cycle

when two S7 stations are communicating with each other, as is shown in Figure 1-19.

Figure 1-19 Global Data Package

3) Parameter C: the number of data area in one data package. Please refer to Figure 1-20,

CPU315-2DP send 4 groups of data to CPU416-2DP, and 4 data area constitute one data

package. As mentioned above, the maximum bytes of one data package is 22. Under this

circumstance, each extra data area occupies two bytes. Thus the maximum data amount is 16

bytes.

version 1.0 page 14 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-20 GD ID in One Data Package

The introduction above to A, B, C parameters is just for the sake of optimizing data

sending and receiving data area, and reduce CPU communication load. When in simple

application, these parameters need not to be considered. They will be generated automatically

after GD ID compiling.

(5) Communication diagnosis When multi-CPUs are communicating, sometimes the

communication will be interrupted, which can be detected by following methods:

After compiling, in the menu "View", click "Scan Rates" and "GD Status" separately to

examine scan rates and GD Status, as shown in Figure 1-21.

Figure 1-21 Examining Global Data Scan Rate and Status Word

version 1.0 page 15 of 38 04/04/2005

MPI communikation

Chapter 1

1) SR: Scan rate. In Figure 1-21, SR1.1 is 225, which means transmission update time is

225×CPU cycle time. The range of SR is 1~255. Communication interruption usually happens

when scan time is configured too fast. The user can prolong scan time properly according to

demand.

2) GDS: Status word (double word) of each data package. Please refer to Table 2-1.

Table 2-1 Programming Error-Processing Program According to Status Word

Status Word Respective program for error handling

1. Bit Length error in sending area

2. Bit Data block does not exist in sending area

4. Bit Loss of entire data package

5. Bit Grammatical error of total data package

6. Bit Data object of total data package lost

7. Bit Length of data object not identical in sending and

receiving area

8. Bit Length error in receiving area

9. Bit Data block does not exist in receiving area

12. Bit Restart at sender

32. Bit New data received in receiving area

3) GST: the result of "OR" all the GDSs. First the user can diagnose the reliability of

wiring by using communication cards such as CP5511/5611 etc. In the case above, S7-300 MPI

address is 2, and S7-400 MPI address is 4. NO.2 and NO.4 station address can be read by

connecting CP communication card to MPI network (having necessary PROFIBUS bus

connector with a programmable interface). The detailed method is as follows: click "control

panel"→"Set PG/PC Interface"→"Diagnostics"→"Read", and read all the site addresses in the

network, as shown in Figure 1-22.

version 1.0 page 16 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-22 Diagnosis Function of PG/ PC Communication Connection

NO.0 station is the site address of CP5611. If NO.2 and NO.4 station addresses are not read,

then there may be some problems existing in hardware connection or software configuration,

which need further analysis.

(6) Event triggered data transmission If the user needs to control the data sending and

receiving process in some event or at a moment, then he can use event triggered data

transmission mode. This communication mode is implemented by calling CPU system function

SFC60 (GD_SND) and SFC61 (GD_RCV). It only supports S7-400 CPU, and configures SR

(scan rate) of CPU as 0 correspondingly. Please refer to menu configuration of global data in

Figure 1-23.

version 1.0 page 17 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-23 SR of Global Data Configuration

Download into CPU after compiling and saving as mentioned above. Then call system

function SFC60/61 in S7-400 to control sending and receiving. The detailed program code is as

follows

Where CIRCLE_ID BLOCK_ID can refer to A, B C parameter in the GD.

In the program above, when M1.1 is 1, CPU416 receives the data from CPU315, and data

from MB20~MB29 of CPU315 is transmitted to MB40~MB49 of CPU416. When M1.0 is 1,

CPU416 send data, and the data from MB60~MB69 of CPU416 is sent to MB60~MB69 of

CPU315.

Sample program refers to the CD, with the project name MPI_GD_EVENT.

version 1.0 page 18 of 38 04/04/2005

MPI communikation

Chapter 1

1.4.2 Non-configured Connection Communication

Non-configured MPI communication is implemented by calling system function block

SFC65~69. This communication mode is applied in communication in S7-300, S7-400 and S7-

200, and there are mainly two methods: dual-side program communication mode and single-side

program communication mode. The communication mode, which is implemented by calling

system function, cannot mix with global data communication mode.

1. Dual-side program communication mode

(1) Introduction Both communication sides need to call communication function block,

and one side send data by calling sending function block, while the other side receives data by

calling receiving function block. This communication mode can be applied in communication in

S7-300/400, and sending function block is SFC65 (X_SEND), while receiving function block is

SFC66 (X_RCV). The following example will illuminate how to implement communication by

calling system function.

(2) Network configuration graph as shown in Figure 1-24.

Figure 1-24 Network Configuration Graph

(3) Hardware and software requirement

Hardware:

1) CPU 315-2 DP.

2) CPU 416-2 DP.

3) MPI cable.

Software: STEP 7 V5.2 SP1.

(4) Network and parameter configuration

1) Creating a new project: create STATION1 and STATION2 in STEP 7. The CPU of

STATION1 is S7 416-2 DP, MPI address 2; The CPU of STATION2 is S7315-2DP, MPI

address 4. In this case, No.2 station send two data packages to No.4 station. No.4 station put the

data packages into corresponding data area after judgment.

2) Programming: Call ”X_SEND” SFC65 in OB35 block of S7 416, and the detailed

program code is as follows

version 1.0 page 19 of 38 04/04/2005

MPI communikation

Chapter 1

Table 2-2 Parameter Instructions

REQ Send request, parameter 1 means sending.

CONT For 1 it means that data are sent as a continuous unit.

DEST_ID MPI-address of destination

REQ_ID User-defined ID of a data package. Identifiers of both data packages in the example

are “1“ and “2“.

SD Defining the data sending area in form of an index pointer. The first data package in

the example has 76 continuous bytes starting with DB1. DBB0. Maximum size of the

sending area is 76 Bytes.

RET_VAL Sending the status word.

BUSY History of communication, 1 means sending, 0 means sent.

The parameter instruction in the program refers to Table 2-2.

In the sample program above, when both M1.1 and M1.3 are ‘1’,CPU 416 will send two

data packages whose identifier are ‘1’ and ‘2’ respectively to CPU 315.

The number of connections one CPU can establish is related to communication resource,

which determines the calling number—dynamic link number. In this case, when both M1.1 and

M1.3 are ‘1’, the connection with NO.4 station is established; on the contrary, when NO.4

station send data and NO.2 station receives data, a connection will also need to be established,

which means when communication between two stations, if both need to send and receive data,

then two dynamic link resources need to be occupied. Please refer to Figure 1-25 to see

communication connection status.

version 1.0 page 20 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-25 Establishing Communication Connection Status

When both M1.1 and M1.3 are ‘0’, the established connection NO.4 station is not released,

which can only be released by calling SFC69. In this case, when M1.5 is ‘1’, connection with

NO.4 station is disconnected, and the connection resource will be released, as shown in Figure

1-26.

version 1.0 page 21 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-26 Releasing of Communication Connection

The receiving function block “X_RCV”SFC66 in OB1 of S7 315 is called, and the detailed

program code is as follows

version 1.0 page 22 of 38 04/04/2005

MPI communikation

Chapter 1

Table 2-3 Parameter Instructions

EN_DT Receiving the instructions

RET_VAL Receiving the status word

REQ_ID Identifier for receiving the data package

NDA 1 means there are new data packages, 0 means no new

package

RD Receiving area in the continuous 76 Bytes starting with

DBB0 within DB1

The parameter instruction in the program refers to Table 2-3.

Receiving function block only identifies the identifier of the data, and does not consider

which CPU send. In this case, it receives two data packages in NO.2 station. When identifier is

‘1’ and M1.3 is ‘1’, data from the receiving data area is copied to ex-76 words of DB2 (calling

SFC20). When identifier is ‘2’ and M1.4 is ‘1’, data from the receiving data area is copied to

ex-76 words of DB3 (calling SFC20).

Sample program refers to the CD, with the project name MPI_SFC_SR.

2. Single-side program communication mode

Different from dual-side program communication mode, single-side program

communication mode, which is an access mode between client and server, only write

communication program on one side. The CPU of the side that writes the programs is customer,

while the other is server. The customer accesses the server via SFC communication function

version 1.0 page 23 of 38 04/04/2005

MPI communikation

Chapter 1

block. This communication mode is applied in communications in S7-300/400/200. The S7-

300/400 CPU can be used as the customer and server at the same time, while S7-200 can only

be used as server. The SFC67 (X_GET) is used to read the data in the data area appointed by

server and store in local data area, SFC68 (X_PUT) is used to write the data from local data area

to data area appointed by server.

(1) Communication between S7-300/400.

1) Network configuration graph as shown in Figure 1-27.

Figure 1-27 Network Configuration Graph

2) Hardware and software requirement

Hardware:

CPU 315-2 DP.

CPU 416-2 DP.

MPI cable.

Software: STEP 7 V5.2 SP1.

3) Creating a new project: create STATION1 and STATION2 in STEP 7. The CPU of

STATION1, which serves as customer, is S7 416, MPI address 2; The CPU of STATION2,

which serves as server, is S7315-2DP, MPI address 4.

4) Programming: CPU416 calls SFC68, and send the continuous 76-bit data beginning with

DB1.DBB0 in local data area to the continuous 76-bit data beginning with DB1.DBB0 in

CPU315; CPU416 calls SFC67, and reads the continuous 76-bit data beginning with

DB1.DBB0 then puts into the continuous 76-bit data beginning with DB2.DBB0 in local data

area. The sample program is as follows:

version 1.0 page 24 of 38 04/04/2005

MPI communikation

Chapter 1

Table 2-4 Parameter Instructions

DEST_ID MPI-address of partner

VAR_ADDR Data area of partner (server side)

SD Local data area (data source). Data from this area are sent if

M1.1 is 1.

RD Local receiving area for data. Received data are stored in the

local area if M1.3 is 1.

The parameter instruction in the program refers to Table 2-4.

The maximum capacity of data area is 76 bytes. Call SFC67 and SFC68 in one CPU at the

same time will occupy one dynamic link source. When M1.5 is ‘1’, communication is

interrupted and the link is released. In the same way, S7-300 can also be used as the customer,

S7-400 the server.

Sample program refers to the CD, with the project name MPI_SFC_PG300.

(2) Communication between S7-300/400 and S7-200

1) Introduction

For S7-200 cannot call SFC communication function block, so it can only be used as

server. And S7-300/400 can serves as customer.

2) Network configuration graph as shown in Figure 1-28.

version 1.0 page 25 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-28 Network Configuration Graph

3) Hardware and software requirement

Hardware:

CPU 315-2 DP.

CPU 416-2 DP.

CP56 11 communication card.

MPI cable.

Software:

STEP 7 V5.2 SP1.

MicroWin3.2.

4) Creating a new project: create S7-300 stations, and configured MPI address as 2, baud

rate 187.5Kbit/s. Open the MicroWIN32, and configure S7-200 parameters. In "System Block",

configure S7-200 station address as 4, baud rate 187.5Kbit/s. Download after finishing

configuration as shown in Figure 1-29.

version 1.0 page 26 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-29 Configuring Station Address and Baud Rate of S7-200

5) Programming: Programming of S7-300

In OB1 of S7-300, call SFC68 and SFC67.

When M1.1 is ‘1’, S7-300 send input data IB0 to QB0 of S7-200; when M1.4 is ‘1’, S7-

300 reads input data IB0 of S7-200 and puts into local output data QB0.

Sample program refers to the CD, with the project name MPI_SFC_200_PPI.

If V data area of S7-200 is read and written, then when defining V data area of S7-200 in

S7-300, DB1 must replace V. For instance, if the latter 16 bytes of VB100 in S7-200 are read

and put into the latter 16 bytes of MB20 in S7-300, system function SFC67 (X_GET) must be

called, and in VAR_ADDR configures S7-200 data area as P # DB1.DBX100.0 BYTE 16,

while in parameter RD, configures S7-300 data area as P # MB20.0 BYTE 16.

Moreover, it also can communicate with the MPI of S7-300/400 via PROFIBUS- DP

module EM277 of S7-200. On S7-200 side, configure the EM277 station address by using

dialing-code switch (configuration becomes effective only when given an electric shock to

restart). When calling SFC67/68 on S7-300/400 side, station address parameter has to be

configured as MPI address of EM277.

1.4.3 Configuration Connection Communication Mode

1. Introduction

In MPI network, this mode is only applied in the communication between S7-300/400 and

S7-400/400. When communicating between S7-300/400, S7-300 only can be used as server, and

S7-400 used as customer to read and write to S7-300; when communicating between S7-

400/400, S7-400 can be used as both customer and server. Communication by calling system

function block in MPI network, the maximum of data package length is 160 bytes. Take this

connection as example to introduce configuration connection communication mode is below.

2. Network configuration graph as shown in Figure 1-30.

version 1.0 page 27 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-30 Network Configuration Graph

3. Hardware and software requirement

Hardware:

1) CPU 315-2 DP.

2) CPU 416-2 DP.

3) MPI cable.

Software: STEP 7 V5.2 SP1.

4. Creating a new project

Create STATION1 and STATION2 in STEP 7. The CPU of STATION1, which serves as

customer, is S7 416, MPI address 2; The CPU of STATION2, which serves as server, is S7315-

2DP, MPI address 4. Suppose S7-400station writes the continuous 20-bit data beginning with

DB1.DBB0 in local data area to the continuous 20-bit data beginning with DB1.DBB0 of S7-

300 station, then reads the continuous 20-bit data beginning with DB1.DBB0 of S7-300 station

and puts into the continuous 20-bit data beginning with DB2.DBB0 in local data area.

5. Connection and parameter configuration

In menu of STEP 7, click "Options"→"Configure Network" to enter into network

configuration window "NetPro", as shown in Figure 1-31.

Figure 1-31 Configuring Communication Connection

Click "CPU 416-2DP" of STATION1, and establish new connection in connection table

selecting "S7 connection" connection type. And select CPU of which needs to connect, and in

this case select CPU315, as shown in Figure 1-32.

version 1.0 page 28 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-32 Configuring Connection Type

Click "Apply" to establish connection, and examine the detailed properties of connection

table, as shown in Figure 1-33.

version 1.0 page 29 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-33 Properties of Connection Menu

Compile and save after configuration, and download the connection configuration to each

CPU respectively.

6. Configuration

Call communication system function block SFB15 in S7-400 station, and send the data to

S7-300 station. The program is as follows:

version 1.0 page 30 of 38 04/04/2005

MPI communikation

Chapter 1

REQ: Rising edge Trigger, and each rising edge triggers once.

Read the data of S7-300 by calling SFB14. The program is as follows.

Sample program refers to the CD, with the project name MPI_SFB_PG.

Compared with the communication of calling the system function block SFC, calling

system function block SFB has greater sending and receiving data quantity in each package, but

need to establish connection table in hardware configuration, and also will occupy

communication resource of S7-300. Under the premise of meeting communication requirement,

the user is suggested to use the non-configured connection communication mode.

1.5 MPI Communication between S7 PLC And HMI Products

MPI communication between S7-300/400 and HMI products needs neither STEP 7

software configuration, nor writing any program, and only need to configure related

communication parameters in HMI configuration software.

1.5.1 Communication between PLC and TP/OP

When TP/OP is communicating with PLC via MPI protocol, the user need to configure

communication parameters by using ProTool configuration software. For example, if the user

wants to connect TP270-10 with S7 PLC, then double-click "Controllers" in the ProTool

interface, and a dialog box as shown in Figure 1-34 will appear.

Figure 1-34 Configuring PLC Communication Parameter

Click the "Parameters" button, and configure the MPI address of CPU which needs to

connect, slot number and other parameters, as is shown in Figure 1-35.

version 1.0 page 31 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-35 Configuring PLC Communication Parameter

In S7-400 multi-CPU system, the user only needs to fill the station number and slot

number of CPU, which needs to connect.

1.5.2 MPI Communication between S7 PLC and Monitoring Software WinCC

Similar to connecting TP/ OP, when communication between S7 PLC and monitoring

software WinCC via MPI protocol, the user also only need to configure station address, slot

number and net card of S7 CPU.

1. Installing and configuring MPI communication card in PC

First, insert CP5611 into PC, and start the computer, then double-click "Set PG/PC

Interface" icon in the control panel of PC, as shown in Figure 1-36.

version 1.0 page 32 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-36 Installing CP5611 Communication Card

2. Adding SIAMTIC S7 communication protocol in WinCC

Open WinCC, and select "Tag Management". Right-click selecting "Add New Driver". In

the appearing window, select "SIAMTIC S7 protocol suite" connection driver, and add it under

"Tag Management", as shown in Figure 1-37.

version 1.0 page 33 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-37 Configuring WinCC Communication Connection

S7 protocol group include S7 protocol applied in different networks, which include MPI

network, PROFIBUS network and the Industrial Ethernet.

3. Selecting WinCC communication card

Select MPI communication protocol and right-click to select "System Parameter", and

enter the system parameter configuration menu as shown in Figure 1-38.

Figure 1-38 Selecting WinCC Communication Card

version 1.0 page 34 of 38 04/04/2005

MPI communikation

Chapter 1

4. Establishing WinCC communication connection

Select MPI communication drive, and right-click to select "New Driver Connection" to

establish a connection. If connecting muti-CPUs, then one connection is established when

connecting to one CPU. The number of connected CPU is related to the network card applied in

host computer. For instance the maximum number supported by CP5611 is 8, and these

connection numbers can be found in relative product data sheet. In this case, the connection

parameters need modification, such as the station address and slot number of selected CPU, as

shown in Figure 1-39.

Figure 1-39 Configuring WinCC Communication Connection Parameter

When connecting to CPU S7-300, slot number is 2, while S7-400, slot number should refer

to the CPU slot number in STEP 7 hardware configuration.

5. Communication diagnosis

If there is something wrong with communication here, first the user should check if the

network card has been rightly installed, and the connections of communication cables and

junctions well contact. Then he should check whether configuration parameters are rightly

configured. Meantime, by using the self-diagnosis function of CP communication card, all the

station addresses in the MPI network can be read in "Set PG/PC Interface" of PC control panel,

as shown in Figure 1-40.

version 1.0 page 35 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-40 Hardware Network Diagnosis via CP Communication Card

In this case, the MPI address of CP5611 is 0, and the MPI address of CPU is 4.

When WinCC cannot establish connection with CPU, if the diagnosis result is that NO.0

and NO.4 station can be read, then it can be judged that there may be some problems with

WinCC configuration, which needs further inspection.

1.5.3 Remote communication between WinCC and PLC

Remote communication, which means using public telephone network to access the data of

PLC, can be implemented by using TeleService software and hardware adapter. Like the remote

program access steps in STEP 7, first dial through PLC stations via TeleService, then configure

interface parameters in "Set PG/PC Interface" of PC control panel, as shown in Figure 1-41.

version 1.0 page 36 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-41 Selecting TS Adapter

Select access point as MPI, and point to TS Adapter.

Finally select MPI under "SIAMTIC S7 Protocol Suite" of WinCC, and right-click

selecting "System Parameter". In the appearing window, select MPI. The selected name of

communication unit should be in accordance with the selected communication card in "Set

PG/PC Interface", as shown in Figure 1-42.

version 1.0 page 37 of 38 04/04/2005

MPI communikation

Chapter 1

Figure 1-42 Configuring TS Adapter System Parameter

Communication can be immediately established after PC dials through PLC.

version 1.0 page 38 of 38 04/04/2005

Potrebbero piacerti anche

- 4035 BDocumento8 pagine4035 Brafael charchabalNessuna valutazione finora

- CP 490Documento73 pagineCP 490rafael charchabalNessuna valutazione finora

- Laptop Chip Notes1Documento45 pagineLaptop Chip Notes1rafael charchabal100% (5)

- Tny267pn PDFDocumento24 pagineTny267pn PDFPham LongNessuna valutazione finora

- Service Manual: Microwave OvenDocumento21 pagineService Manual: Microwave Ovenpereira64Nessuna valutazione finora

- TDA9302H: Vertical Deflection Output CircuitDocumento5 pagineTDA9302H: Vertical Deflection Output Circuittecnico1069Nessuna valutazione finora

- TDA9302H: Vertical Deflection Output CircuitDocumento5 pagineTDA9302H: Vertical Deflection Output Circuittecnico1069Nessuna valutazione finora

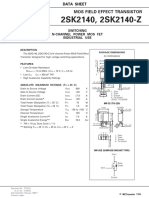

- K2140 NecDocumento6 pagineK2140 Necrafael charchabalNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 12 Ip Sample Model Paper Oct2021Documento8 pagine12 Ip Sample Model Paper Oct2021niyamathNessuna valutazione finora

- Inventory System For Supply OfficeDocumento1 paginaInventory System For Supply OfficeJomiener Bawar RamosNessuna valutazione finora

- M72!01!04 ChipKey Encoder Owners ManualDocumento37 pagineM72!01!04 ChipKey Encoder Owners ManualpablosandoNessuna valutazione finora

- List of Vlsi BooksDocumento15 pagineList of Vlsi BooksMahesh100% (2)

- Materi Prof. Mulyowidodo (Prediksi Lanskap Teknologi)Documento44 pagineMateri Prof. Mulyowidodo (Prediksi Lanskap Teknologi)amelia nikoNessuna valutazione finora

- Test UM Product CatalogDocumento28 pagineTest UM Product Catalogdonhacbang100% (1)

- AE 24 Business Analysis ProjectsDocumento23 pagineAE 24 Business Analysis ProjectsJyle Mareinette ManiagoNessuna valutazione finora

- Blue and White Corporate Illustrated Blue Connections PresentationDocumento26 pagineBlue and White Corporate Illustrated Blue Connections PresentationveroNessuna valutazione finora

- CS - Class XII 2021-22 Programs List For Record: Part A - Python (Use User Defined Functions)Documento7 pagineCS - Class XII 2021-22 Programs List For Record: Part A - Python (Use User Defined Functions)Megha RajeshNessuna valutazione finora

- Ipoque Product Brochure Net-Reporter WebDocumento4 pagineIpoque Product Brochure Net-Reporter WebmickysouravNessuna valutazione finora

- Service Manual: For Hyundai Heavy Industries Co.,LtdDocumento27 pagineService Manual: For Hyundai Heavy Industries Co.,LtdDmitry100% (1)

- Very GoodDocumento5 pagineVery GoodManjulya YeddiNessuna valutazione finora

- Aberdeen Research Report Big Data AnalyticsDocumento11 pagineAberdeen Research Report Big Data AnalyticsRosie3k90% (1)

- ConfigAdmin AG v2016EEDocumento156 pagineConfigAdmin AG v2016EEpatologicoNessuna valutazione finora

- Chapter 10 AnswersDocumento6 pagineChapter 10 AnswersJohn HoltNessuna valutazione finora

- Send and Fax GuideDocumento322 pagineSend and Fax GuideBhupendra SengarNessuna valutazione finora

- AGC-4 Operator's Manual DU-2Documento24 pagineAGC-4 Operator's Manual DU-2Delio DuranNessuna valutazione finora

- Electrical Thumb Rules (Part-2) PDFDocumento2 pagineElectrical Thumb Rules (Part-2) PDFElectrical RadicalNessuna valutazione finora

- Chapter 0 Intro & IndexDocumento12 pagineChapter 0 Intro & IndexMAT-LIONNessuna valutazione finora

- Using Lightweight MLS With Oracle E-Business Suite Release 12.1.3 and Higher Document 1077709Documento11 pagineUsing Lightweight MLS With Oracle E-Business Suite Release 12.1.3 and Higher Document 1077709Ravi BirhmanNessuna valutazione finora

- Presentation5 3Documento16 paginePresentation5 3Abhirami SNessuna valutazione finora

- WORKSHOP ON Business AnalyticsDocumento2 pagineWORKSHOP ON Business AnalyticssubramonianNessuna valutazione finora

- AFCI Technical White PaperDocumento16 pagineAFCI Technical White PaperSon NguyenNessuna valutazione finora

- Technology For Building SystemsDocumento31 pagineTechnology For Building SystemsSunny Sharma100% (1)

- FenilModi PDFDocumento7 pagineFenilModi PDFSavan JaviaNessuna valutazione finora

- SFERE Energy Meter3706581013667435464Documento2 pagineSFERE Energy Meter3706581013667435464Cho Cho MyintNessuna valutazione finora

- p4-01 Construct Kickoff 8Documento2 paginep4-01 Construct Kickoff 8Ahmed Daahir AdenNessuna valutazione finora

- 4.development of Electricity Theft Detection Using Smart Meter in Power Distribution Network Based On Wireless TechnologyDocumento9 pagine4.development of Electricity Theft Detection Using Smart Meter in Power Distribution Network Based On Wireless Technology1382aceNessuna valutazione finora

- Brochure Seamless Tubes For Hycy 20210525Documento28 pagineBrochure Seamless Tubes For Hycy 20210525Carlos BenitezNessuna valutazione finora

- Puff PlantDocumento9 paginePuff Planttauseef52Nessuna valutazione finora